Surface-decorative mortar and preparation method thereof

A technology of facing mortar and quartz sand, which is applied in the field of building materials, can solve the problems such as easy whitening of facing mortar, and achieve the effect of convenient application method, simple production process and long-lasting color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A facing mortar is composed of the following raw materials in parts by weight: 65 parts of aluminate cement, 10 parts of Portland cement, 25 parts of hemihydrate gypsum, 160 parts of 40-70 mesh quartz sand, 70-100 mesh quartz sand 240 parts, 9 parts of latex powder, 0.4 parts of cellulose ether, 9 parts of iron oxide red, 0.3 parts of retarder, 90 parts of water. The preparation method is as follows:

[0028] The preparation method is as follows:

[0029] (1) Dry mix aluminate cement, Portland cement, hemihydrate gypsum, quartz sand, latex powder, retarder and pigment to a uniform state to obtain dry powder;

[0030] (2) Add water into the mixer, then add the dry powder into the mixer and stir for 2 to 3 minutes to get the finished product.

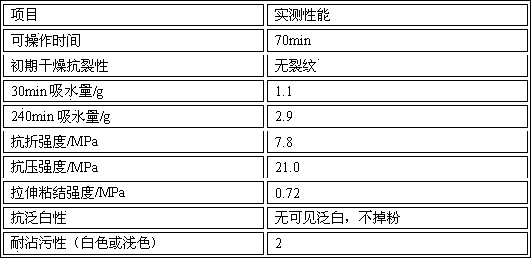

[0031] The mortar properties of the present embodiment are as follows.

[0032] Table 2 Performance index of facing mortar in Example 1

[0033]

Embodiment 2

[0035] A facing mortar is composed of the following raw materials in parts by weight: 75 parts of aluminate cement, 5 parts of Portland cement, 20 parts of hemihydrate gypsum, 140 parts of 40-70 mesh quartz sand, 70-100 mesh quartz sand 210 parts, 9 parts of latex powder, 0.4 parts of cellulose ether, 4 parts of iron oxide red, 0.2 parts of retarder, and 85 parts of water. The preparation method is the same as in Example 1.

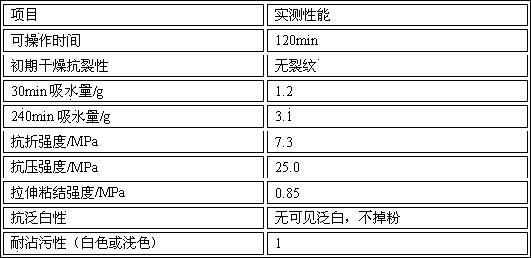

[0036] The mortar properties of the present embodiment are as follows.

[0037] Table 3 Performance index of facing mortar in Example 2

[0038]

Embodiment 3

[0040] A facing mortar is composed of the following raw materials in parts by weight: 60 parts of aluminate cement, 10 parts of Portland cement, 30 parts of hemihydrate gypsum, 152 parts of 40-70 mesh quartz sand, 70-100 mesh quartz sand 228 parts, 6 parts of latex powder, 0.3 parts of cellulose ether, 3 parts of iron oxide red, 0.15 parts of retarder, 80 parts of water. The preparation method is the same as in Example 1.

[0041] The mortar properties of the present embodiment are as follows.

[0042] Table 4 Performance index of facing mortar in Example 3

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com