Patents

Literature

121results about How to "Improve long-term use effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

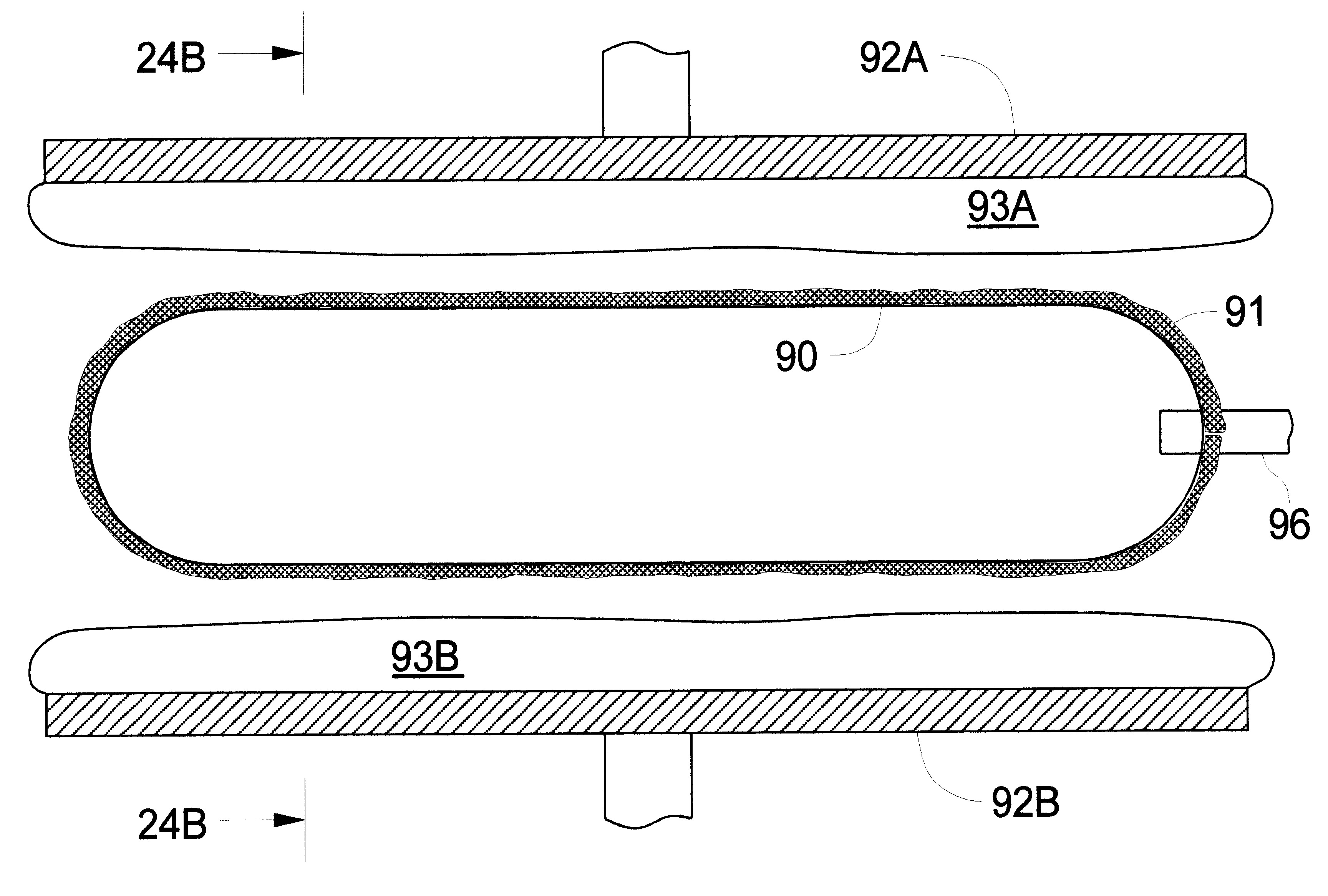

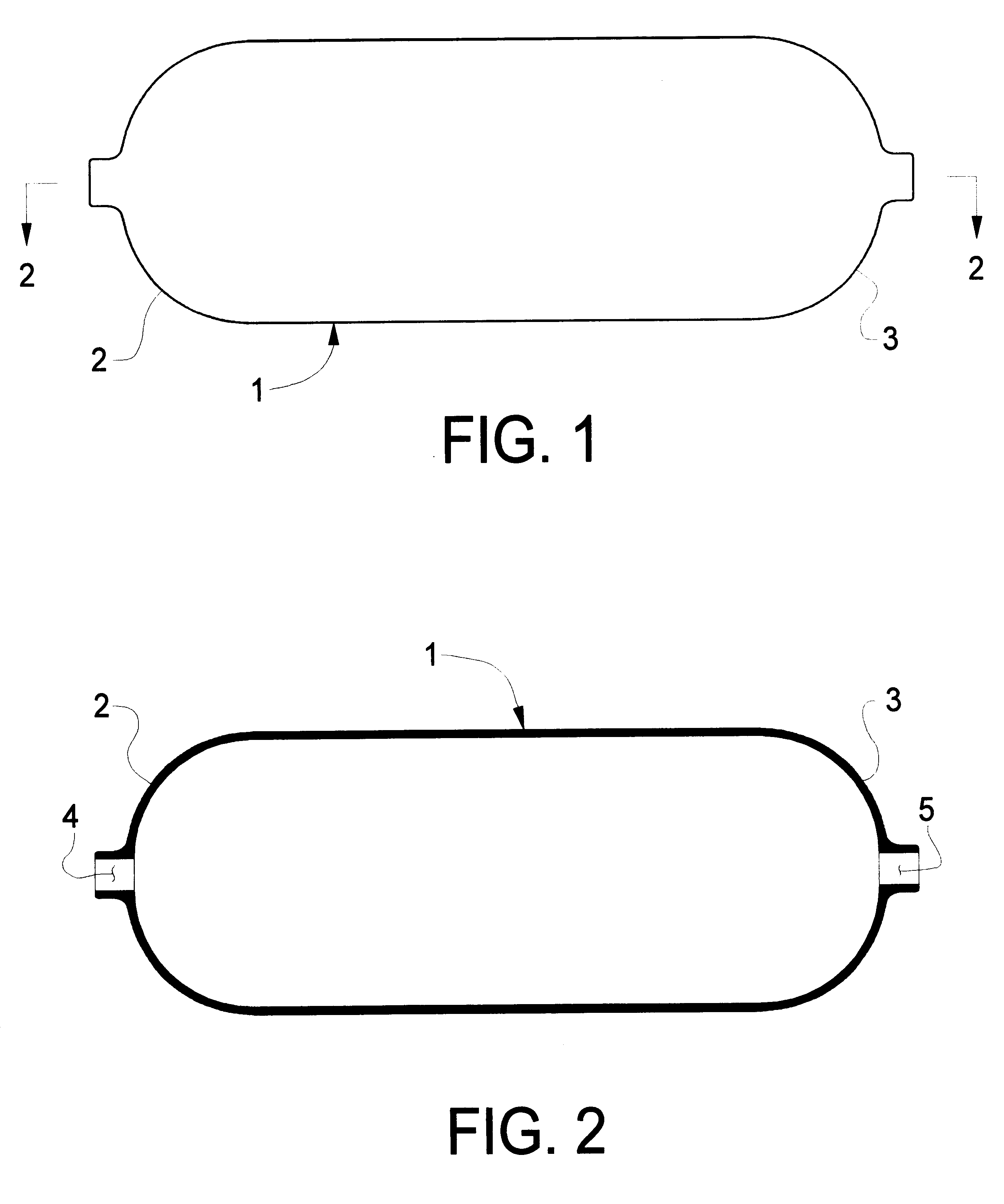

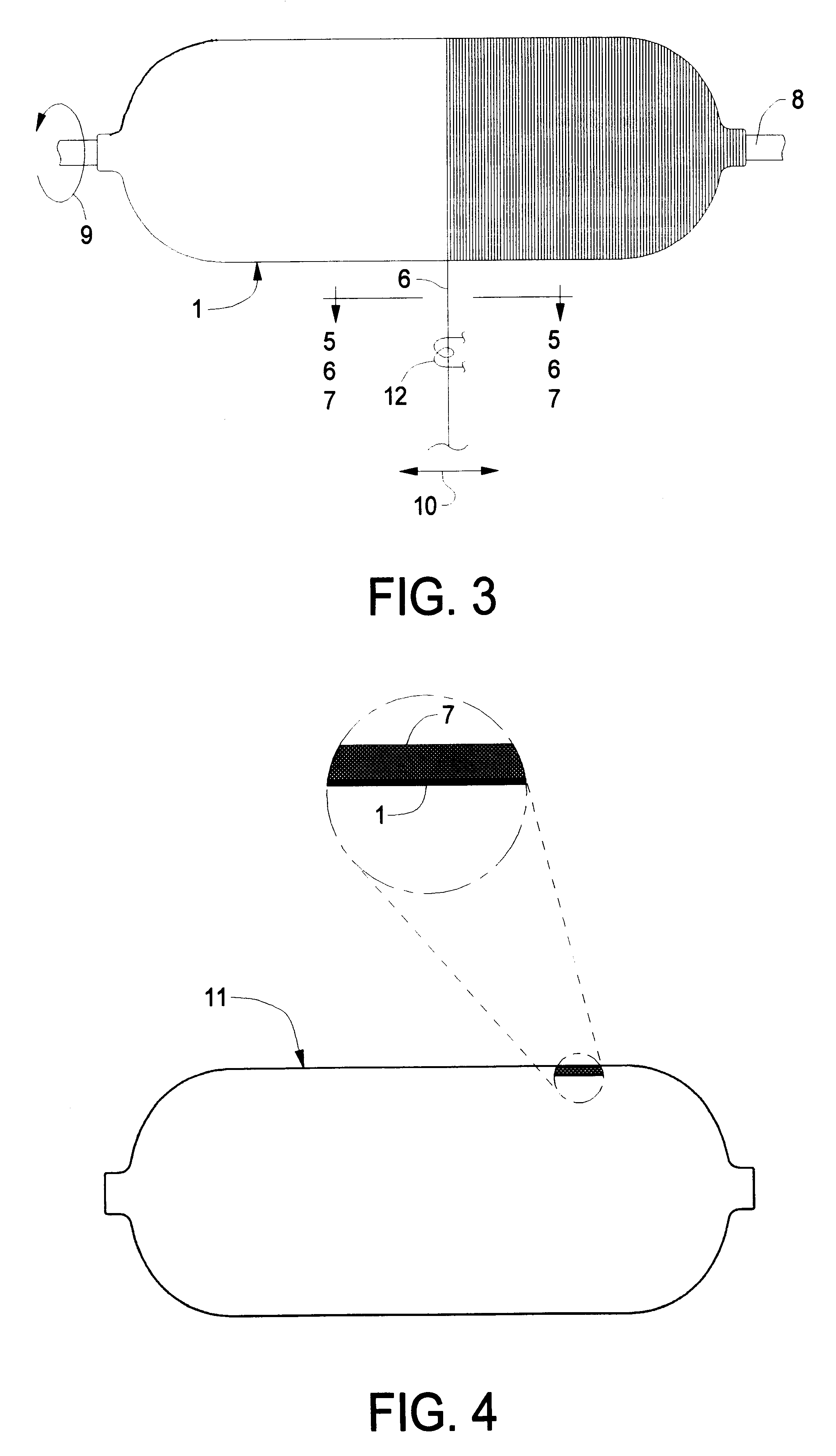

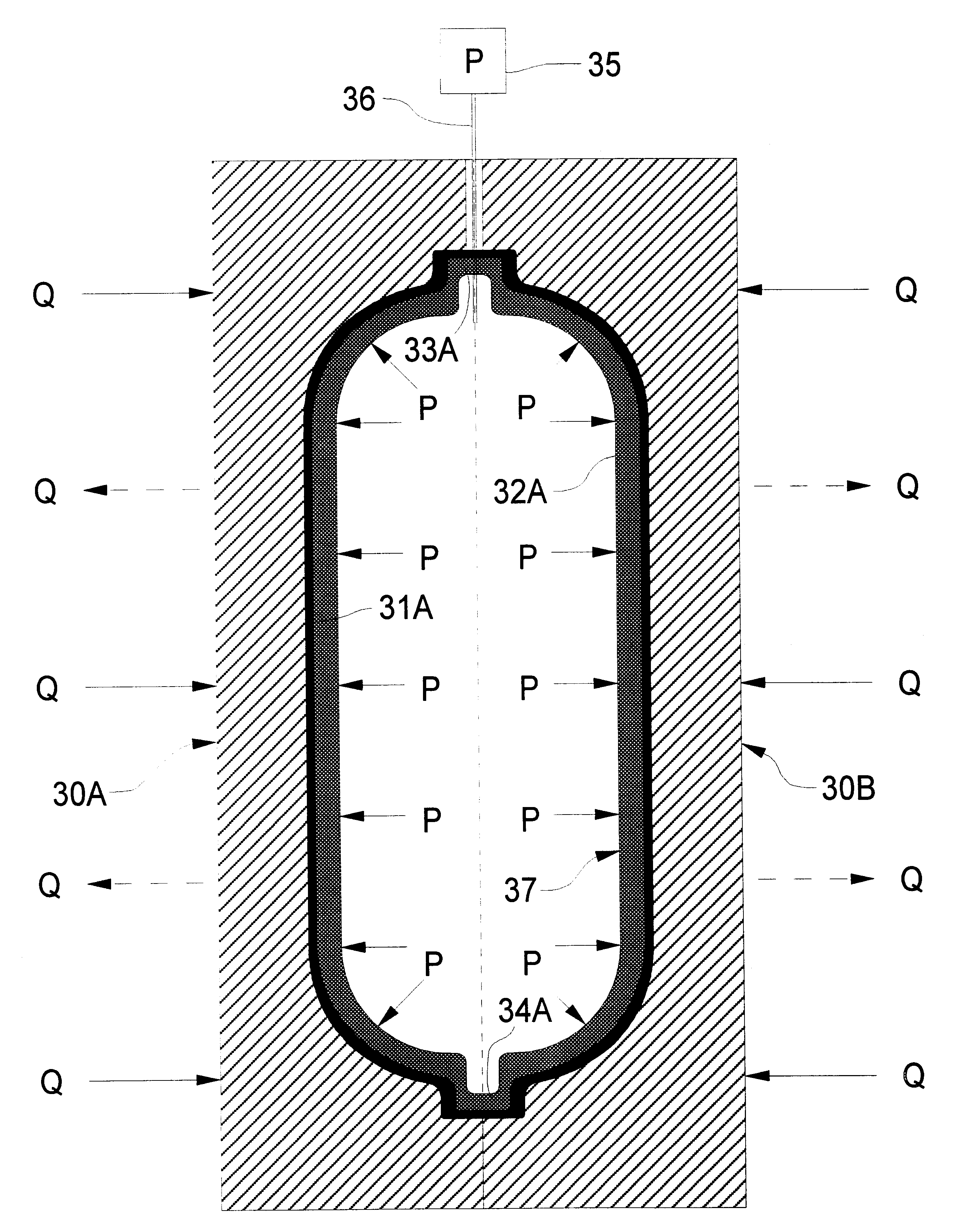

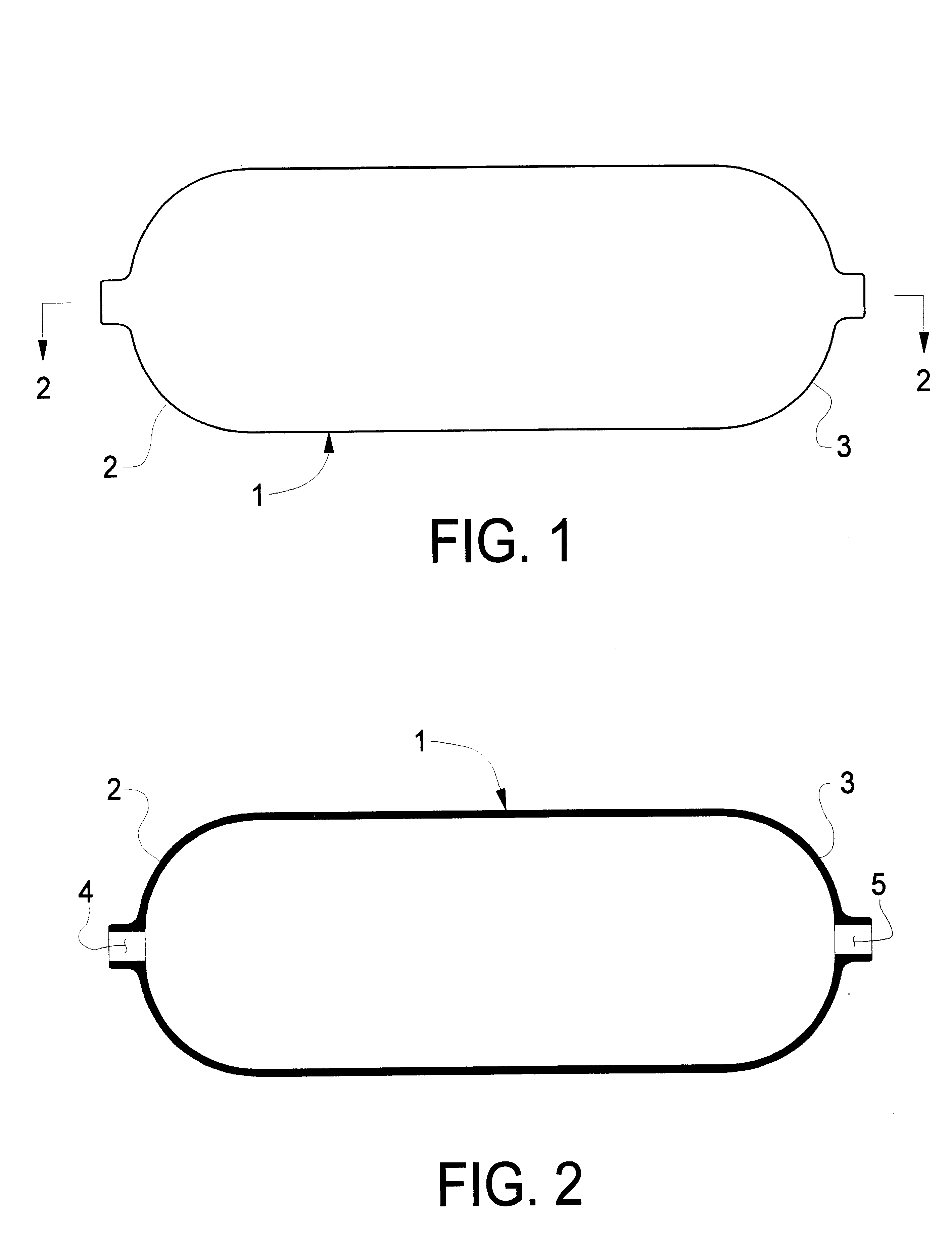

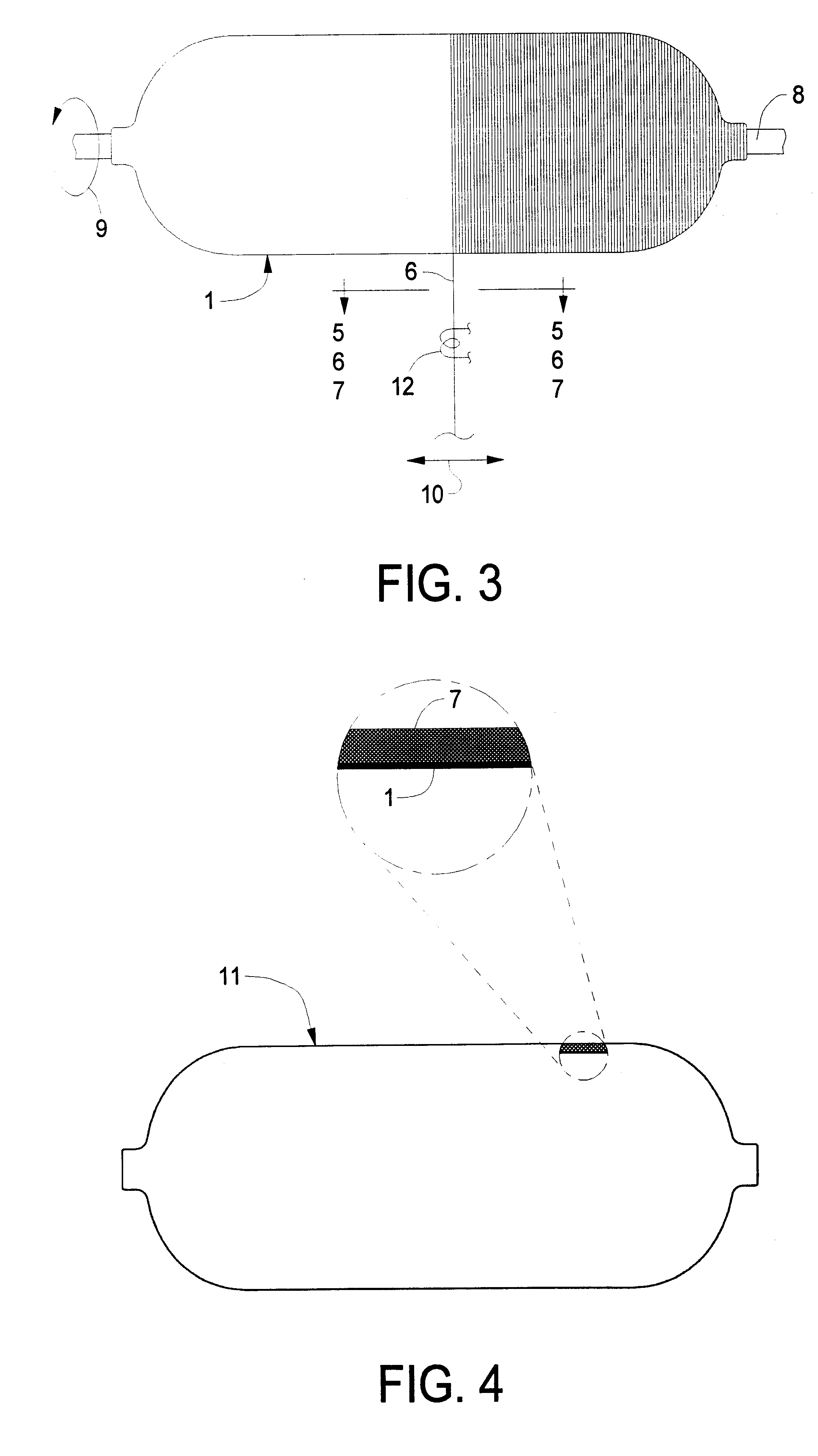

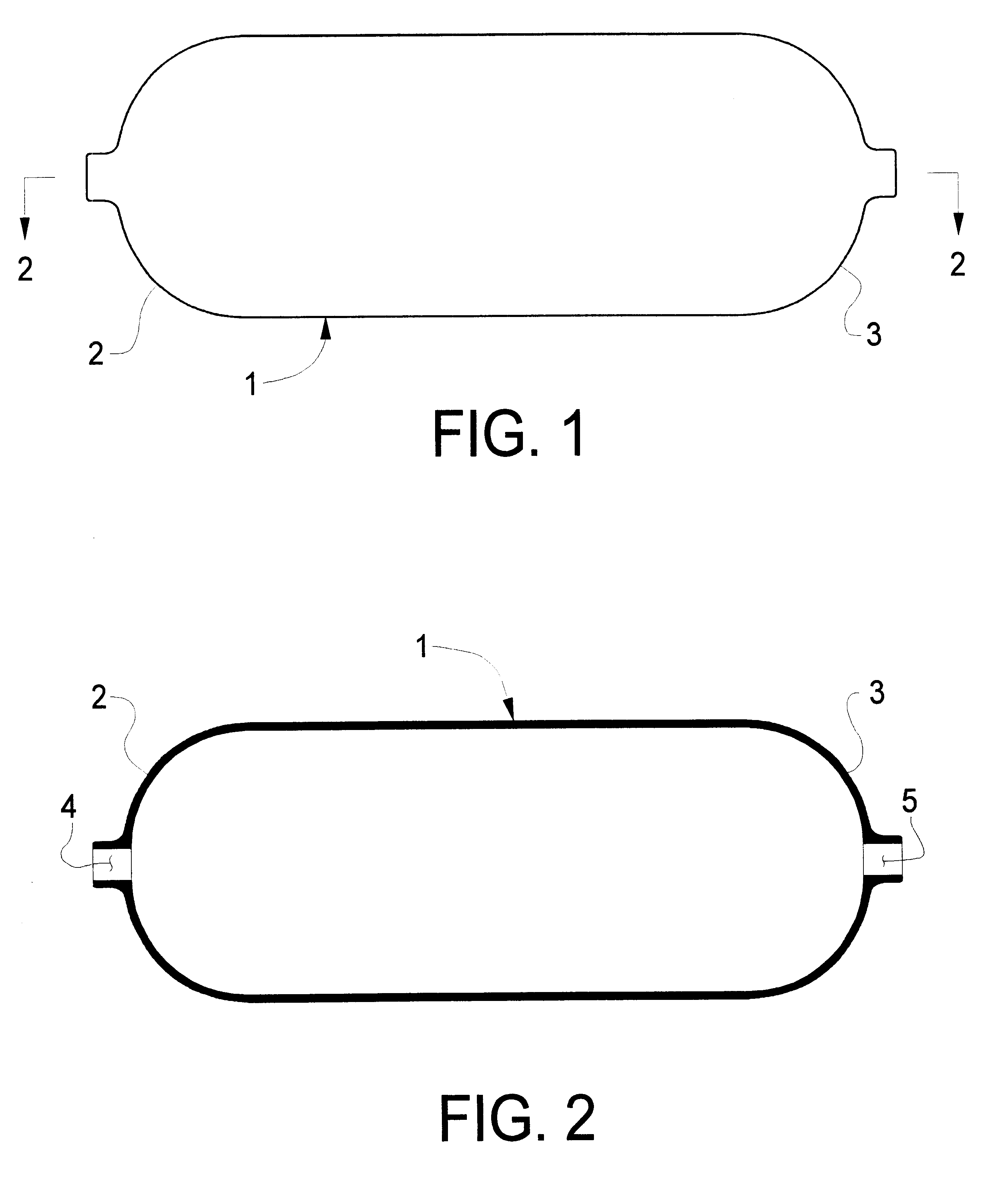

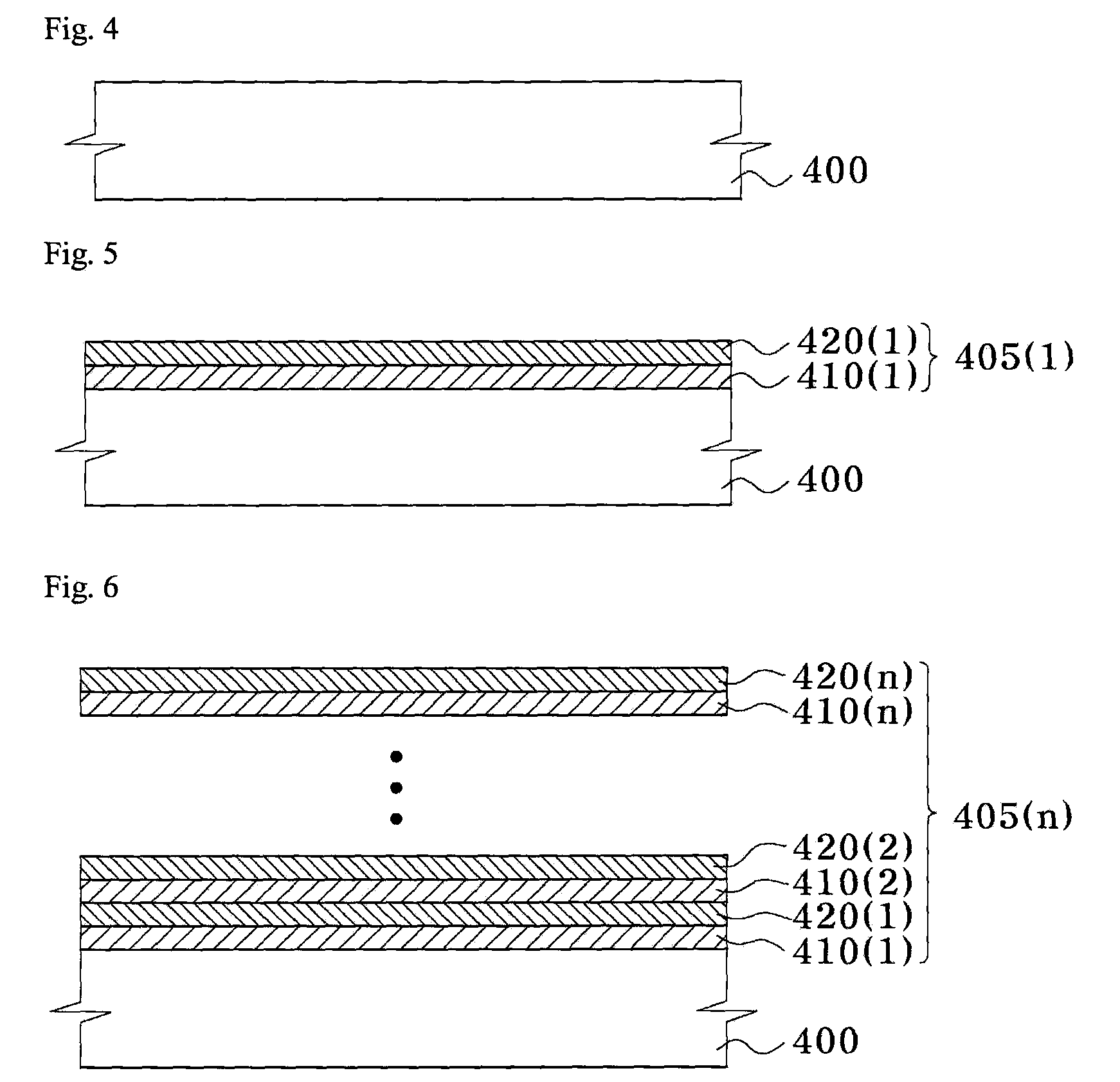

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

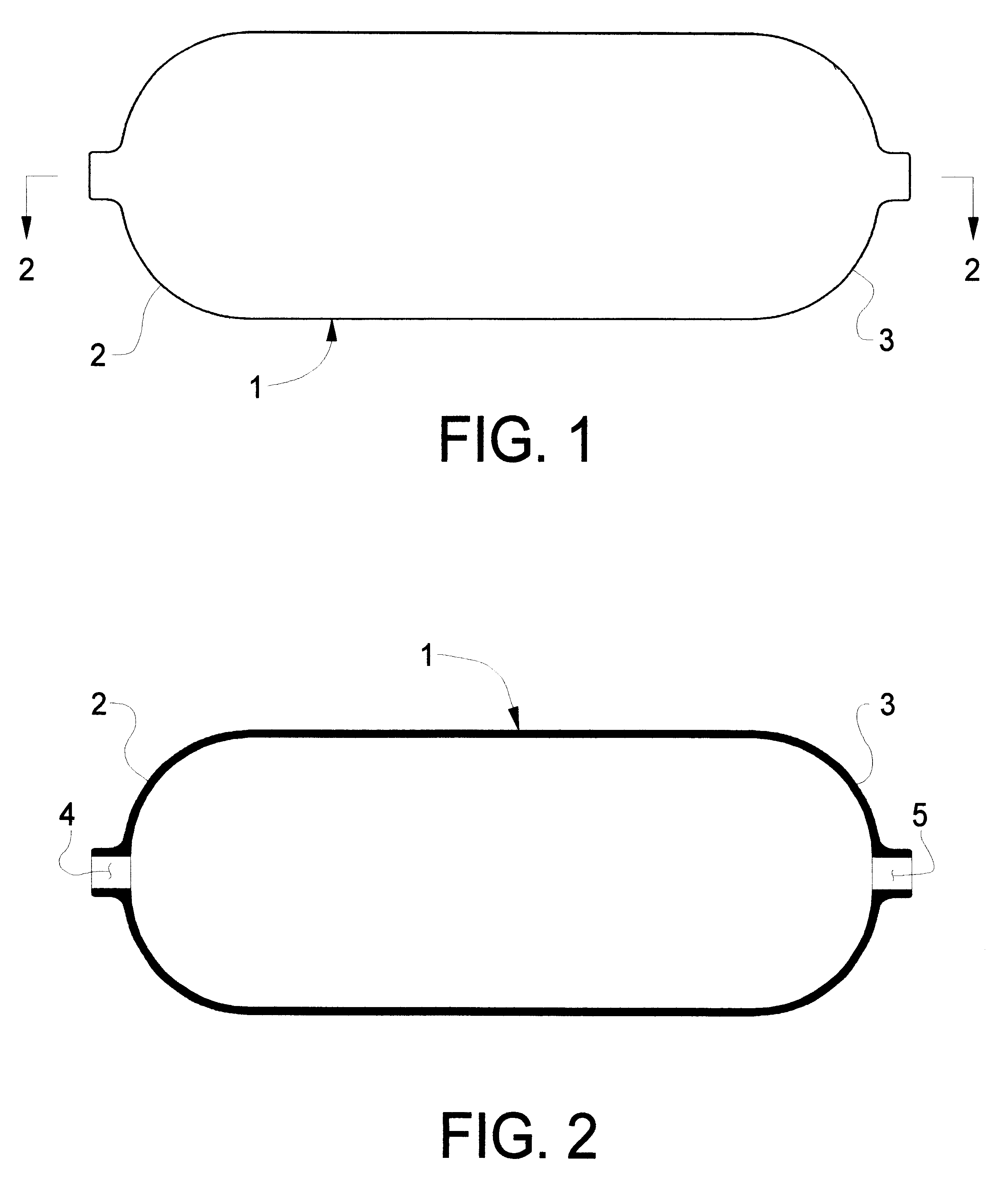

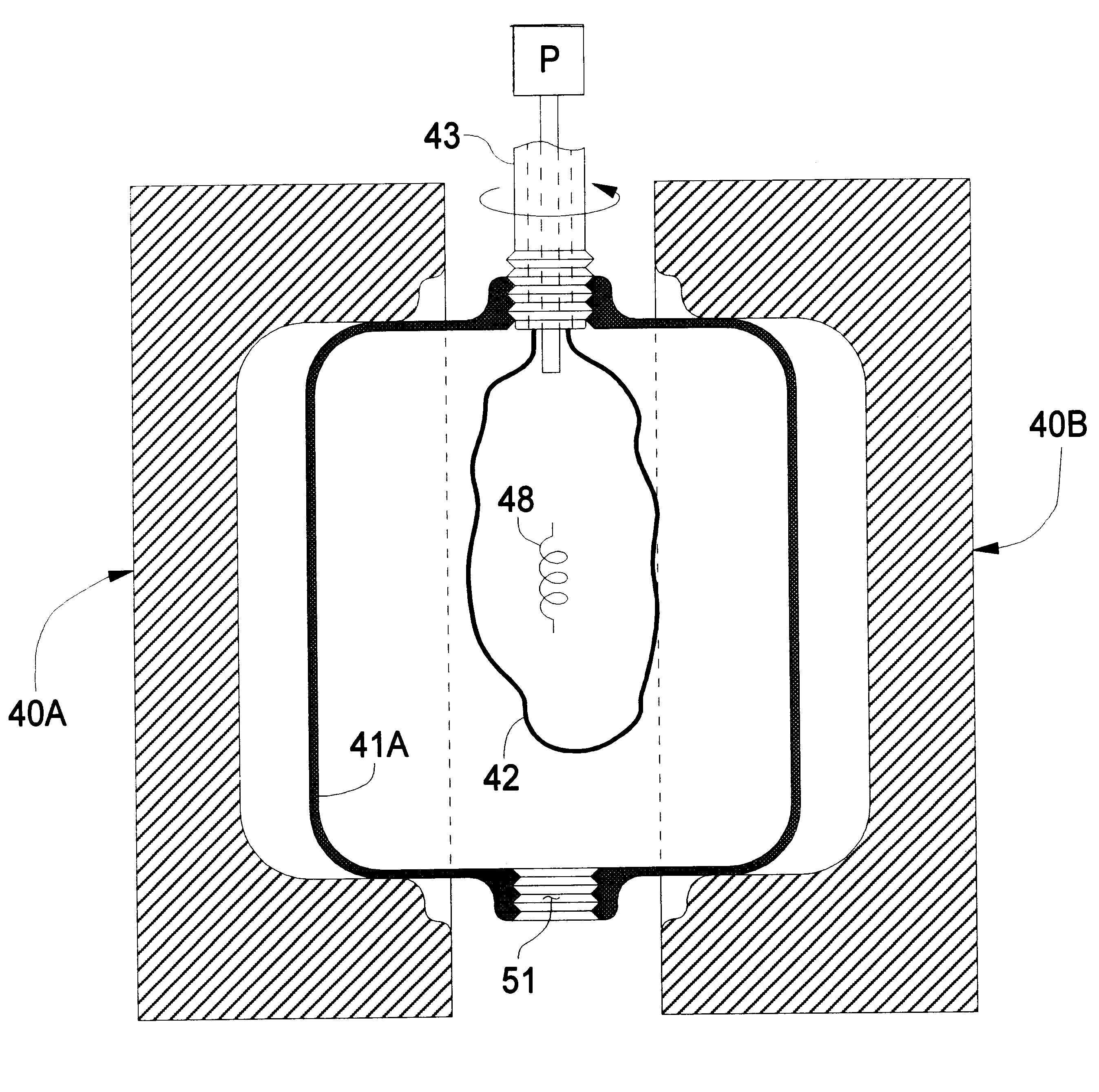

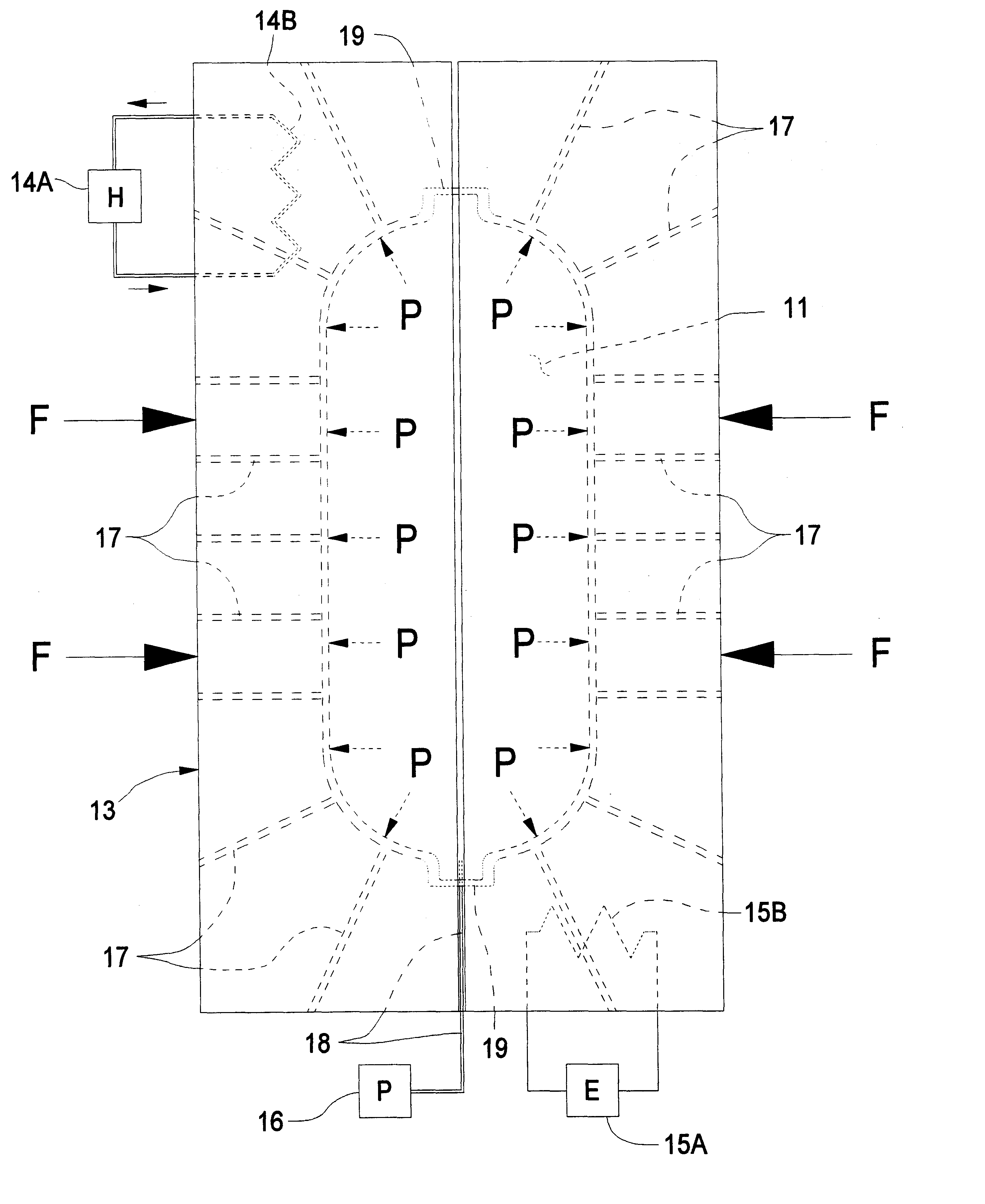

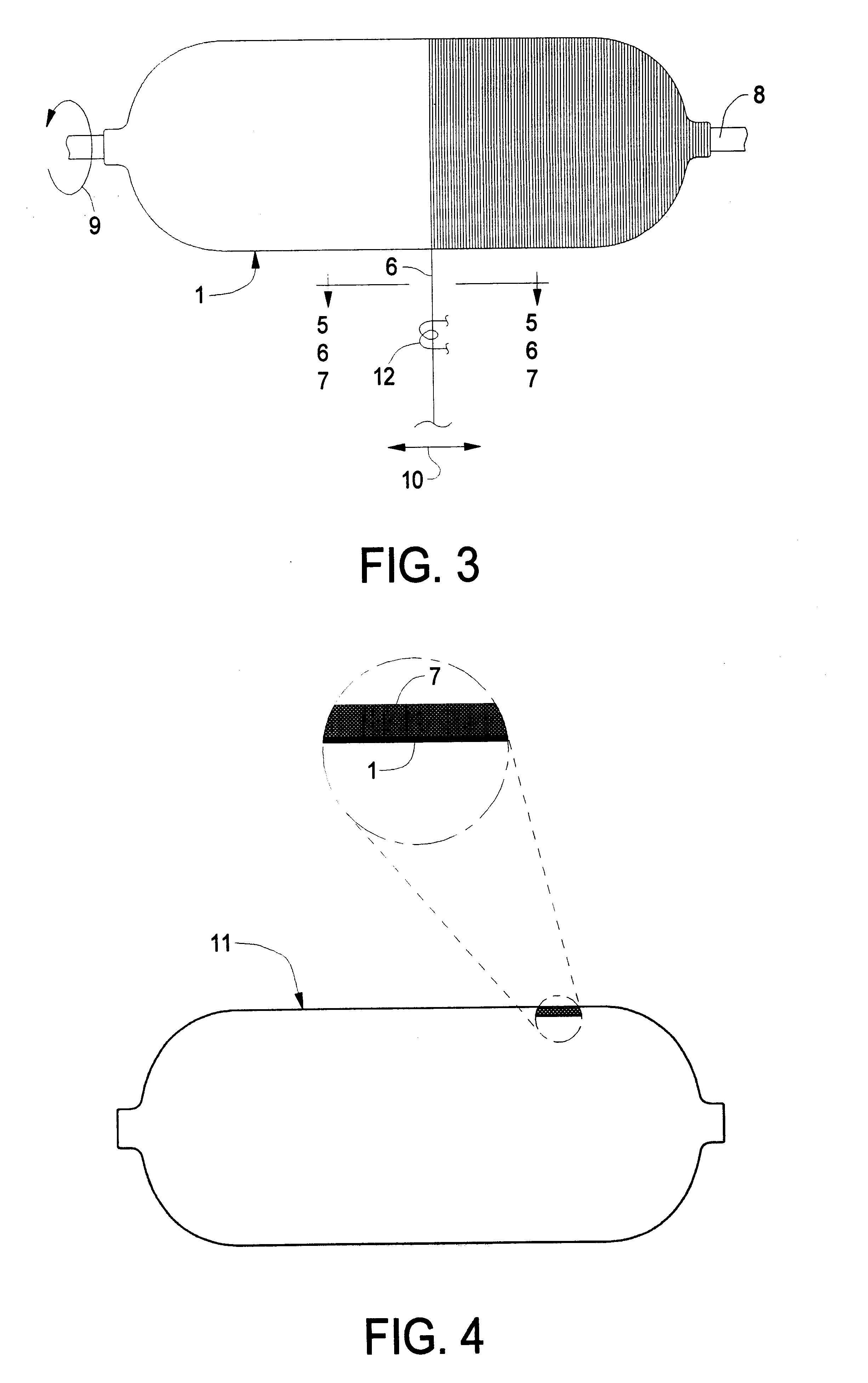

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

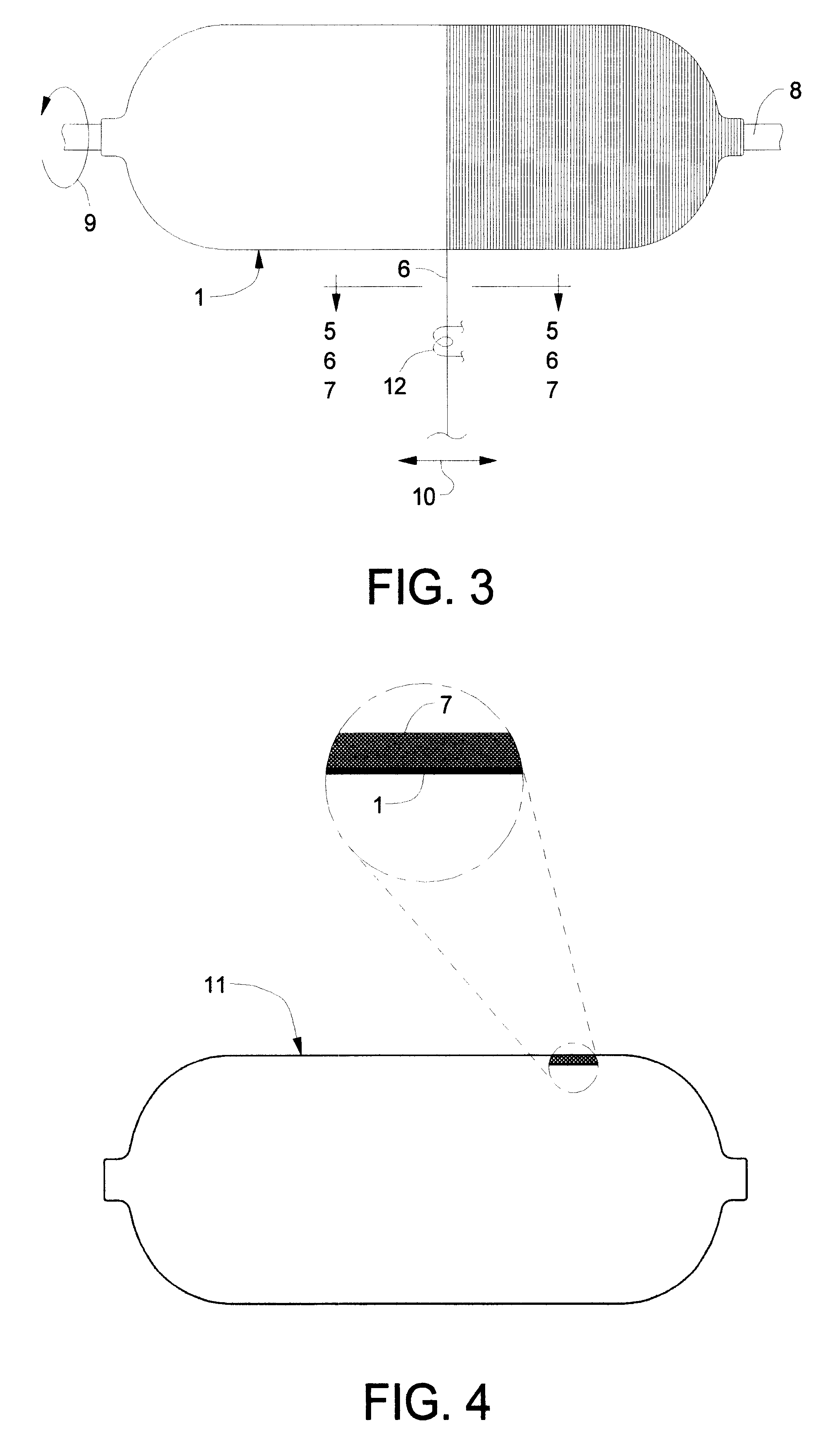

Method for fabricating composite pressure vessels

InactiveUS6171423B1Speed up the processRatio is limitedVessel manufacturingCylinder headsPolytetramethylene terephthalateFiber

A process for fabricating a composite vessel includes the steps of: A) preforming (e.g., by winding fiber and at least one thermoplastic substance onto a thermoplastic liner) a thermoplastic shell which has at least one opening for access to the interior; B) extruding a circular cross section of a fluid parison of thermoplastic material (which preferably is chosen to have a melting point lower than that of the thermoplastic shell) into the interior of the thermoplastic shell through the opening; C) in a mold, applying at least one force (such as gas under pressure) which tends to urge the fluid parison toward the interior walls of the thermoplastic shell (which may be preheated prior to introduction into the mold) such that the fluid parison imparts heat to the thermoplastic shell; D) continuing step C) until the thermoplastic shell and the fluid parison consolidate to form a composite vessel; E) cooling the vessel until it is solidified; and F) removing the vessel from the mold. For some composite vessels, prior to step C), an insert may be introduced into the interior of the parison and positioned in alignment with the opening in the thermoplastic shell such that the insert is rendered integral with the composite vessel during step D). Suitable thermoplastic materials include polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

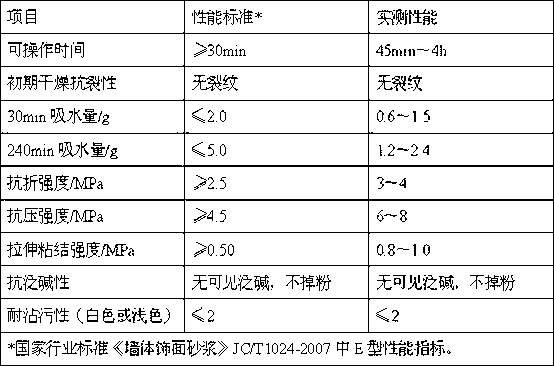

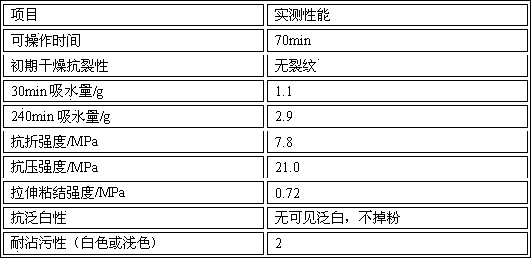

Nano modified Portland cement base facing mortar and preparation method thereof

The invention belongs to the field of building materials and particularly relates to nano modified Portland cement base facing mortar and a preparation method thereof. The nano modified Portland cement base facing mortar comprises the following components in percent by weight: 12-17 percent of cement, 3-8 percent of mineral mixture, 0.2-0.6 percent of nano materials, 8-12 percent of ground calcium carbonate, 60-70 percent of quartz sand, 1.5-2.2 percent of latex powder, 0.6-1 percent of cellulose ether, 0.4-1 percent of pigment and 0.2-0.4 percent of other additives. The nano modified Portland cement base facing mortar solves the problem that the Portland cement base facing mortar is apt to be efflorescent and be stained, has the advantages of good construction performance, high construction efficiency, good compatibility and match with various base materials, uniform color, higher strength, good weather resistance, good air permeability, good waterproof performance, low cost and the like, and can be particularly used as a facing decoration material for external heat insulation systems of exterior walls of buildings.

Owner:TONGJI UNIV

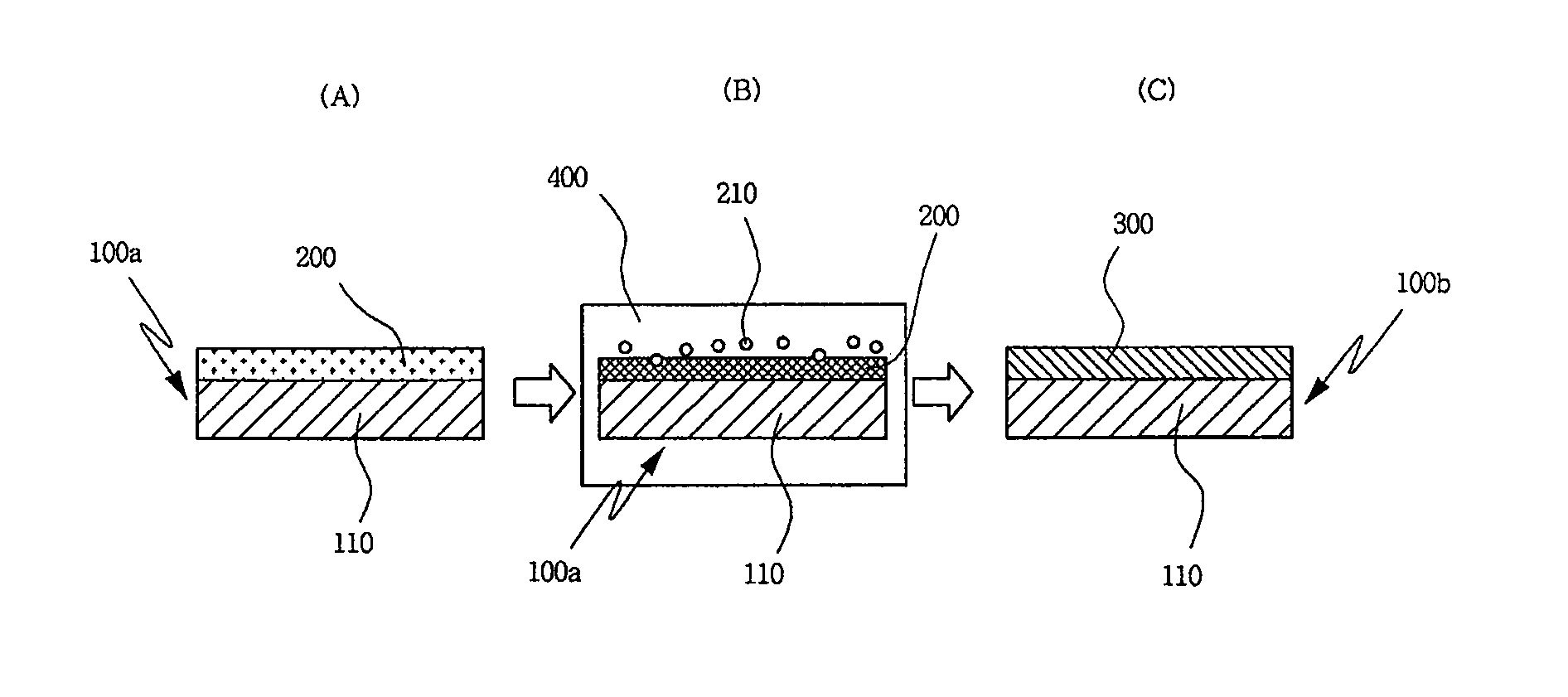

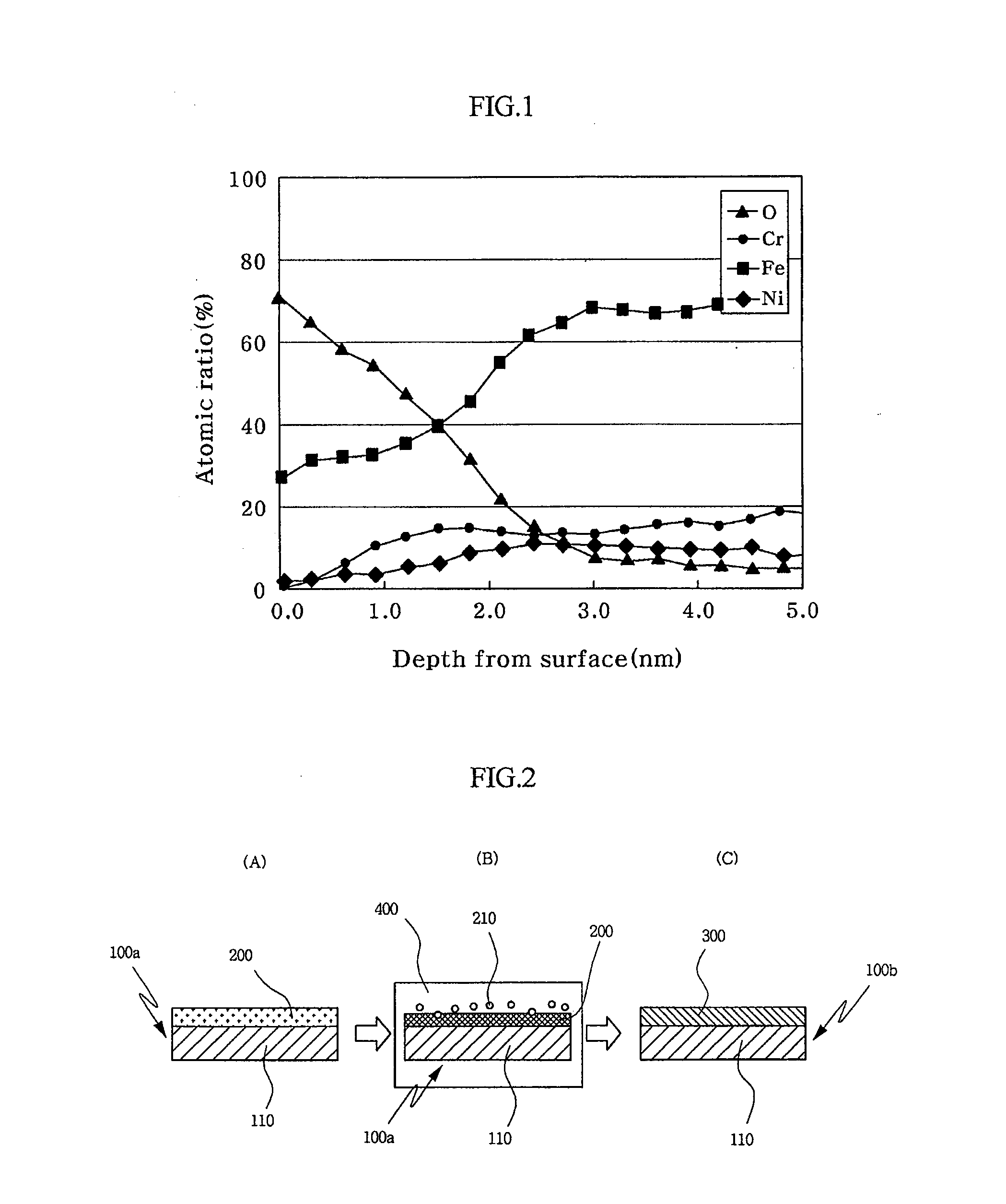

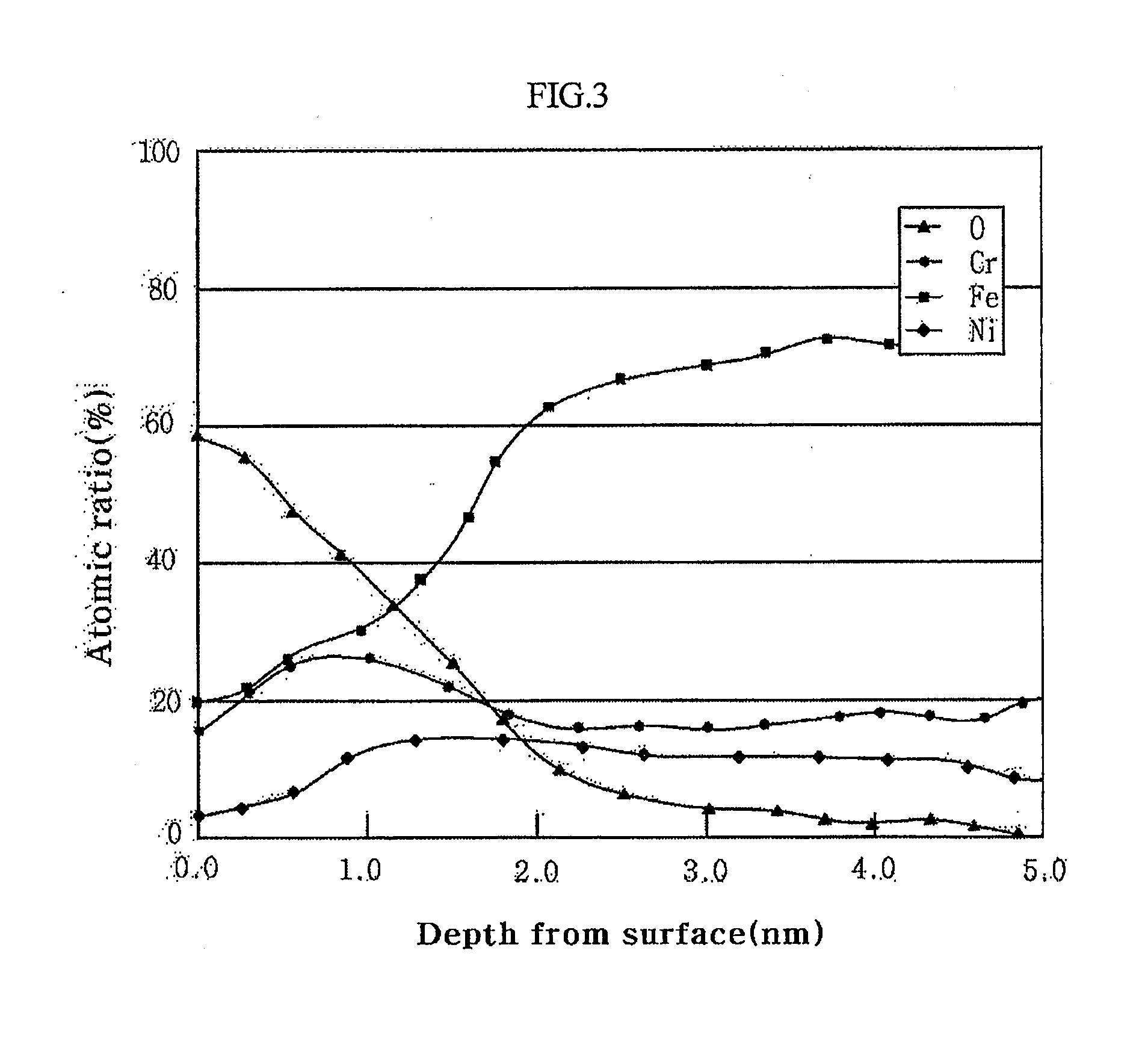

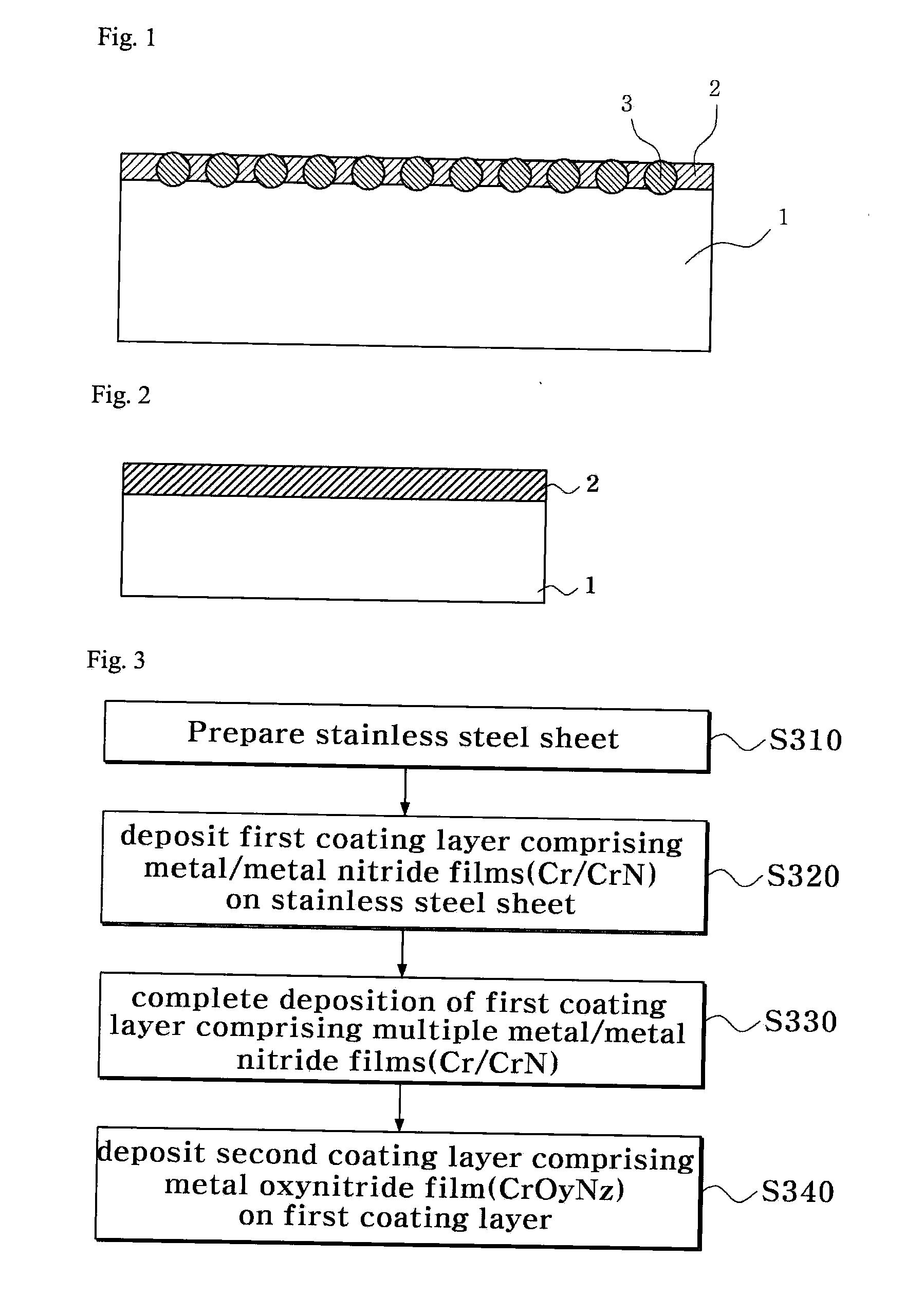

Stainless stell separator for fuel cell and the manufacturing method thereof

ActiveUS20100129697A1Improve corrosion resistanceImprove conductivityAnodisationDecorative surface effectsFuel cellsFerric

A method for surface treatment of a stainless steel separator for a fuel cell comprises preparing a stainless steel sheet containing nickel, chrome and iron, and having a passive film on a surface of the stainless steel sheet, and dipping the stainless steel sheet into a mixed etching solution of nitric acid (HNO3) and sulfuric acid (H2SO4) at a temperature of 50-70° C. for 30 seconds to 30 minutes to selectively lower an amount of Fe in the passive film formed on the surface of the stainless steel sheet.

Owner:HYUNDAE STEEL CO LTD

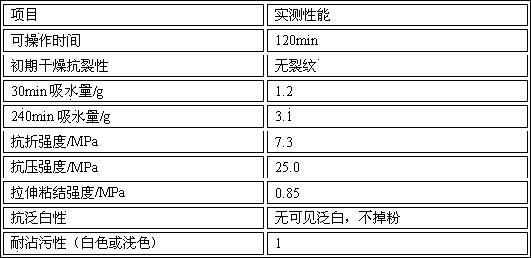

Surface-decorative mortar and preparation method thereof

The invention discloses a surface-decorative mortar for solving the problems that an existing surface-decorative mortar is easily whitened and solving the problems of crisis plant growth. The surface-decorative mortar consists of the following raw materials in parts by weight: 40-80 parts of aluminate cement, 1-30 parts of Portland cement, 20-30 parts of semi-hydrated gypsum, 350-400 parts of quartz sand, 4-12 parts of latex powder, 0.1-0.5 parts of cellulose ether, 0.01-0.5 parts of a retarder, 1-9 parts of a pigment and 75-90 parts of water, wherein the sum of the aluminate cement, the Portland cement and the semi-hydrated gypsum is 100 parts. The surface-decorative mortar disclosed by the invention does not have whitening phenomenon, is good in stain resistance, low in water absorbing capacity, high in bonding strength, good in long-term application performance, durable in color and luster and good in water-proof and air-permeable performance.

Owner:SICHUAN INSITITUTE OF BUILDING RES

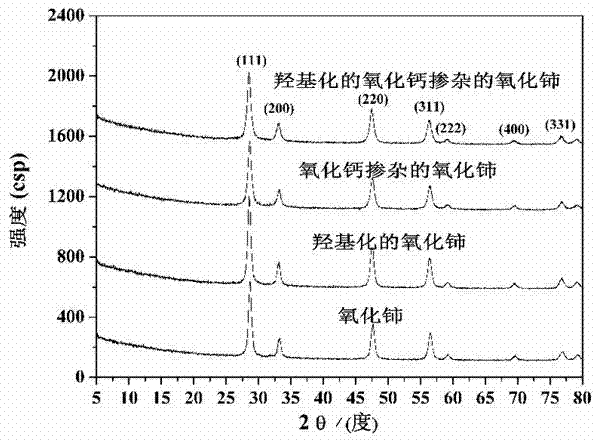

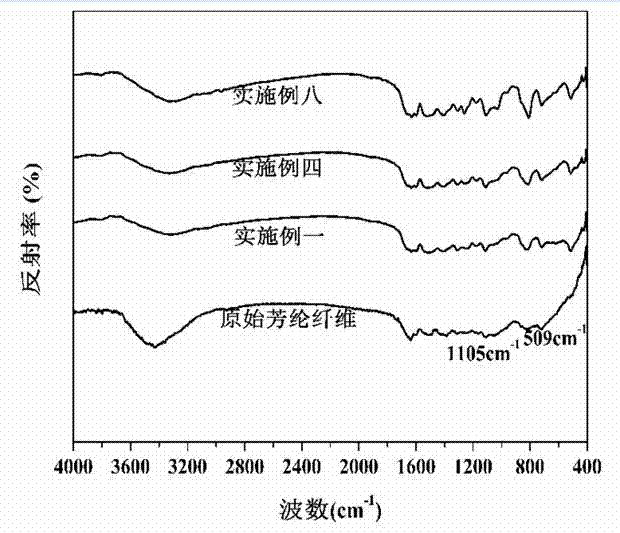

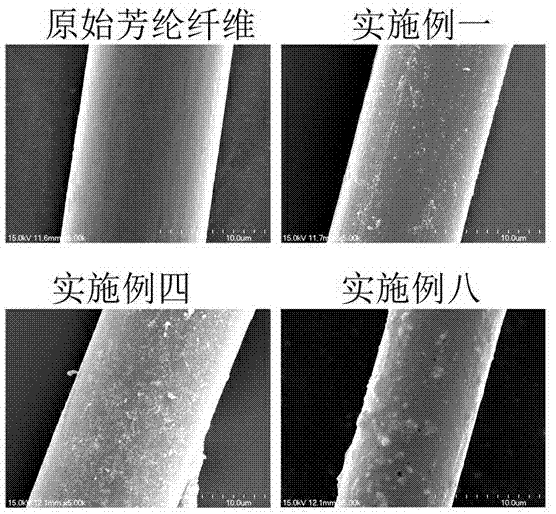

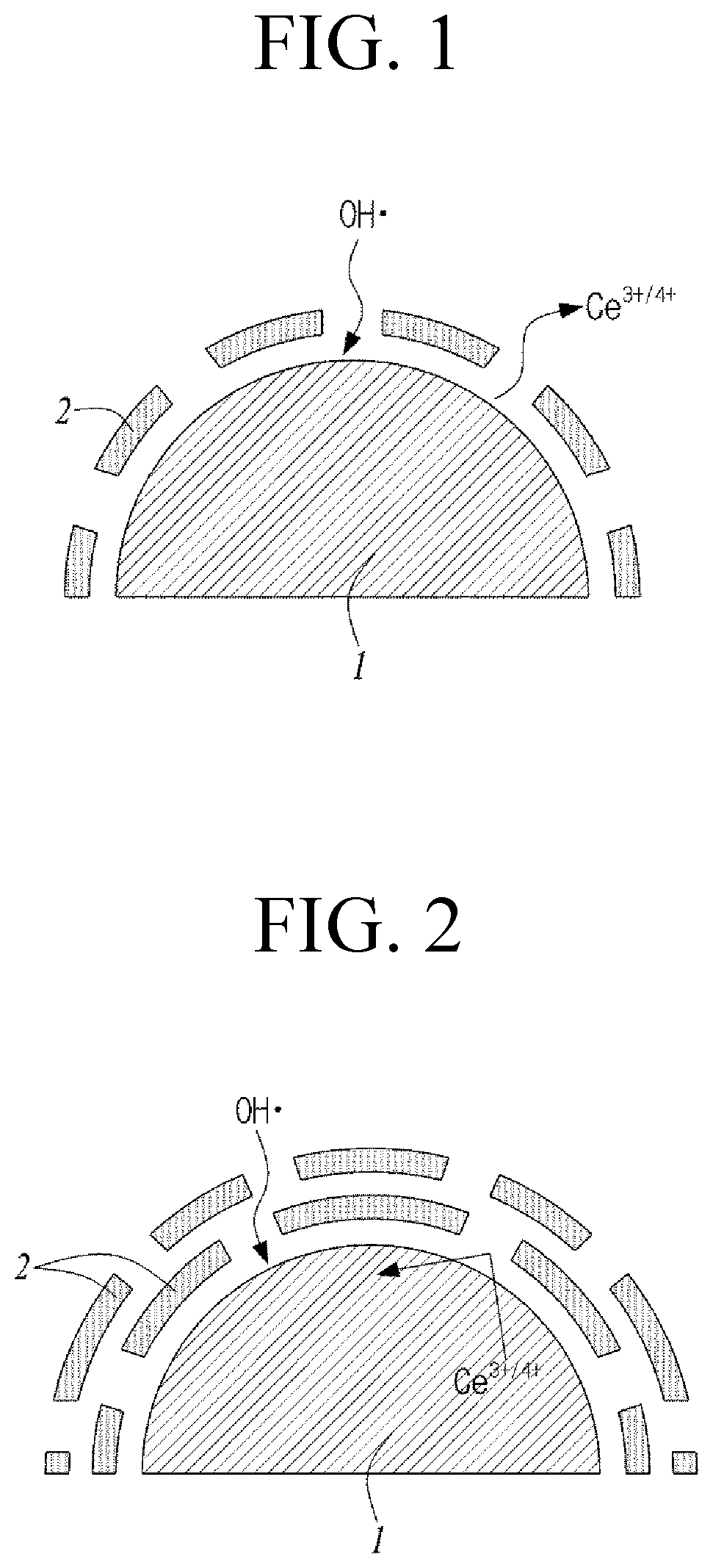

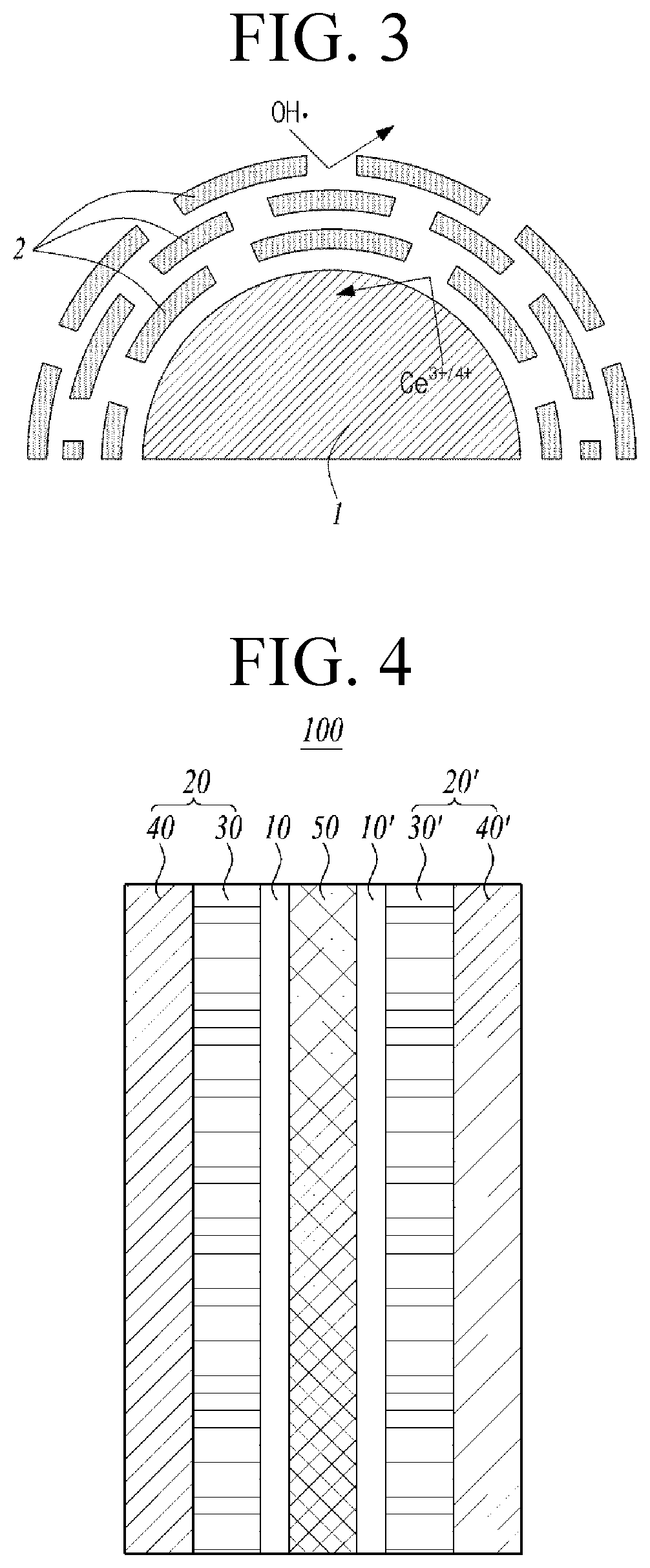

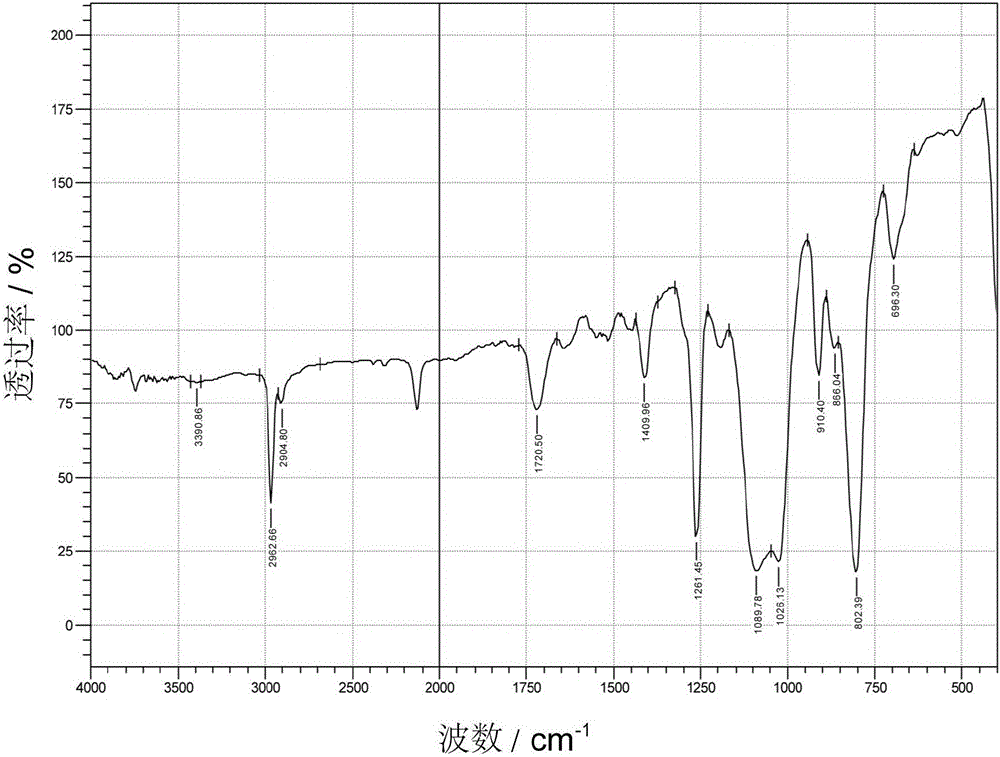

Aramid fiber coated with inorganic nanoparticles on surface and preparation method thereof

InactiveCN103572583AGood long-term usabilityWide UV absorption rangeFibre typesRare earth metal compoundsInorganic nanoparticlesUltraviolet

The invention relates to aramid fiber coated with inorganic nanoparticles on the surface and a preparation method thereof. The preparation method comprises the following steps: functionalizing the surface of the aramid fiber to enable the surface of the fiber to contain methoxy groups; hydroxylating calcium-oxide-doped cerium oxide and reacting the cerium oxide with the fiber to obtain the aramid fiber coated with the inorganic nanoparticles on the surface. According to the invention, the hydroxylated calcium-oxide-doped cerium oxide is an inorganic particle with the photocatalytic activity much lower than that of ultraviolet absorbents such as TiO2 and zinc oxide; the inorganic particles can absorb ultraviolet rays to protect the fiber from damage caused by the ultraviolet rays, and the damage caused by a photocatalytic action of the inorganic particles to the fiber during ultraviolet radiation can be avoided, so that the hydroxylated calcium-oxide-doped cerium oxide is a safe, effective and long-lasting ultraviolet absorber. The surface of the modified aramid fiber is provided with a large number of reactive groups, so that adhesion of the modified aramid fiber to a lot of substrates can be improved, and thus the application field of the fiber is widened; the nanoparticles with high heat resistance are coated on the surface of the fiber, so that the thermal property of the fiber can be effectively improved.

Owner:SUZHOU UNIV

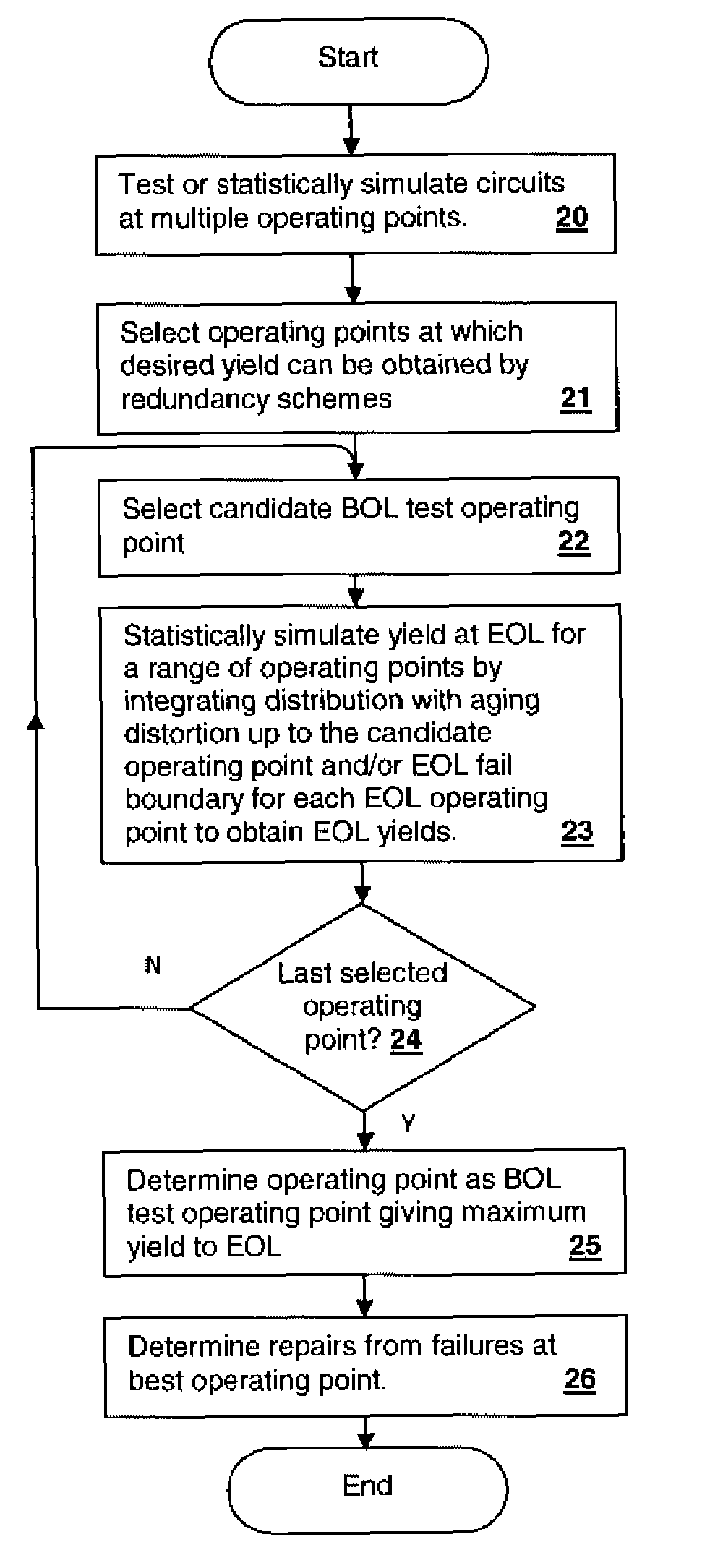

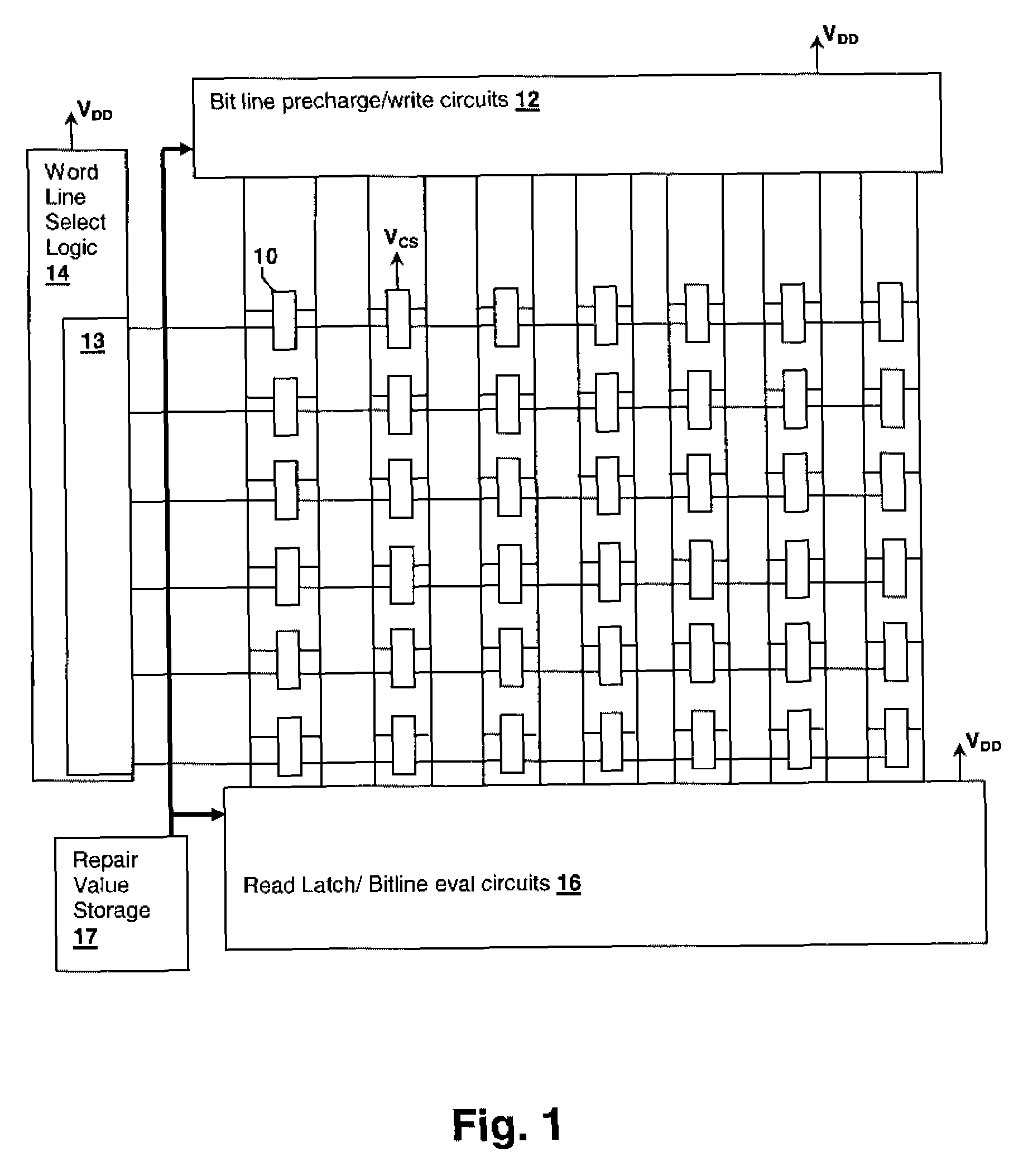

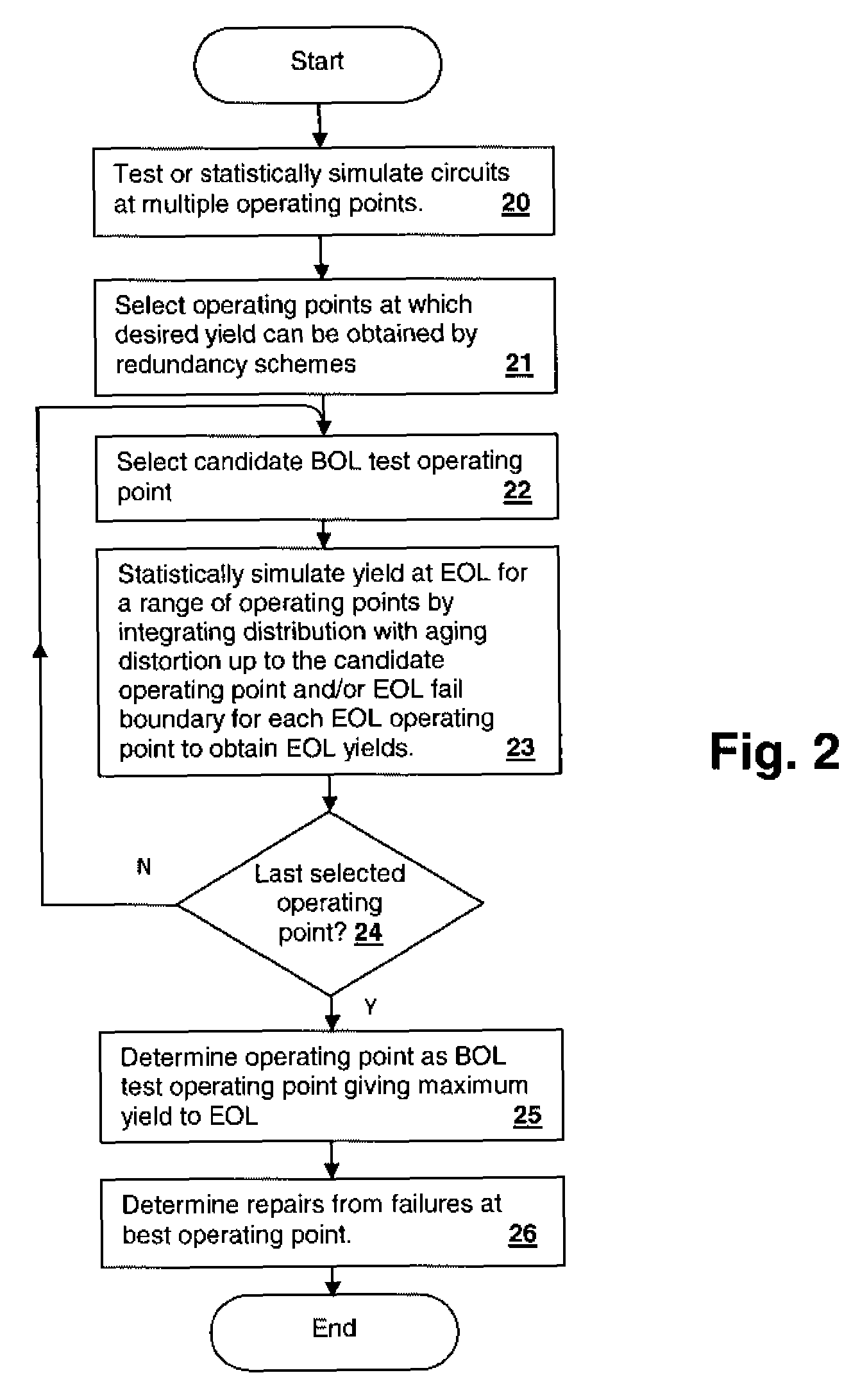

Method and computer program for selecting circuit repairs using redundant elements with consideration of aging effects

ActiveUS7827018B2Valid choiceImprove long-term use effectElectronic circuit testingError detection/correctionOperating pointLife time

A method and computer program for selecting circuit repairs using redundant elements with consideration of aging effects provides a mechanism for raising short-term and long-term performance of memory arrays beyond present levels / yields. Available redundant elements are used as replacements for selected elements in the array. The elements for replacement are selected by BOL (beginning-of-life) testing at a selected operating point that maximizes the end-of-life (EOL) yield distribution as among a set of operating points at which post-repair yield requirements are met at beginning-of-life (BOL). The selected operating point is therefore the “best” operating point to improve yield at EOL for a desired range of operating points or maximize the EOL operating range. For a given BOL repair operating point, the yield at EOL is computed. The operating point having the best yield at EOL is selected and testing is performed at that operating point to select repairs.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

Method for fabricating composite pressure vessels

InactiveUS6565793B1Speed up the processRatio is limitedLabelling non-rigid containersLaminationFiberPolytetramethylene terephthalate

A process of fabricating a composite vessel includes the steps of: A) fabricating a thermoplastic liner for the vessel; B) overlaying a layer comprising fiber and a thermoplastic material (preferably by winding commingled filaments, rovings or yarns) onto the thermoplastic liner to obtain a composite intermediate structure (the fiber and thermoplastic material can be heated if desired during the overlaying, e.g. winding, step); C) heating the composite intermediate structure in a mold while applying at least one force thereto tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold; D) continuing step C) until the thermoplastic liner and the overlaid layer consolidate to form a composite vessel; E) cooling the mold and composite vessel until the composite vessel is solidified; and F) removing the formed composite vessel from the mold. The at least one force applied during step C) may be obtained by introducing gas pressure into the interior of the composite intermediate structure. Suitable materials for the thermoplastic material include: polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

Hydrophobic Fiberglass Thermal Insulation Materials

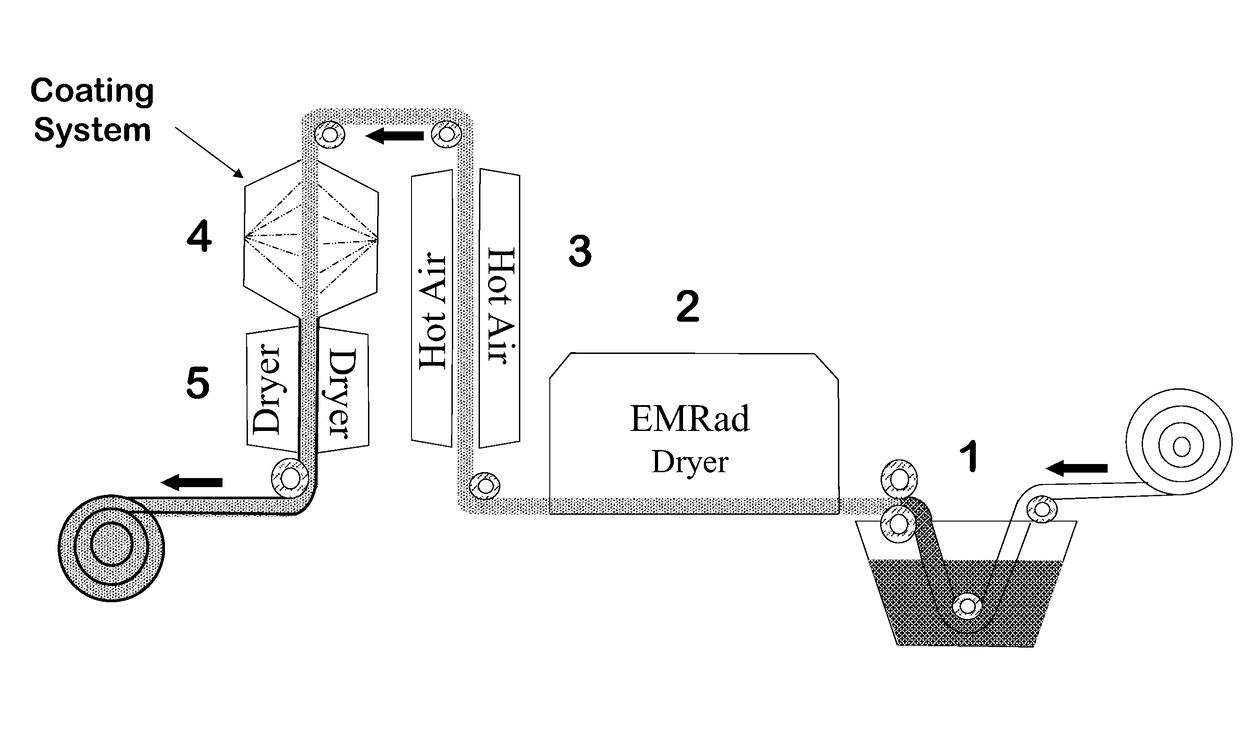

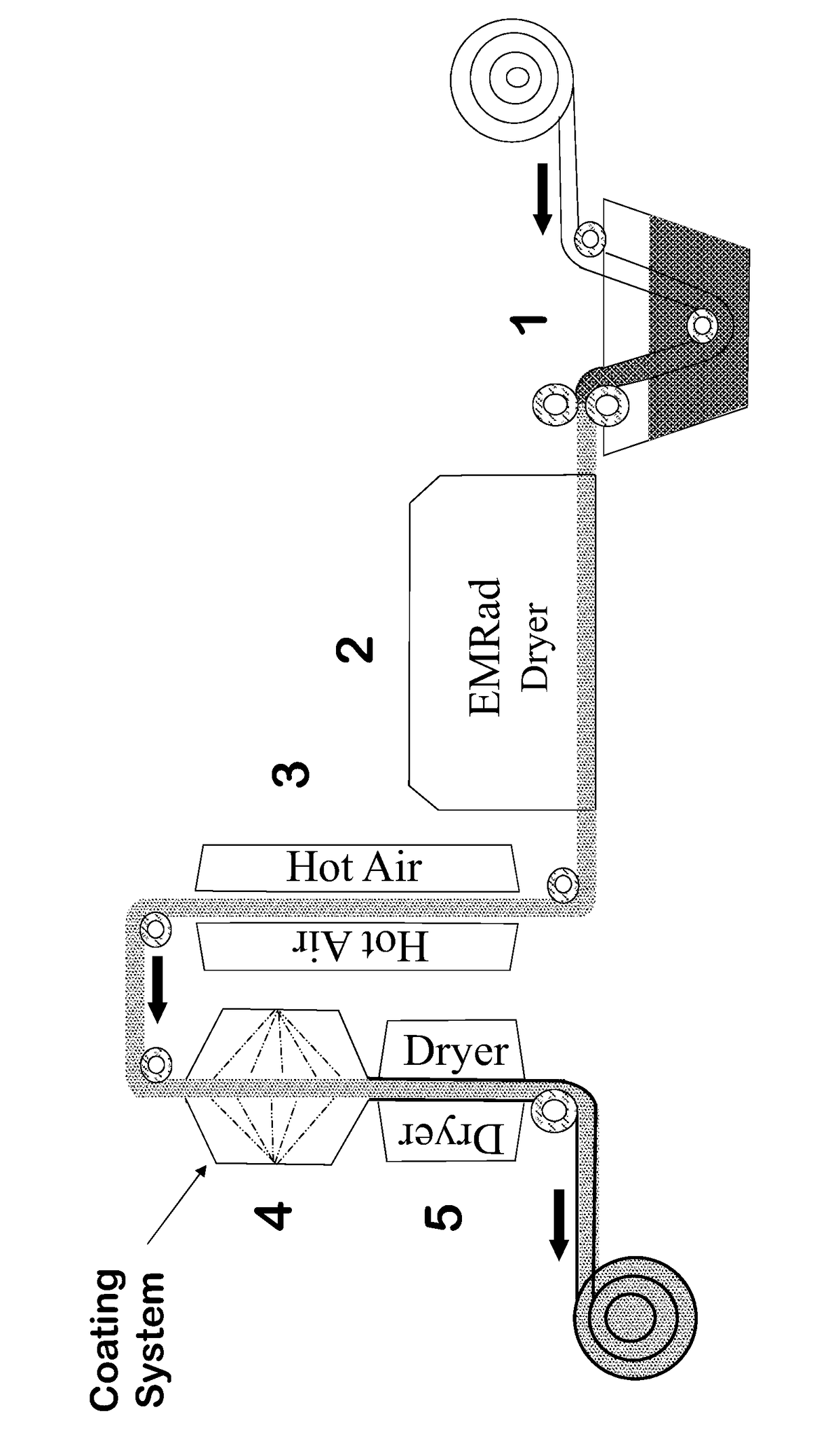

ActiveUS20180022059A1Cost efficient to manufactureImprove hydrophobicitySynthetic resin layered productsCoatingsFiberPolymer science

Hydrophobic thermal insulation fiberglass flexible blanket using a textile grade fiberglass is produced by impregnating a hydrophobic polymer (e.g. a fluoropolymer) dispersion into a fiberglass blanket / mat, such as a needle felted fiberglass (FG) blanket / mat. The preferred FG needle felt blanket is a mechanically, rather than organically, bound glass fiber insulating blanket. The hydrophobic polymer dispersion forms a hydrophobic coating on the surface of the fiberglass filaments. Integral hydrophobicity is achieved and maintained without the need to add commonly-used hydrophobic inorganic particles, such as treated silica aerogels or fumed silica. Optionally, to enhance overall hydrophobicity and to inhibit fibrous surface lofting, a super-hydrophobic coating of fluoropolymer and inorganic particles such as silica particles may be dispersed onto one or more surfaces of the blanket. The resulting blanket thermally insulates better than mineral wool; it is equal in insulating properties to (or is slightly better than) untreated FG mat; and it slightly less insulating than aerogel-based blanket materials. It is relatively inexpensive to manufacture, it is flexible, it is durable, it can optionally be made moldable, it eliminates dust, and it remains hydrophobic after long-term heating to 600° F. (315° C.), or after short-term excursions to temperatures as high as 700° F. (370° C.).

Owner:DILL LEWIS +1

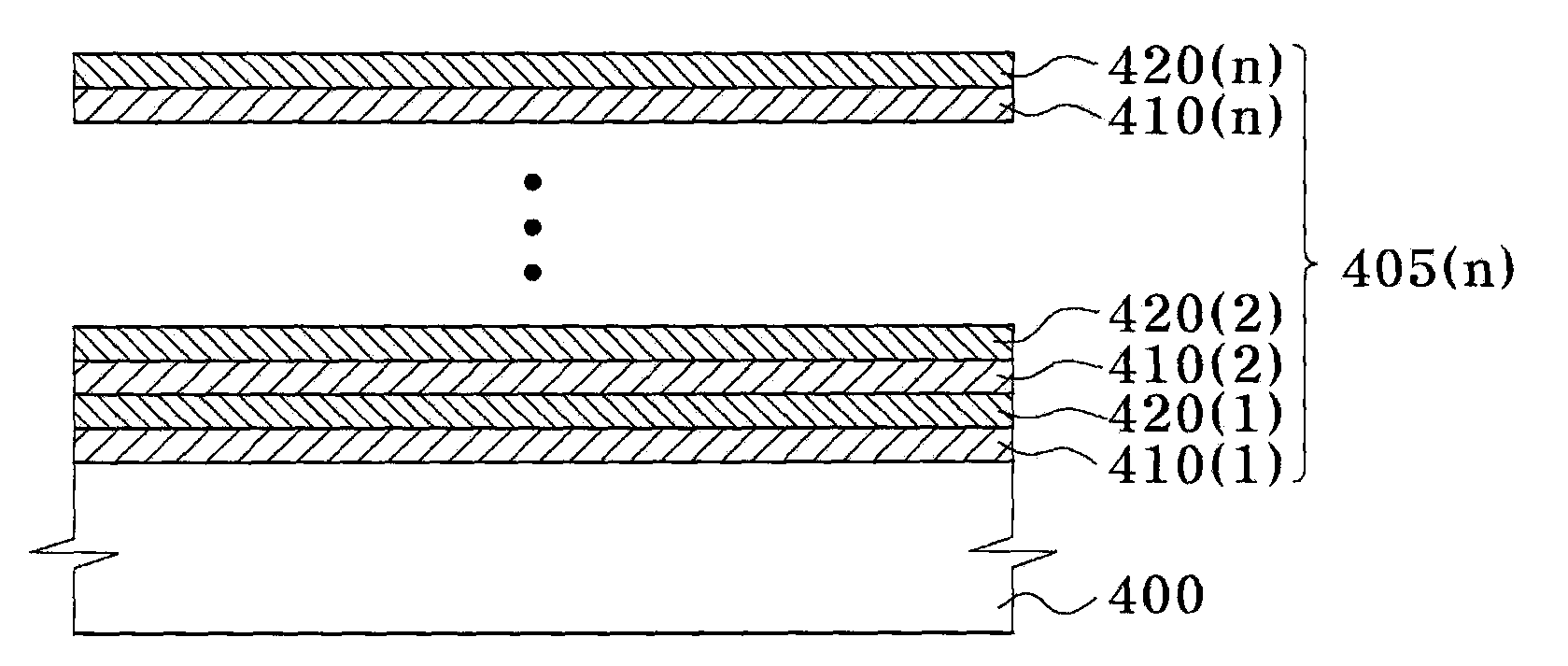

STAINLESS STEEL SEPARATOR FOR FUEL CELL HAVING M/MNx AND MOyNz LAYER AND METHOD FOR MANUFACTURING THE SAME

ActiveUS20110065024A1Improve corrosion resistanceImprove conductivityFinal product manufactureFuel cell auxillariesFuel cellsNitride

Owner:HYUNDAE STEEL CO LTD

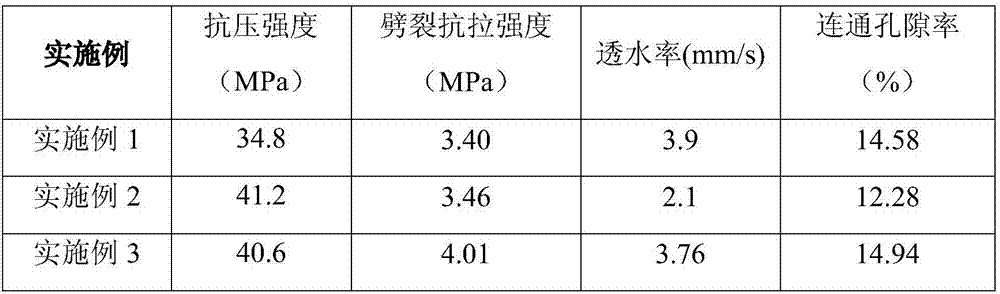

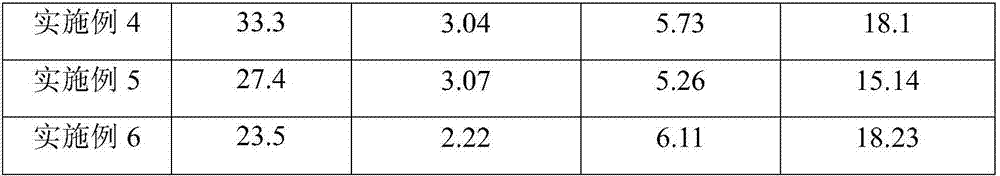

Permeable alkali slag concrete suitable for heavy load pavements and preparation method thereof

The invention relates to a permeable alkali slag concrete suitable for heavy load pavements. The concrete is composed of the following components by mass: 70-79 parts of aggregate; 16-20 parts of slag; 0-4 parts of an admixture; 0-0.08 part of an additive; 3-6 parts of an activator; and 3-4 parts of water. The invention also discloses a preparation method of the permeable alkali slag concrete. The method uses alkali slag as the cementitious material, and optimizes the water glass, slag and gravel components to prepare the permeable concrete. Compared with problems of low compressive strength, poor durability and difficult applicability to heavy load pavements in existing permeable concrete, the permeable alkali slag concrete obtained by the invention has certain water permeability, high compressive strength and good wear resistance. The permeable concrete also has good anti-stripping ability and excellent long-term usability.

Owner:CHONGQING UNIV

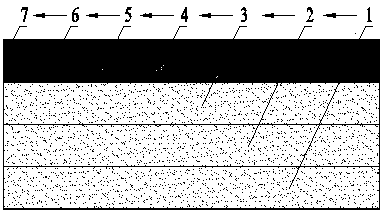

Asphalt pavement paving method achieving quick construction and forming

InactiveCN103741570AShorten construction molding timeReduce waiting timeIn situ pavingsSolid waste managementEnvironmental resistanceChipseal

The invention discloses an asphalt pavement paving method achieving quick construction and forming, belonging to the field of road engineering. The method is characterized by paving a subbase, a lower base course and an upper base course made from lime-flyash macadam mixtures and a surface course made from asphalt mixtures on an earth base in sequence, carrying out gradation design on the lime-flyash macadam mixtures into a dense skeleton type structure, and forming the pavement once by adopting a continuous layered paving and compaction process during construction. Compared with the prior art, the paving method has the beneficial effects that the technical problem of quick construction and forming of the asphalt pavement is solved; the construction time and cost are effectively saved; the traffic pressure is eased; the aims of quick construction of the pavement, saving, durability and environment friendliness are achieved; therefore, the method has good popularization and application values.

Owner:山东省交通科学研究所

Welding material and fuel tank thereby welded

ActiveUS20080021158A1Improve performanceExcellent performance balanceSynthetic resin layered productsLarge containersGasolineFuel tank

To provide a welding material for a fuel tank, which can be readily welded to a fuel tank made of a resin and maintain the welded strength even after being in contact with a fuel such as gasoline and yet is excellent in the long-term performance, a fuel tank attachment constituted by the welding material, and a fuel tank thereby welded. A welding material for a fuel tank, comprising a modified polyethylene resin composition (Z) comprising from 0.5 to 95 wt % of a modified polyethylene resin (X) having at least one monomer selected from the group consisting of an unsaturated carboxylic acid and its derivative, grafted to a polyethylene resin (A) having a density of from 0.910 to 0.965 g / cm3 and a melt flow rate (temperature: 190° C., load: 2.16 kg) of from 0.1 to 5.0 g / 10 min, and from 5 to 99.5 wt % of an unmodified polyethylene resin (Y) having a density of from 0.930 to 0.965 g / cm3, a melt flow rate (temperature: 190° C., load: 2.16 kg) of from 0.01 to 5.0 g / 10 min and a melt flow rate ratio (high load melt flow rate HL-MFR (temperature: 190° C., load: 21.6 kg) / melt flow rate MFR (temperature: 190° C., load: 2.16 kg)) of from 40 to 270, and having a density of from 0.938 to 0.965 g / cm3 and a melt flow rate (temperature: 190° C., load: 2.16 kg) of from 0.05 to 1.0 g / 10 min.

Owner:JAPAN POLYETHYLENE CORP

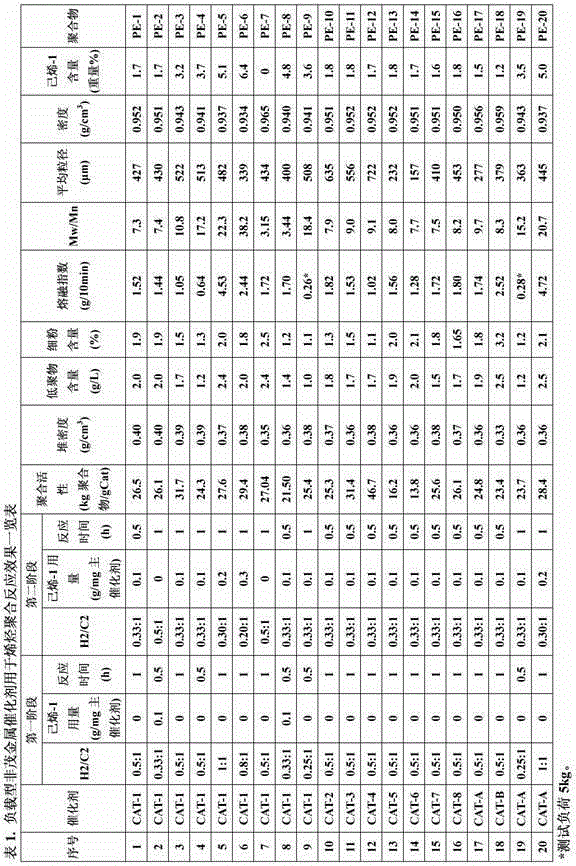

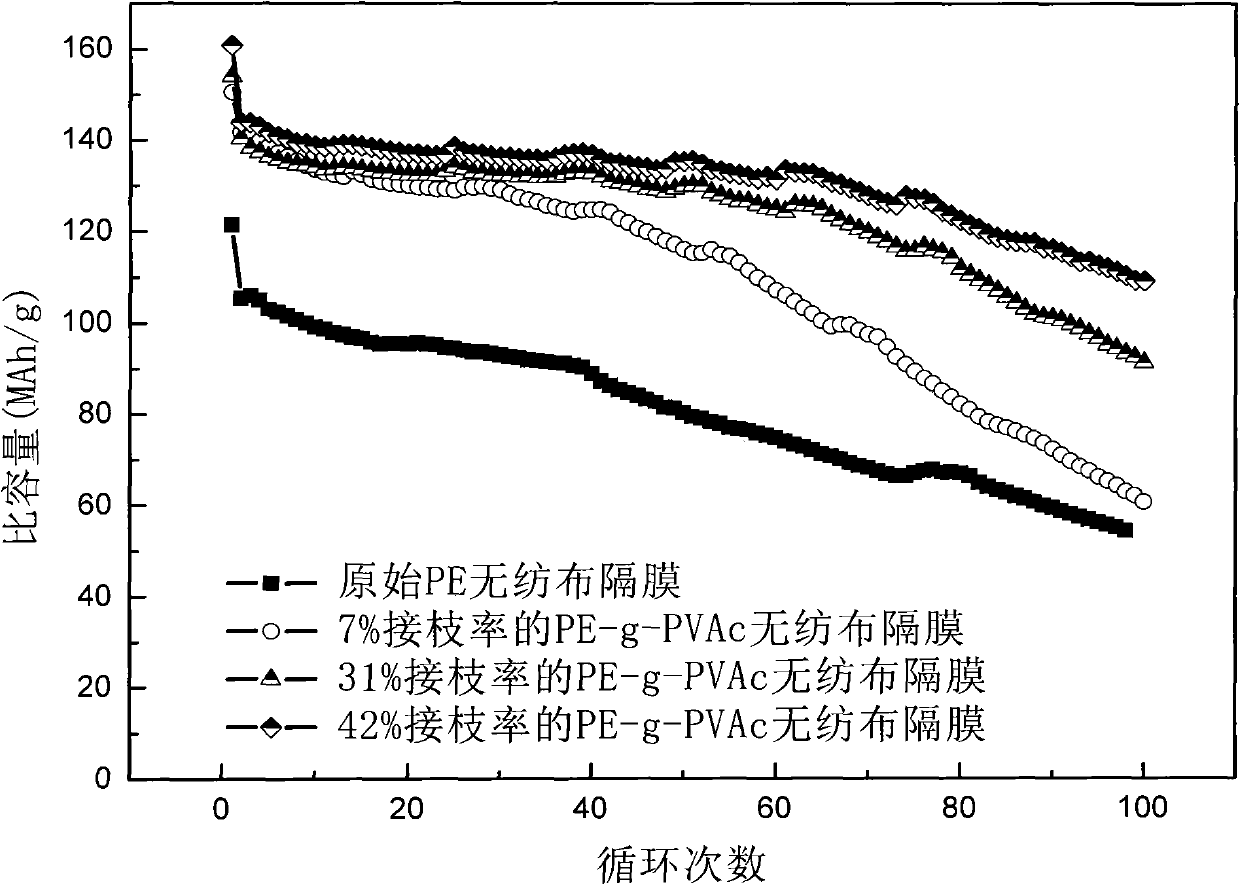

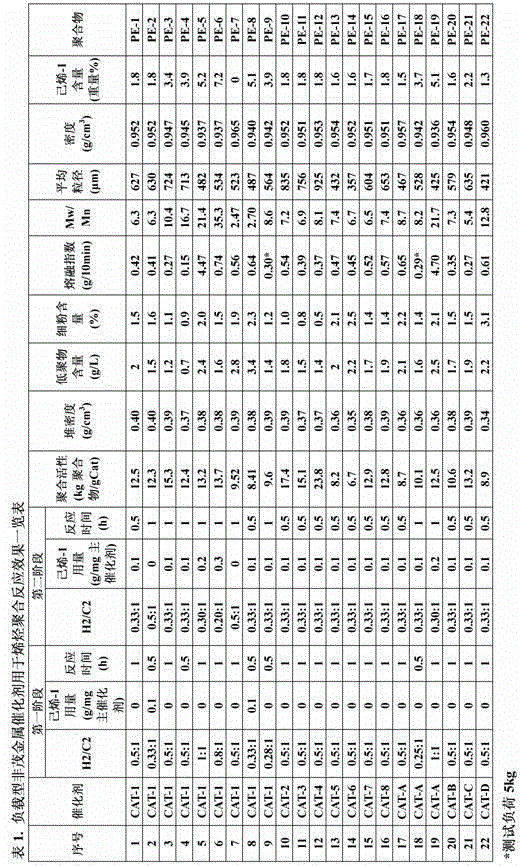

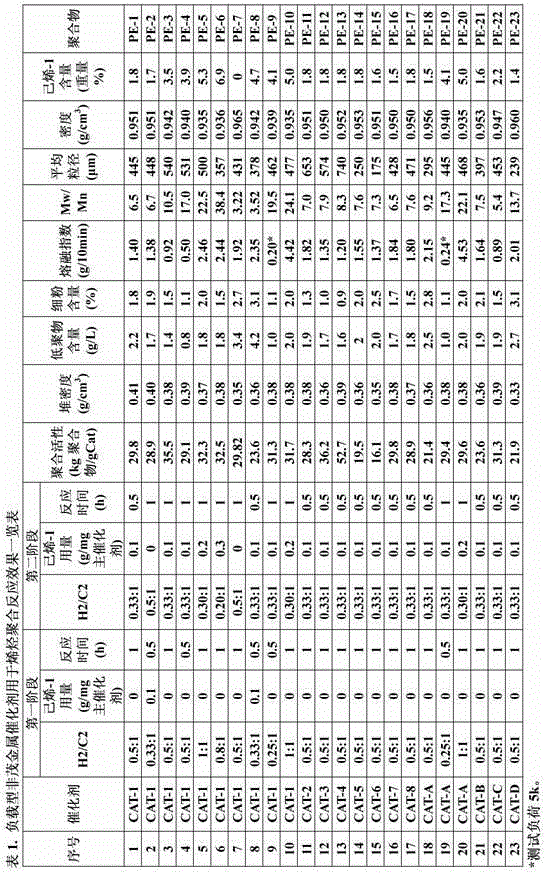

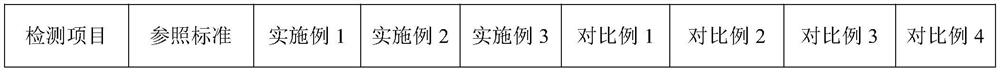

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017626AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105001360AUniform particle sizeAppropriate molecular weight distributionComposite materialAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molded product manufacturing. According to the present invention, the ethylene-alpha-olefin copolymer has advantages of balanced and excellent processability and mechanical property compared with the product in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

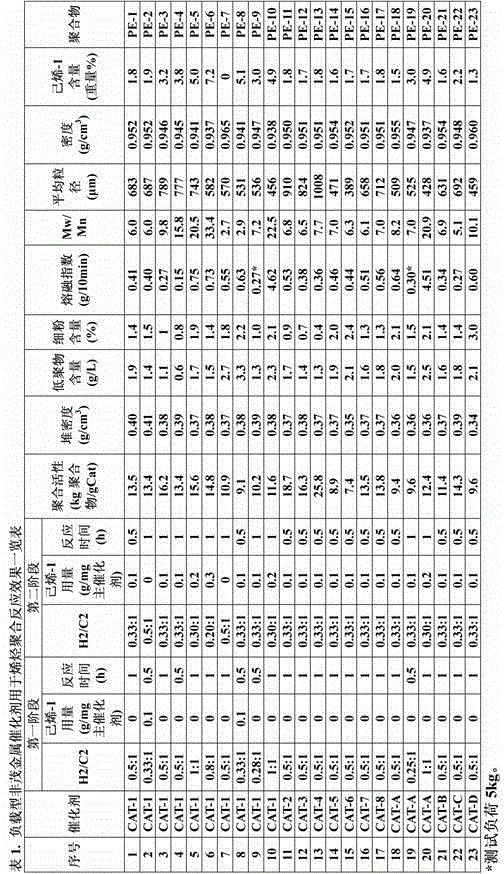

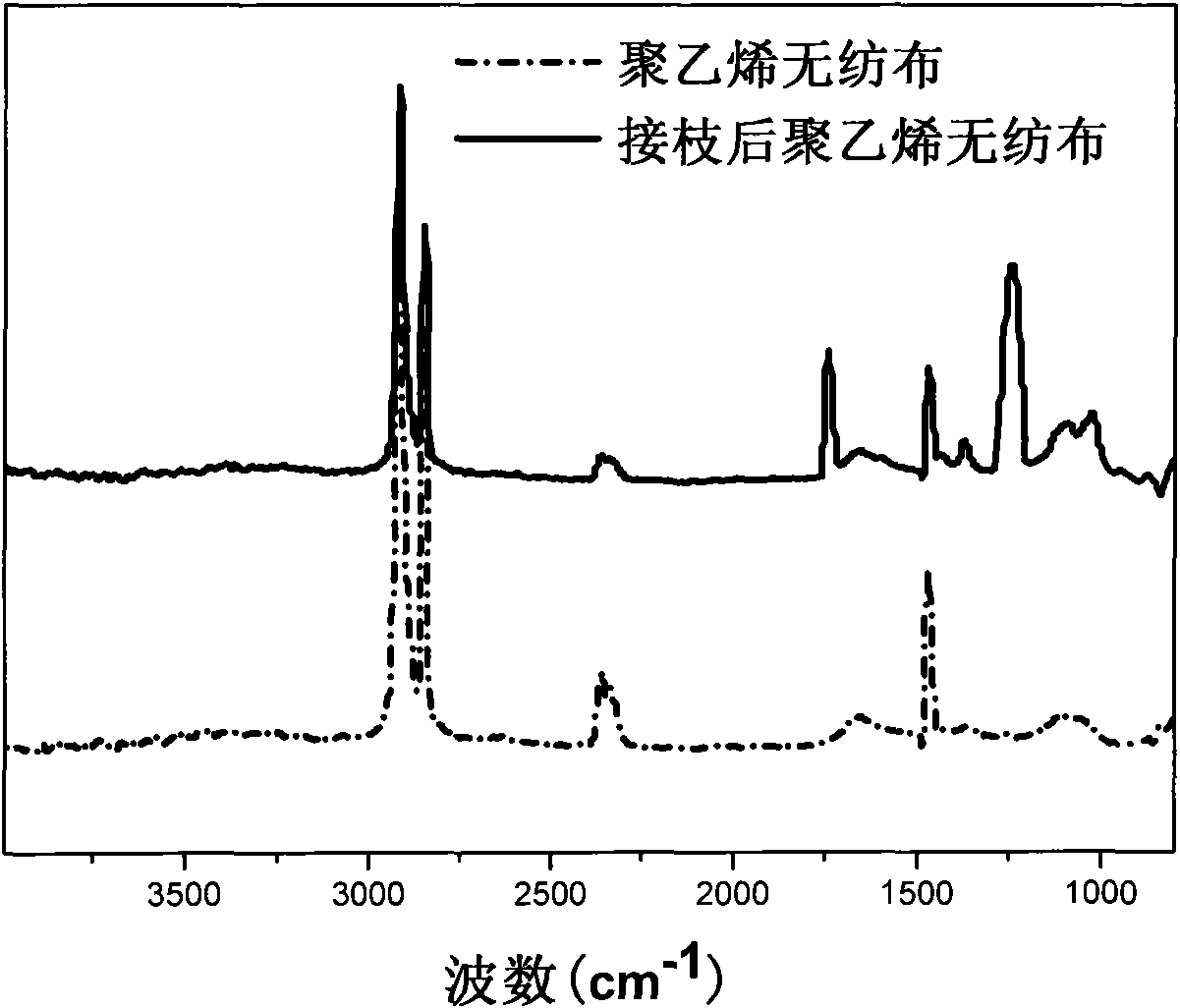

Grafting modified high polymer material, and preparation method and application thereof

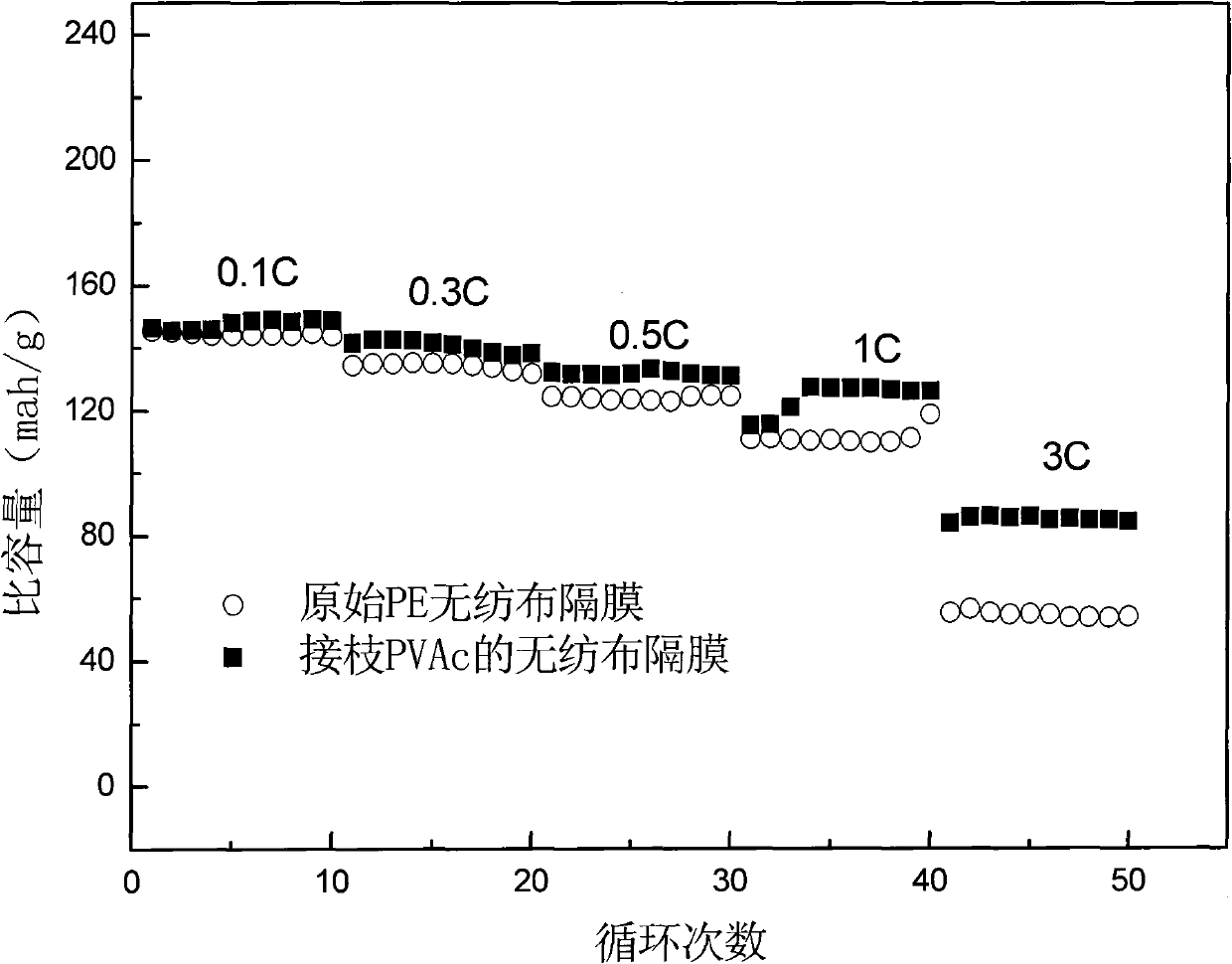

ActiveCN102432906AReduce crystallinityImprove lithium ion conductivityFibre treatmentCell component detailsPolymer sciencePolyolefin

The invention discloses a grafting modified high polymer material which is a high polymer micro-porous membrane or a high polymer non-woven fabric with a graft chain, wherein the graft chain is a polymeric chain of more than one monomer; the polymeric chain is a homo-polymer chain formed by the same monomer or a random copolymer chain formed by different monomers; and the monomer is provided with at least one C=C double bond and at least one ether group or a group shown in the formula I. The invention overcomes the defect that the affinity of the polyolefin micro-porous membrane is improved by coating the affinity group, but the affinity group is easy to drop in the process of using the lithium ion battery, and provides the grafting modified polymer material and a preparation method thereof. The high polymer material is especially suitable for serving as the lithium ion battery separator, reduces the crystallinity of the polyolefin separator and has good affinity for the ester organic electrolyte, and at the same time, the polymer material is not easy to drop from the separator in the use process and can lengthen the use performance of the battery.

Owner:上海世龙科技有限公司

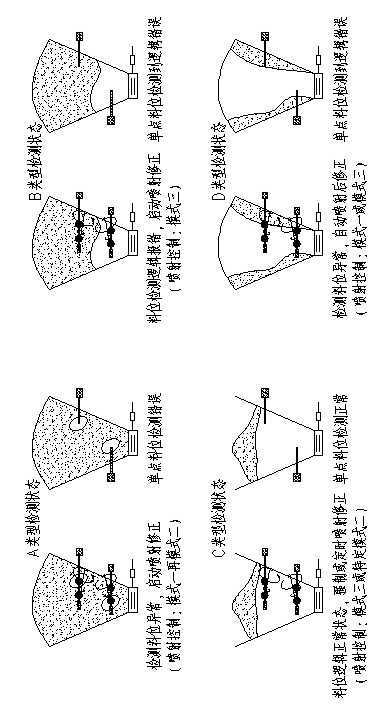

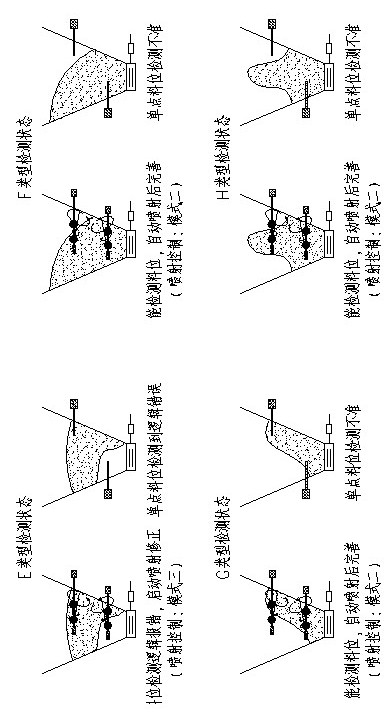

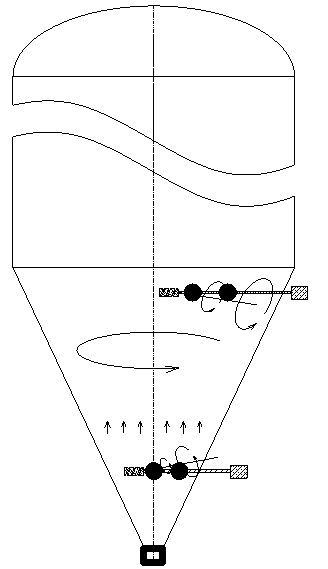

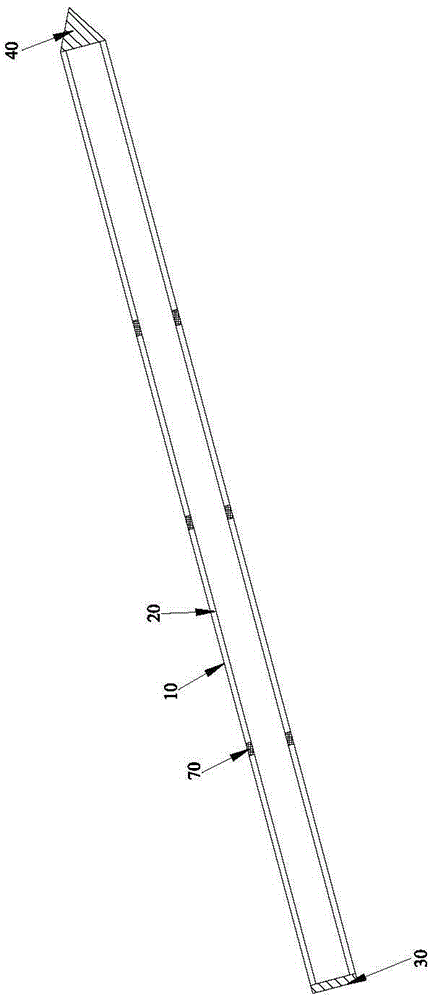

Rod, device and method for detecting dust position

ActiveCN102107108AImprove long-term use effectExtend working lifeDispersed particle filtrationMachines/enginesAutomatic controlEngineering

The invention discloses a rod, a device and a method for detecting a dust position. The rod for detecting the dust position is provided with a plurality of enlarged radio frequency admittance level gage probes, a sheathed temperature gauge and gas spray equipment; and the outer surface of the rod is covered with an insulation protection jacket, a supporting protection sleeve and the like. The device for detecting the dust position consists of a material detection controller which comprises operation display equipment, an external gas source device and the like. In the method for detecting the dust position, three gas spray automatic control modes are set; the first detection of a material signal and a temperature signal is a core event; a mutual checking working manner of a dust position confirmation signal is sent out until at least two material signals are stably consistent with each other after triggering and spraying is finished; and two manual modes protect the safety of a person in a special working state. The arrangement mode of the enlarged detection probes and the plurality of level gauges enlarges the contact area and is very favorable for materials having poor flowability; and then, due to the equal arrangement area, the detection and the sampling are more typical.

Owner:CISDI ENG CO LTD +1

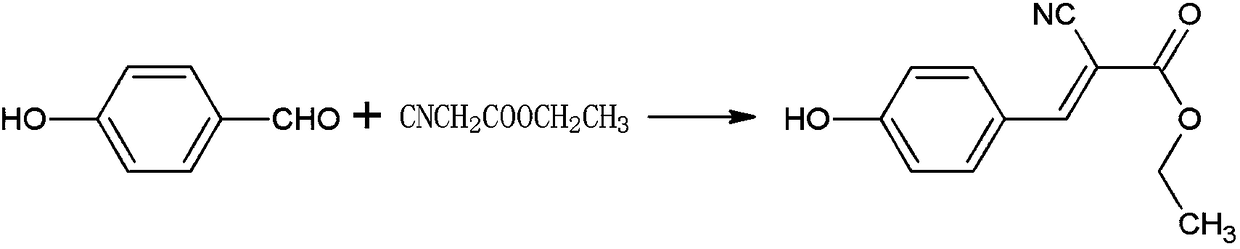

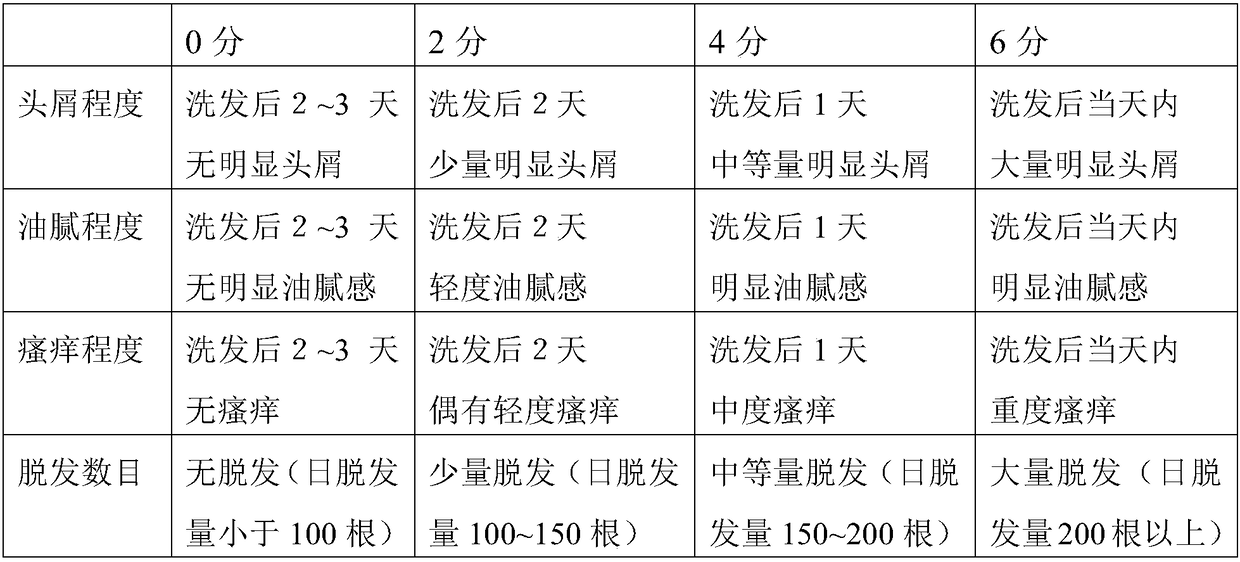

Anti-dropping hair growth shampoo and preparation method thereof

ActiveCN108143669AGuaranteed activityGuaranteed withdrawal rateCosmetic preparationsHair cosmeticsIrritationEthyl cinnamate

The invention discloses an anti-dropping hair growth shampoo and a preparation method thereof. The anti-dropping hair growth shampoo is prepared from, by weight, 80-85 parts of shampoo substrate and 15-20 parts of anti-dropping hair growth lotion, wherein the anti-dropping hair growth lotion is prepared from, by weight, 70-80 parts of fresh ginger-moutan bark extractive lipidosome suspension and 20-30 parts of astragalus membranaceus extractive lipidosome suspension. The anti-dropping hair growth lotion is also prepared from, by weight, 0.01-0.1 part of alpha-cyanogroup-4-p-hydroxyl ethyl cinnamate. The anti-dropping hair growth shampoo has the advantages of having good stability, good detergency, capable of effectively preventing hair loss and inducing and promoting hair growth, having amild formula, having no irritation on scalp, and being suitable for long-term use.

Owner:广州星愉贸易有限公司

Fu moxibustion traditional Chinese pharmaceutical oil and preparation method thereof

InactiveCN106215157AReach activityAchieve anti-inflammatory and pain-relieving effectNervous disorderAntipyreticAlcoholEucalyptus oil

The invention provides Fu moxibustion traditional Chinese pharmaceutical oil and a preparation method thereof. The traditional Chinese pharmaceutical oil is prepared from the following raw materials in parts by weight: 2 to 8 parts of cortex cinnamomi oil, 5 to 10 parts of wintergreen oil, 5 to 10 parts eucalyptus oil, 1 to 5 parts of mint oil, 1 to 5 parts of rose oil, 1 to 5 parts of lavender oil, 2 to 8 parts of rhizoma acori graminei oil, 2 to 8 parts of clove oil, 1 to 5 parts of ginger oil, and 2 to 8 parts of ethyl alcohol. The Fu moxibustion traditional Chinese pharmaceutical oil has the effects of dispelling the wind, invigorating the blood circulation, dispelling cold, diminishing inflammation, relieving pain, quieting the heart, soothing the nerves and calming. Based on the yin-yang theory in the traditional Chinese medicine theory, the drug effects can be quickly played through exhaling, exterior syndrome relieving and warming of the externally applied drug. Due to the action of the ethyl alcohol, the drug can quickly penetrate through skin and permeate into muscular striae, and the effects of dispelling the wind, invigorating the collateral, diminishing inflammation and relieving pain can be obtained. The kind of medium medicine can dispel cold through warmness to achieve the effects of dispelling the wind, removing cold, clearing heat, diminishing inflammation, invigorating the blood circulation, activating meridians and relieving pain.

Owner:张东旭

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017455AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

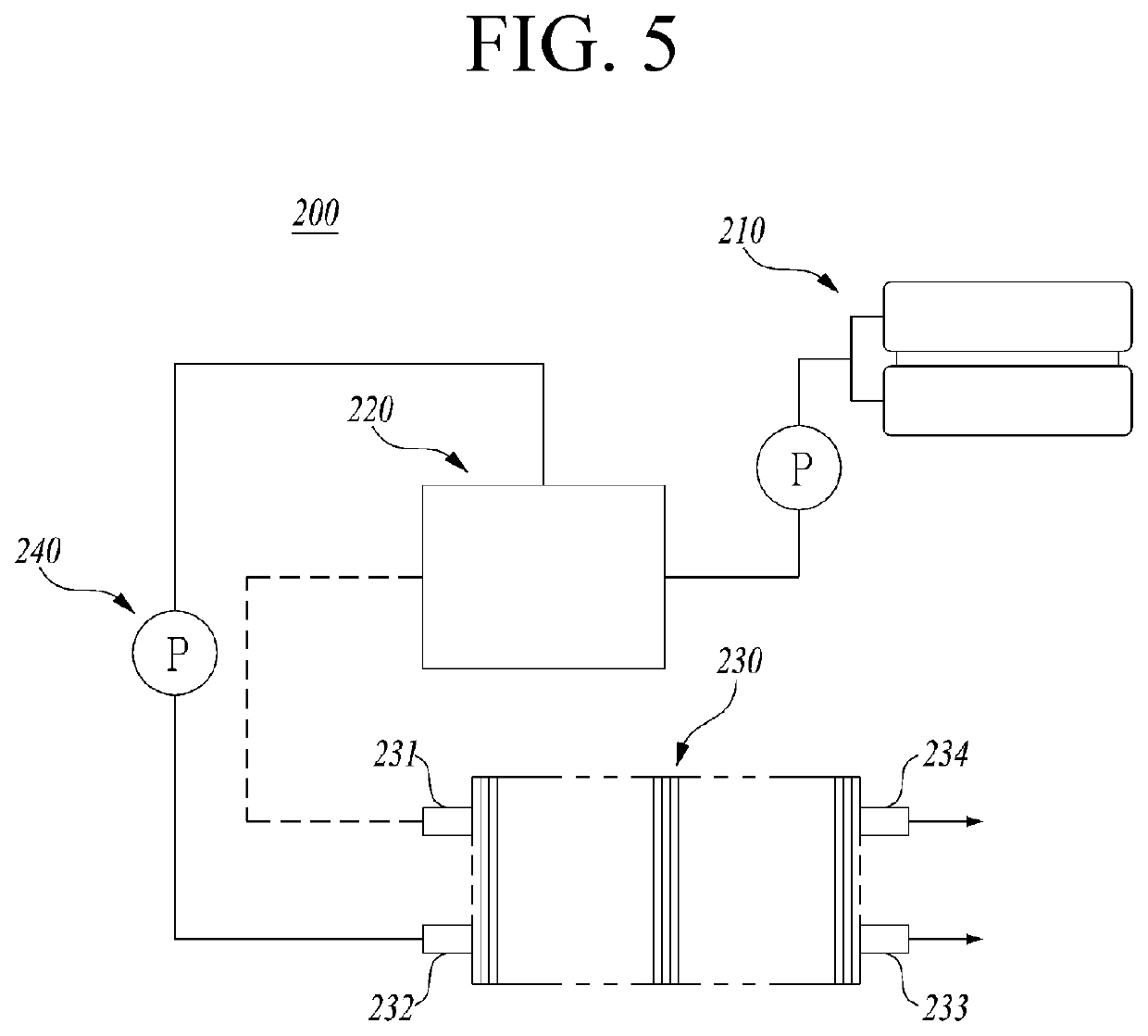

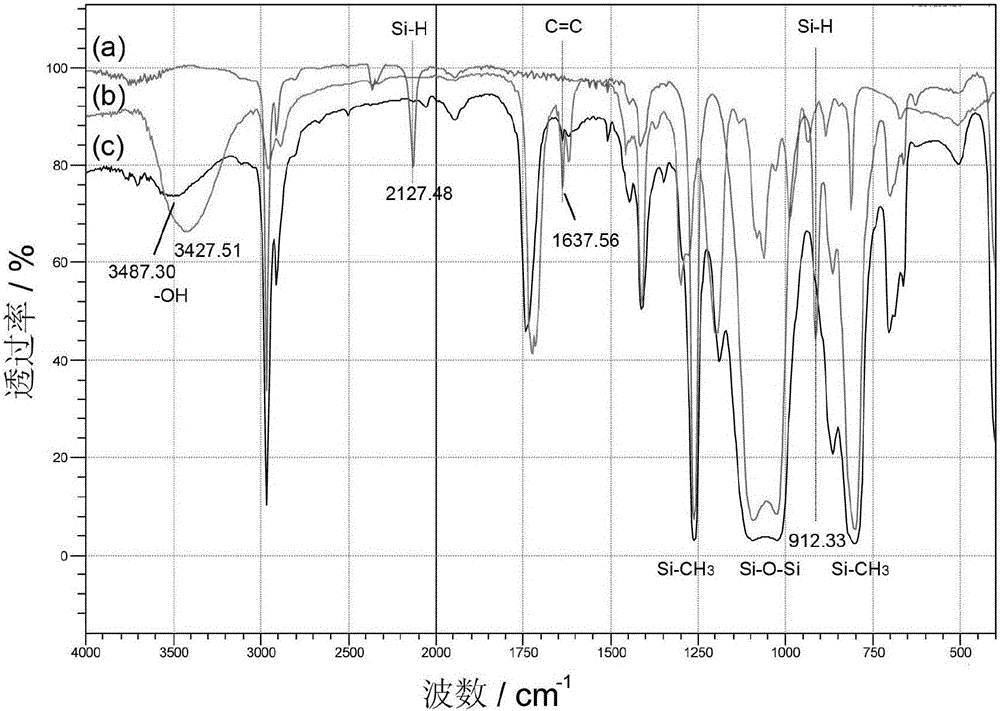

Radical scavenger, manufacturing method therefor, membrane-electrode assembly comprising same, and fuel cell comprising same

PendingUS20200280074A1Minimizing in ion conductivity of ionExcellent chemical durabilityCell electrodesFuel cellsFuel cellsPtru catalyst

A radical scavenger, a manufacturing method therefor, a membrane-electrode assembly including the radical scavenger, and a fuel cell including the membrane-electrode assembly are disclosed. The membrane-electrode assembly contains an ion exchange membrane; catalyst electrodes disposed on both surfaces of the ion exchange membrane, respectively; and a radical scavenger disposed at any one position selected from the group consisting of in the catalyst electrodes, in the ion exchange membrane, between the ion exchange membrane and the catalyst electrodes, and a combination thereof.

Owner:KOLON IND INC +1

Flexible bionic active pigment printing formaldehyde-free bonding agent and preparation method and application thereof

ActiveCN105064084AEasy to manufactureImprove stabilityDyeing processHydrophilic monomerAcrylonitrile

The invention relates to a flexible bionic active pigment printing formaldehyde-free bonding agent and preparation method and application thereof. The bonding agent comprises acyloxy hydroxyalkyl polysiloxane, acrylic acid, methacrylic acid, acrylic monomers, acrylamide, styrene, vinyl acetate, acrylonitrile, N-glycidyl acrylamide, unsaturated strongly hydrophilic monomers and reactive surfactant which are subjected to copolymerization and condensation reactions in cooperation with initiator, and the flexible bionic active pigment printing formaldehyde-free bonding agent is prepared. The bonding agent is free of formaldehyde, the color fastness meets the corresponding national standards, the agent can be used for pigment printing as well as pigment dyeing, the printed or dyed fabric is very soft in hand feeding, and the bonding agent has the advantages of being free of being sticky to rolls and blocking screens, stable in property, high in color fastness and the like.

Owner:SICHUAN YIXIN TECH

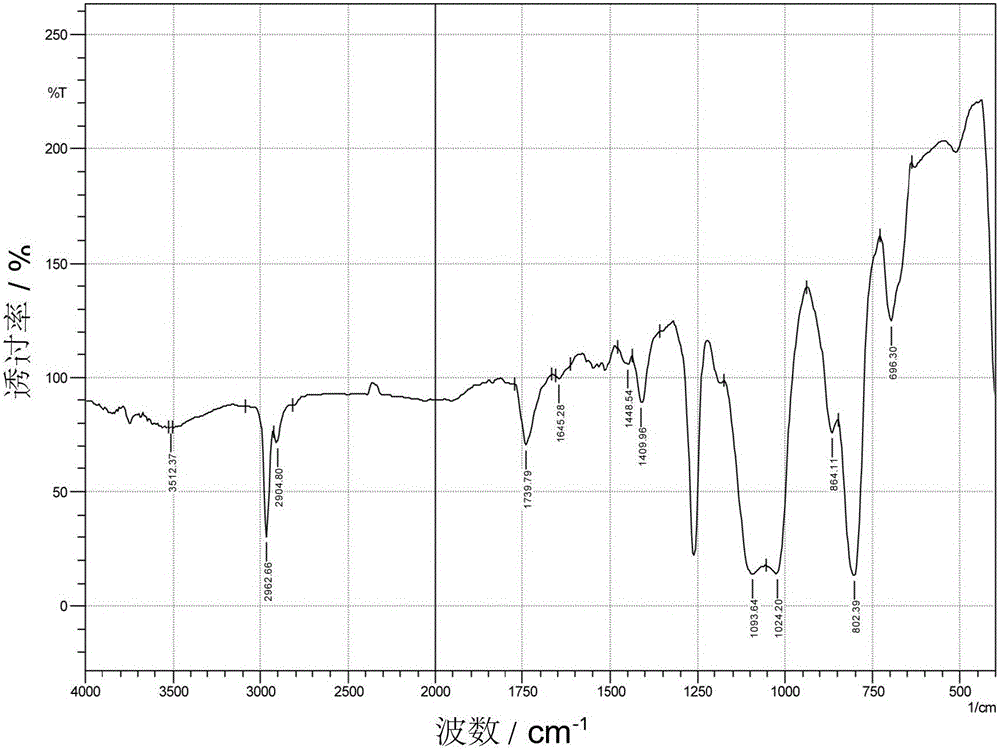

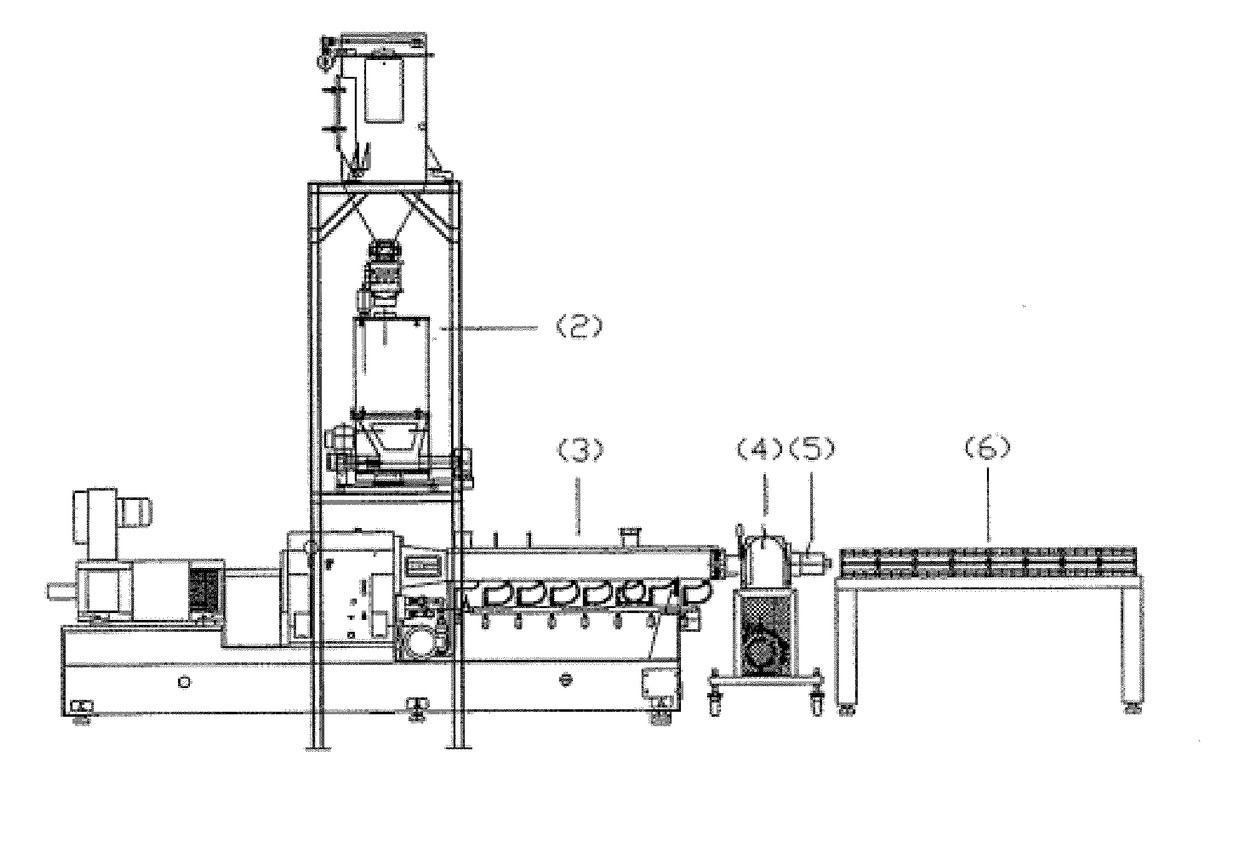

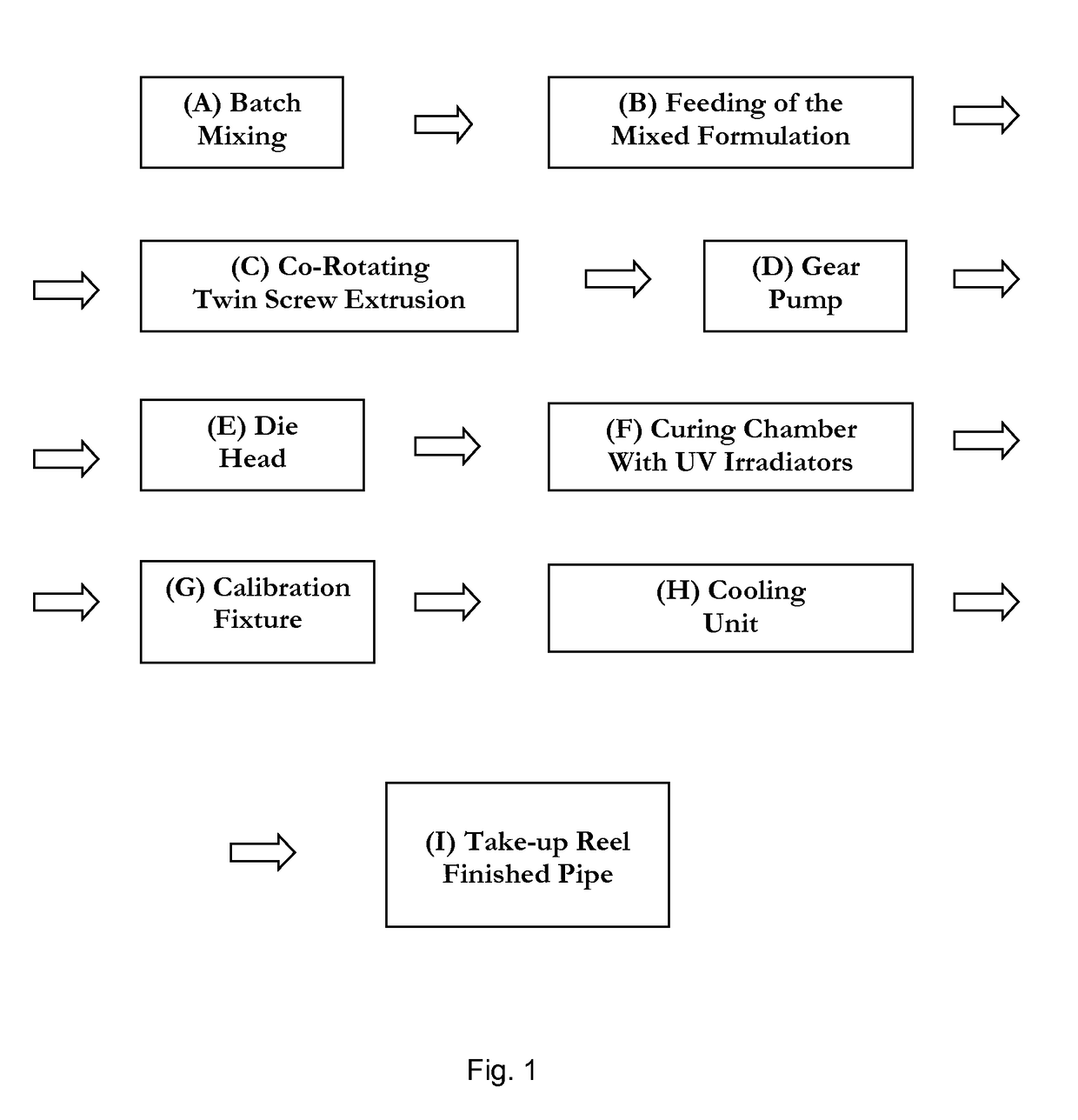

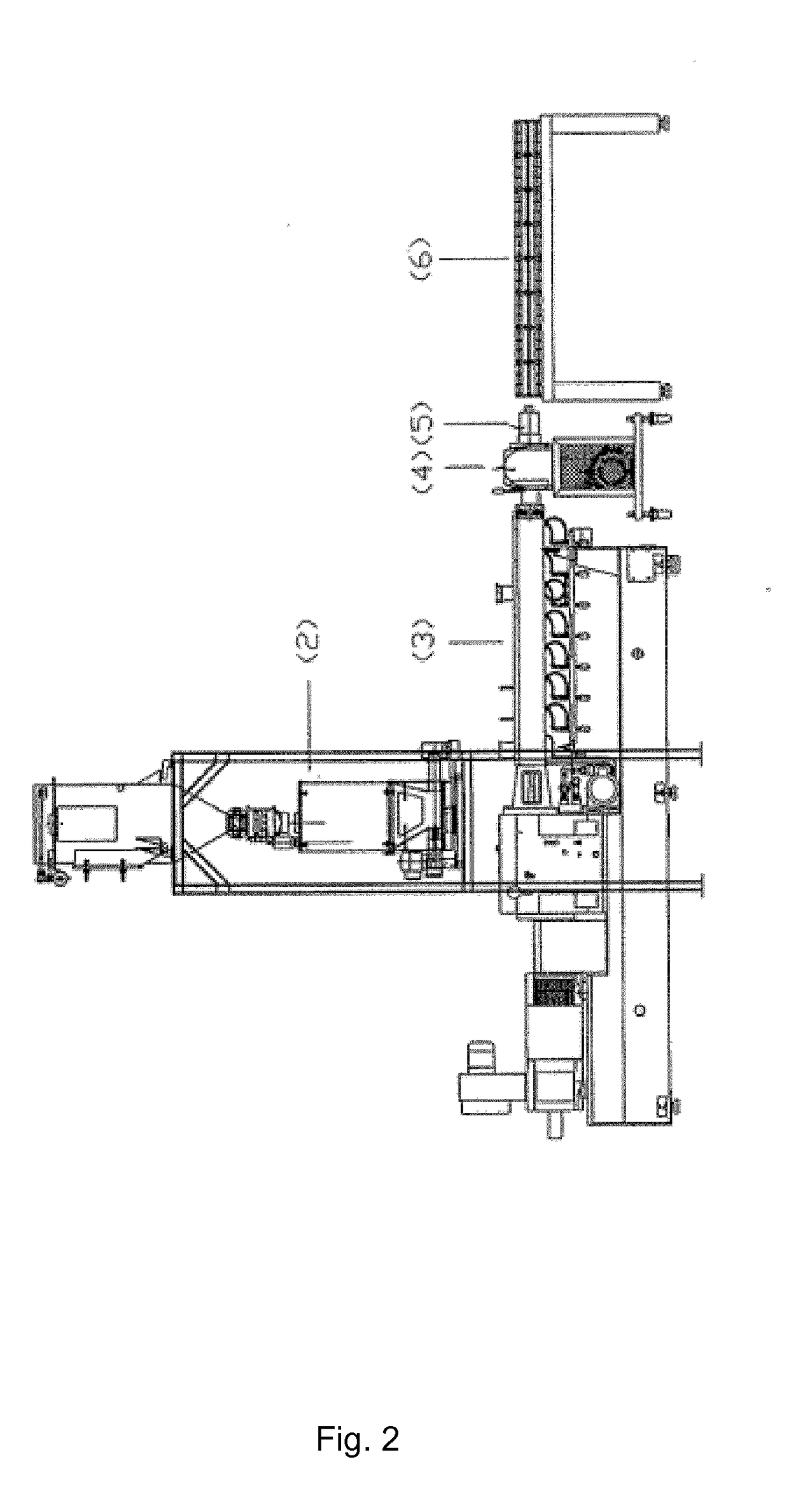

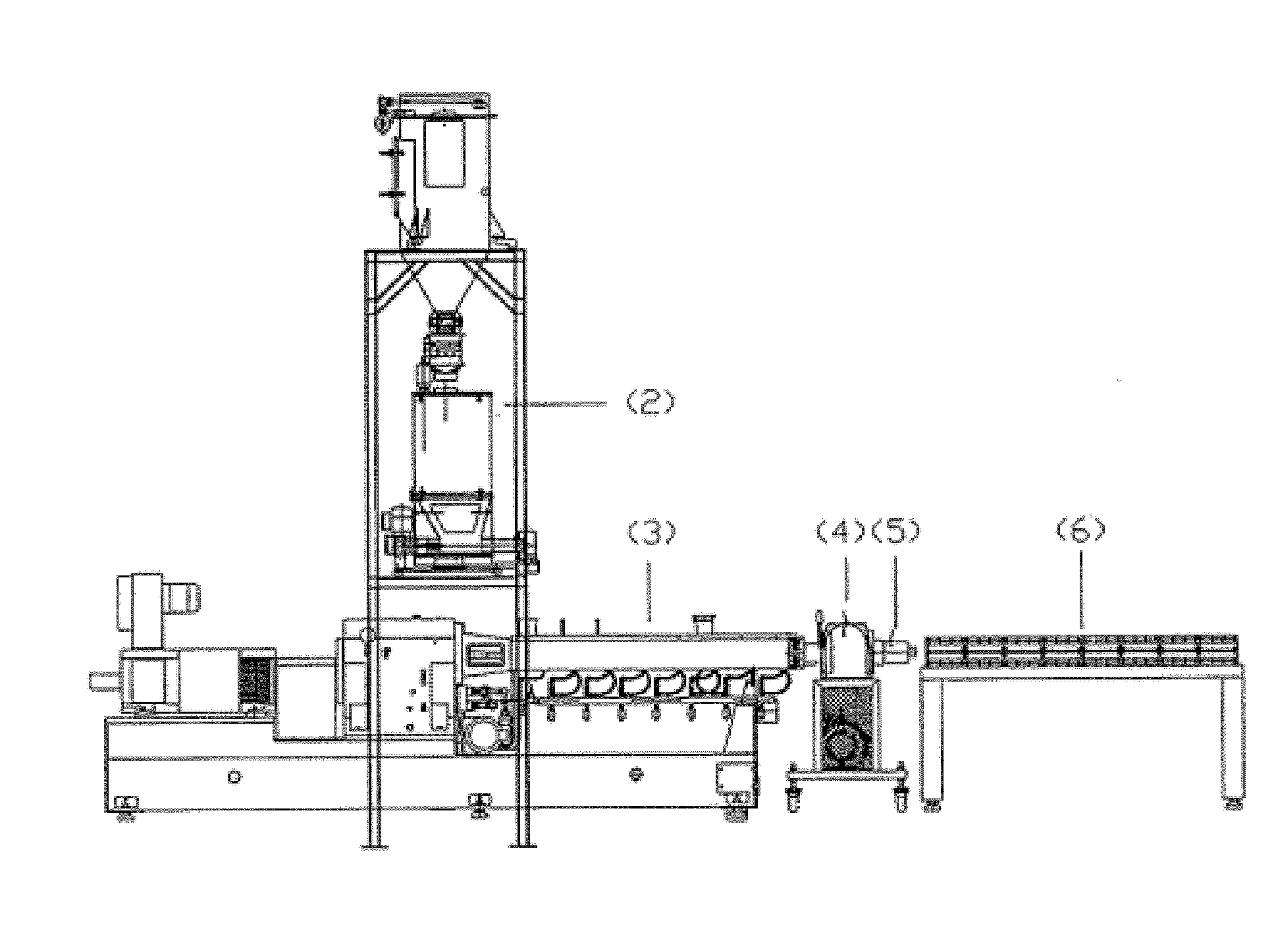

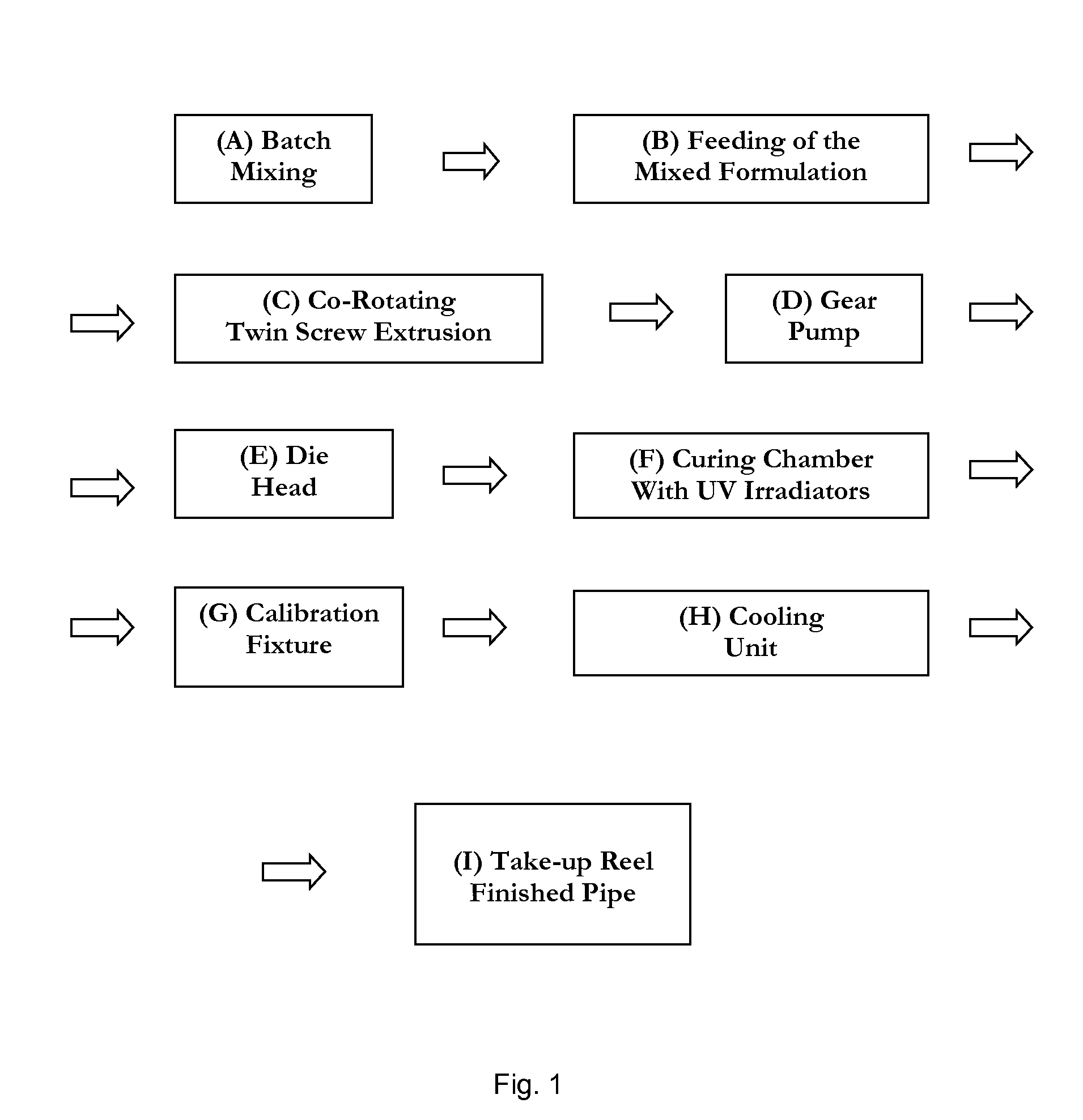

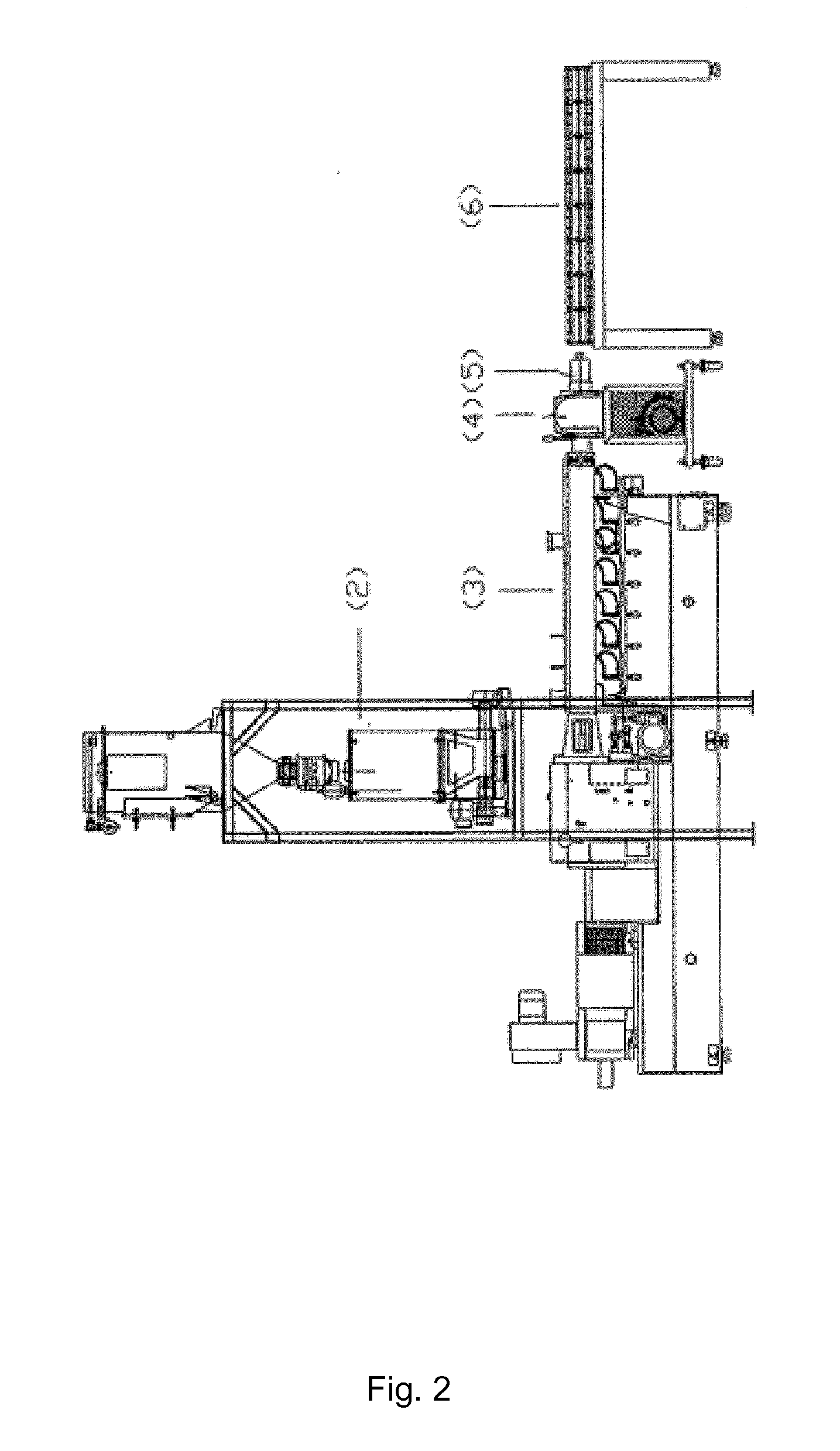

Polyolefin Pipe

ActiveUS20170114193A1Reduced level of leachingImprove chlorine resistanceRigid pipesPolyolefinEngineering

This invention relates to a polymeric pipe, and more particularly a polymeric pipe where the pipe comprises a crosslinked polyolefin formed from extruded polyolefin comprising a photoinitiator. More particularly, this invention relates to the manufacturing of plastic pipes and tubing by utilizing co-rotating twin screw extrusion combined with photo-induced cross-linking, of thermoplastic polymers such as polyethylene, to produce PEX pipes and tubing.

Owner:UPONOR INNOVATION AB

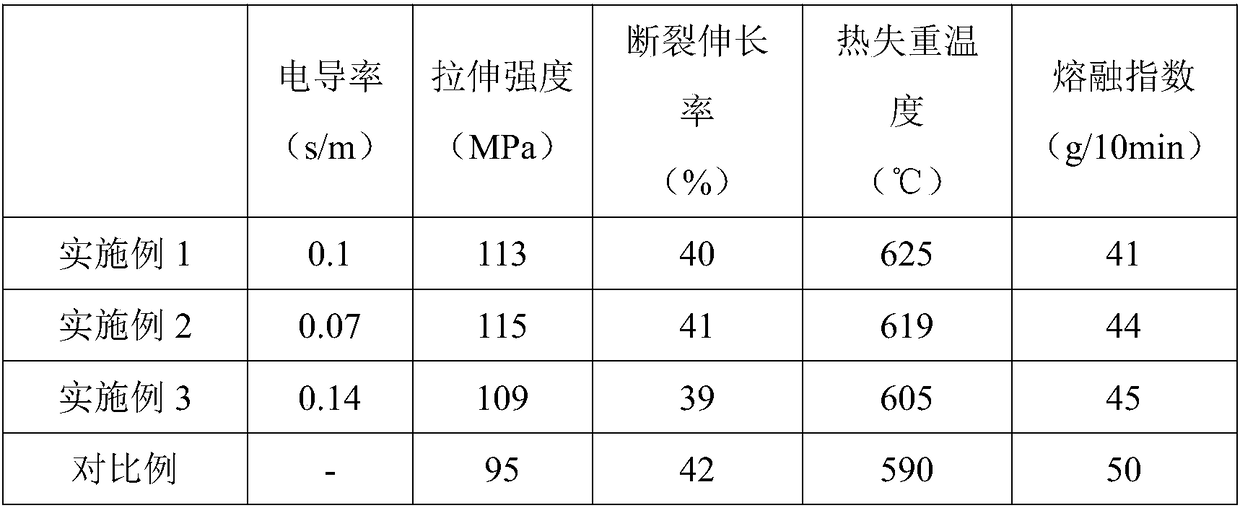

Preparation method of conductive polyether ether ketone composite material

The invention belongs to the technical field of high molecular materials and specifically discloses a preparation method of a conductive polyether ether ketone composite material. After a large numberof comparative tests on a polyether ether ketone substrate, a conductive filler and an additive, an optimal formula is finally obtained; the prepared conductive composite material can be used for a long term under the condition of 250-300 DEG C and has a very good mechanical property; compared with an existing alkane-based and rubber-based material, the conductive polyether ether ketone compositematerial has higher mechanical property and is greatly improved in tensile, compression and impact resistance; the conductive polyether ether ketone composite material can be widely used in chemical,metallurgy, medicine and other industries, so that the application field of the high molecular composite material under high-temperature and severe conditions is expanded.

Owner:YIBIN TIANYUAN GRP CO LTD

Polyolefin Pipe

ActiveUS20160130420A1Reduced level of leachingImprove chlorine resistanceRigid pipesPolyolefinEngineering

This invention relates to a polymeric pipe, and more particularly a polymeric pipe where the pipe comprises a crosslinked polyolefin formed from extruded polyolefin comprising a photoinitiator and a reactive extrusion species. More particularly, this invention relates to the manufacturing of plastic pipes and tubing by utilizing co-rotating twin screw extrusion combined with photo-induced crosslinking, of thermoplastic polymers such as polyethylene, to produce PEX pipes and tubing.

Owner:UPONOR INNOVATION AB

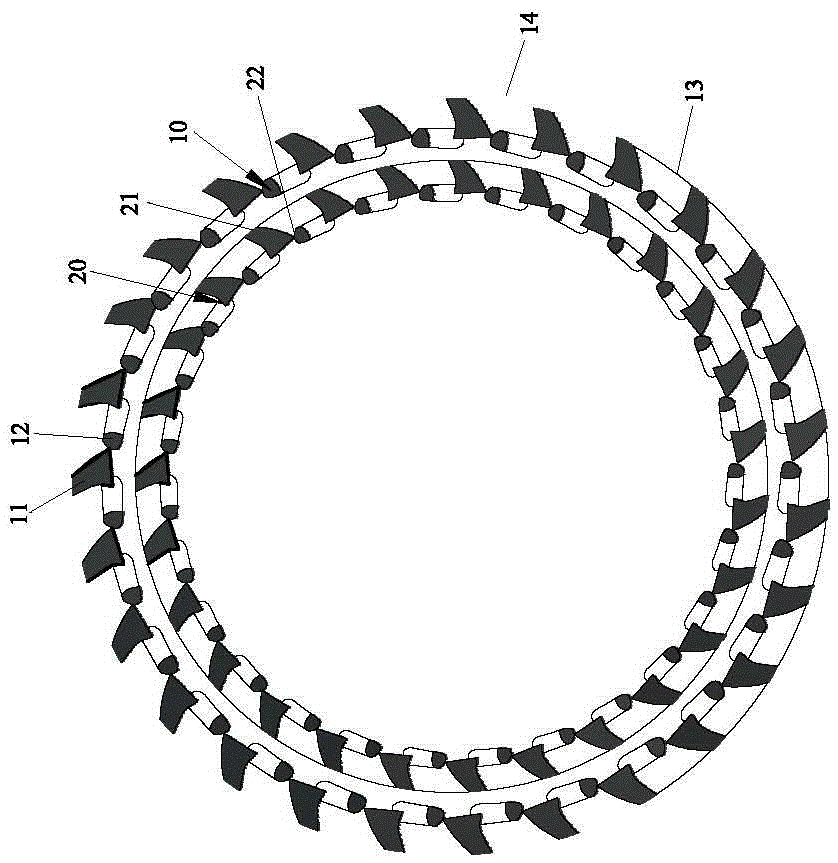

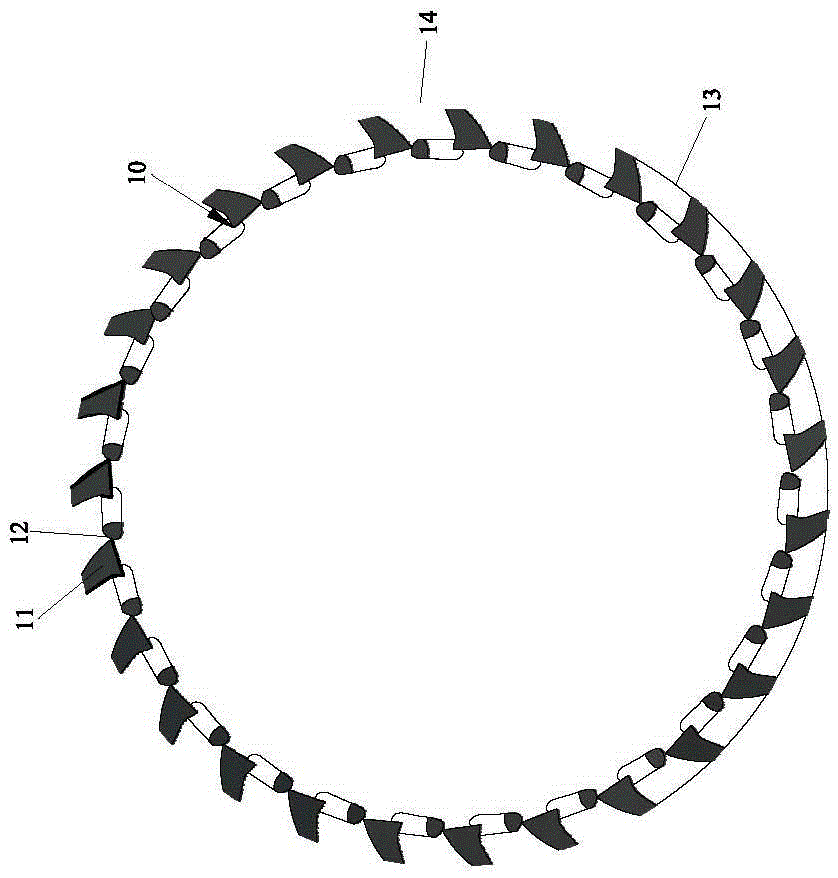

Novel replaceable hard and rigid combined double-layer curved-grain net-shaped pervious pipe for slope

The invention discloses a novel replaceable hard and rigid combined double-layer curved-grain net-shaped pervious pipe for a slope. The novel replaceable hard and rigid combined double-layer curved-grain net-shaped pervious pipe comprises an outer pipe, an inner pipe, a top cover and a bottom cover. The outer pipe is a semi-pervious type curved-grain net-shaped pervious pipe body, and the outer wall face of the outer pipe is provided with first curved-grain ribs and first pervious holes. The inner pipe is a full-pervious type curved-grain net-shaped tough pervious pipe body, and the outer wall face of the inner pipe is provided with second curved-grain ribs and second pervious holes. The inner pipe is detachably sleeved with the outer pipe. According to the novel replaceable hard and rigid combined double-layer curved-grain net-shaped pervious pipe for the slope, the construction cost can be indirectly reduced; and the good long-term use performance is achieved, so that the maintenance cost can be greatly reduced. Due to the technical advantages of replaceability of a new material and a new technology in the process of maintaining and governing sludge plugging of backwards-slanting drain holes, corrosion resistance, admissible hardness, circular rigidity, flexibility, durability of pipes and other aspects, application and popularization intensity can be enlarged so that the technology can serve for engineering construction as soon as possible, and more economic and social benefits are created.

Owner:广东华路交通科技有限公司

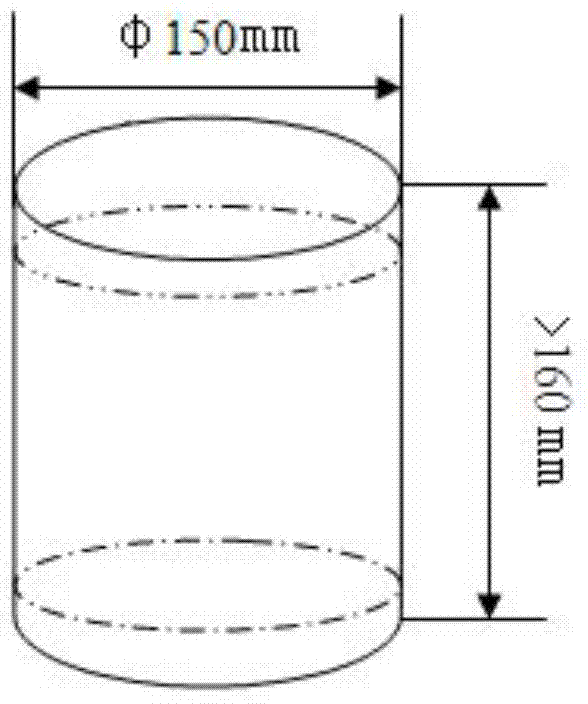

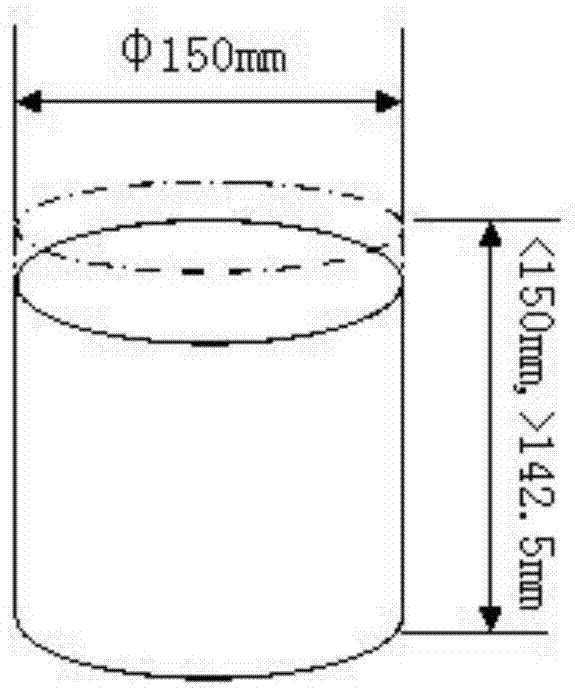

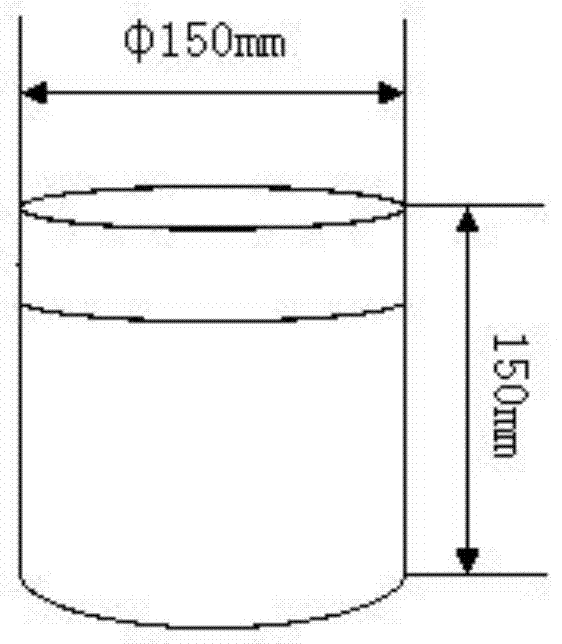

Test method for semi-rigid base core sample compressive strength

InactiveCN104515704AEnsure the number of trialsReduce mistakesPreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

The invention relates to a test method for semi-rigid base core sample compressive strength. The test method comprises the following steps: selecting core drilling positions and sampling core samples; inspecting and screening the sampled core samples; carrying out end face treatment on the core samples, and performing humidity treatment on the core samples after end face treatment; carrying out tests of compressive strength; calculating the test data to obtain the compressive strength of the core samples, organizing and calculating the obtained all compressive strength, and obtaining the compressive strength value of each data group. The test method for semi-rigid base core sample compressive strength, provided by the invention, can solve the problems that in the prior art, as the compressive strength test method is not provided to test the semi-rigid base core sample on the road in the period of use, whether the semi-rigid base strength is qualified or not cannot be scientifically assessed and judged in the road overhaul design and construction, and further engineering measures cannot be adopted for reasonable treatment.

Owner:北京市道路工程质量监督站

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017456AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

Anti-condensation coating and preparation method thereof

The invention discloses an anti-condensation coating. The anti-condensation coating comprises a mixed emulsion formed by a pure acrylic emulsion and a silicon resin emulsion and a heat insulation material formed by combining microbeads and aerogel slurry, wherein the mixed emulsion accounts for 20-40% of the total mass of the anti-condensation coating; and the heat insulation material accounts for 15-20% of the total mass of the anti-condensation coating. According to the anti-condensation coating disclosed by the invention, the heat insulation material containing the microbeads and the aerogel is added, so a temperature difference between a wall surface and air is reduced, the wall surface is prevented from condensation, and the problems of moisture absorption saturation, moisture absorption expansion and adhesive force reduction of a traditional anti-condensation coating due to moisture absorption of water vapor in air are also solved; and meanwhile, the pure acrylic emulsion and the silicon resin emulsion are used, and the water resistance and excellent physical performance of the pure acrylic waterproof emulsion and the air permeability and hydrophobicity of the silicon resin emulsion are effectively combined, so the coating has better physical performance, is not prone to damage, and has waterproof and lotus leaf self-cleaning effects to prevent external water from invading.

Owner:SUZHOU GUARDEX NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com