Grafting modified high polymer material, and preparation method and application thereof

A polymer material and graft modification technology, which is applied in the field of graft modified polymer materials and its preparation and application, can solve the problem of battery performance degradation, easy electrolyte leakage, affecting lithium ion conductivity and long-term use performance And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

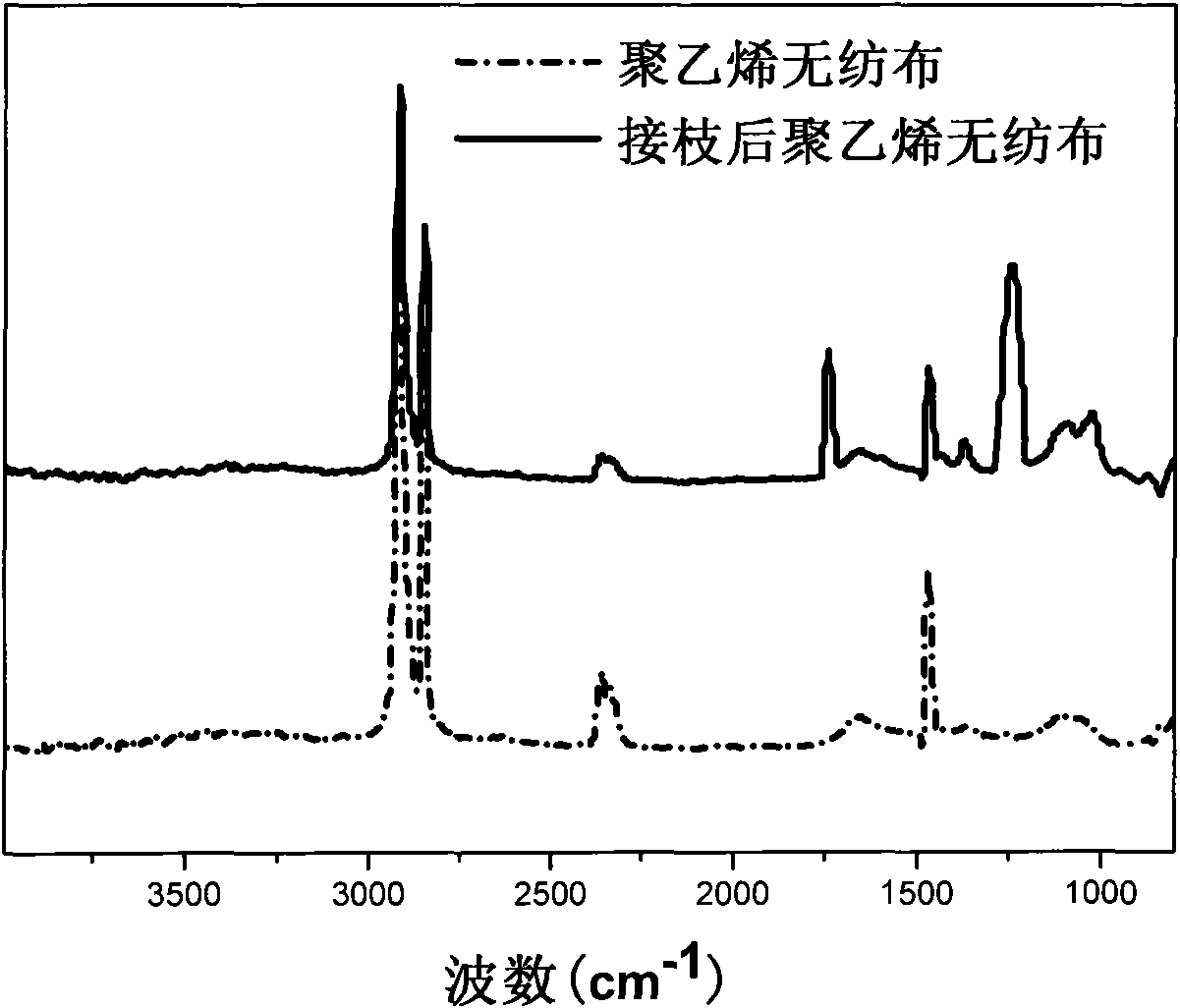

[0052] Select thickness to be 5g polyethylene non-woven fabrics of 50 microns as macromolecule material (number-average molecular weight is 200,000, average pore diameter is 1.7 microns), this polyethylene non-woven fabrics is soaked in by 10g vinyl acetate and 40g ethyl acetate The resulting solution was irradiated to 30kGy with gamma rays produced by a cobalt source in a nitrogen atmosphere, taken out and extracted with ethyl acetate for 2 days in a Soxhlet extractor to obtain a modified PE-g with a grafting rate of 90%. -PVAc non-woven fabric, which is the desired Li-ion separator.

Embodiment 2

[0054] Select the polypropylene non-woven fabric 20g that thickness is 100 microns as macromolecule material (number-average molecular weight is 250,000, and average aperture is 2.5 microns), this non-woven fabric is soaked in by 10g ethyl acrylate and 90g ethyl acetate composition In the solution, irradiate to 20kGy with the ray that electron beam produces in nitrogen atmosphere, take out and extract with acetone in Soxhlet extractor for 2 days, obtain the modified non-woven fabric of ethyl acrylate grafting rate 30%, namely Li-ion separator required.

Embodiment 3

[0056] Select the PVDF microporous membrane 10g that thickness is 40 microns as macromolecule material (the number average molecular weight is 550,000, and aperture is 2 microns on average), utilizes cobalt 60 gamma ray source to irradiate it in air, and irradiation dose is 20kGy. Mix 20g of ethyl methacrylate and 2g of Tween 20 into an emulsion in 78g of water, immerse the irradiated PVDF microporous membrane into the emulsion, raise the temperature to 60°C for 6 hours under nitrogen protection, and take it out. Extract with acetone for 2 days to obtain a modified PVDF-g-PEMA microporous membrane with a graft rate of 70%, which is the desired lithium ion separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com