Water-based diatom ooze coating and preparation method thereof

A diatom mud coating and water-based technology, which is applied in the field of environmentally friendly interior wall coatings, can solve the problems of unsatisfactory service life, no indoor air purification, and poor scrub resistance, so as to ensure environmental protection, strong covering and strong bonding force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

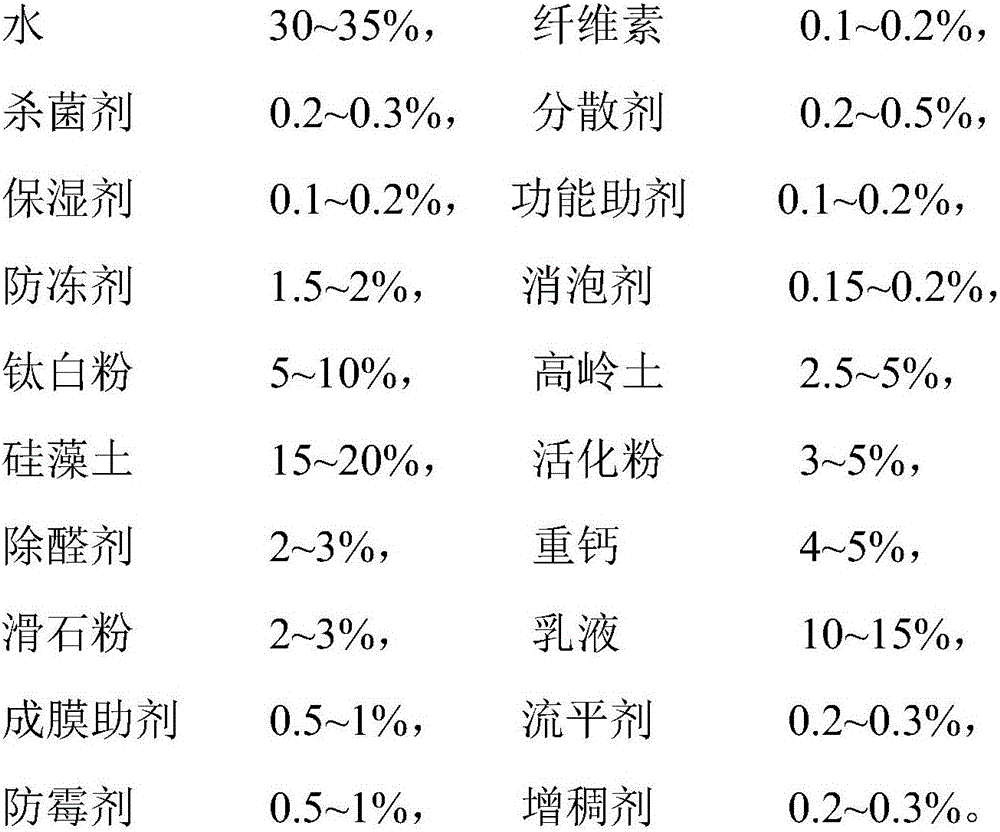

[0026] A water-based diatom mud coating, by weight percentage, consists of the following components:

[0027]

[0028] The preparation method of the above-mentioned water-based diatom mud coating comprises the following steps: firstly water is placed in a stainless steel dispersion tank, and the dispersion tank is placed under a hanging high-speed dispersion machine, and then the cellulose, bactericide, dispersant, humectant , functional additives, antifreeze and defoamer are added to the dispersion tank, and stirred at a speed of 400 rpm for 15 minutes; then titanium dioxide, kaolin, diatomaceous earth, activation powder, aldehyde remover, heavy calcium and talc powder into the dispersion tank, and stirred at 600 rpm for 30 minutes, then grind the mixture with a sand mill, the grinding fineness is less than 25 μm; after grinding, add emulsion, film-forming aids, leveling Stir for 10 minutes at a speed of 400 rpm with antifungal agent and antifungal agent, and finally add t...

Embodiment 2

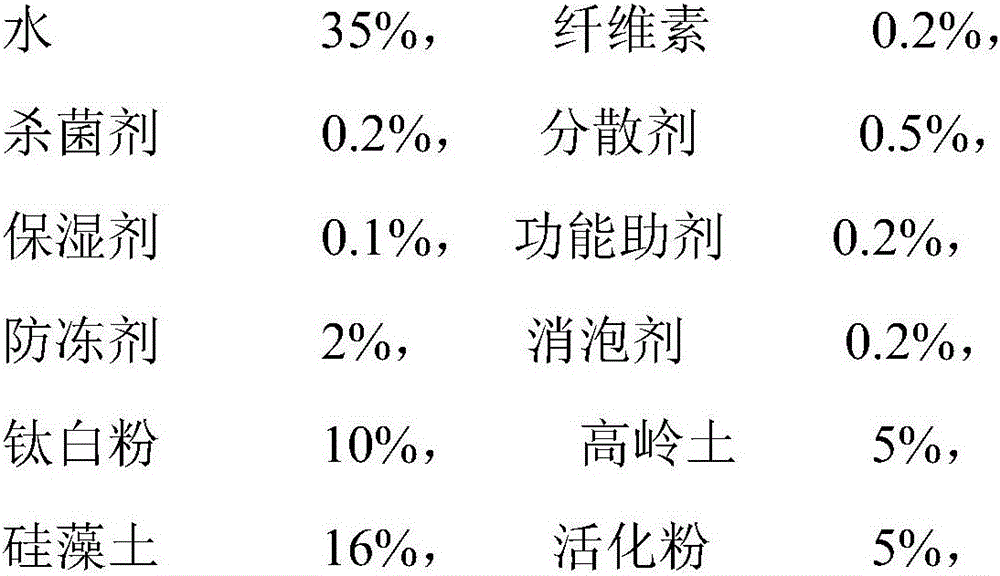

[0030] A water-based diatom mud coating, by weight percentage, consists of the following components:

[0031]

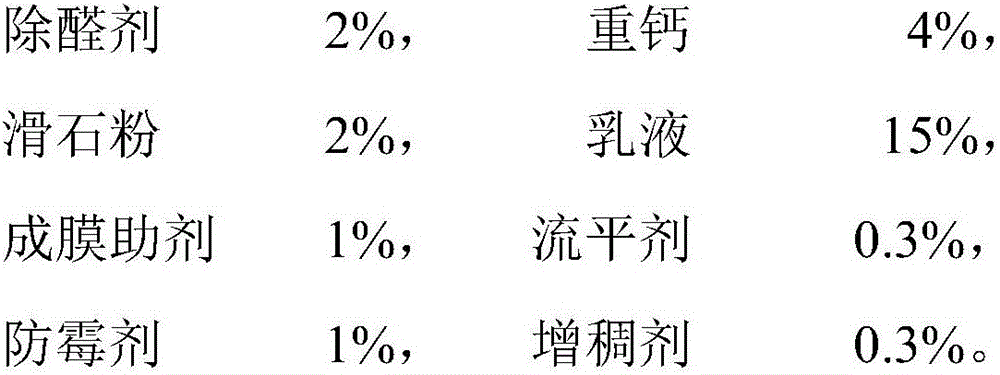

[0032]

[0033] The preparation method of the above-mentioned water-based diatom mud coating comprises the following steps: firstly water is placed in a stainless steel dispersion tank, and the dispersion tank is placed under a hanging high-speed dispersion machine, and then the cellulose, bactericide, dispersant, humectant , functional additives, antifreeze and defoamer are added to the dispersion tank, and stirred at a speed of 400 rpm for 15 minutes; then titanium dioxide, kaolin, diatomaceous earth, activation powder, aldehyde remover, heavy calcium and talc powder into the dispersion tank, and stirred at 800 rpm for 30 minutes, then grind the mixture with a sand mill, and the grinding fineness is less than 25 μm; after grinding, add emulsion, film-forming aids, leveling Stir for 10 minutes at a speed of 400 rpm with antifungal agent and antifungal agent, a...

Embodiment 3

[0035] A water-based diatom mud coating, by weight percentage, consists of the following components:

[0036]

[0037] The preparation method of the above-mentioned water-based diatom mud coating comprises the following steps: firstly water is placed in a stainless steel dispersion tank, and the dispersion tank is placed under a hanging high-speed dispersion machine, and then the cellulose, bactericide, dispersant, humectant , functional additives, antifreeze and defoamer are added to the dispersion tank, and stirred at a speed of 400 rpm for 15 minutes; then titanium dioxide, kaolin, diatomaceous earth, activation powder, aldehyde remover, heavy calcium and talc powder into the dispersion tank, and stirred at 600 rpm for 30 minutes, then grind the mixture with a sand mill, the grinding fineness is less than 25 μm; after grinding, add emulsion, film-forming aids, leveling Stir for 10 minutes at a speed of 400 rpm with antifungal agent and antifungal agent, and finally add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com