Aqueous softening aid for synthetic leather

A synthetic leather, water-based technology, applied in coatings, textiles and papermaking, polyurea/polyurethane coatings, etc., can solve problems such as air bubbles and pinholes in synthetic leather, achieve soft and smooth feel, improve environmental protection, and improve softness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 2g of polyvinylpyrrolidone and 1g of methylene bisacrylamide to 100g of water, heat up to reflux state and keep stirring for 10min, then add 20g of polyvinyl butyral and 0.3g of polylysine, continue to reflux and keep stirring 30min to obtain water-based polyvinyl butyral emulsion;

[0024] (2) Add 2g of oligosaccharides and 1g of pregelatinized potato starch to 5g of microcrystalline cellulose, heat up to 85-90°C and grind for 15min, then transfer to -5-0°C and let stand for 30min, then heat up to Grinding at 85-90°C for 15 minutes to obtain swellable modified microcrystalline cellulose;

[0025] (3) Add 3g of water-based α-pinene / diacetone acrylamide copolymer, swelling type modified microcrystalline cellulose and 1g of calcium stearoyl lactylate to 50g of water, heat up to reflux state and keep stirring for 15min, then add water-based polymer Vinyl butyral emulsion, 1g of nano-titanium dioxide-loaded rosin glyceride and 0.5g of hexamethylolmelamine hexamethy...

Embodiment 2

[0029] (1) Add 3g of polyvinylpyrrolidone and 0.5g of methylene bisacrylamide to 100g of water, heat up to reflux state and keep stirring for 10min, then add 25g of polyvinyl butyral and 0.3g of polylysine, and continue to reflux and keep warm Stir for 30 minutes to obtain water-based polyvinyl butyral emulsion;

[0030] (2) Add 2g of oligosaccharides and 1g of pregelatinized potato starch to 5g of microcrystalline cellulose, heat up to 85-90°C and grind for 15min, then transfer to -5-0°C and let stand for 30min, then heat up to Grinding at 85-90°C for 15 minutes to obtain swellable modified microcrystalline cellulose;

[0031] (3) Add 5g of water-based α-pinene / diacetone acrylamide copolymer, swelling type modified microcrystalline cellulose and 1g of calcium stearoyl lactylate to 50g of water, and heat up to reflux state and keep stirring for 15min, then add water-based polymer Vinyl butyral emulsion, 1g of nano-titanium dioxide-loaded rosin glyceride and 0.5g of hexamethyl...

Embodiment 3

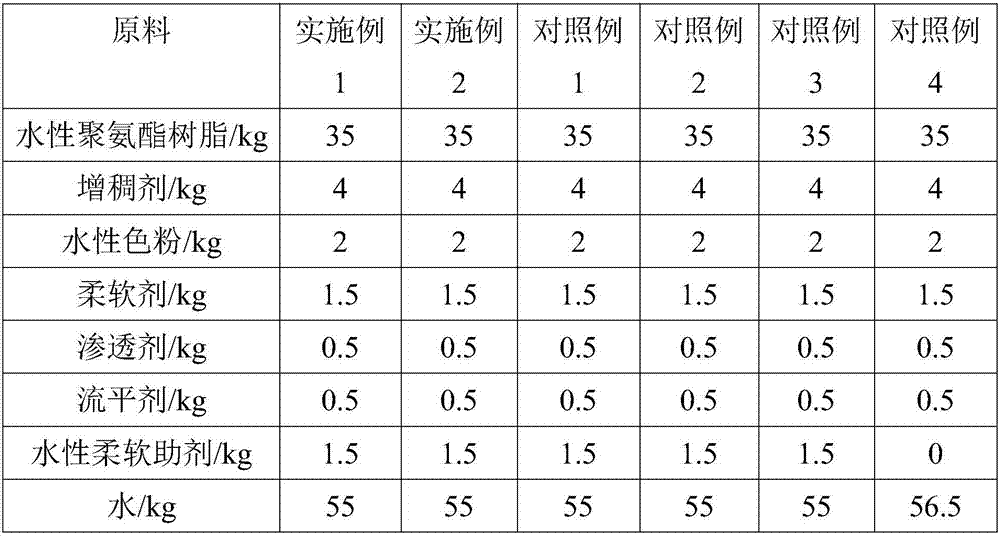

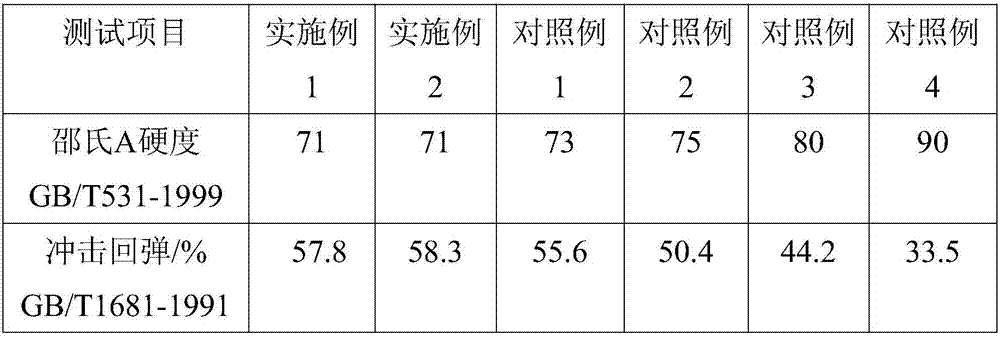

[0047] The water-based softening auxiliary agent made by equal amount of embodiment 1, embodiment 2, comparative example 1, comparative example 2 and comparative example 3 is added in the water-based polyurethane slurry (each raw material ratio is as shown in Table 1, wherein water-based softening auxiliary agent Addition amount of additive is 1.5wt%, in solid content), and the comparative example 4 that does not add water-based softening auxiliary agent is set at the same time, and the synthetic leather is made by the same processing technology, the softness of the synthetic leather made is tested, the test result As shown in table 2.

[0048] Table 1 Synthetic leather preparation slurry ratio table

[0049]

[0050] The softness test result of the made synthetic leather of table 2

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com