Anti-condensation coating and preparation method thereof

An anti-condensation and coating technology, applied in the coating and other directions, can solve the problems of affecting the adhesion of the coating, difficult to condense, use, etc., to improve the long-term use effect, prevent the intrusion of external water, and solve potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of anti-condensation coating of the present invention specifically comprises the following steps:

[0036] Step 1: Add water into the container and stir, add bentonite;

[0037] Step 2: After the solution is uniform and thickened, add multifunctional additives, dispersants, defoamers and anti-mold and anti-algae agents and stir evenly;

[0038] Step 3: Slowly add titanium dioxide, mica powder, and heavy calcium to the mixture in step 2, and disperse to a high degree evenly;

[0039] Step 4: Add pure acrylic emulsion and silicone resin emulsion and mix well;

[0040] Step 5: Add insulation material and mix well;

[0041] Step 6: Add film-forming aids, antifreeze agents and waterproofing agents and stir evenly to obtain finished products.

[0042] The heat insulating material is prepared as follows: uniformly mixing microbeads and airgel slurry in proportion to obtain the heat insulating material.

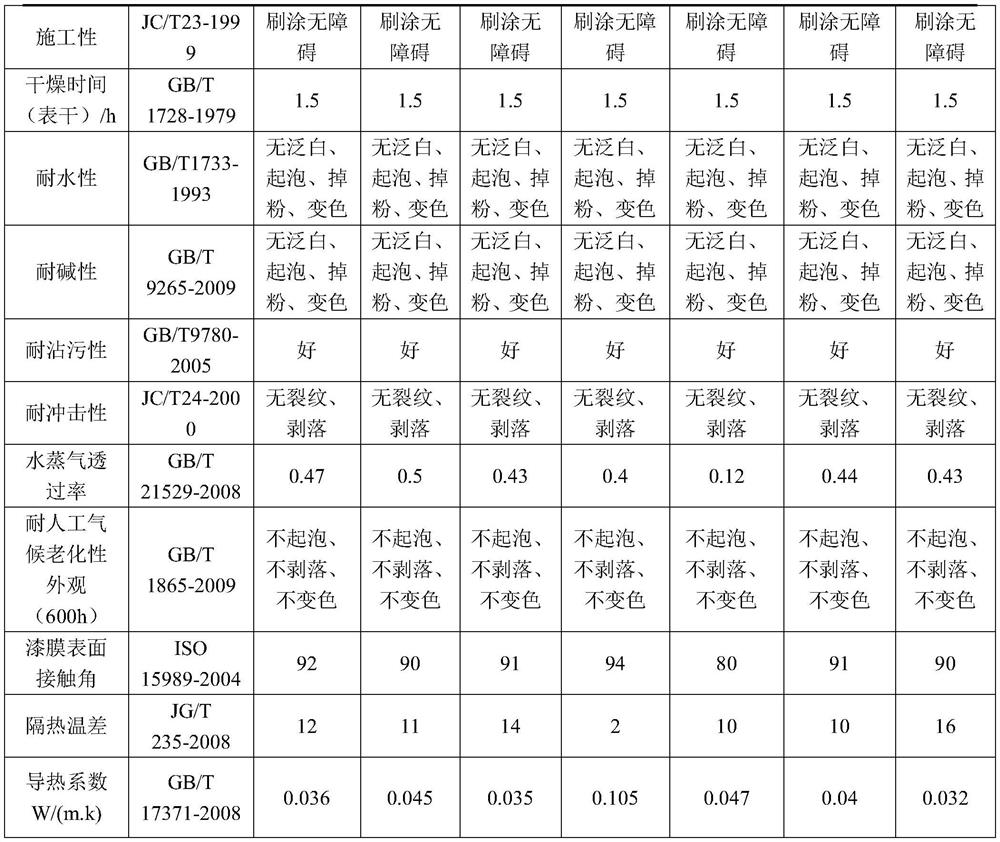

Embodiment 1

[0044] In parts by weight, the anti-condensation coating in this embodiment consists of the following components:

[0045] 37 parts of water, 0.4 parts of bentonite, 0.3 parts of multifunctional additives, 0.5 parts of dispersant, 0.5 parts of defoaming agent, 0.3 parts of anti-mold and anti-algae agent, 8 parts of titanium dioxide, 8 parts of hollow glass microspheres, 2 parts of floating beads , 5 parts of airgel slurry, 3 parts of mica powder, 6 parts of heavy calcium, 16 parts of pure acrylic emulsion, 8 parts of silicone resin emulsion, 1 part of film-forming aid, 1 part of antifreeze, and 5 parts of waterproofing agent.

Embodiment 2

[0047] In parts by weight, the anti-condensation coating in this embodiment consists of the following components:

[0048] 30.3 parts of water, 0.4 parts of bentonite, 0.2 parts of multifunctional additives, 0.4 parts of dispersant, 0.4 parts of defoaming agent, 0.3 parts of anti-mold and anti-algae agent, 8 parts of titanium dioxide, 14 parts of hollow glass microspheres, airgel slurry 3 parts of material, 3 parts of mica powder, 7 parts of heavy calcium, 18 parts of pure acrylic emulsion, 9 parts of silicone resin emulsion, 1.5 parts of film-forming aid, 1.5 parts of antifreeze, and 3 parts of waterproofing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com