Preparation method of rosin modified epoxy ester resin

An epoxy ester resin and rosin modification technology, which is applied in the field of deep processing of rosin, can solve problems such as poor weather resistance, and achieve the effects of good scrub resistance, fast drying and strong adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

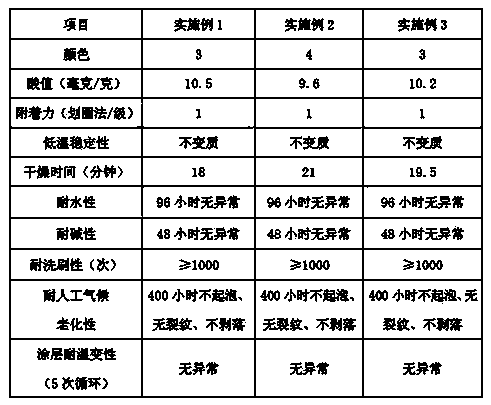

Examples

Embodiment 1

[0012] Add 1 kg of epoxy resin and 1 kg of soy-oleic acid into the reactor, stir evenly, heat up to 90°C, react for 60 minutes, then add 200 g of rosin and 125 g of diallyl phthalate, stir evenly, and heat up to 120° C., reacting for 60 minutes to obtain a rosin-modified epoxy ester resin.

Embodiment 2

[0014] Add 10 kg of epoxy resin and 12 kg of soybean oil into the reaction kettle, stir evenly, heat up to 100°C, react for 30 minutes, then add 3 kg of rosin and 1 kg of glycerin, stir evenly, heat up to 115°C, react for 80 minutes, A rosin-modified epoxy ester resin was obtained.

Embodiment 3

[0016] Add 50 kg of epoxy resin and 40 kg of soybean oil into the reaction kettle, stir evenly, heat up to 95°C, react for 45 minutes, then add 12.5 kg of rosin and 7.5 kg of trimethylolpropane, stir evenly, heat up to 110°C, React for 70 minutes to obtain rosin-modified epoxy ester resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com