Formula of nano-antibacterial paint and its production technology

A technology of antibacterial coating and production process, which is applied in the formulation and production process of nano-antibacterial coatings, and can solve problems such as inconvenient operation, unpleasant smell, and short drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

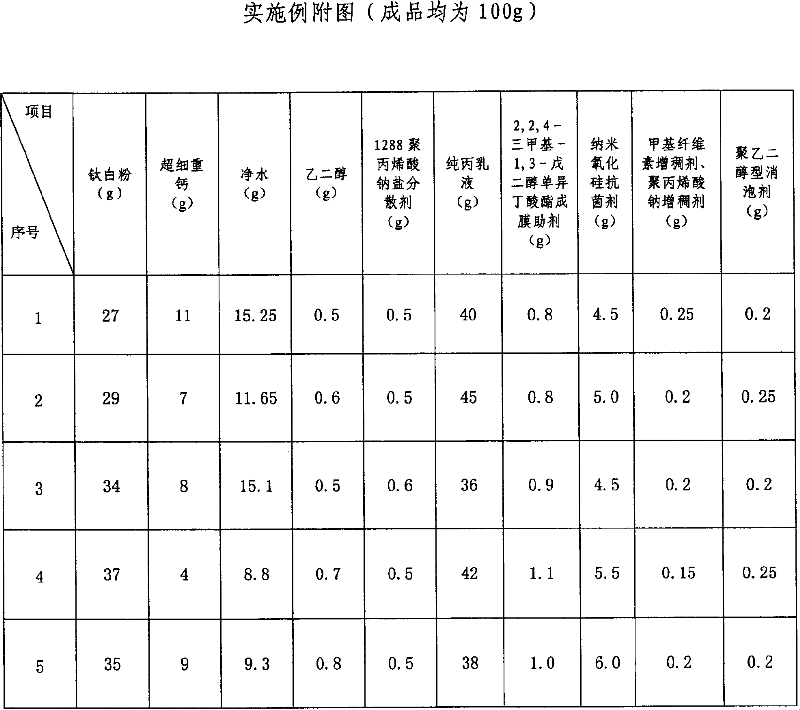

Examples

Embodiment 1

[0008] Weigh 30g of titanium dioxide, 8g of superfine heavy calcium, dilute with 19.6g of clean water, add 0.5g of ethylene glycol and 0.5g of 1288 polyacrylic acid sodium salt dispersant, carry out high-speed dispersion stirring and grinding, put the ground materials back into the mixer in order Sequentially add 40g pure acrylic emulsion, 1g2,2,4-trimethyl-1,3-pentanediol monoisobutyrate film-forming aid and pre-dispersed 4g nano-silica antibacterial agent, 0.2g sodium polyacrylate Stir the thickener, 0.2g polyethylene glycol type defoamer, etc. evenly, and pay attention to constantly adjust the pH value to 9-10 during the stirring process. After being uniformly dispersed, the product is obtained, and can be measured, packaged, discharged, and stored.

Embodiment 2

[0010] The raw materials weighed according to the weight ratio are: 32g of titanium dioxide, 8g of superfine heavy calcium, 11.4g of purified water, 0.5g of ethylene glycol, 0.5g of 1288 polyacrylic acid sodium salt dispersant, 42g of pure acrylic emulsion, 1g2,2,4- Trimethyl-1,3-pentanediol monoisobutyrate, polyethylene glycol type defoamer 0.2g, the process steps are the same as in Example 1.

[0011] See accompanying drawing 1 for other embodiments.

[0012] The invention is novel in concept and can effectively solve the problems of traditional interior wall coatings such as being susceptible to moisture and easily multiplying bacteria and mold, as well as overcoming the unpleasant smell, short drug effect and difficult operation caused by using physical or chemical methods to disinfect the surface of the interior wall. Convenience, physical method one-time investment is big etc. deficiency, is conducive to the protection of environment and people's disease prevention and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com