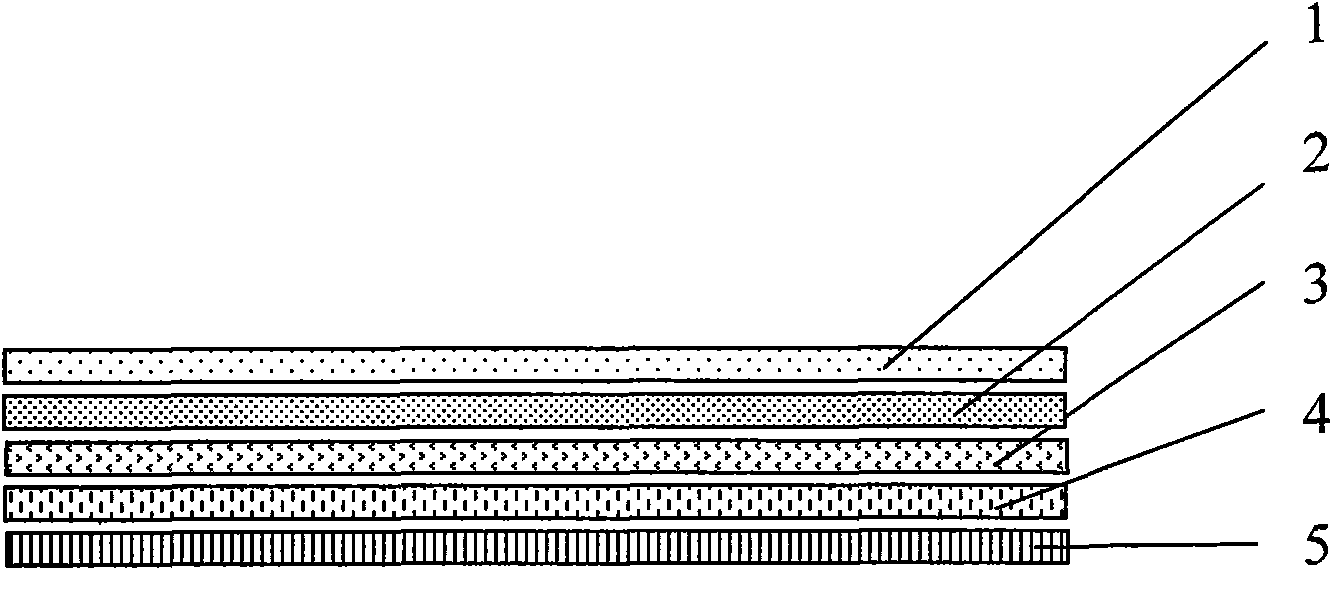

Method for preparing coating transfer film for decoration

A transfer film and coating technology, applied in wax coatings, decorative arts, decorative structures, etc., can solve the problems of complex construction process, poor environmental protection and weather resistance, and high cost of wallpaper production, and achieve beautiful and diverse indoor environments, wear-resistant. And the effect of strong scrub resistance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0026] Embodiment 1-3, the preparation of adhesive layer

[0027] (1), polyvinyl alcohol (10% solution) 70-95 parts

[0028] 5-Chloro-2-methyl-4-isothiazolin-3-one 0.2-1 parts

[0029] Ethylene-vinyl acetate polymer emulsion 5-12 parts

[0030] OP-10 1-2 parts

[0031] 10-20 parts of deionized water

[0032] (2), modified starch (5% solution) 70-90 parts

[0033] 2-Methyl-4-isothiazolin-3-one 0.5-1 part

[0034] Ethylene-vinyl acetate polymer emulsion 5-15 parts

[0035] Pingpingjia O 1-2 parts

[0036] 5-20 parts of deionized water

[0037] (3), polyvinyl alcohol (10% solution) 40-60 parts

[0038] Modified starch (5% solution) 50-60 parts

[0039] 1,3-dimethylol-5,5-dimethylhydantoin 0.8-1.5 parts

[0040] Silicone surfactant 0.2-0.8 parts

[0041] 10-20 parts of deionized water

[0042] Preparation method:

[0043] Add 10kg of polyvinyl alcohol and 90kg of water to the reaction kettle, heat it to about 95°C under the stirring state of 80-100 revolutions per min...

Embodiment 4

[0046] Embodiment 4, the preparation of coating layer:

[0047] Titanium dioxide 8-14 parts

[0048] Light calcium carbonate 10-16 parts

[0049] Talcum powder 5-7 parts

[0050] Acrylic acid emulsion 16-25 parts

[0051] Polyvinyl alcohol (10% solution) 40-60 parts

[0052] UV-531 anti-ultraviolet agent 0.5-0.8 parts

[0053] Hexadecyltrimethylammonium bromide 0.4-0.6 parts

[0054] 1,3-dimethylol-5,5-dimethylhydantoin 0.4-0.8 parts

[0055] Antioxidant 1076 0.6-1.2 parts

[0056] Pigment 0-2 parts

[0057] 60-80 parts of deionized water

[0058] Preparation method:

[0059] Add 10kg of polyvinyl alcohol and 90kg of water to the reaction kettle, heat it to about 95°C under the stirring state of 80-100 revolutions per minute, keep it for 30-40 minutes, and wait until the polyvinyl alcohol is completely dissolved for later use;

[0060] Add 30-35kg of water to the titanium dioxide into the container, and disperse at a stirring speed of 1500 rpm for 30-40 minutes for l...

Embodiment 5

[0065] Embodiment 5, the preparation of coating layer:

[0066] Titanium dioxide 8-15 parts

[0067] Aluminum oxide 10-25 parts

[0068] Water-based polyurethane emulsion 10-25 parts

[0069] Polyvinyl alcohol (10% solution) 40-60 parts

[0070] Ethylene-vinyl acetate copolymer emulsion 10-15 parts

[0071] Ciba BT-202 anti-ultraviolet agent 0.4-0.6 parts

[0072] Hexadecyltrimethylammonium bromide 0.6-1.2 parts

[0073] 5-Chloro-2-methyl-4-isothiazolin-3-one 0.2-0.5 parts

[0074] Antioxidant 1010 0.2-0.8 parts

[0075] Pigment 0-2 parts

[0076] Deionized water 95-120 parts

[0077] Preparation method:

[0078] Add 10kg of polyvinyl alcohol and 90kg of water to the reaction kettle, heat it to about 95°C under the stirring state of 80-100 revolutions per minute, keep it for 30-40 minutes, and wait until the polyvinyl alcohol is completely dissolved for later use;

[0079] Add 30-40kg of water to the titanium dioxide into the container, and disperse at a stirring spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com