Test method for semi-rigid base core sample compressive strength

A technology of semi-rigid base layer and compressive strength, which is applied in the direction of applying stable tension/compression to test the strength of materials and the preparation of test samples. and judging the strength of the semi-rigid base layer, and the inability to take engineering measures, etc., to achieve the accuracy of calculation results, reduce errors, and ensure the effect of the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a test method for the compressive strength of a semi-rigid base layer core sample, using the following instruments and equipment:

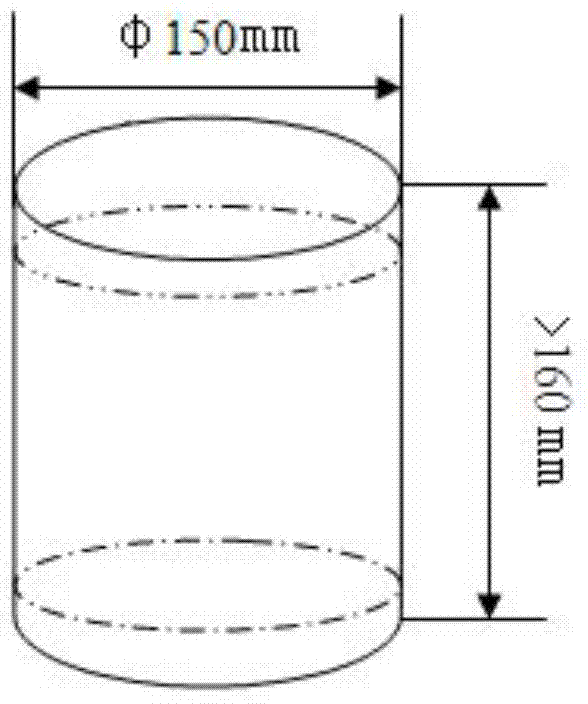

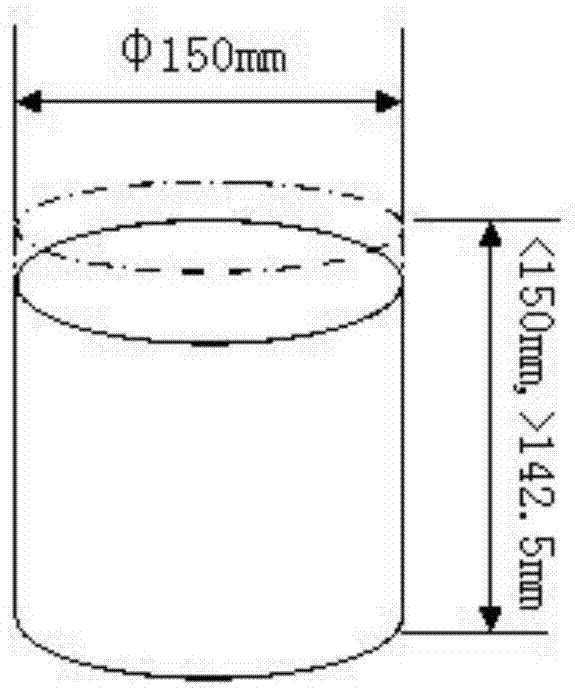

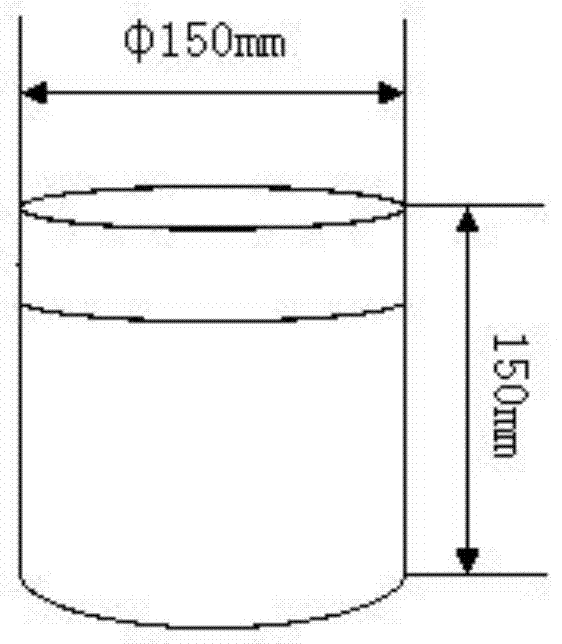

[0081] 1. Road coring drilling rig: traction or vehicle-mounted, the drilling rig is driven by an engine, and should be selected 150mm drill bit diameter, equipped with water spray cooling device; select the drill bit length according to the thickness of the pavement structure layer;

[0082] 2. Electronic balance: measuring range 15kg, sensitivity 0.1g;

[0083] 3. Sample container or iron plate, etc.;

[0084] 4. Sample label;

[0085]5. Press or universal testing machine: The press shall meet the requirements of the current "Hydraulic Pressure Testing Machine" (GB / T3722) and the General Technical Requirements for Testing Machines (GB / T 2611), and its measurement accuracy shall be ±1%. At the same time, it has a loading rate indicating device or a loading rate control device. The upper and lower platens are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com