Patents

Literature

64results about How to "Strong scrub resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Odorless anti-formaldehyde environment-friendly internal wall latex paint and preparation method thereof

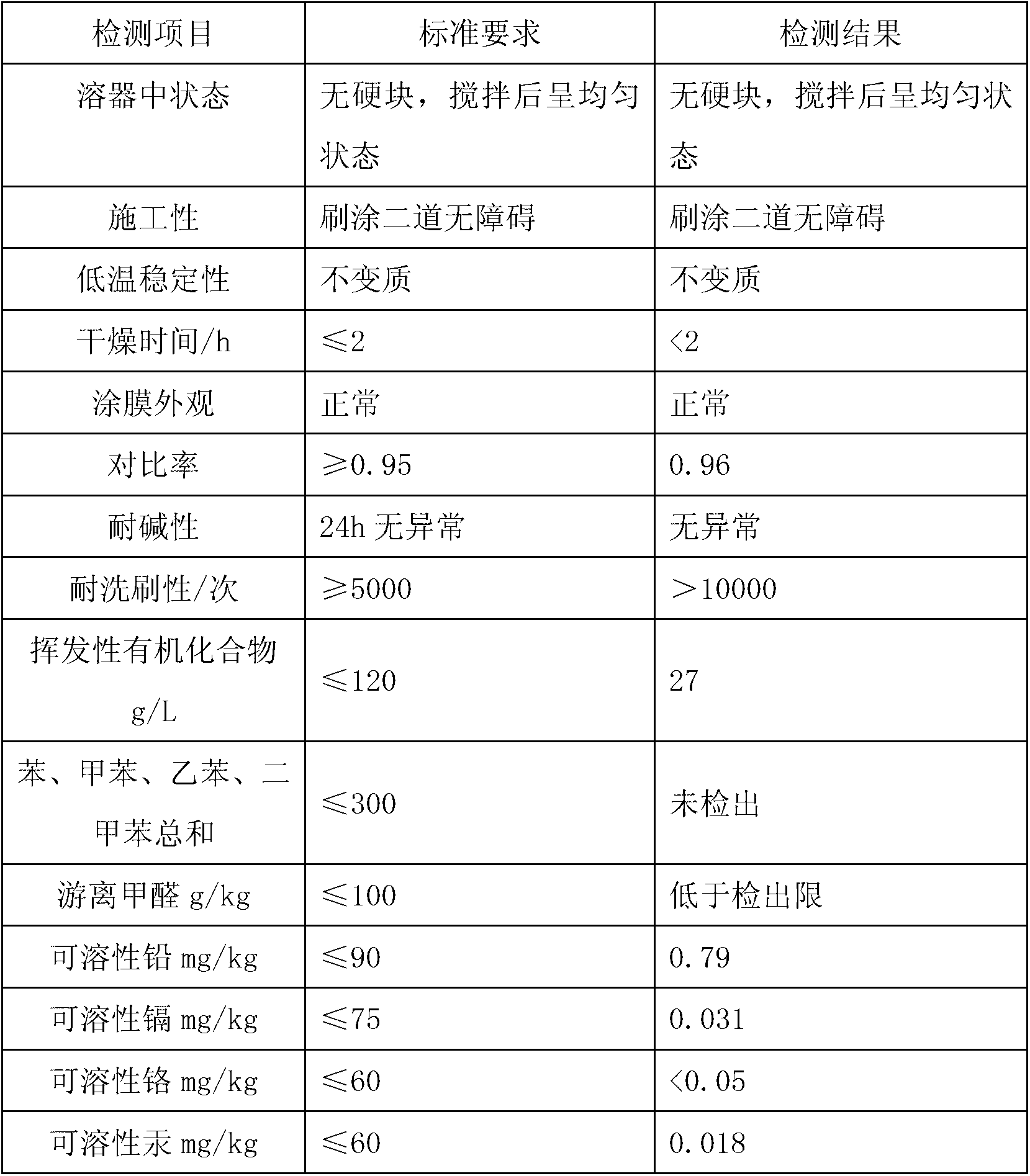

ActiveCN103059679AStrong absorption capacityStrong sustainable degradation abilityEmulsion paintsEmulsionSlurry

The invention discloses an odorless anti-formaldehyde environment-friendly internal wall latex paint and a preparation method thereof. The odorless anti-formaldehyde environment-friendly internal wall latex paint is prepared from the following components in percentage by weight: 1-15% of visible light induced nano titanium dioxide photocatalyst slurry, 15-35% of odorless emulsion, 1-15% of formaldehyde absorbent, 0.5-2% of dispersing agent, 0.2-3% of thickening agent, 0.2-1% of wetting agent, 0.1-1% of defoaming agent, 0.5-5% of film-forming assistant, 0.2-3% of anti-freeze agent, 20-40% of pigment and filler, 0.1-1% of pH regulator, 0.01-0.1% of anticorrosive bactericide and 15-40% of deionized water. The invention adopts an IPS+odorless technique, and the visible light induced nano titanium dioxide photocatalyst and the formaldehyde absorbent are added, thereby achieving the optimal effect of removing formaldehyde and other harmful substances through physical adsorption and chemical decomposition. The invention can be widely used for decorative spraying of various internal walls and other constructions.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

Long action negative ion antiseptic function paint

InactiveCN1648178AStrong coverageStrong scrub resistanceAntifouling/underwater paintsPaints with biocidesAir pollutantsWhiskers

The functional paint capable of releasing negative ion for sterilizing and bacteriostasis has nano zinc oxide whisker and negative ion material added into paint. After the paint forms the film, the film will release negative ion and emit infrared ray continuously, and under rubbing and extruding, the film can release negative ion as much as 12000 / cu cm. The negative ion emits far infrared radiation and neutralizes and coats pollutant in the air, so as to eliminate air pollution, purify air, and reach sterilizing and bacteriostasis aim.

Owner:范存玉

Nano waterproof paint

ActiveCN103555090AImprove waterproof performanceStrong scrub resistanceCoatingsAcrylic resinMetasilicate

The invention discloses a nano waterproof paint, which is prepared by the raw materials by weight: 70-80 parts of polyvinyl acetate emulsion, 3-5 parts of potassium metasilicate, 2-4 parts of lithium silicate, 8-10 parts of potassium titanate whisker, 5-7 parts of aqueous self-drying organosilicon modified acrylic resin HA88405, 15-20 parts of nanometer powdered carbon, 2-3 parts of nano zinc oxide, 3-5 parts of oxidation starch, 1-2 parts of urea, 1-2 parts of actinolite powder, 2-3 parts of ethylene dimethacrylate, 7-10 parts of bonding auxiliary agent, and 10-20 parts of deionized water. The waterproof paint has good waterproof paint, strong scrub resistance, and good stain resistance, and also has certain anticorrosion and sterilization efficacies, and good comprehensive properties.

Owner:湖南亚仕龙建材商贸有限公司

Environment-friendly latex paint for external wall

Disclosed is an environment-friendly latex paint for external wall which comprises water, thinning agent methyl glycol, dispersing agent P-998, multifunctional adjuvant AMP-95, wetting agent PE-100, water solution of thickening agent HEC, defoaming agent 220, titanium dioxide R215, porcelain clay, ultra-fine grammite, ultra-fine aluminum silicate, talcum powder, antiseptic 981, polyurethane thickening agent SN636, thickening agent 2020, levelling agent DSX 2000, defoaming agent 202 and thixotropic agent AT.

Owner:OCEAN UNIV OF CHINA

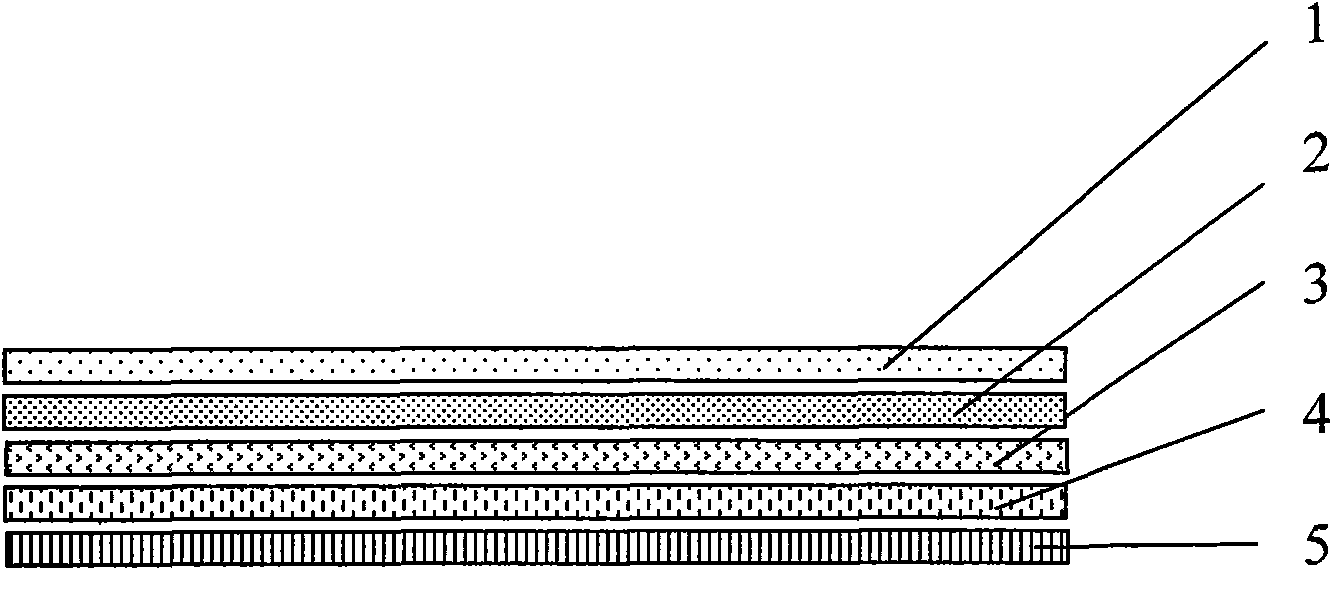

Method for preparing coating transfer film for decoration

ActiveCN101905621AStrong abrasion resistance and scrub resistanceEasy constructionWax coatingsOrnamental structuresChemistryAdhesive

The invention discloses a coating transfer film, in particular relates to a coating transfer film for decoration and a preparation method thereof. The coating transfer film consists of a support layer, a parting layer, a printing layer, a coating layer and a bonding layer from outside to inside in turn. In the coating transfer film, a coating which is suitable for machine coating is coated to nonpolar resin materials such as PET, BOPP, PP and the like directly, and by utilizing the difficult bonding performance of the nonpolar materials, a coating dry film is transferred to a wall surface directly by taking water or rubber latex as an adhesive, so the wall surface to which the coating film is transferred has the characteristics of cleanness, beauty, environmental protection, high abrasionand scrubbing resistance, elegant appearance, convenient construction, cost conservation and the like. In addition, personalized patterns such as embossing, stamping and the like can be manufactured according to the requirements of different customers, and various vector patterns can also be engraved by a die cutting machine or a carving machine, so that the originally single wall surface is bright-colored and beautiful, and indoor environment is more beautiful and colorful.

Owner:陈武

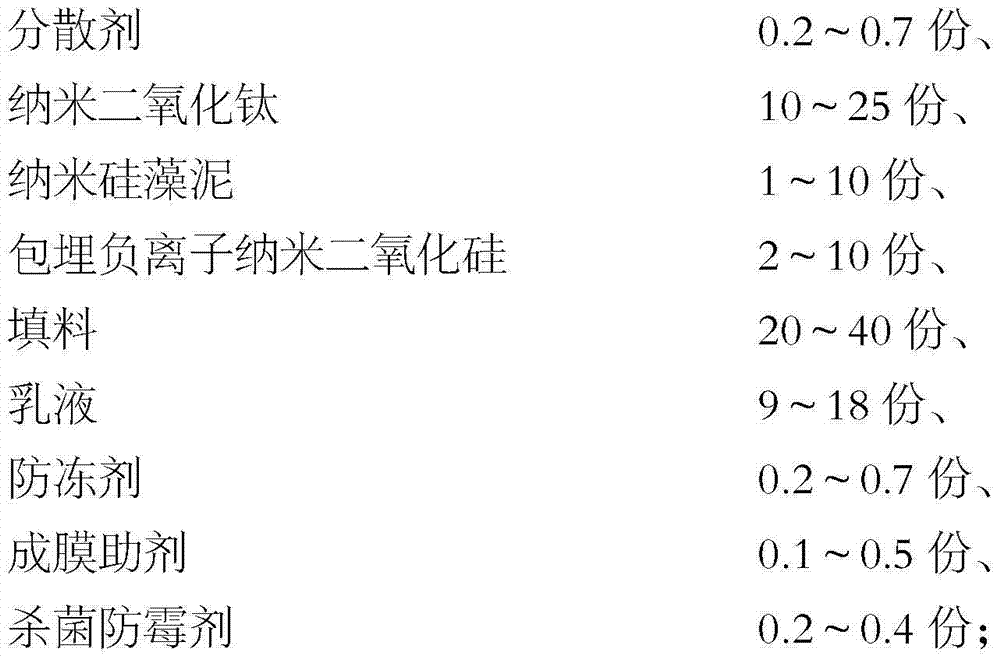

Special-effect heath indoor wall aqueous paint composition and preparation method thereof

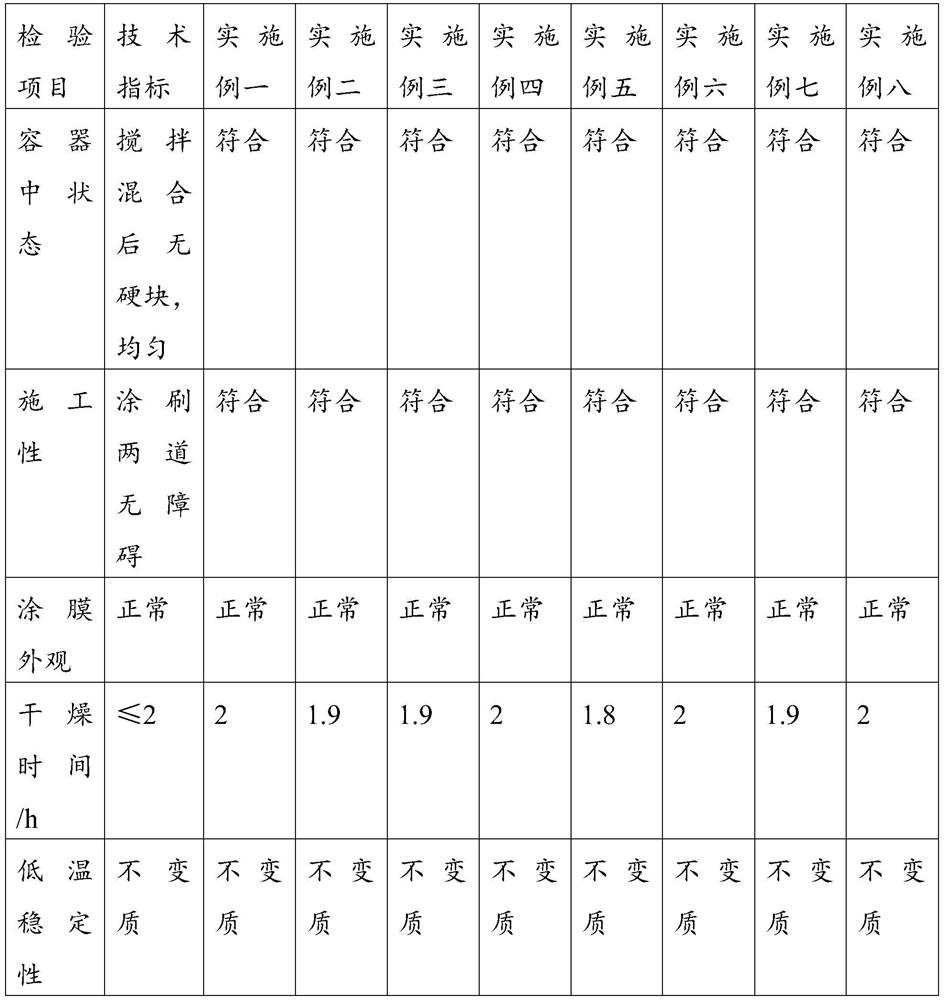

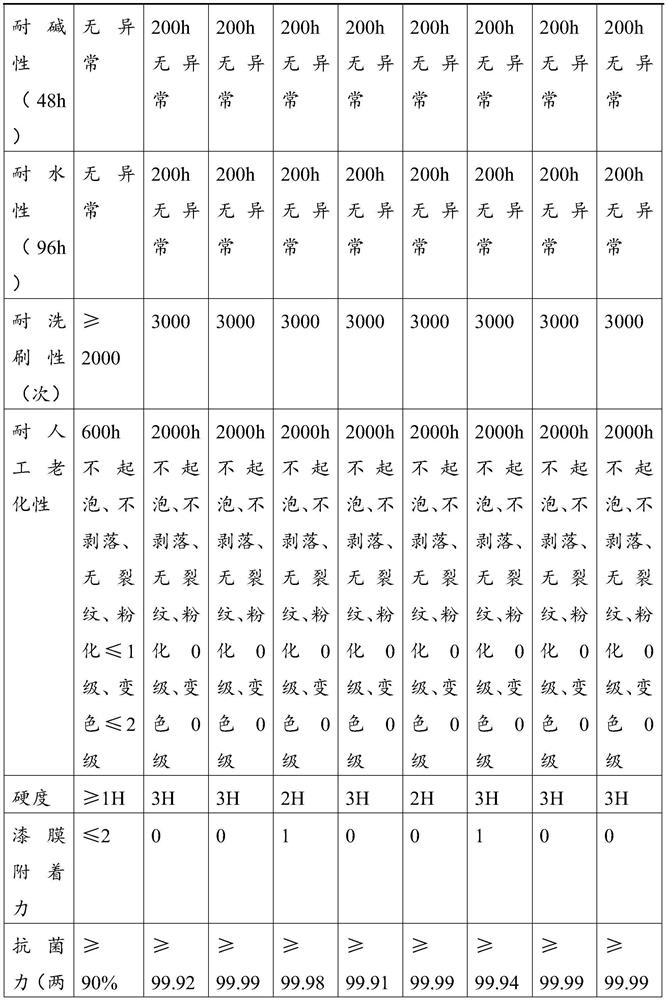

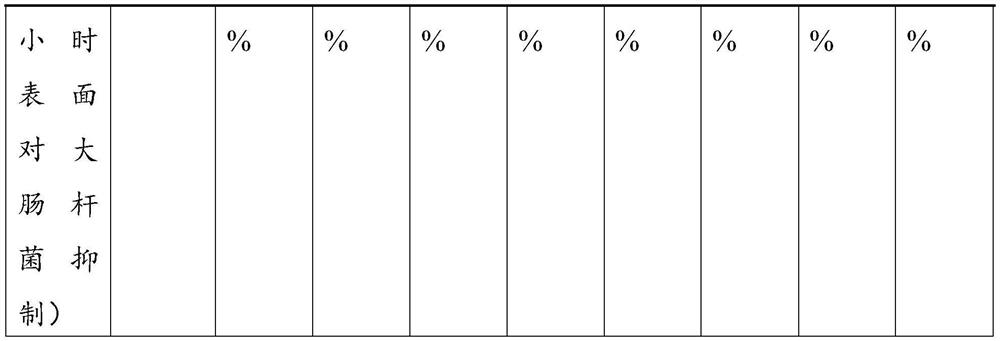

The invention relates to a special-effect health indoor wall aqueous paint composition and a preparation method thereof, and belongs to the field of aqueous paint compositions for construction decoration. The paint composition is composed of the following raw materials in parts by weight: 20 to 30 parts of water, 0.2 to 0.5 part of thickening agent, 0.05 to 0.2 part of pH adjuster, 0.1 to 0.3 part of antifoaming agent, 0.1 to 0.4 part of wetting agent, 0.2 to 0.7 part of dispersant, 10 to 25 parts of nano titanium dioxide, 1 to 10 parts of nano diatom ooze, 2 to 10 parts of embedded anionic nano silicon dioxide, 20 to 40 parts of filling material, 9 to 18 parts of emulsion, 0.2 to 0.7 part of anti-freezing agent, 0.1 to 0.5 part of film-forming auxiliary agent, and 0.2 to 0.4 part of bactericidal mildew inhibitor. The paint composition can absorb the harmful components in air, is healthy and environment-friendly, and also has the advantages of excellent color retention, scrubbing resistance, water and alkali resistance, and proper softness of paint film.

Owner:SKSHU PAINT

Coating for color roof tile and its use method

The present invention discloses one kind of paint for color roof tile and its usage. The paint consists of silicon / fluorine modified acrylic acid emulsion, pigment, stuffing, assistant and water in proper proportion. It has the features of high weather resistance, high wash resistance, good antibiotic property, high endurance, high hardness, high brightness, no toxicity, stable coating, etc.

Owner:陈敬福

Water-based diatom ooze coating and preparation method thereof

Owner:欧亚绿邦(北京)科技有限公司

Strong-acid-resistant high-strength anticorrosive paint and preparation method thereof

InactiveCN104629588APlay the role of anti-corrosion protectionStrong scrub resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholEpoxy

The invention discloses a strong-acid-resistant high-strength anticorrosive paint which comprises the following components in parts by mass: 25-28 parts of epoxy resin, 22-26 parts of polyurethane, 9-13 parts of silicon dioxide, 5-7 parts of titanium dioxide, 3-6 parts of zinc powder, 2-5 parts of barium sulfate, 4-6 parts of graphite, 7-9 parts of diacetone alcohol, 5-9 parts of polytetrafluoroethylene, 7-11 parts of polydimethylsiloxane, 4-8 parts of carboxymethyl cellulose, 1-3 parts of tributyl phenol polyethenoxy ether and 33-45 parts of deionized water. The invention also discloses a preparation method of the strong-acid-resistant high-strength anticorrosive paint. The product can resist corrosion of strong acid and strong alkali, performs the protective and anticorrosive functions on equipment in extreme weather, and has the advantages of excellent mechanical properties, high scrub resistance, high aging resistance, high powdering resistance, higher weather resistance, higher wear resistance, better high-temperature resistance, high safety and environment friendliness.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Cloud wire coating and preparation method thereof

The invention relates to a cloud wire coating and a preparation method of the cloud wire coating. The cloud wire coating comprises the following raw constituents by weight: 4-7 parts of cellulose, 1-4 parts of AMP-95, 1-4 parts of wetting agent, 15-25 parts of coalescing agent, 1-3 parts of preservatives, 8-20 parts of ethylene glycol, 1-4 parts of defoamer, 150-240 parts of pearl powder, 350-500 parts of emulsion, 2-6 parts of thickeners, 3-9 parts of dispersing agent and 200-40 parts of deionized water. The cloud wire coating disclosed by the invention is fine and smooth in quality, and prevents the phenomena of wire fracture and tearing during wire drawing; with the coating, a film can be well adhered, and the seaming, the peeling and the cracking are prevented; and particularly, the coating has strong scrub resistance, water resistance and alkali resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Environment-friendly waterproof stain-resistant silicon acrylate cover finishing paint and preparation method thereof

InactiveCN107603387AImprove water resistanceImprove stain resistanceAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceStain

The invention discloses environment-friendly waterproof stain-resistant silicon acrylate cover finishing paint and a preparation method thereof. The silicon acrylate cover finishing paint comprises the following components in parts by weight: 30 to 40 parts of organosilicon modified pure acrylic acid emulsion, 15 to 25 parts of styrene-acrylic emulsion, 10 to 15 parts of nano-titanium dioxide, 5 to 10 parts of tetraethyl orthosilicate, 5 to 10 parts of glycol, 5 to 10 parts of ethylene glycol butyl ether, 1 to 5 parts of a hydrophobing agent, 1 to 5 parts of a preservative, 1 to 5 parts of a film-forming aid, 1 to 5 parts of a defoaming agent, 1 to 5 parts of an anti-freezing agent, 1 to 5 parts of a wetting agent and 40 to 50 parts of deionized water. The silicon acrylate cover finishingpaint is compact in film, high in water tolerance, high in stain resistance and high in scrubing resistance, avoids fog change, ageing and bacterial growth, and is high in durability and high in clean-keeping property.

Owner:苏州振振好新型建材科技有限公司

Inorganic nano paint and preparation method thereof

The invention provides an inorganic nano coating. The coating is characterized in that the coating consists of the following components by weight percentage: 1 to 10 percent of CH3CH2OH, 0.1 to 10 percent of nano TiO2, 1 to 10 percent of TiO2, 0.1 to 10 percent of nano ZnO, 10 to 30 percent of Mg(OH)2, 12 to 50 percent of filler, 1 to 20 percent of base material, 0.5 to 40 percent of auxiliary agent, and the balance being water. The invention also provides a method for preparing the coating. The method comprises: the nano TiO2 and the nano ZnO are dispersed in the CH3CH2OH to prepare nano pulp, the nano pulp is added with the mixture of water, the TiO2, the Mg(OH)2, the filler, the base material and the auxiliary agent, and dispersed and stirred to obtain the finished product. The coating has the functions of light purification, sterilization and removal of foreign flavor indoors.

Owner:SHANGHAI KEWANG NEW MATERIAL RES CENT

Environmentally-friendly multi-effect nanometer water-based paint

InactiveCN105176221AHigh strengthImprove the finishAntifouling/underwater paintsPaints with biocidesWater basedSurface-active agents

The invention discloses environmentally-friendly multi-effect nanometer water-based paint. The water-based paint is prepared from, by weight, 40-60 parts of macromolecular synthesis resin emulsion, 3-6 parts of nanometer scale silicon dioxide, 0.5-2 parts of nanometer titanium dioxide, 1-2 parts of water-based paint thickening agents, 0.5-2 parts of polyether type surface active agents, 0.4-1 part of preservative, 1-3 parts of anti-freezing agents, 1-2 parts of solidifying agents, 0.4-1.2 parts of dispersing agents, 25-45 parts of filling and 10-30 parts of water. The environmentally-friendly multi-effect nanometer water-based paint is waterproof, high in hardness, resistant to washing, high in adhesive force, smoothness and cleanness and resistant to oil stains, ageing and bacteria, meanwhile the content of VOC and formaldehyde is low, and the water-based paint is safe, environmentally friendly, excellent in performance and wide in application range.

Owner:ZIBO KUAKE MEDICINE TECH

Computer color-mixed base paint

InactiveCN101338164AImprove versatilityReduce production and sales costsStarch coatingsEmulsion paintsMedicineLacquer

The invention discloses a computer tinting basic paint, the formulation of which is as follows: 20-30 portions of ionic water, 0.15-1.5 portions of dispersant, 0.1-1 portions of wetting agent, 0.03-0.3 portions of defoaming agent, 0-25 portions of titanium dioxide, 10-45 portions of filling, 0.1-2 portions of nano-material, 0.3-3 portions of propylene glycol, 0.2-2 portions of Eastman Teaxnol, 0.06-0.7 portions of mildewproof and anticorrosion agent, 20-40 portions of latex and 0.01-1 portions of thickener. Compared with other products, the computer tinting basic paint has the advantages that firstly, the generality is good, the paint can be applied to internal and external walls, and the production and sale costs can be lowered; secondly the tinting is accurate and the color reproducibility is good; thirdly, organic pollutants can be degraded, and the paint is provided with self-cleaning function and super-strong adhesion, rigidity, rinsing resistance and durability.

Owner:GUANGDONG SANVO CHEM IND TECH

Preparation method of rosin modified epoxy ester resin

InactiveCN104211908AStrong toughnessGood flexibilityNatural resin chemical modificationEpoxyAging resistance

The invention discloses a preparation method of rosin modified epoxy ester resin, and relates to the technical field of deep processing of rosin. The preparation method comprises the following steps: adding epoxy resin and soya oil acid, uniformly stirring, heating to 90-100DEG C, reacting for 30-60min, adding rosin and a chain extender, uniformly stirring, heating to 110-120DEG C, and reacting for 60-80min to obtain the rosin modified epoxy ester resin. The rosin modified epoxy ester resin prepared through the method has the advantages of strong toughness and flexibility, aging resistance, water resistance, scrubbing resistance, contamination resistance and good weatherability.

Owner:GUANGXI ZHONGCHANG RESIN

Method for preparing multifunctional inner wall paint

A preparation method for multifunctional interior wall coating material comprises the following steps: nanometer zinc oxide, titanium dioxide and silicon dioxide are weighed and put into a mixing tank to be stirred; dispersing agent which is weighed and is added into water to be mixed uniformly is sprinkled into a mixing tank containing nanometer powder to be evenly mixed with the nanometer components and is under closed standing 6 hours to 7 hours for further use; water, nanometer components, sodium hexametaphosphate and dispersing agent are added into a dispersing kettle in turn to be stirred at high speed for 20 minutes till the materials are fully dispersed; then, stirring speed is slowed down and superfine calcium carbonate powder, titanium pigment wollastonite powder, talcum powder, preservative, light ethyl cellulose and antifoaming agent are added in turn to be stirred at high speed for 60 minutes till the materials are fully dispersed; and then, stirring speed is slowed down again and pure acrylic emulsion, antifoaming agent, film-forming auxiliary agent, rheological agent and propylene glycol are added in turn to be stirred slowly; finally, coating material viscosity is adjusted through thickening agent, and finished product can be obtained after canning. The invention has the advantages that: the invention guarantees full dispersing of the nanometer components; meanwhile, the coating material possesses super-strong scrubbing resistance, weathering resistance and antibacterial performance and self-cleaning.

Owner:TIANJIN ZHENDONG PAINTS CO LTD

Water-resistant paint for building external wall ceramic tile renovation, and preparation method and application thereof

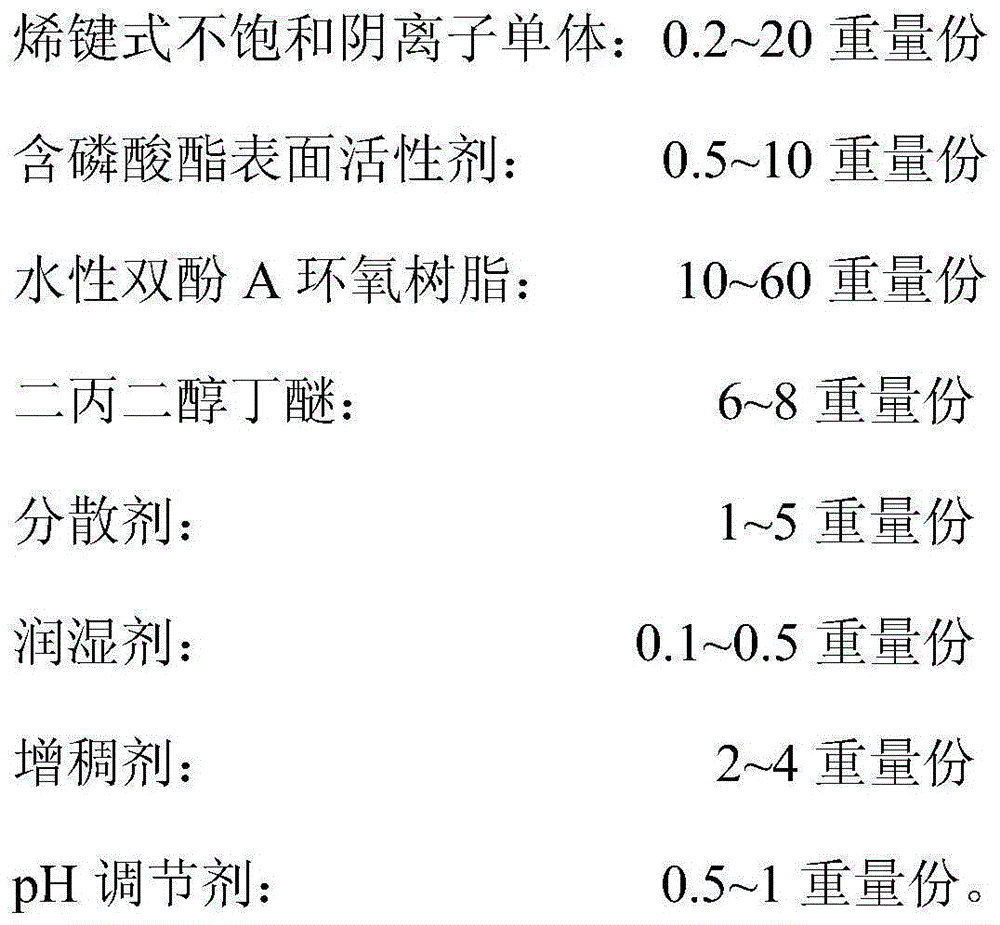

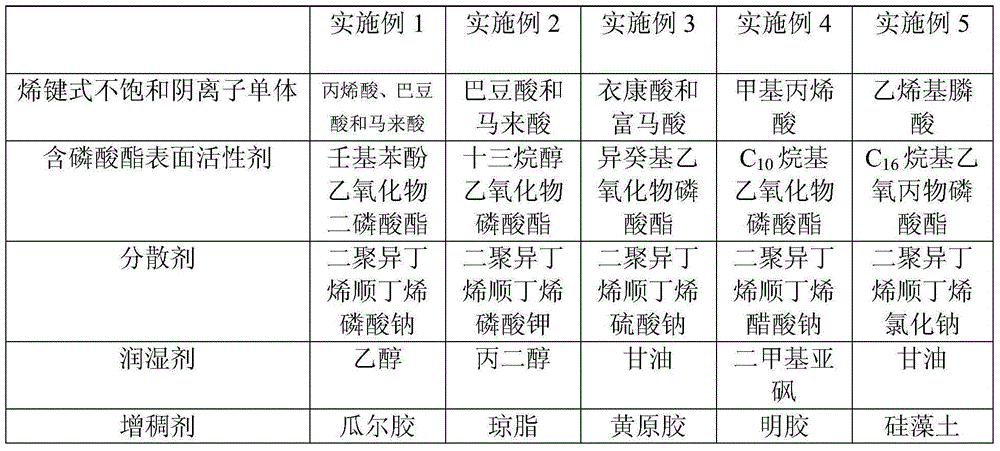

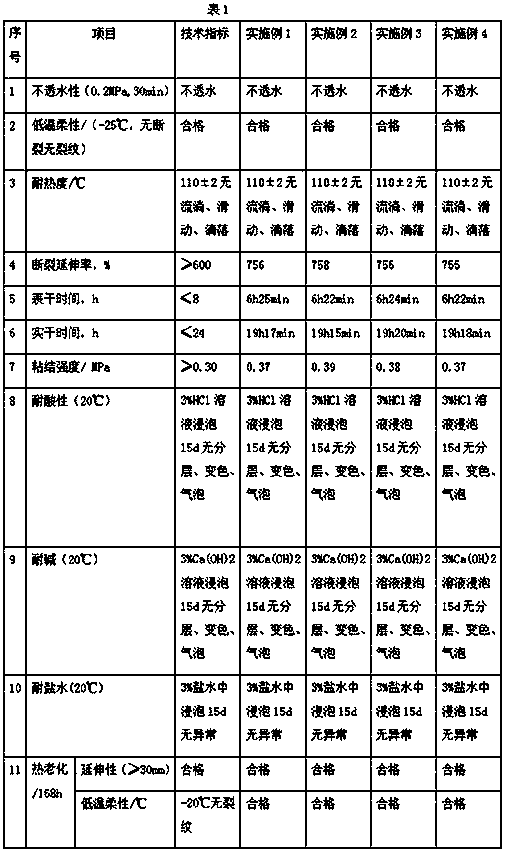

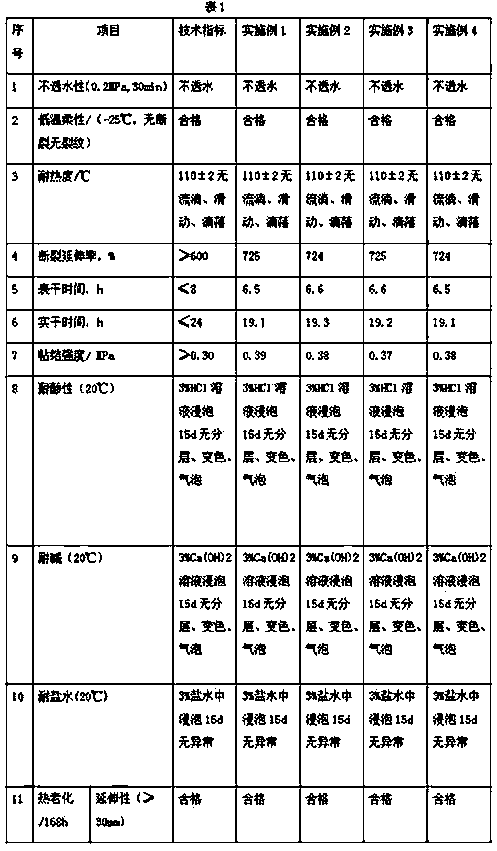

The invention discloses a water-resistant paint for building external wall ceramic tile renovation, and a preparation method and application thereof. The water-resistant paint comprises the following components in parts by weight: 0.2-20 parts of olefinic-bond unsaturated anion monomer, 0.5-10 parts of phosphate-containing surfactant, 10-60 parts of water-based bisphenol A epoxy resin, 6-8 parts of dipropylene glycol monobutyl ether, 1-5 parts of dispersing agent, 0.1-0.5 part of wetting agent, 2-4 parts of thickener and 0.5-1 part of pH regulator. The preparation method comprises the following steps: (1) stirring the water, olefinic-bond unsaturated anion monomer and phosphate-containing surfactant at 1200-1500 r / min to prepare a monomer premixture; sequentially adding the thickener, pH regulator, dispersing agent and wetting agent to prepare an emulsion polymer; (2) stirring the water, dipropylene glycol monobutyl ether and water-based bisphenol A epoxy resin for 30-50 minutes to prepare a film formation polymer; and (3) stirring the emulsion polymer and film formation polymer for 20-40 minutes to prepare the water-resistant paint.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Polyurethane modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047949AGood storage stabilityImprove high temperature resistanceFireproof paintsAntifouling/underwater paintsBituminous waterproofingPolyvinyl alcohol

The invention relates to a polyurethane modified asphalt waterproof paint, which is composed of the following raw materials by weight: 25-30 parts of a polyurethane prepolymer; 70-75 parts of 90# petroleum asphalt; 40-60 parts of water; 20-25 parts of polychloroprene latex; 4-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 1-2 parts of polypropylene glycol;3-5 parts of trihexyl o-acetylcitrate; 0.1-0.5 part of pentaerythritol ester of hydogenated rosin; 1-3 parts of polyacrylamide; and 10-15 parts of modified nano calcium carbonate. The polyurethane modified asphalt waterproof paint prepared by the method provided by the invention has good film compactness and high stability, a waterproof layer formed by the waterproof paint in a building has largebonding strength with a building base surface and good waterproof effect, moreover, after modification, the product has substantially improved water tolerance, aging resistance, acid and alkaline resistance and the like, has a simple making process, and overcomes the disadvantages of tedious making, poor film compactness, poor waterproofness and aging resistance in previous water emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047952AImprove physical performanceImprove waterproof performanceAnti-corrosive paintsBituminous coatingsBituminous waterproofingPolyvinyl alcohol

The invention relates to a modified asphalt waterproof paint for buildings. The modified asphalt waterproof paint is composed of the following raw materials by weight: 50-65 parts of 90# petroleum asphalt; 60-70 parts of water; 25-28 parts of styrene butadiene latex; 5-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 5-7 parts of polyoxypropylene glycerol ether; 3-5 parts of triethyl citrate; 0.1-0.5 part of rosin glycerin ester; 1-3 parts of sodium polyacrylate; and 10-15 parts of modified nano calcium carbonate. The modified asphalt waterproof paint for buildings prepared by the method provided by the invention has good film compactness and high stability, can be used for buildings to form a waterproof layer, which has large bonding strength with the base surfaces of buildings and has good waterproof effect, moreover, after modification, the product has greatly improved water resistance, aging resistance, acid and alkali resistance and other properties, the making process is simple, and the modified asphalt waterproof paint overcomes the shortcomings of tedious making, poor film compactness, poor water resistance and aging resistance in previous water-emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

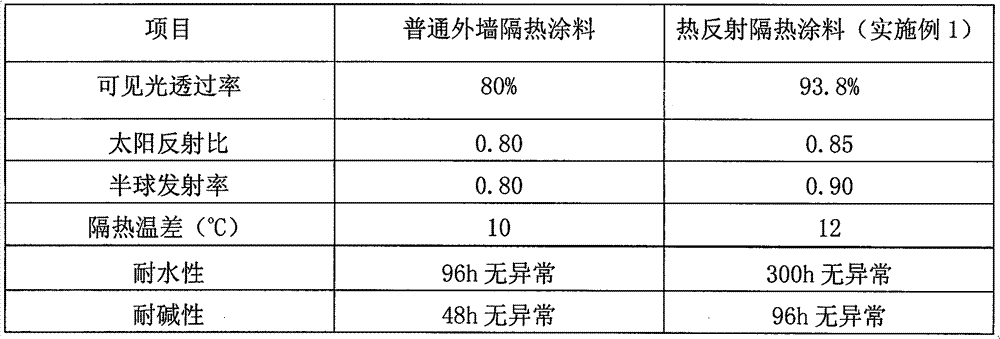

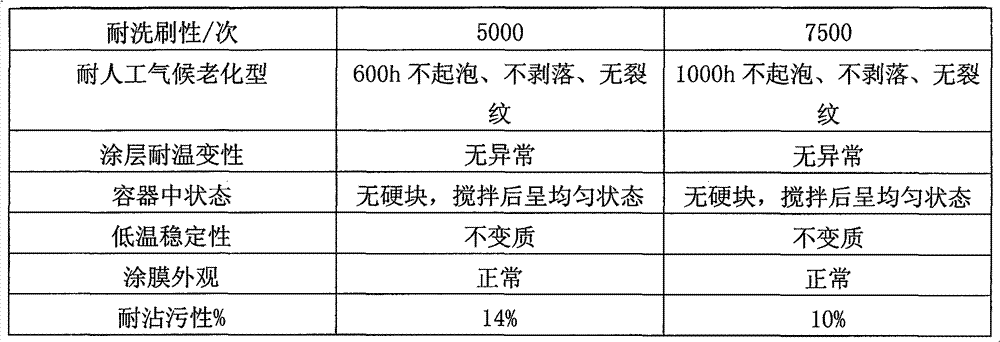

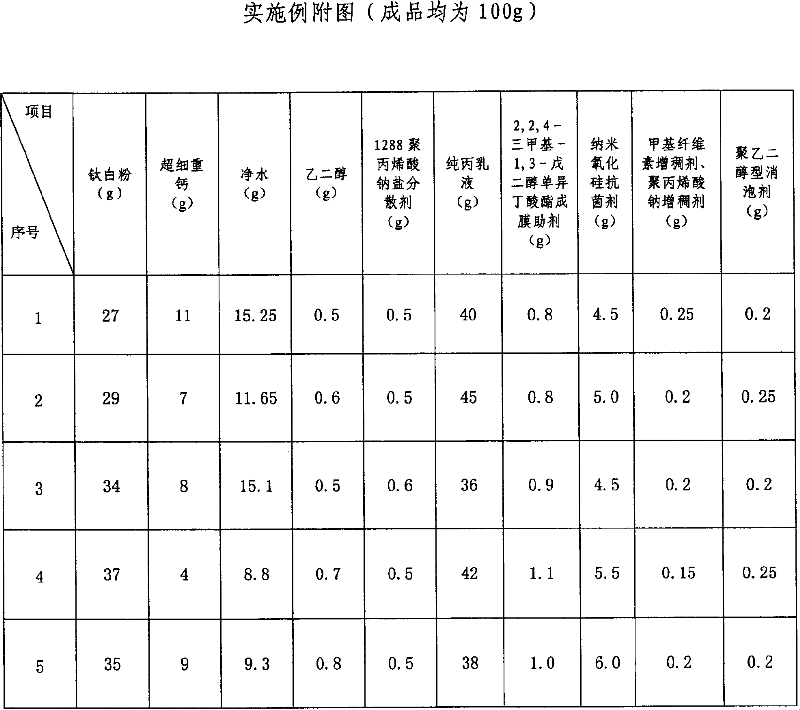

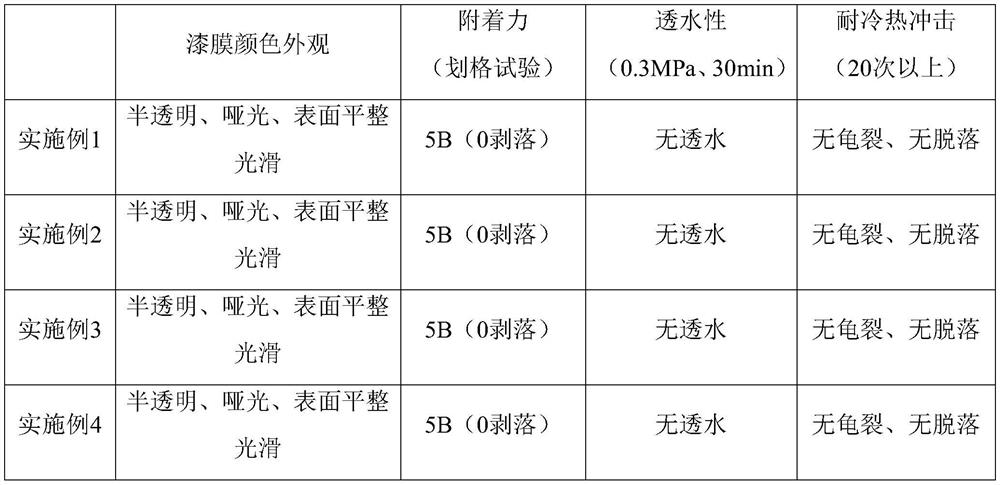

Preparation method of heat-reflecting insulation coating

InactiveCN101665648BHigh visible light transmittanceEffective shieldingReflecting/signal paintsWater bathsUltraviolet

The invention relates to a preparation method of a heat-reflecting insulation coating, which is characterized by comprising the following steps of: 1) preparation of heat-reflecting nano-powder slurry; 2) preparation of insulation powder slurry; 3) preparation of heat-reflecting insulation coating: adding silicone-modified acrylic emulsion or styrene-acrylic emulsion, a defoamer, a thickener and a film-forming auxiliary agent to the heat-reflecting nano-powder slurry, later adjusting the pH to 6.5-7. 0, and stirring for 2-3h, so as to obtain the heat-reflecting emulsion; and then treating theinsulation powder slurry for 1-2h at the temperature of 85-90 DEG C under water bath, which is then added to the heat-reflecting emulsion and stirred for 3h, and finally obtaining the heat-reflectinginsulation coating. The preparation method of the heat-reflecting insulation coating has the advantages of simple preparation process, higher visible light transmittance rate and infrared reflection for the coating, transparent and uniform coating, good adhesion and washing resistance, and outstanding ultraviolet aging resistance, and can be widely used on the exterior walls and the outdoor sunshade fabrics for heat insulating and cooling.

Owner:WUHAN UNIV OF TECH

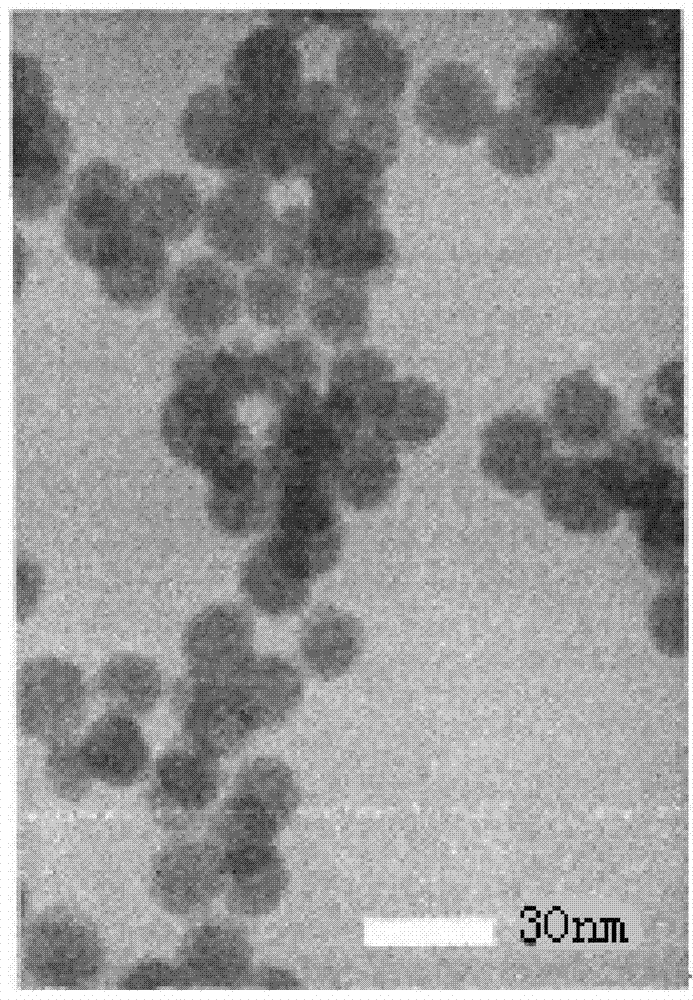

Formula of nano-antibacterial paint and its production technology

InactiveCN100355839CIncreased durabilityImprove securityAntifouling/underwater paintsPaints with biocidesMetallurgyAcrylic paint

A nano-class antibacterial paint is prepared from environment protection type water-soluble acrylic paint titanium oxide powder and nano-class antibacterial silicon oxide. Its advantages are high effect and durability, high compactness, and high adhesion.

Owner:陈家灯

Semitransparent multifunctional water-based paint

InactiveCN111909578AIncrease reflectionIncrease refractionAnti-corrosive paintsPolyurea/polyurethane coatingsCrack resistanceMicrosphere

The invention discloses a semitransparent multifunctional water-based paint which is characterized by mainly comprising the following components in parts by mass: 60-100 parts of water-based acrylic acid or water-based polyurethane emulsion, 0.1-0.5 part of pH value multifunctional assistant, 1-5 parts of a water-based antifreezing agent, 0.1-0.5 part of a wetting agent, 1-5 parts of a coalescingagent, 0.5-1 part of defoaming agent, 0.5-2 part of a mildew-proofing agent, 0.1-0.5 part of a preservative, 0.5-2 part of a flash-rust inhibitor, 0.5-2 part of a water-based coupling agent, 0.5-1 part of fumed silica and 10-20 parts of light heat-insulating microspheres. The product is semitransparent; when light-transmitting materials such as glass and color light tiles are coated with the coating, the light is not shielded and a matte surface is formed, and light pollution is avoided. Meanwhile, the heat insulation performance is more excellent. Tests show that the heat-insulating waterproof paint provided by the invention has the heat-insulating property of more than 15 DEG C, and the coating film has strong adhesion on the base material, and excellent water permeation resistance and cracking resistance.

Owner:张贞霞

High-adhesive force interior wall coating material and preparation method thereof

The invention discloses a high-adhesive force interior wall coating material. The high-adhesive force interior wall coating material is prepared from the following raw materials in parts by weight: 40-50 parts of styrene acrylic emulsion, 20-26 parts of modified adhesive, 20-25 parts of mica powder, 20-25 parts of nanometer calcium carbonate, 2-3 parts of hydroxyethyl cellulose, 2-3 parts of allyl alcohol, 3-4 parts of ethylene glycol, 3-4 parts of sodium tripolyphosphate, 1-2 parts of hexamethylphosphoric triamide, 2-3 parts of 2,2,4-trimethyl-1,3-pentanediol mono(2-methylpropanoate), 3-4 parts of sodium ethylenediamine tetramethylene phosphonate, 0.2-0.3 part of calcium-zinc stabilizer, 0.8-1 part of gamma-3-aminopropyl triethoxysilane and 20-40 parts of deionized water. The formula components of the high-adhesive force interior wall coating material have good compatibility, dispersibility and temperature property; a coating formed by the prepared coating material product is firm, safe and environmentally-friendly and has smooth surfaces, strong adhesive force, washing resistance, acid-base resistance and strong contamination resistance; the cohesiveness of the coating is further enhanced due to the addition of the modified adhesive, so that the coating is unlikely to fall off, and the property of the coating material is improved.

Owner:ANHUI ZHENXIN PAINT

High-scrubbing resistance diatom mud and preparation method thereof

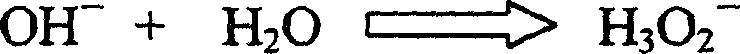

The invention relates to high-scrubbing resistance diatom mud and a preparation method thereof. The high-scrubbing resistance diatom mud comprises, by weight, 10-20 parts of water-washed diatomaceous earth, 10-15 parts of calcined diatomaceous earth, 2-5 parts of sepiolite, 10-15 parts of nano-calcium, 20-30 parts of quartz powder, 2-3 parts of redispersible gum powder, 1.5-3 parts of a photocatalyst, 0.1-0.2 part of cellulose, 0.1-0.15 part of a dispersant, 0.1-0.2 part of an antifoaming agent and 0.3-0.8 part of a mildew inhibitor. The high-scrubbing resistance diatom mud adopts the decomposition and synthesis principle of water to make a coating film synthesize water-insoluble CaSiO3, so the coating surface has an environmental protection function and also has a special water resisting function; and the preparation method has the advantages of simplicity, convenience in construction, greenness, environmental protection, high scrubbing resistance and good technologic effect.

Owner:欧亚绿邦(北京)科技有限公司

Scrubbing resistant shell powder coating

InactiveCN109777163AImprove adsorption capacityHigh hardnessAntifouling/underwater paintsPaints with biocidesCelluloseDecomposition

The invention discloses a scrubbing resistant shell powder coating which is prepared from the following raw materials: 40-60% of shell powder, 3-5% of nano-grade titanium dioxide, 30-50% of silica sol, 4-6% of a defoaming agent, 2-3% of a film-forming agent, 1-2% of cellulose, 1-2% of zinc oxide and 4-9% of attapulgite. By adding a small amount of the nano-grade titanium dioxide into the shell powder coating, the adsorption and decomposition functions of the shell coating upon free formaldehyde molecules can be improved, and meanwhile, the sterilizing and antibacterial effects of the shell powder coating can be enhanced; due to addition of the attapulgite into the shell powder coating, the adsorption capability and the hardness of the shell powder coating can be improved, and the shell powder coating has certain plasticity and adhesive properties; in addition, the attapulgite has the characteristics of being free of expansion or deformation, light in mass, large in flexibility, and thelike, and has relatively good scrubbing resistance when being combined with the silica sol.

Owner:吉林省艺梵新型材料有限公司

Preparation method of antibacterial coating

InactiveCN113122034AImprove water resistanceImprove fire performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganic solvent

The invention provides a preparation method of an antibacterial coating. The preparation method comprises the following steps: (1) sequentially and respectively adding a silane coupling agent, an adhesive, an antibacterial agent and an organic solvent into a reaction kettle to obtain a polymer, wherein the weight part ratio of the silane coupling agent to the adhesive to the antibacterial agent to the organic solvent is (1-348): (2-250): (3-120): (16-340); (2) dropwise adding 200-980 parts by weight of deionized water or distilled water into the polymer in the step (1), and stirring at the rotating speed of 100-300rpm while dropwise adding to obtain the antibacterial coating; (3) stirring the antibacterial coating obtained in the step (2) at the rotating speed of 20-50rpm for 2 hours, transferring into a sealed container, and standing for more than 12 hours; the preparation method has the beneficial effects that the sprayed coating has a long-acting antibacterial effect and has relatively high alkali resistance, water resistance and artificial aging resistance.

Owner:CYPRESS BIO TECH CO LTD +1

Water-based paint for indoor wall surfaces

InactiveCN110746810AReduce the amount of solutionMeet brushing requirementsAntifouling/underwater paintsPaints with biocidesHazardous substanceNano titania

The invention belongs to the technical field of water-based paint for architectural decoration and particularly relates to water-based paint for indoor wall surfaces. The water-based paint comprises the following ingredients in parts by weight: 40 parts of water, 1 part of thickener, 0.5 part of pH adjuster, 0.5 part of antifoamer, 1 part of humectant, 0.9 part of dispersant, 30 parts of nano-titania, 20 parts of nano diatom ooze, 7 parts of anion embedded nano-silica, 50 parts of fillers, 15 parts of emulsion, 0.6 part of antifreezer, 0.5 part of film forming assistant and 2 parts of bactericidal mildew preventive. The water-based paint for the indoor wall surfaces, provided by the invention, can be used for effectively adsorbing formaldehyde released due to indoor fitment, organic aromatic hydrocarbon benzene solvents on sheets and substances harmful to human bodies such as amine substances; and through actions such as neutralization with harmful gases with positive charges and coating and settling of ions or particles of electrically-neutral harmful gases, the activity of the substances harmful to the human bodies is lost or lowered, and thus, a safe air quality environment fordwelling and living is provided.

Owner:高卫

High-alkali-resistance internal wall paint and preparation method thereof

The invention discloses a high-alkali-resistance internal wall paint which is prepared from the following raw materials in parts by weight: 42-50 parts of styrene-acrylic emulsion, 13-20 parts of modified bonding agent, 10-20 parts of calcite powder, 15-20 parts of feldspar powder, 3-4 parts of methyl hydroxyethyl cellulose, 1-2 parts of vanadium oxytrichloride, 1-3 parts of 2-methyl-1,3-propanediol, 2-3 parts of ethylene glycol, 2-4 parts of sodium monofluorophosphate, 1-2 parts of diethylene glycol butyl ether, 2-3 parts of 2,2,4-trimethyl-1,3-pentanediol mono(2-methylpropanoate), 1-2 parts of diethanolamine, 1-3 parts of sodium ethylenediamine tetramethylene phosphonate, 1-2 parts of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane, 0.2-0.4 part of polyoxypropylene glycerol ether and 20-40 parts of deionized water. The formula components have favorable compatibility, dispersity and temperature property; the produced paint product has the advantages of firm coating, smooth surface, high adhesive force, high scrub resistance, high acid / alkali resistance, high fouling resistance, high safety and environmental protection; and the added modified bonding agent further enhances the bonding property of the coating, so that the coating can not easily fall off, and the properties of the paint are enhanced.

Owner:ANHUI ZHENXIN PAINT

Strong-acid-resisting high-strength hanging beam and preparation method thereof

InactiveCN106590388APlay the role of anti-corrosion protectionStrong scrub resistanceFireproof paintsAnti-corrosive paintsEpoxyStrong acids

The invention discloses a strong-acid-resisting high-strength hanging beam. A component A and a component B contain the following components in parts by weight: the component A comprises the following components in parts by weight: 11-14 parts of epoxy resin, 19-23 parts of polyurethane: titanium dioxide, 12-17 parts of graphite fluoride, 19-24 parts of barium sulfate, 21-24 parts of a thixotropic agent, 13-19 parts of epoxy diacrylate, 8-13 parts of polydimethylsiloxane, 4-9 parts of active amine, 13-17 parts of a pH (Potential of Hydrogen) regulator, 9-14 parts of a silane coupling agent and 16-22 parts of an auxiliary material; the component B comprises the following components in parts by weight: 13-18 parts of tributylphenol polyoxyethylene ether, 12-18 parts of fine-grained aluminum oxide, 9-14 parts of carboxymethyl cellulose, 13-19 parts of barium sulfate, 2-7 parts of hexamethyl cyclotrisiloxane, 3-11 parts of light calcium carbonate, 25-31 parts of de-ionized water, 13-18 parts of a de-foaming agent, 4-9 parts of a coupling agent and 2-9 parts of a flame retardant.

Owner:苏州富艾姆工业设备有限公司

Antibacterial polyurethane-modified asphalt waterproof coating and preparation method thereof

InactiveCN107903819ALow shrinkageHigh bonding strengthAntifouling/underwater paintsPaints with biocidesFumed silicaTackifier

Antibacterial polyurethane-modified asphalt waterproof coating and a preparation method thereof are provided. The antibacterial polyurethane-modified asphalt waterproof coating is prepared from polyurethane prepolymer, No. 90 petroleum asphalt, modified nano calcium carbonate, 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane, a tackifier, n-butyl acetate, citric acid, dibutyltin dilaurate, polyoxyethylene polyoxypropylene ether, fumed silica, chitosan and 2-methyl-4-isothiazoline-3-one. The preparation method comprises: modifying No. 90 petroleum asphalt with polyurethane prepolymerand modified nano calcium carbonate; adding 3-[2-(2-aminoethylamino)ethylamino]propyl-trimethoxysilane, citric acid and n-butyl acetate into a reactor, and stirring well; adding chitosan, 2-methyl-4-isothiazoline-3-one, fumed silica, the tackifier and dibutyltin dilaurate, and stirring well; adding polyoxyethylene polyoxypropylene ether; continuing to stir until no powder floats; shearing all thematerials until good dispersion to obtain the coating.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com