Nano modified Portland cement base facing mortar and preparation method thereof

A facing mortar and nano-modification technology, which is applied in the field of building materials, can solve the problems of uneven distribution of white matter and affect the decorative effect, and achieve simple and convenient preparation process and application method, good long-term performance and long operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: A nano-modified Portland cement-based finishing mortar, its components and ratio (mass percentage) are: cement: 12%, slag powder: 6%, metakaolin: 2%, nano-SiO 2 : 0.2%, heavy calcium powder: 12%, 40-70 mesh quartz sand: 41.9%, 70-100 mesh quartz sand: 23%, latex powder: 2.2%, cellulose ether: 0.08%, water repellent: 0.2% , starch ether: 0.02%, iron oxide red: 0.4%.

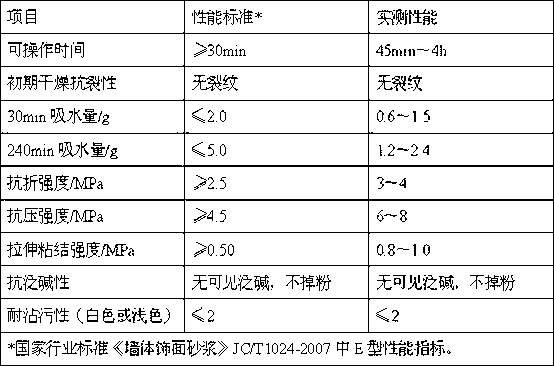

[0034] Table 2 Example-1 Performance Index of Nano-modified Portland Cement-based Finishing Mortar

[0035] project Measured performance Operational time 150min Initial drying crack resistance no crack 30min water absorption / g 0.7 240min water absorption / g 1.2 Flexural strength / MPa 3.2 Compressive strength / MPa 7.5 Tensile bond strength / MPa 0.8 Anti-pantothenic No visible efflorescence, no powder shedding Stain resistance (white or light) 2

Embodiment 2

[0036] Example 2: A nano-modified Portland cement-based finishing mortar, its components and proportions (mass percentage) are: cement: 15%, slag powder: 4%, metakaolin: 1%, nano-SiO 2 : 0.4%, heavy calcium powder: 10%, 40-70 mesh quartz sand: 38%, 70-100 mesh quartz sand: 28.58%, latex powder: 2%, cellulose ether: 0.1%, water repellent: 0.2% , starch ether: 0.02%, wood fiber: 0.1%, iron oxide black: 0.6%.

[0037] Table 3 Example-2 Performance Index of Nano-modified Portland Cement-based Finishing Mortar

[0038] project Measured performance Operational time 180min Initial drying crack resistance no crack 30min water absorption / g 1.5 240min water absorption / g 2.4 Flexural strength / MPa 3.5 Compressive strength / MPa 7.5 Tensile bond strength / MPa 0.7 Anti-pantothenic No visible efflorescence, no powder shedding Stain resistance (white or light) 1

Embodiment 3

[0039] Example 3: A nano-modified Portland cement-based finishing mortar, its components and ratio (mass percentage) are: cement: 16%, slag powder: 3%, metakaolin: 1%, nano-SiO 2 : 0.4%, heavy calcium powder: 11%, 40-70 mesh quartz sand: 37%, 70-100 mesh quartz sand: 28.48%, latex powder: 1.8%, cellulose ether: 0.1%, water repellent: 0.2% , starch ether: 0.02%, wood fiber: 0.2%, iron oxide yellow: 0.8%.

[0040] Table 4 Example-3 Performance Index of Nano-modified Portland Cement-based Finishing Mortar

[0041] project Measured performance Operational time 160min Initial drying crack resistance no crack 30min water absorption / g 0.9 240min water absorption / g 1.5 Flexural strength / MPa 3 Compressive strength / MPa 7 Tensile bond strength / MPa 0.9 Anti-pantothenic No visible efflorescence, no powder shedding Stain resistance (white or light) 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com