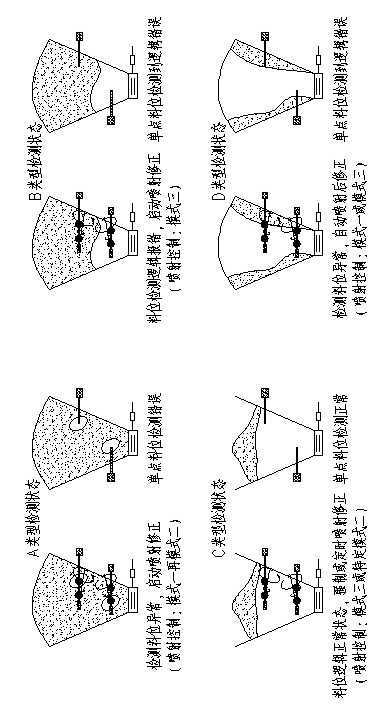

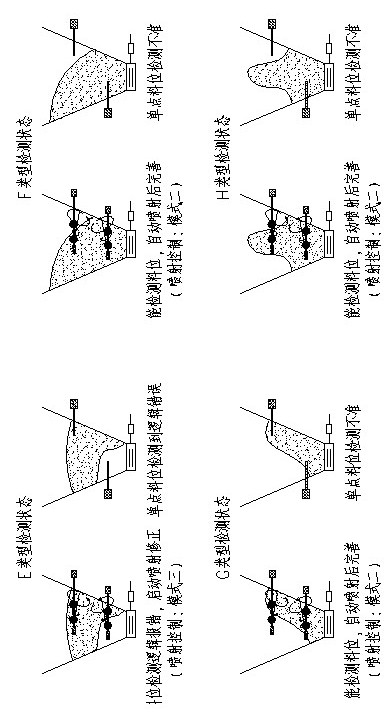

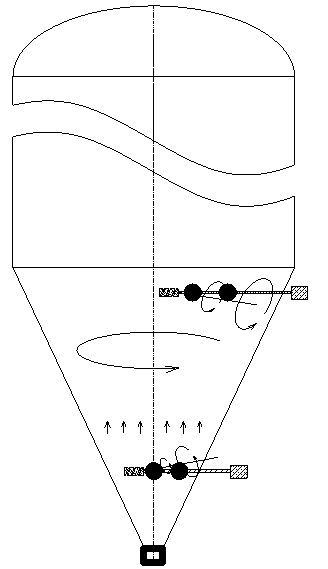

Rod, device and method for detecting dust position

A detection method and detection device technology, applied in the direction of measuring devices, chemical instruments and methods, separation methods, etc., can solve the problems of high energy consumption and operation cost, failure to achieve the expected effect well, limited effective distance, etc., and achieve extended Working life, the effect of improving the effect of long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described:

[0049] The radio frequency admittance level gauge continuously detects the three parameters of capacitance, resistance and inductance of the measured medium, and converts them into level signals through intelligent circuits. Radio frequency is high-frequency radio waves, so it can be understood as measuring admittance with high-frequency radio waves. The prerequisite for determining the dust level signal during work is that the detection probe of the radio frequency admittance level gauge touches the material and forms a radio frequency conduction path with the ground electrode (such as the wall of the metal ash tank). The greater the distance between the detection probe and the ground electrode, the greater the measured admittance change when the material changes. As far as the radio frequency admittance level gauge is concerned, it is a mature product....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com