Permeable alkali slag concrete suitable for heavy load pavements and preparation method thereof

A technology of concrete and alkali slag, which is applied in the field of building materials, can solve the problems of low compressive strength, peeling, cracked aggregates, etc., and achieve the effects of excellent long-term use performance, good peeling resistance and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

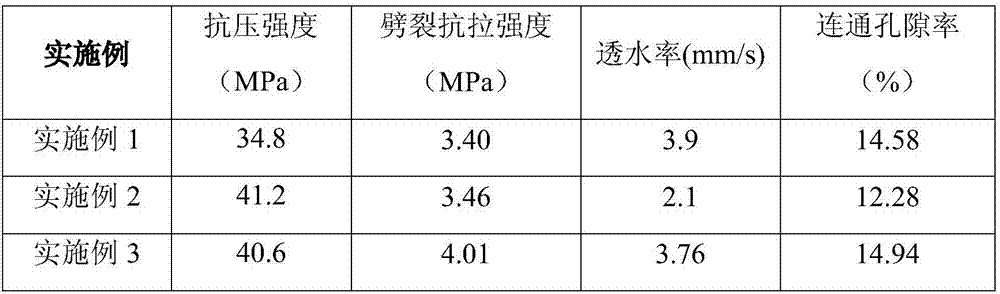

Examples

Embodiment 1

[0029] The amount of raw materials per cubic meter of permeable alkali slag concrete is: 1649kg of 5-10mm single-grained basalt gravel, 412kg of alkali slag, 91kg of water glass, and 78kg of water. The alkali slag cement is all composed of slag. When preparing permeable alkali slag concrete, first mix water glass and water evenly to obtain an activator solution, and after the solution is cooled to about 30°C, put all the gravel and 50% solution into the mixer and mix for 30 seconds to wet the aggregate surface , then add the slag to the mixer and mix for 60s, and finally pour the remaining 50% solution into the mixer and mix for 60s, then pour out the machine to form, demould after 24 hours of film curing, and perform strength and water permeability tests after 28 days of standard curing.

Embodiment 2

[0031] It is basically the same as in Example 1, except that 5% of the mass of the slag is replaced by silica fume, and the silica fume and the slag are stirred before preparing concrete to obtain a uniformly mixed powder.

Embodiment 3

[0033] It is basically the same as in Example 1, except that 0.1% of the mass of the slag is replaced by polypropylene fiber, and the polypropylene fiber and the slag are stirred before preparing concrete to obtain a uniformly mixed powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com