Water-resistant paint for building external wall ceramic tile renovation, and preparation method and application thereof

A technology for waterproof coatings and building exterior walls, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of scrub resistance, opacity stability, viscosity and hardness indicators are not ideal, and achieve strong viscosity and hardness, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

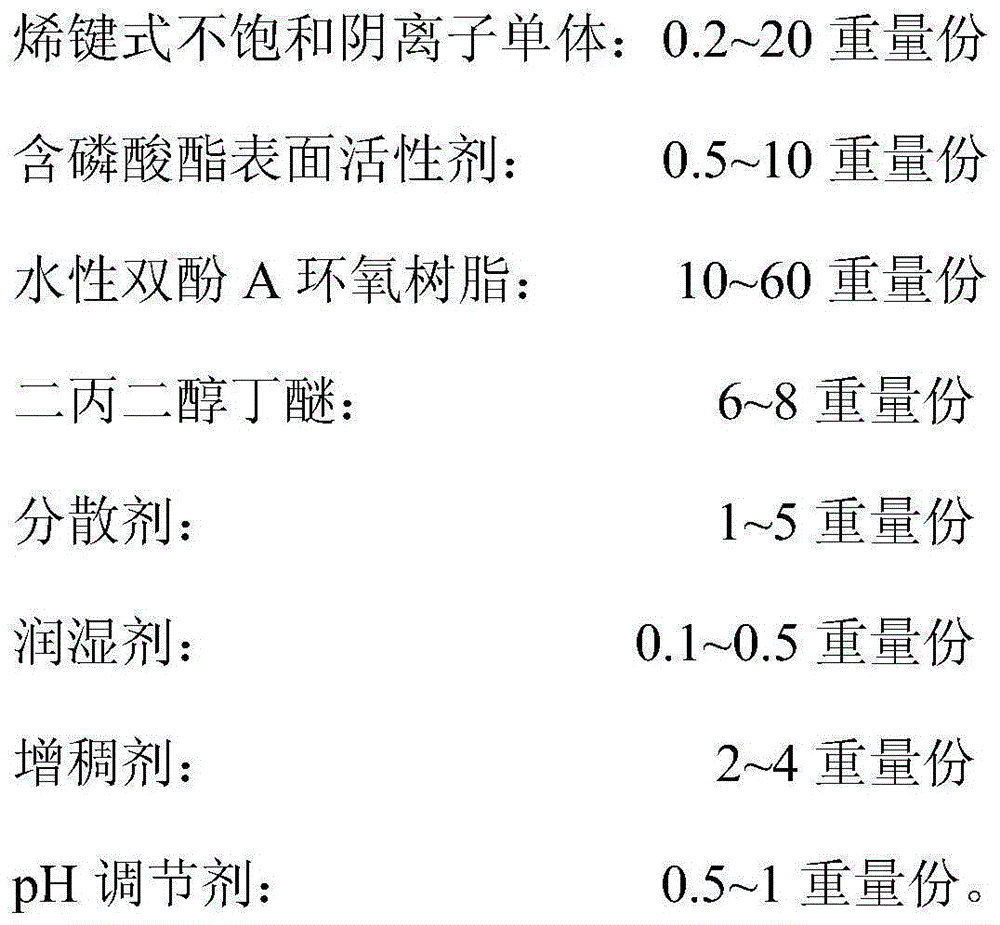

Method used

Image

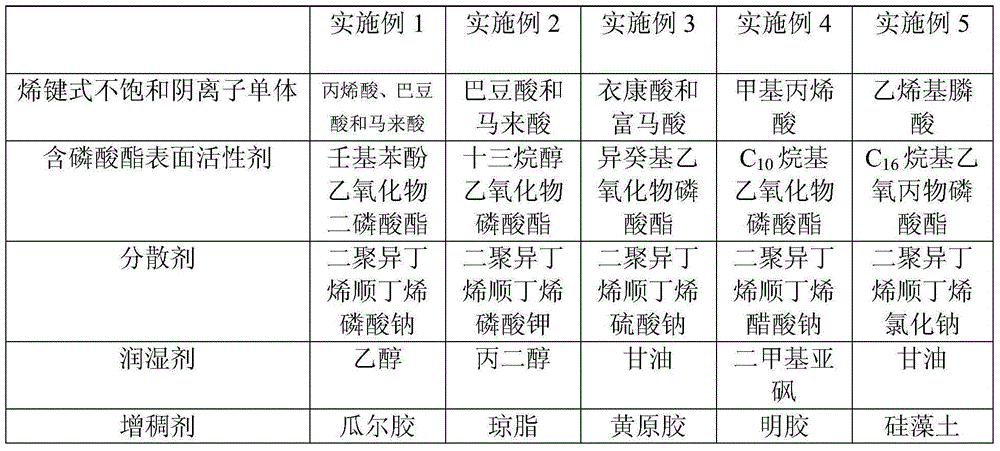

Examples

Embodiment 1

[0042] (1) Preparation of emulsion polymer: mix water, ethylenically unsaturated anionic monomer and phosphate-containing surfactant, stir at 1200r / min to prepare monomer premix; then add thickener and pH regulator in sequence , dispersant and wetting agent, made into emulsion polymer;

[0043] (2) Preparation of film-forming polymer: mix water, dipropylene glycol butyl ether and water-based bisphenol A epoxy resin, stir for 50min, and make film-forming polymer;

[0044] (3) Preparation of waterproof coating: mixing the emulsion polymer and the film-forming polymer, stirring for 20 minutes, to prepare the waterproof coating.

Embodiment 2

[0046] (1) Preparation of emulsion polymer: mix water, ethylenically unsaturated anionic monomer and phosphate-containing surfactant, stir at 1500r / min to prepare monomer premix; then add thickener and pH regulator in sequence , dispersant and wetting agent, made into emulsion polymer;

[0047] (2) Preparation of film-forming polymer: mix water, dipropylene glycol butyl ether and water-based bisphenol A epoxy resin, stir for 30min, and make film-forming polymer;

[0048] (3) Preparation of waterproof coating: mixing emulsion polymer and film-forming polymer, stirring for 40 min, to prepare the waterproof coating.

Embodiment 3

[0050] (1) Preparation of emulsion polymer: mix water, ethylenically unsaturated anionic monomer and phosphate-containing surfactant, stir at 1350r / min to prepare monomer premix; then add thickener and pH regulator in sequence , dispersant and wetting agent, made into emulsion polymer;

[0051] (2) Preparation of film-forming polymer: mix water, dipropylene glycol butyl ether and water-based bisphenol A epoxy resin, stir for 40min, and make film-forming polymer;

[0052] (3) Preparation of waterproof coating: mixing emulsion polymer and film-forming polymer, stirring for 30 min, to prepare the waterproof coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com