Preparation method of antibacterial coating

A technology of antibacterial coatings and antibacterial agents, applied in the field of preparation of antibacterial coatings, can solve the problems of antibacterial properties, scrub resistance, alkali resistance, water resistance and artificial aging resistance, and complex preparation methods. , to achieve the effects of easy operation, strong adhesion and strong resistance to artificial aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

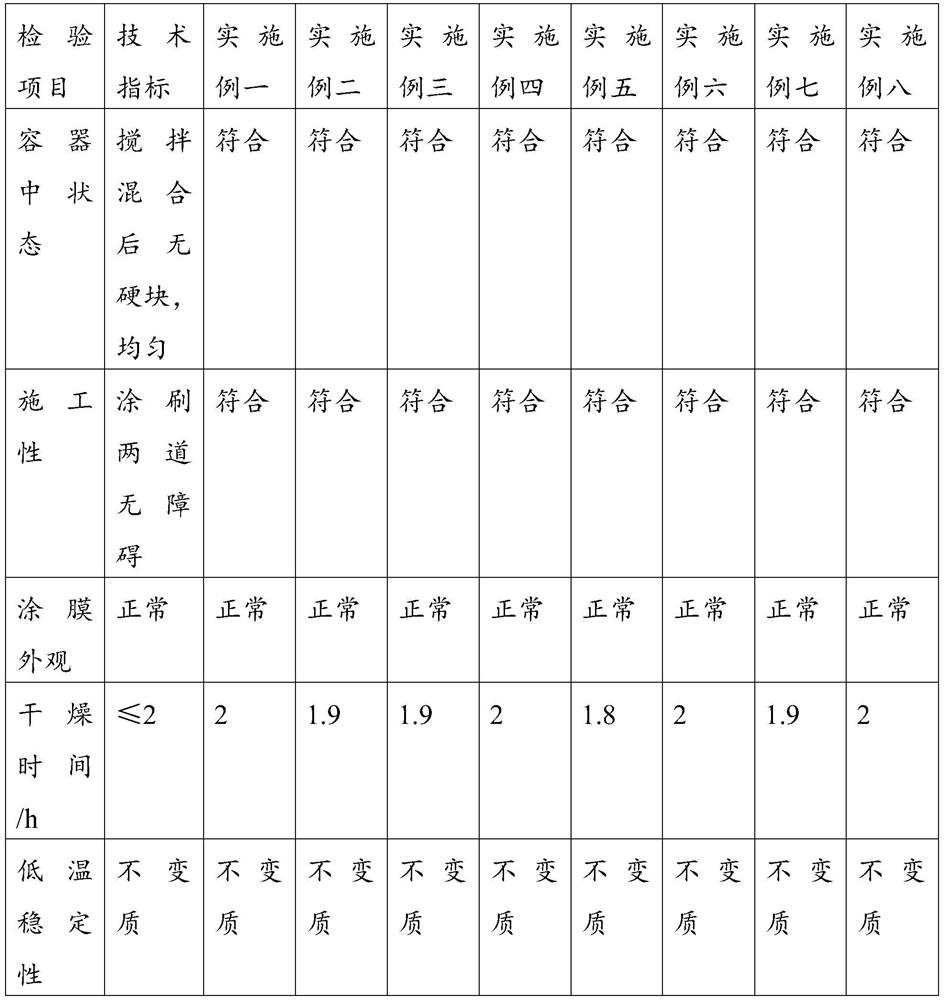

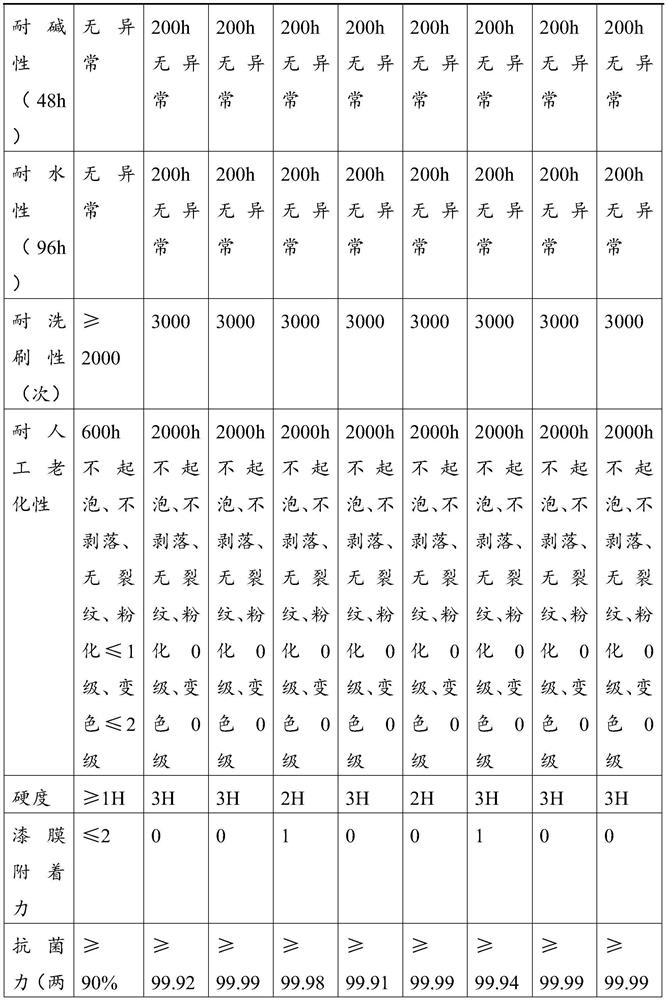

Examples

Embodiment 1

[0025] 1) Will Evonik SIVO 160 silane coupling agent 40 parts, Evonik 10 parts of SIVO110 coupling agent, 18 parts of antibacterial agent dimethyl octadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 100 parts of adhesive acrylic acid and 200 parts of organic solvent ethanol were added in turn The polymer is obtained in the reactor, and the above parts are parts by weight.

[0026] SIVO 160 is an aqueous silane sol-gel system, in the form of colorless to light yellow, low viscosity liquid, SIVO 110 is a water-based silane sol-gel system, opaque to emulsion, color from colorless to light yellow.

[0027] 2) Drop deionized water or distilled water that is 632 parts by weight into the polymer of step (1), and stir at 150 rpm to obtain an antibacterial coating;

[0028] 3) Stir the antibacterial coating obtained in step 2) for 2 hours at a speed of 30 rpm, then transfer it to a sealed container and let it stand for 12 hours.

Embodiment 2

[0030] 1) 223 parts of silane coupling agent methyltrimethoxysilane, 18 parts of antibacterial agent dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 83 parts of adhesive acrylic acid 30 parts of crosslinking agent triethoxyvinyl silane and 92 parts of organic solvent ethanol were respectively added into the reaction kettle to obtain a polymer, and the above parts are parts by weight.

[0031] 2) Drop deionized water or distilled water that is 554 parts by weight into the polymer in step (1), and stir at 180 rpm to obtain an antibacterial coating;

[0032] 3) Stir the antibacterial coating obtained in step 2) for 2 hours at a speed of 35 rpm, then transfer it to a sealed container and let it stand for 12 hours.

Embodiment 3

[0034] 1) Add 218 parts of silane coupling agent methyltrimethoxysilane, 15 parts of 3-(2,3-epoxypropoxy)propyltrimethoxysilane, 14 parts of (2-cyanoethyl)triethoxysilane 16 parts, 16 parts of antibacterial agent dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride, 91 parts of adhesive acrylic acid and 91 parts of organic solvent ethanol are respectively added in the reactor to obtain polymerization The above parts are parts by weight.

[0035] 2) Drop deionized water or distilled water with 555 parts by weight into the polymer of step (1), and stir at 200 rpm to obtain antibacterial coating;

[0036] 3) Stir the antibacterial coating obtained in step 2) for 2 hours at a speed of 30 rpm, then transfer it to a sealed container and let it stand for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com