Wear-resistant and scratch-resistant coating and preparation method thereof

A kind of anti-scratch and coating technology, applied in the field of wear-resistant coating, can solve the problems such as not being able to meet the demand, and achieve the effect of prolonging the service life, easy mass production and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

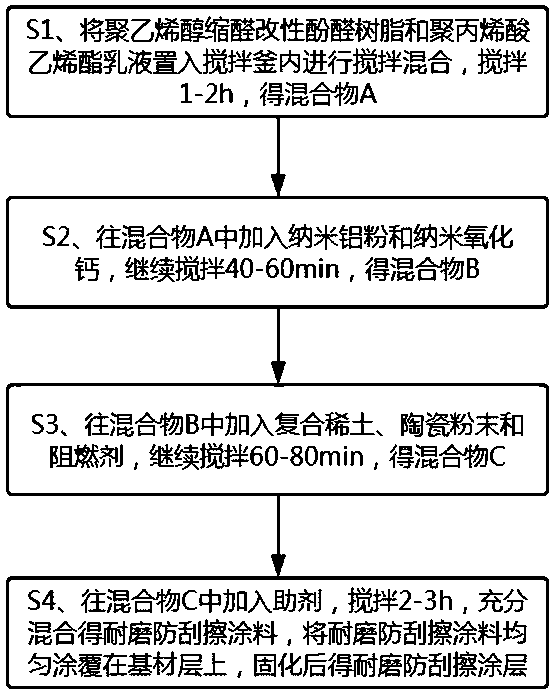

Method used

Image

Examples

Embodiment 1

[0032] A wear-resistant and anti-scratch coating, which is a wear-resistant and anti-scratch coating formed after the wear-resistant and anti-scratch coating is uniformly coated on a composite film and cured, and the wear-resistant and anti-scratch coating includes the following Component:

[0033] 30-40 parts of polyvinyl acetal modified phenolic resin, 40-60 parts of polyvinyl acrylate emulsion, 1-2 parts of composite rare earth, 5-10 parts of nano-aluminum powder, 5-10 parts of nano-calcium oxide, and 10 parts of ceramic powder -15 parts, 8-12 parts of flame retardant, 6-10 parts of auxiliary agent.

[0034] The weight ratio of polyacryl acetal modified phenolic resin to polyvinyl acrylate emulsion is 1:1.5-2.5.

[0035] The composite rare earth contains the following components by weight percentage: La: 22.5-22.7%, Y: 12.6-12.8%, Sc: 15.2-15.5%, Yb: 9-11%, Ho: 18-20%, and the rest: Pr.

[0036] The particle size of the nano-aluminum powder is 30-60nm, and the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com