Flexible bionic active pigment printing formaldehyde-free bonding agent and preparation method and application thereof

A pigment printing and imitation reactive technology, applied in the direction of dyeing, textile and papermaking, can solve the problems of easy sticking rollers, stiff hand feeling of printed fabrics, poor color fastness, etc., and achieve good adhesion, soft hand feeling and fastness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

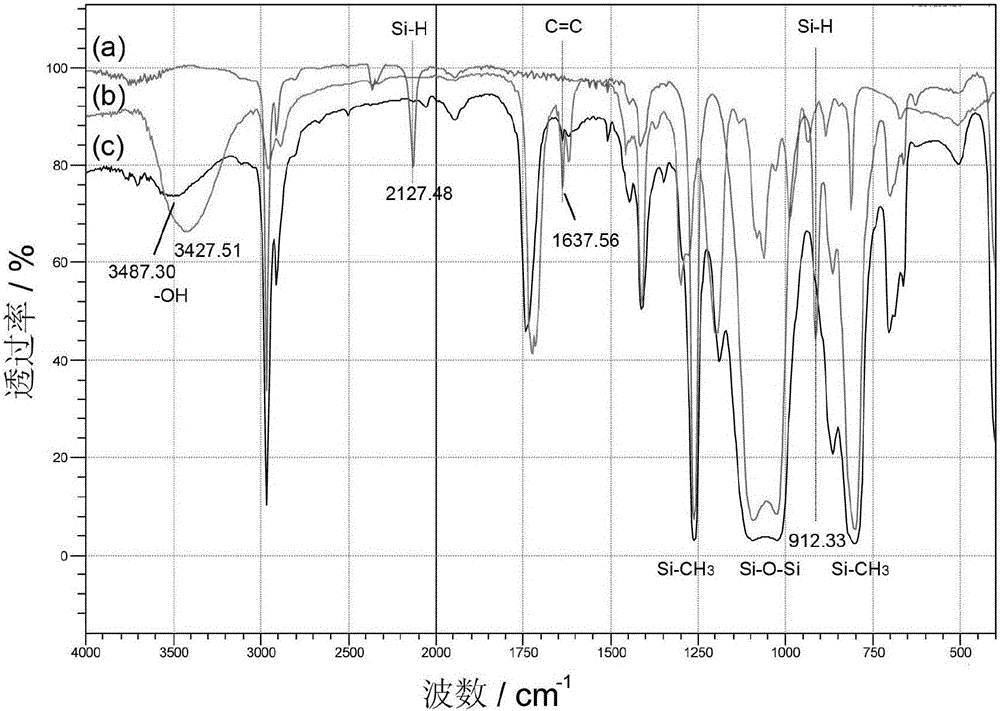

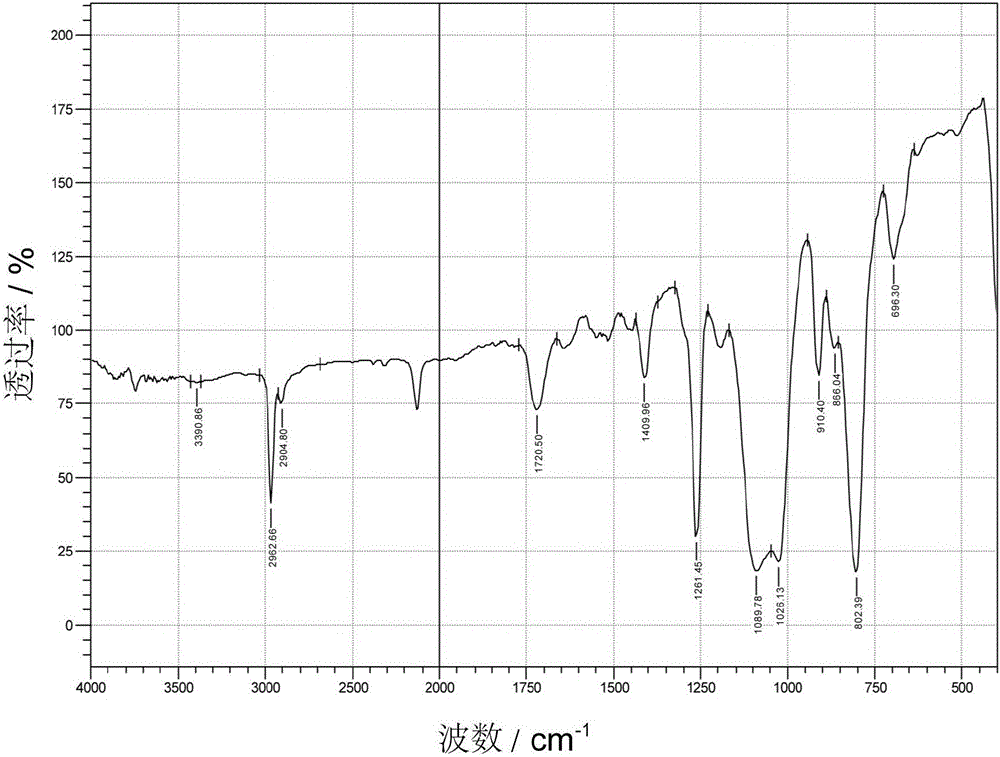

[0075] In a 500mL three-necked flask with a thermometer, stirrer and condenser, 100g of hydrogen-containing polysiloxane, 11.6g of hydroxyethyl acrylate (C=C:Si-H molar ratio 1.0:1.0), 111.6g of toluene ( 100% of the total weight of reaction raw materials), 0.58g hydroquinone (0.05% of hydroxyethyl acrylate), through N 2 Replace it three times, gradually increase the temperature to 90°C, and add 11.2 g of 1 wt% chloroplatinic acid-ethanol solution (378 ppm) as a catalyst. The system heats up rapidly. After the system temperature stabilizes, the temperature is gradually increased to 95°C for 3 hours. After the reaction, the temperature is lowered to room temperature. The unreacted hydroxyethyl acrylate is removed by washing with water three times. , Removal of toluene under reduced pressure under -0.090MPa vacuum. It was cooled to room temperature and filtered to obtain acyloxy-terminated hydroxyethyl polysiloxane. The infrared spectra of hydrogen-terminated polysiloxane, hydro...

Embodiment 2

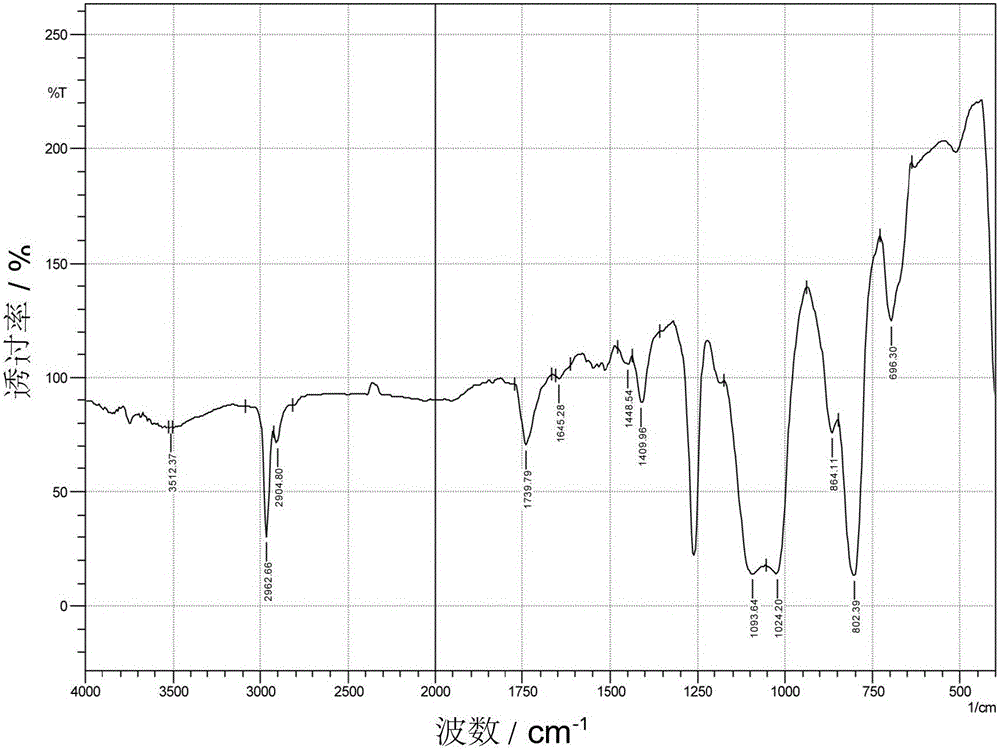

[0077] Into a 250mL three-necked flask with a thermometer, agitator and condenser, 100g of hydrogen-containing polysiloxane, 26.0g of hydroxypropyl acrylate (C=C:Si-H molar ratio 2.0:1.0), 0.26g of p-benzene Diphenol (1% of hydroxypropyl acrylate), pass N 2 Replace three times, gradually increase the temperature to 90°C, and add 33.46 g of 1 wt% chloroplatinic acid-isopropanol solution (1000 ppm). The system heats up rapidly, and after the system temperature is stable, the temperature is gradually raised to 100°C for 3 hours. After the reaction is over, the temperature is lowered to room temperature, and the excess hydroxypropyl acrylate is removed by washing with water three times. After the water is separated, an appropriate amount of toluene is added to increase the temperature to remove water. Then the temperature was raised to 100°C, and the toluene was removed under reduced pressure under a vacuum of -0.090MPa. It was cooled to room temperature and filtered to obtain acy...

Embodiment 3

[0079] Into a 250mL three-necked flask with a thermometer, agitator and condenser, 50g of hydrogen-containing polysiloxane, 12.8g of hydroxyethyl acrylate (C=C:Si-H molar ratio 1.1:1.0), 50g of toluene (reaction 79.6% of the total weight of raw materials), 0.2g 2-tert-butyl hydroquinone (1.56% of hydroxyethyl acrylate), through N 2 Replace it three times, gradually increase the temperature to 90°C, and add 0.01g platinum dioxide (137ppm) as a catalyst. The system heats up rapidly, and after the system temperature is stable, the temperature is gradually raised to 95°C for 5 hours. After the reaction, the temperature was lowered to room temperature, and the excess hydroxyethyl acrylate was removed by washing with water three times. Then the temperature was raised to 100°C, and the toluene was removed under reduced pressure under a vacuum of -0.090MPa. It was cooled to room temperature and filtered to obtain pendant acyloxy hydroxyethyl polysiloxane. The infrared spectrum of pen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com