Window lamination method for paper

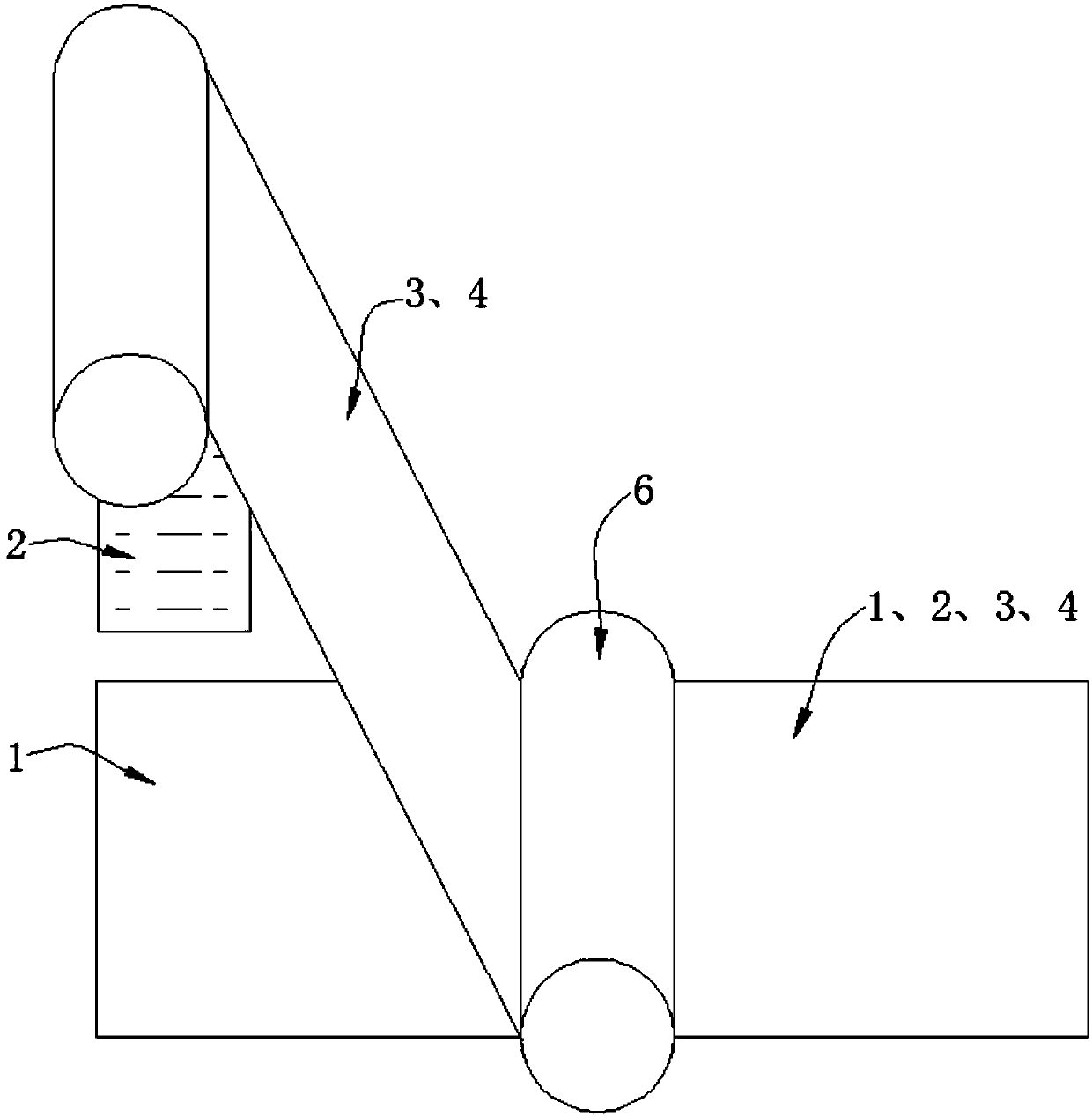

A film-coating and window-opening technology, which is applied to chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of uneven paper, difficult control, and difficult production, and achieve small thermal expansion and deformation. The effect of reducing the difficulty of the process and easy control of the coating amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

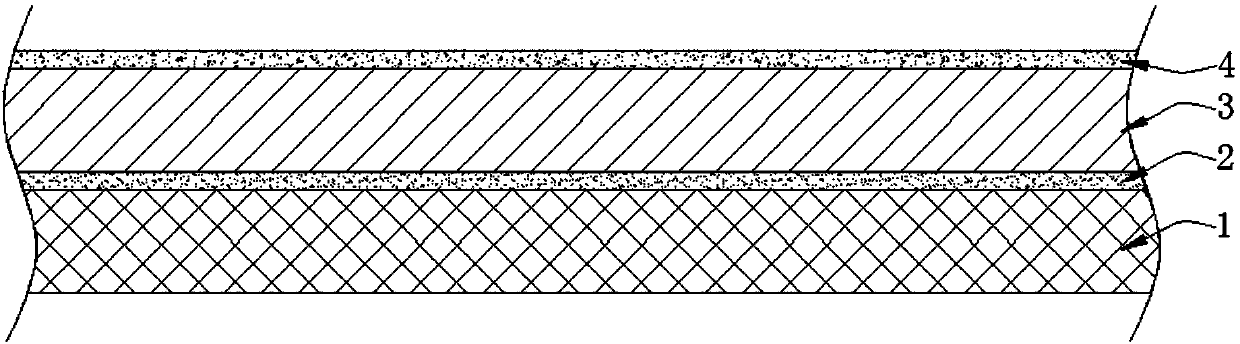

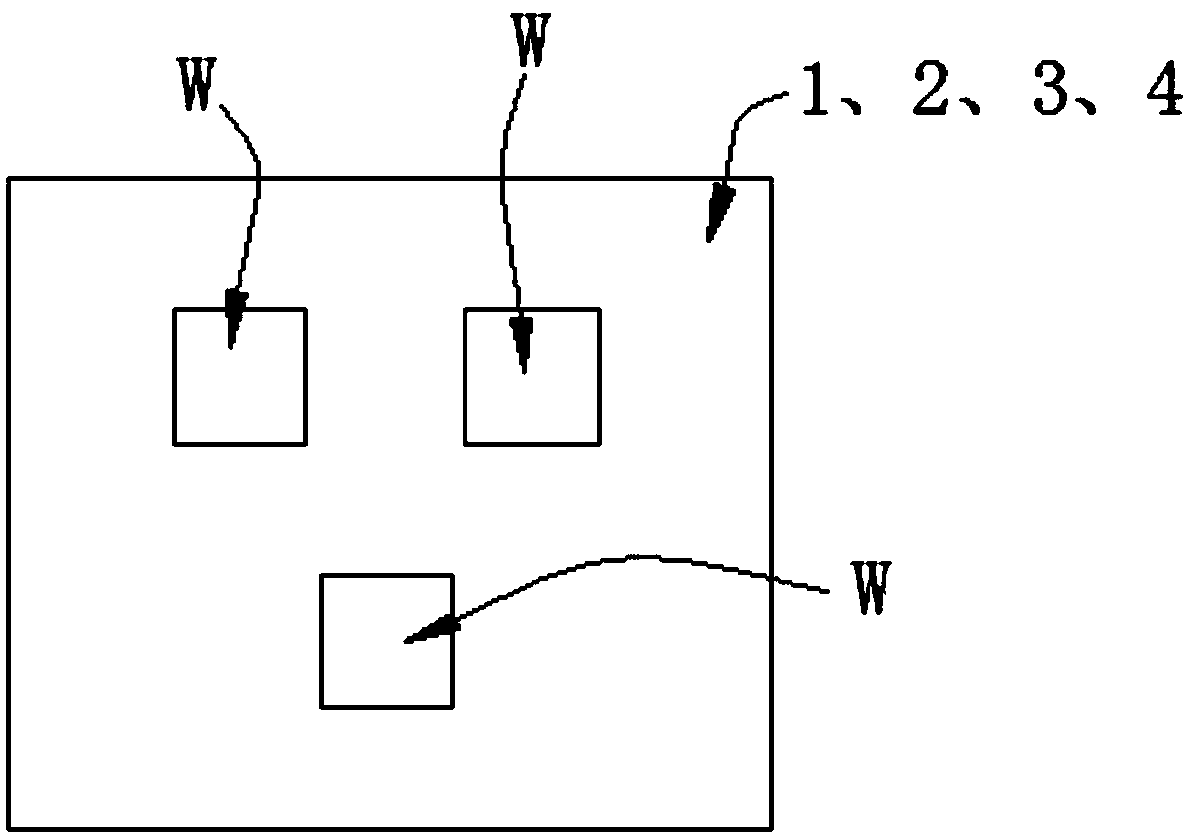

[0055] As a preferred embodiment of the present invention: in step 1, when the double-sided corona film 3 is bonded to the paper 1, the side of the double-sided corona film 3 pre-coated with the hot melt adhesive 4 is arranged facing upward.

[0056] As a preferred embodiment of the present invention: in step 3, the heat-pressing roller 7 is directly pressed on the heat-sealing film 5 .

[0057] As a preferred embodiment of the present invention: in Step 3, the thickness of the heat-sealing film 5 is between 0.2mm and 0.7mm, and the temperature of the hot pressing roller 7 is between 80°C and 85°C.

[0058] As a preferred embodiment of the present invention: in Step 3, the thickness of the heat-sealing film 5 is 0.35mm, and the temperature of the hot pressing roller 7 is between 80°C and 85°C.

[0059] As a preferred embodiment of the present invention: the paper 1 is silver cardboard, and the cold paste glue 2 is food-grade water-based cold paste glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com