Patents

Literature

54results about How to "Less regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

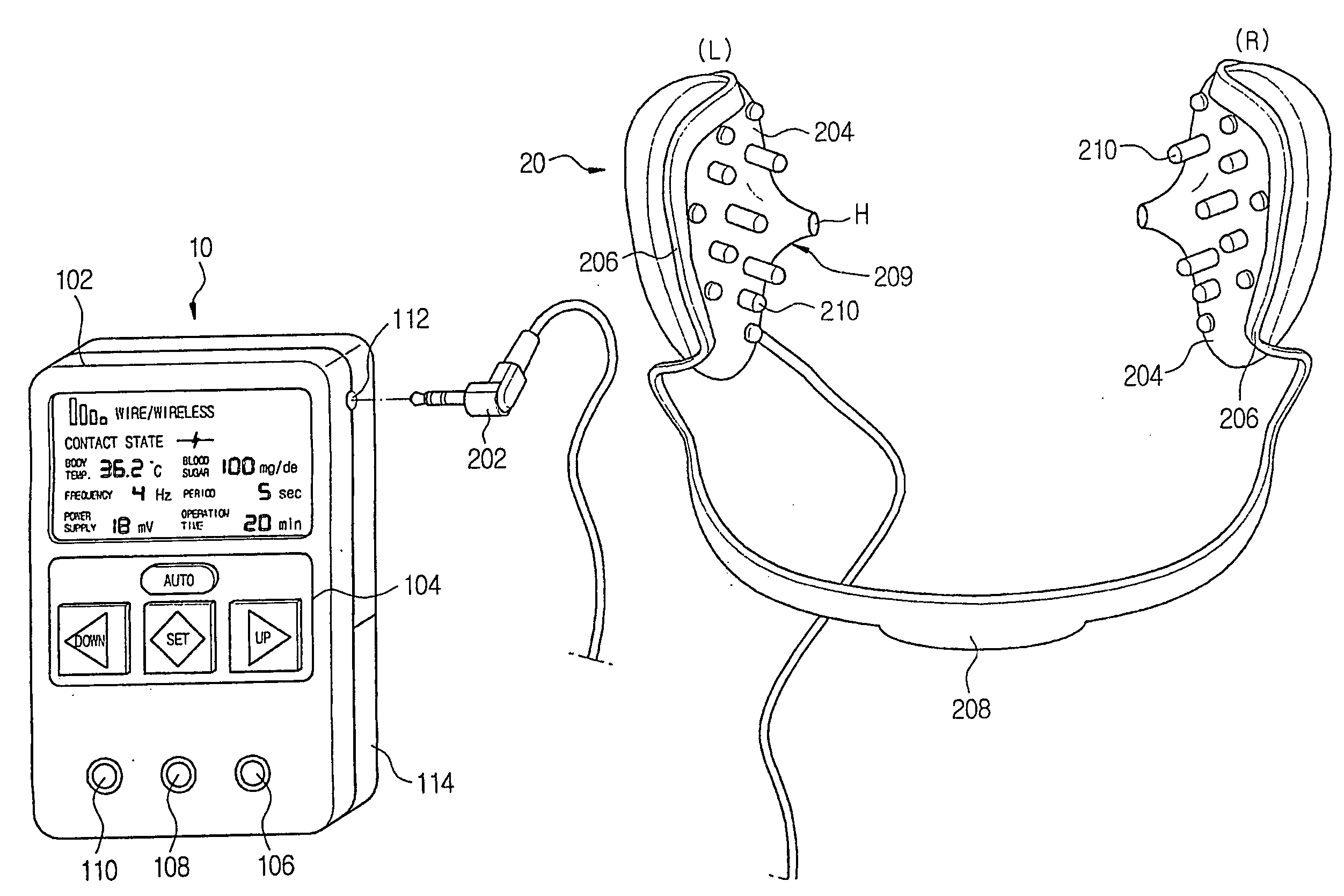

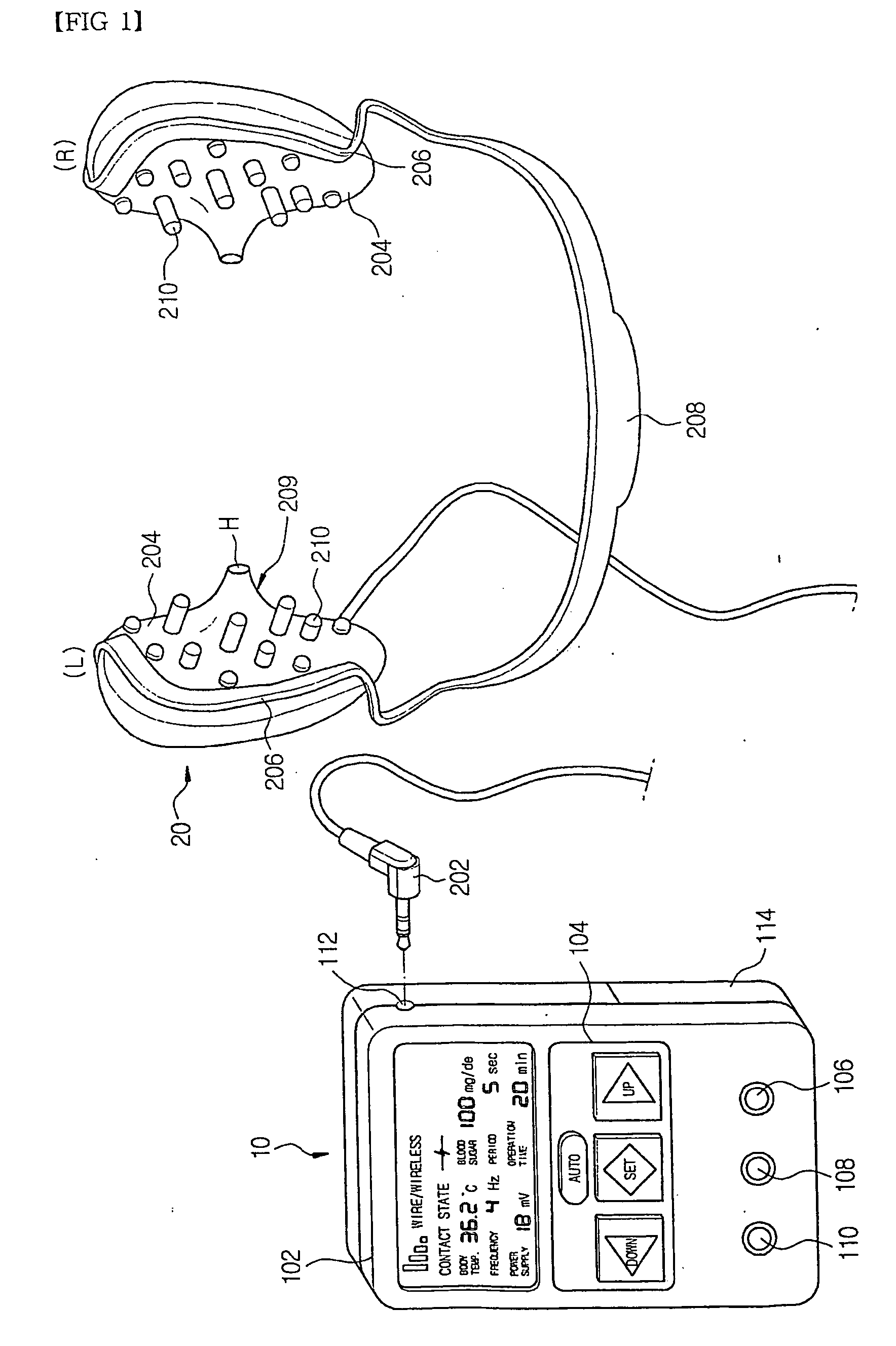

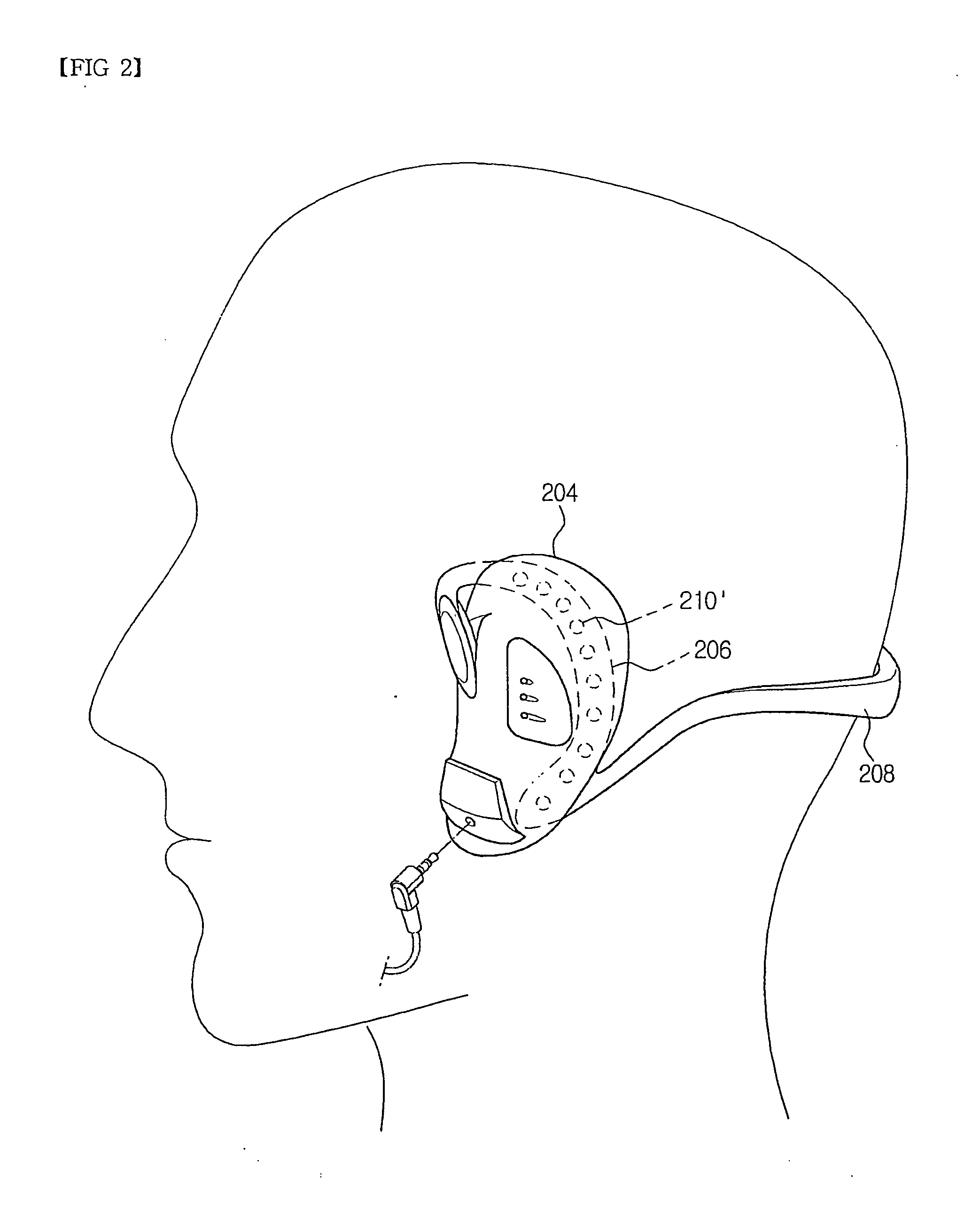

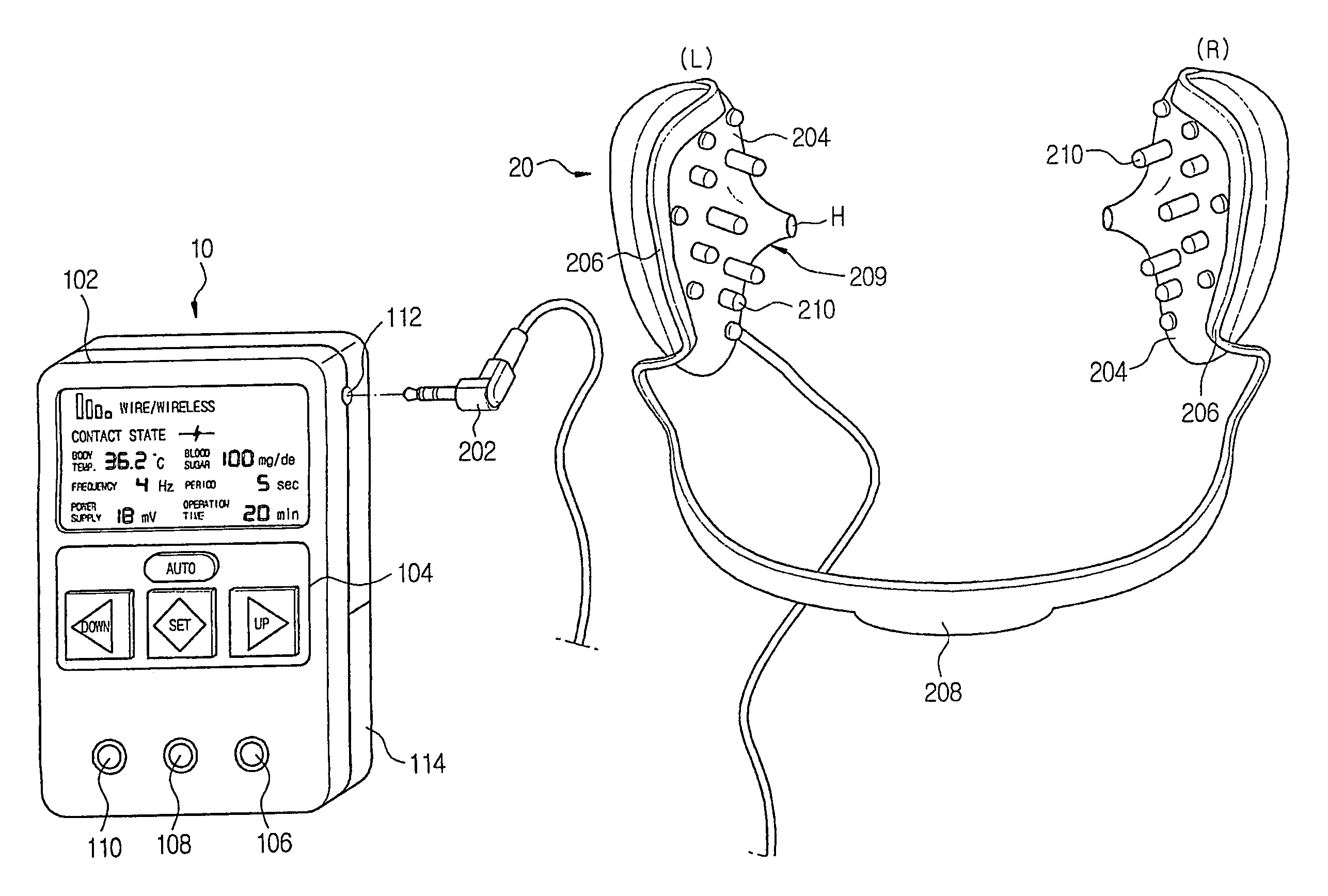

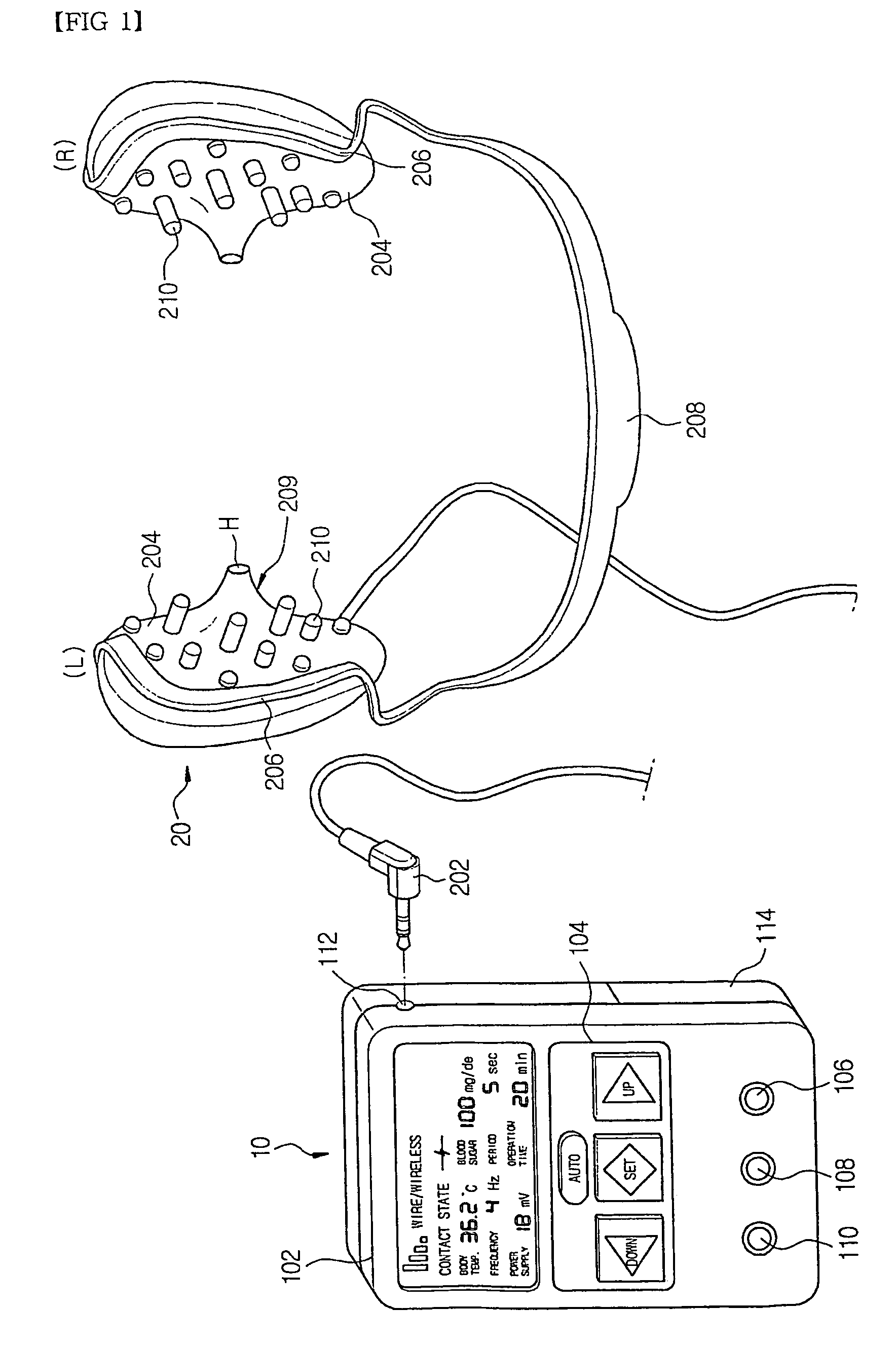

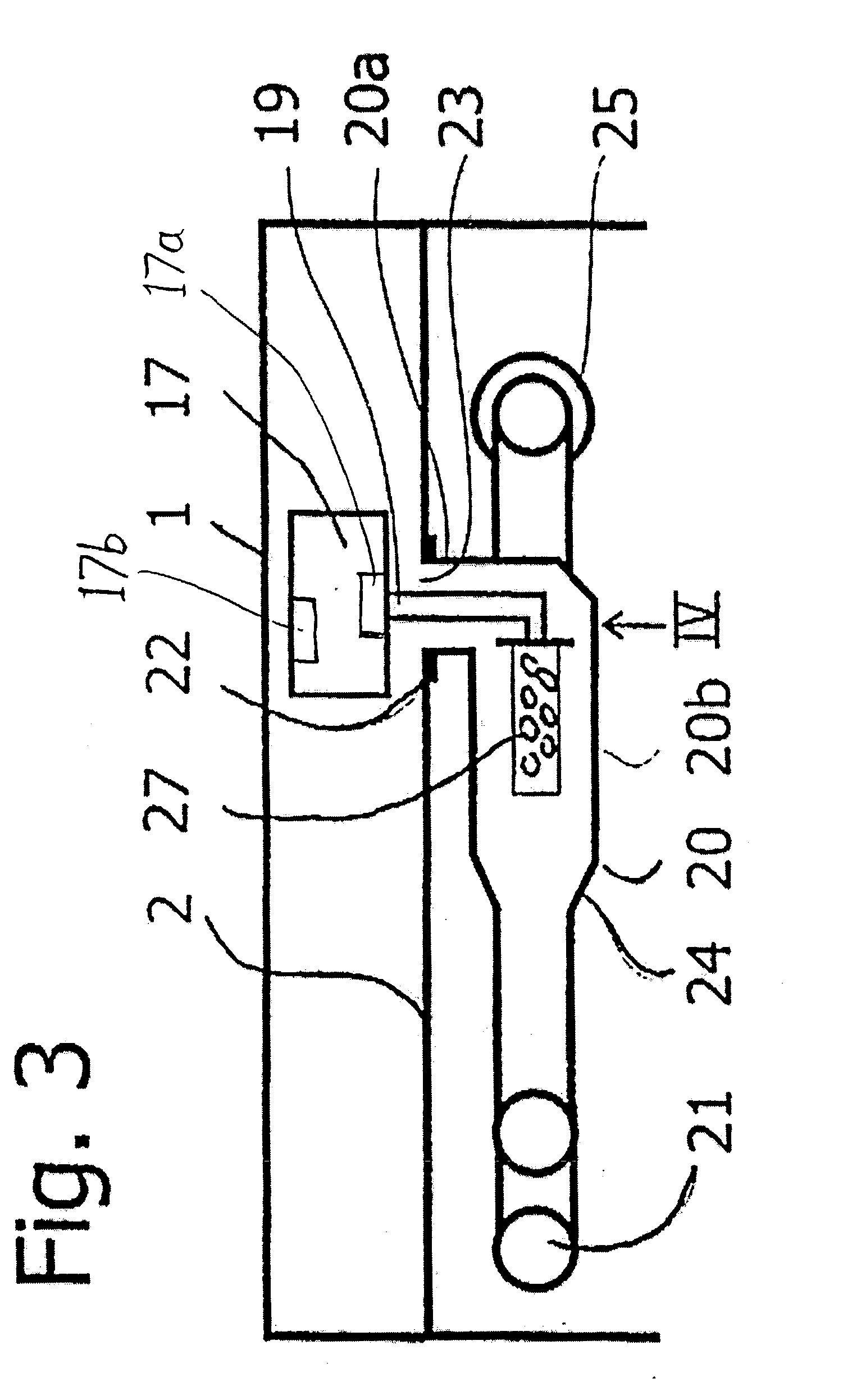

Electric stimilator for alpha-wave derivation

InactiveUS20060064139A1Efficient implementationMaximize the effect of treatmentInternal electrodesMedical devicesHuman bodyDisease

An electric stimulator for alpha-wave derivation is characterized in that frequency selected from a range of 1 Hz to 50 Hz, preferably, 7 Hz to 14 Hz, and an output voltage are applied to auricle of a patient's ears to derive alpha-waves, and that cycle and intensity of stimulation are varied depending upon body temperature and blood sugar. Prompt reaction may be obtained by directly applying the voltage to the ears, and the reaction may continue when stimulation is extended. In addition, it is suitable to treat various diseases having common cause due to stress or arousal reaction in the human body.

Owner:CHUNG JONG PIL

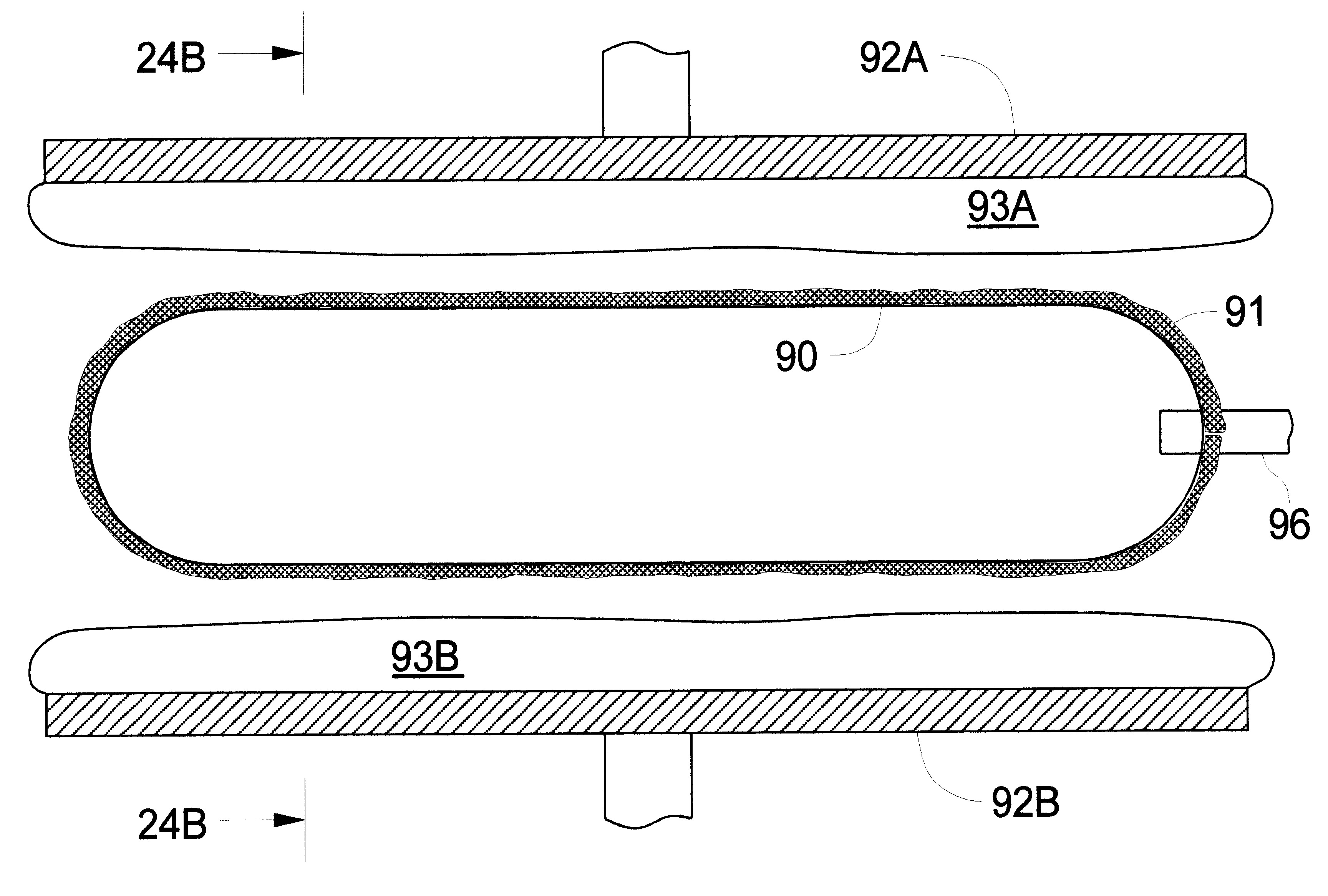

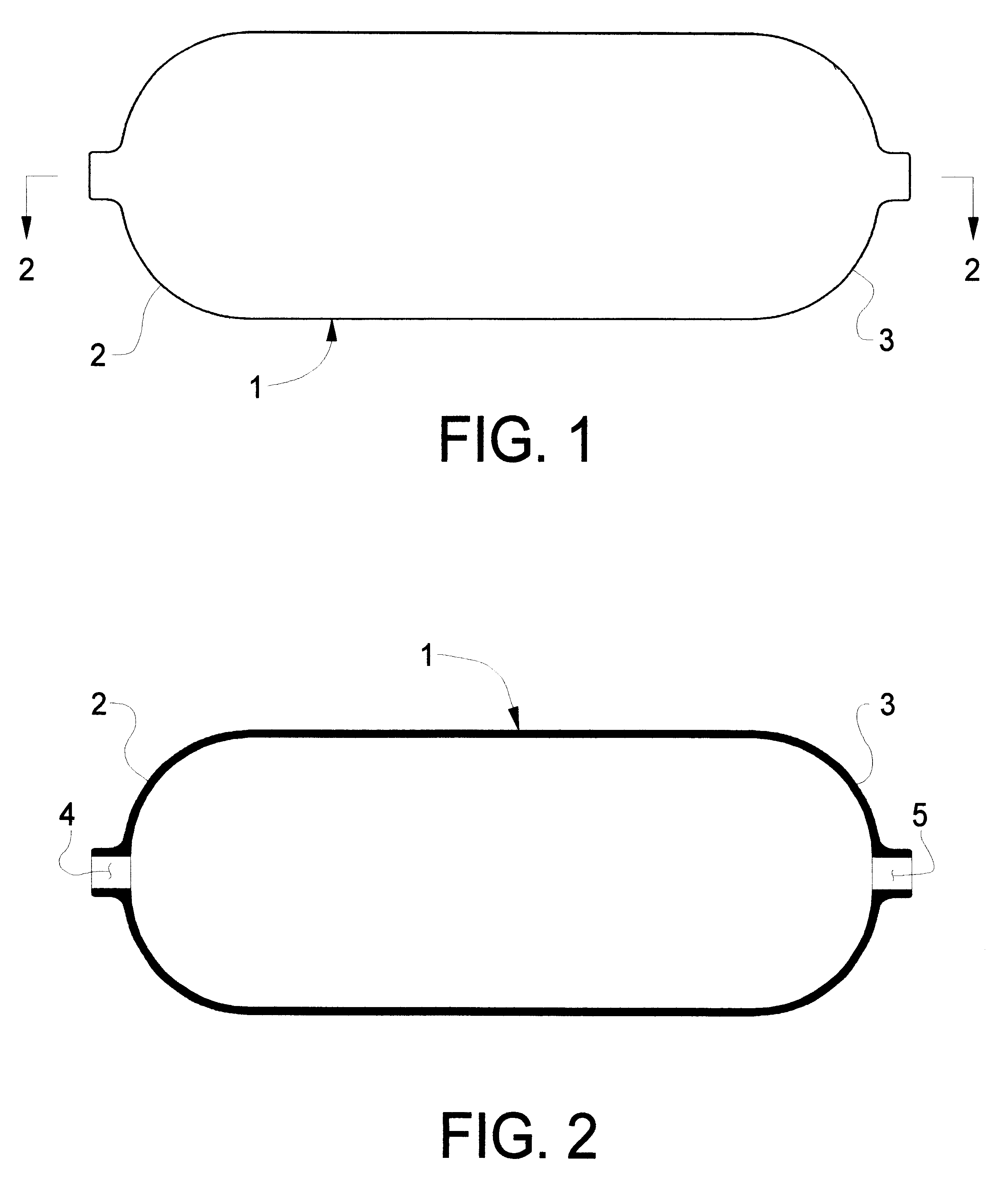

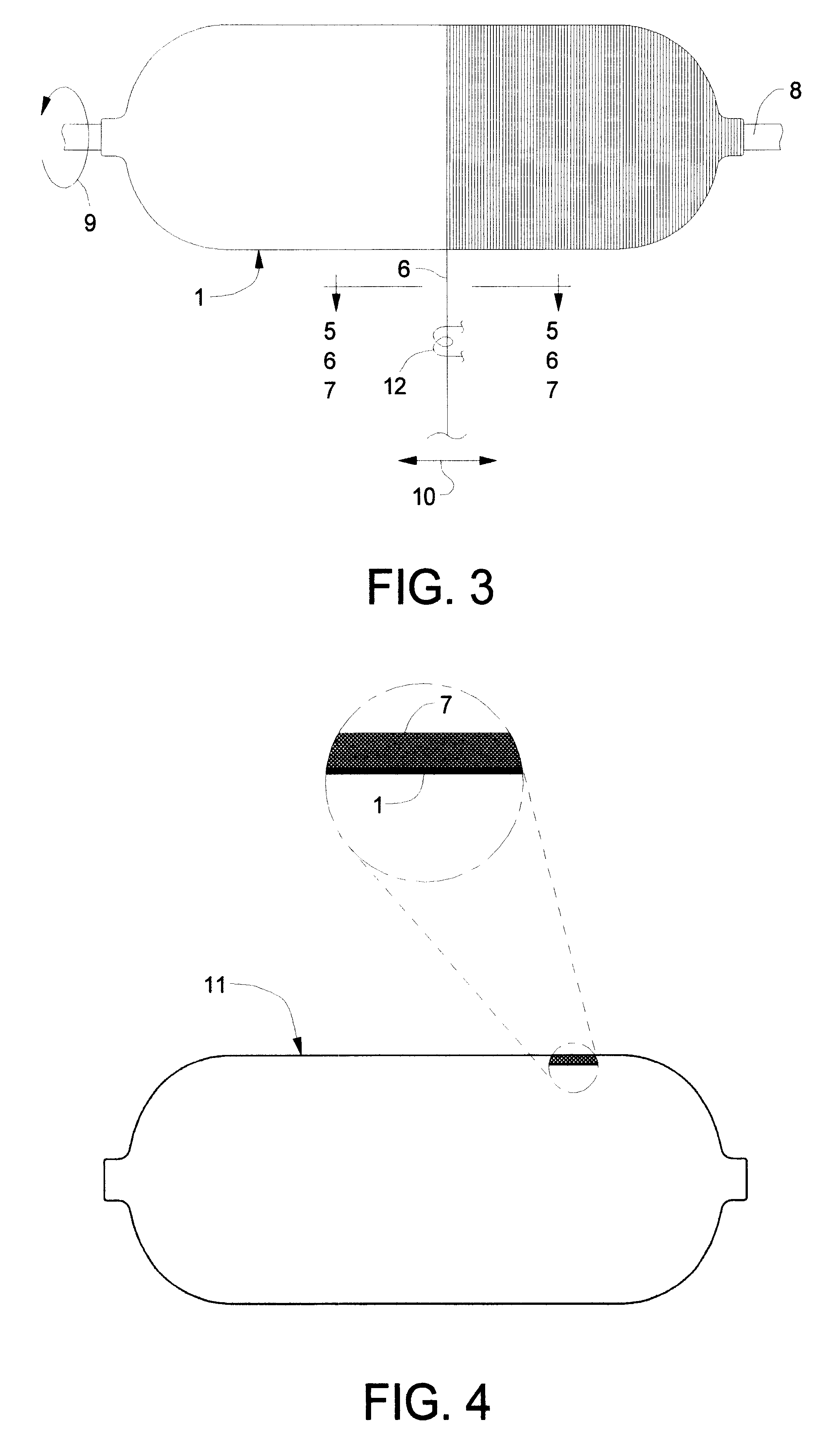

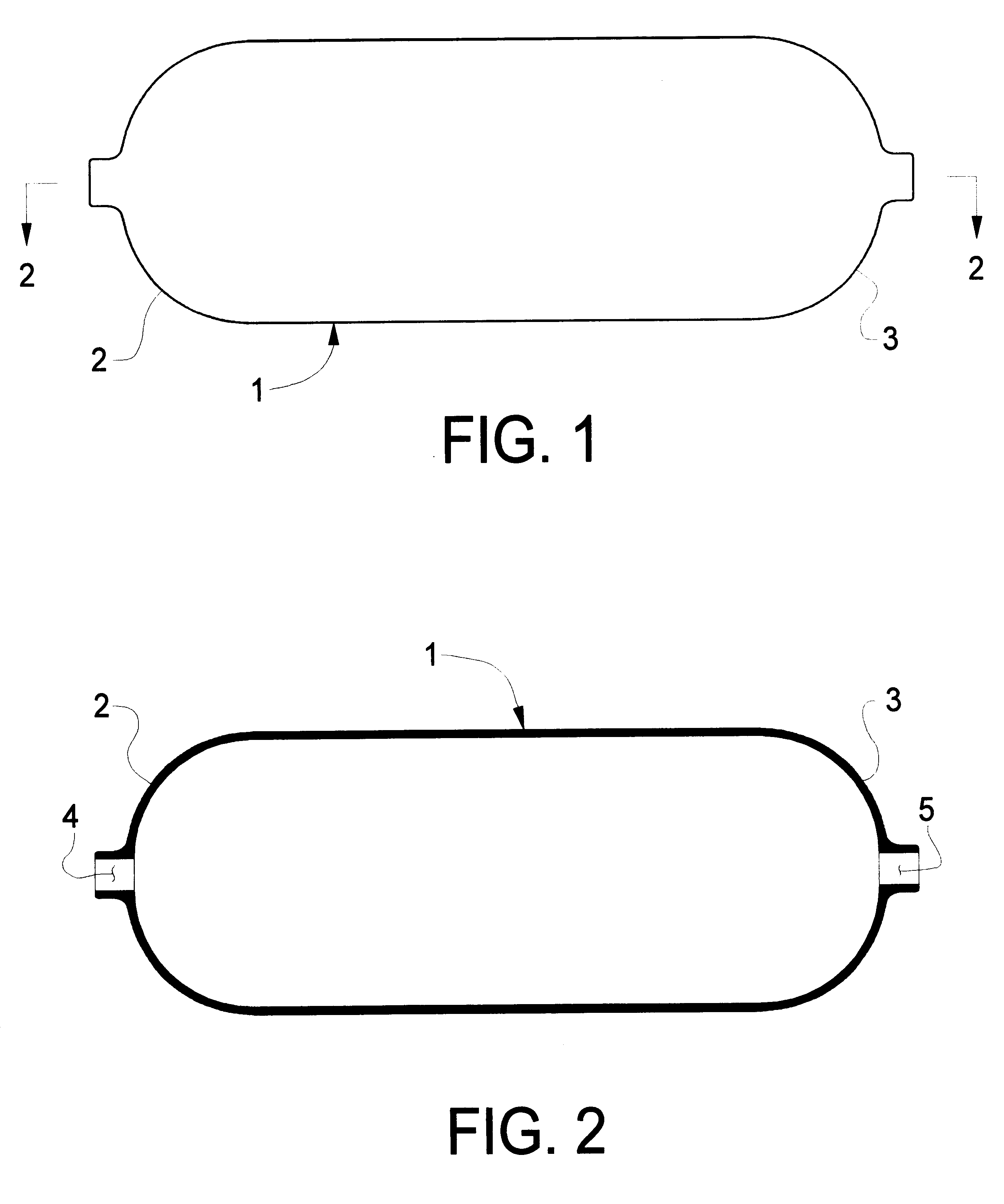

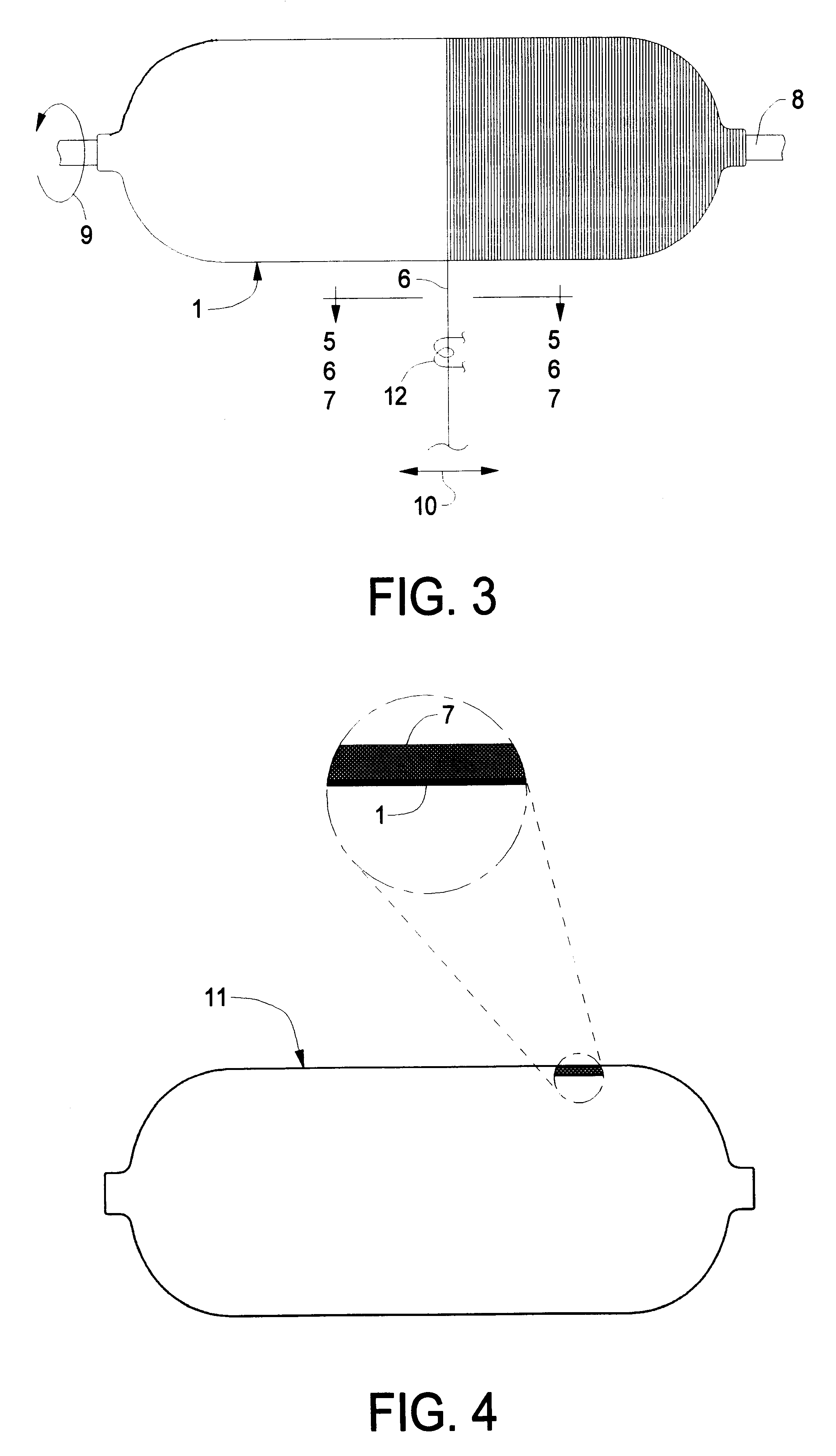

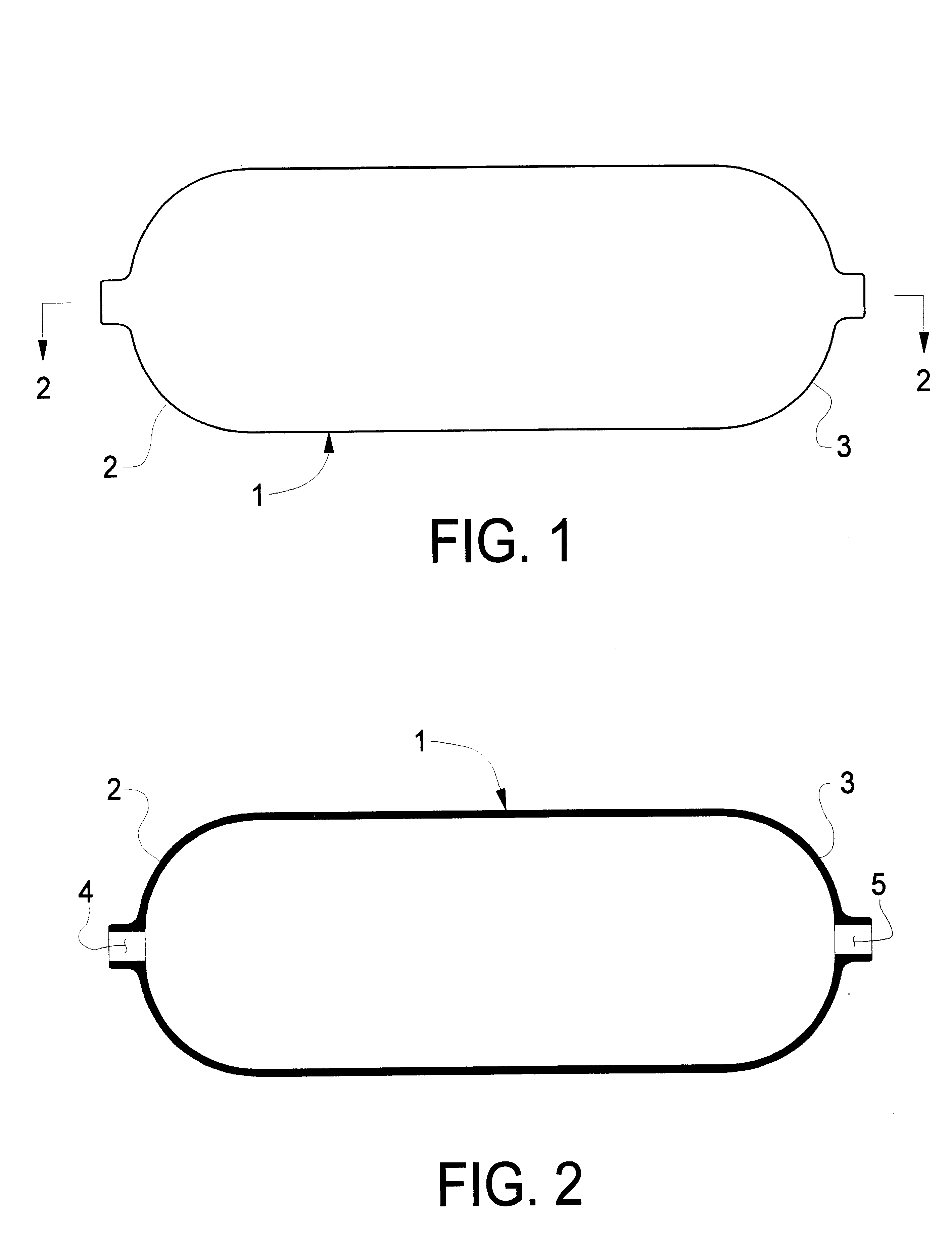

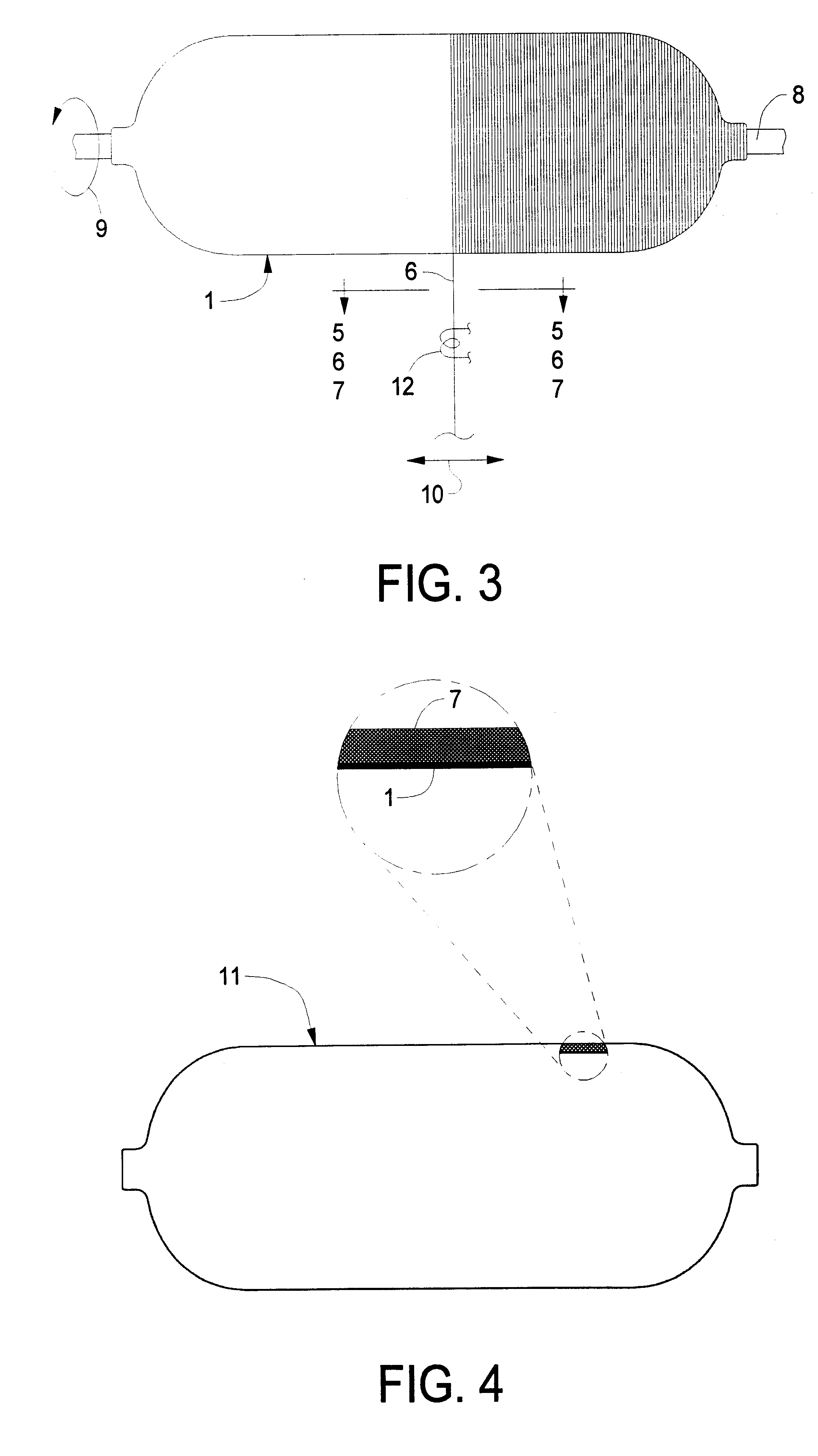

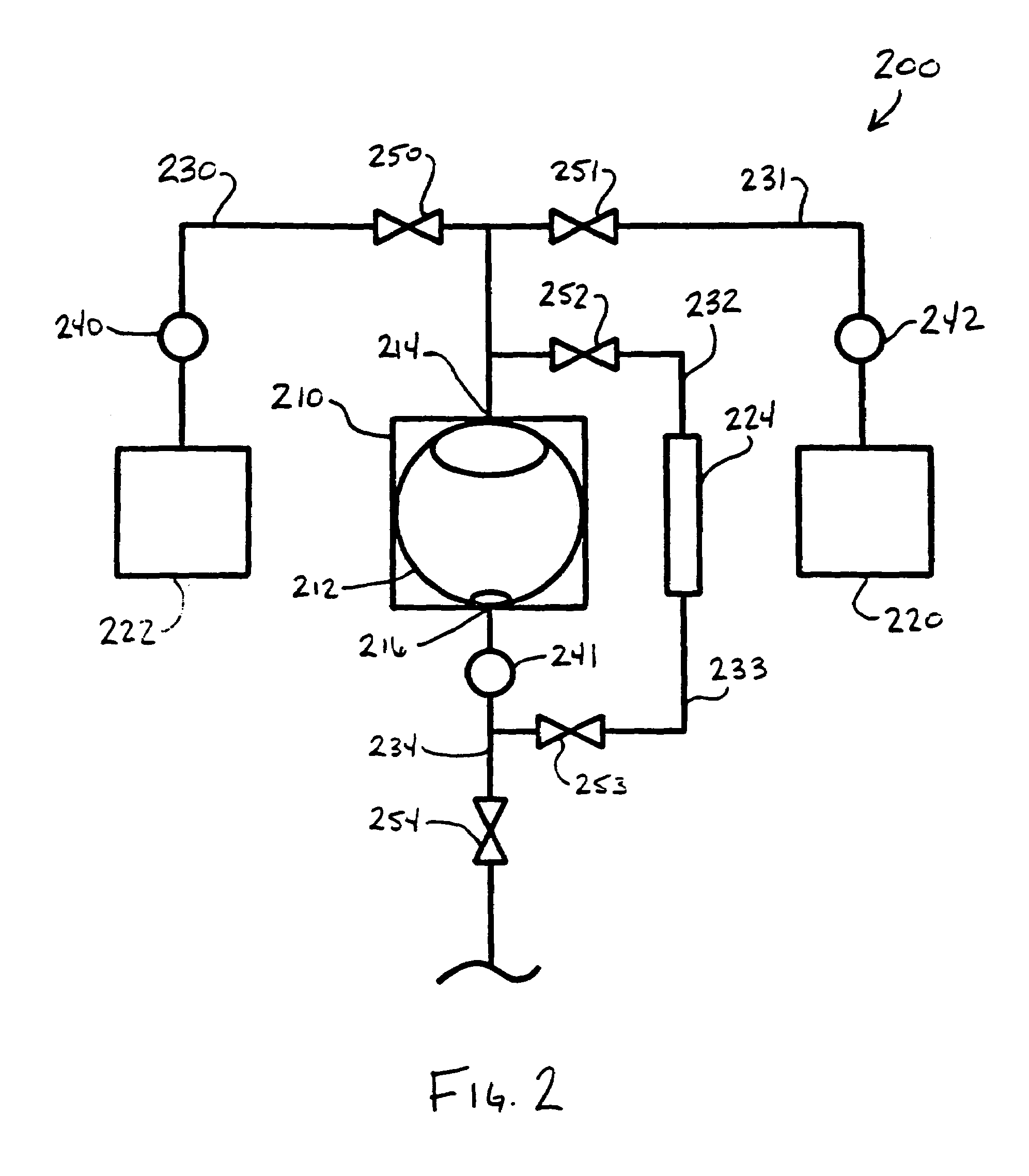

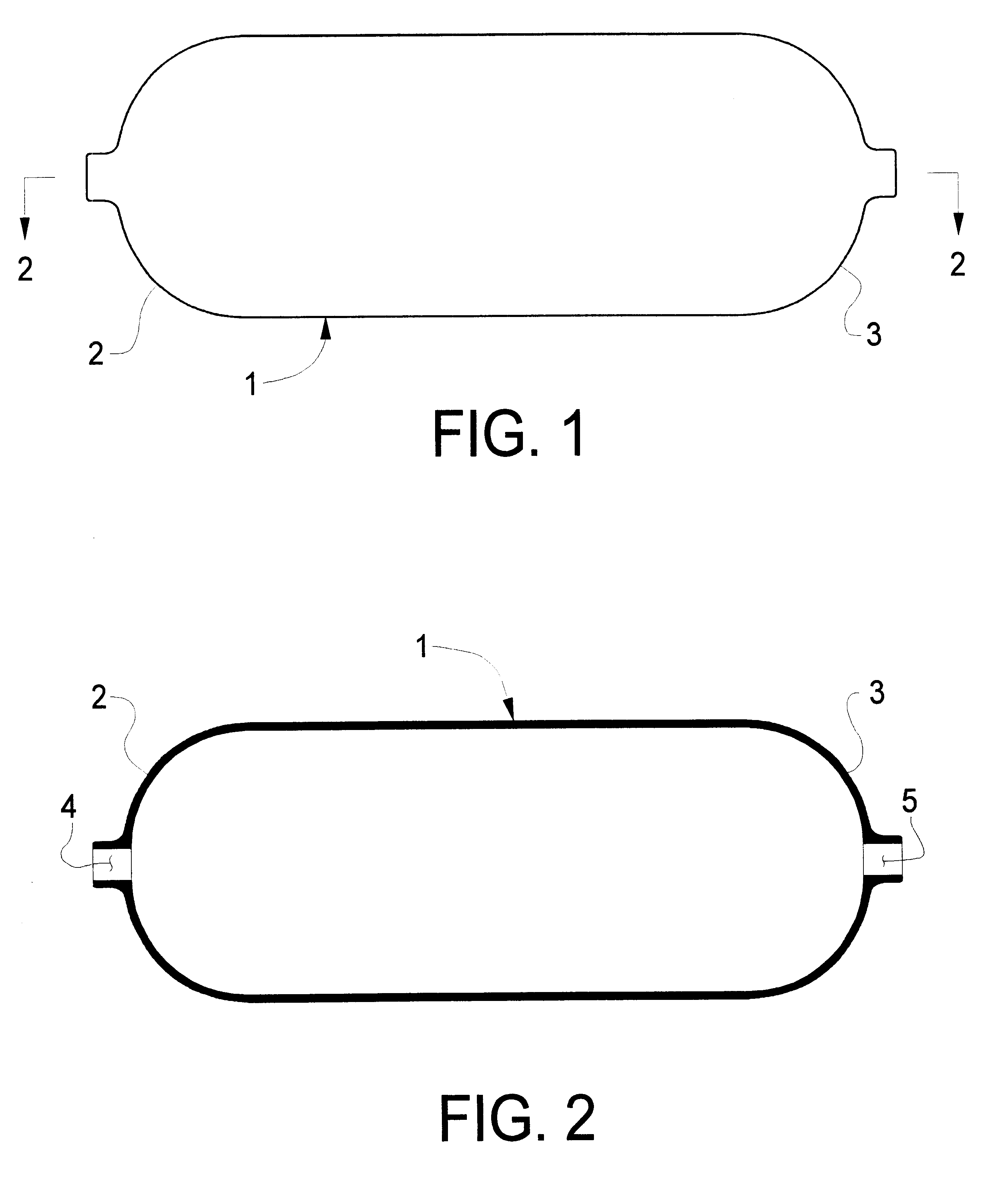

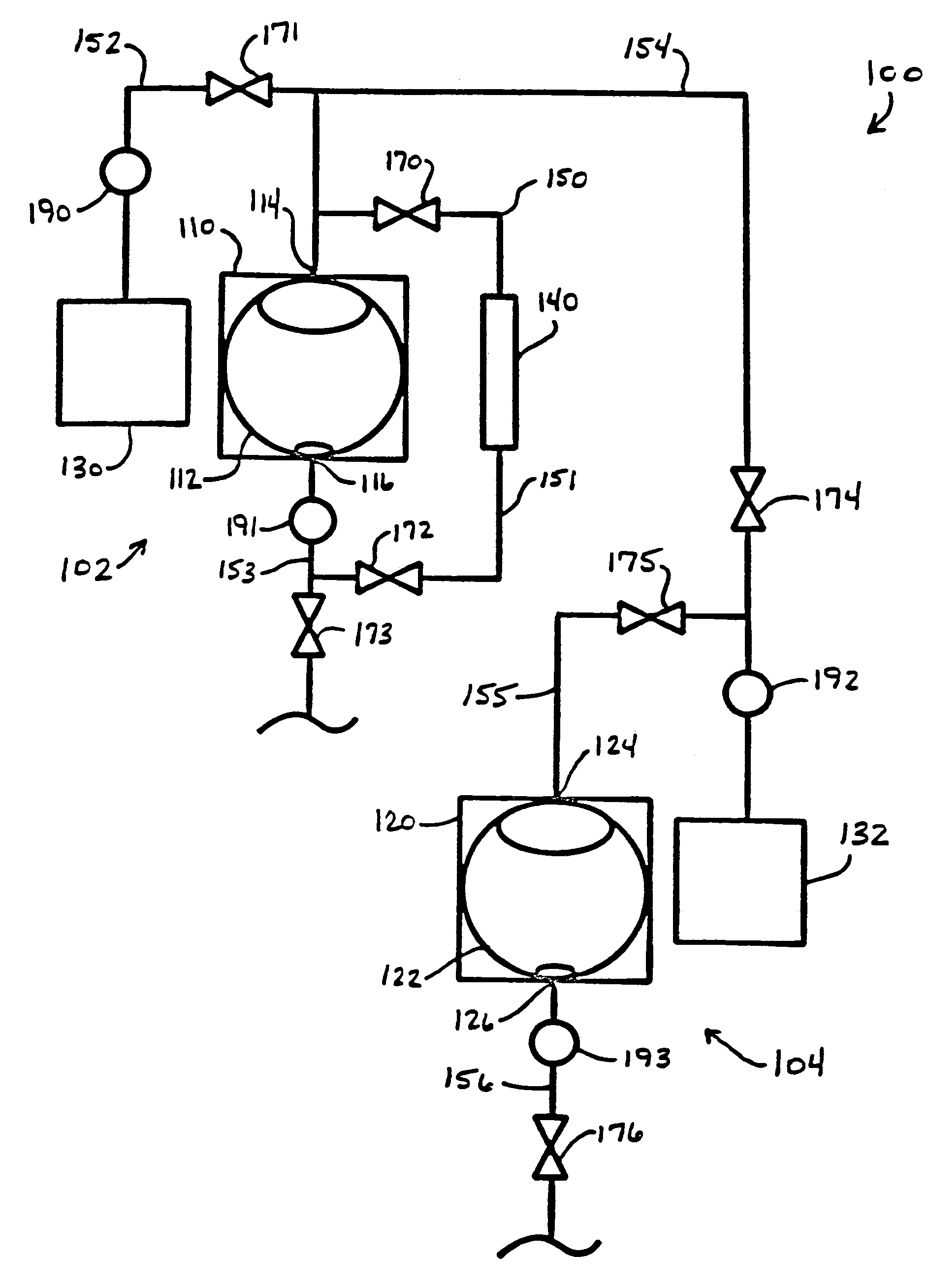

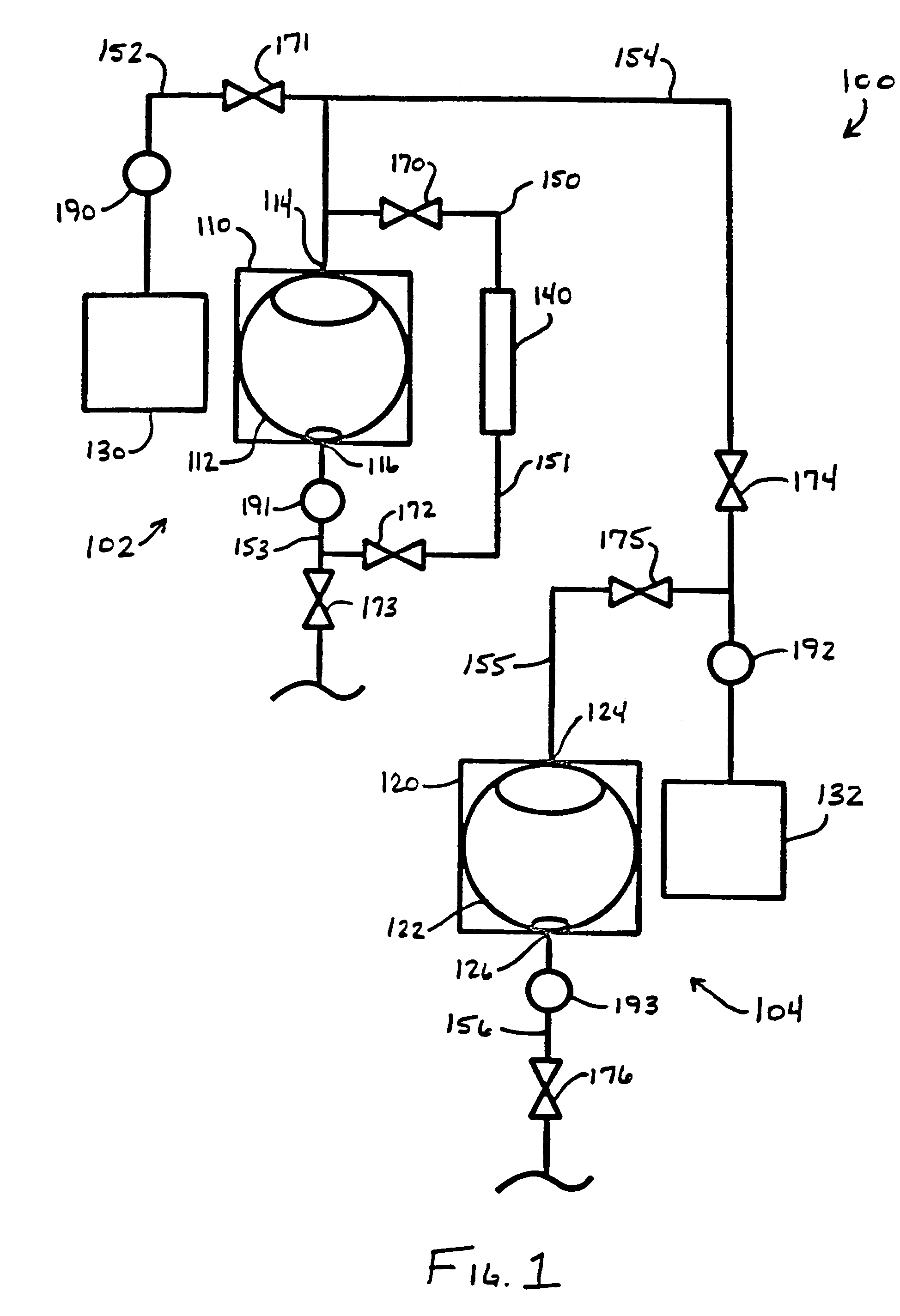

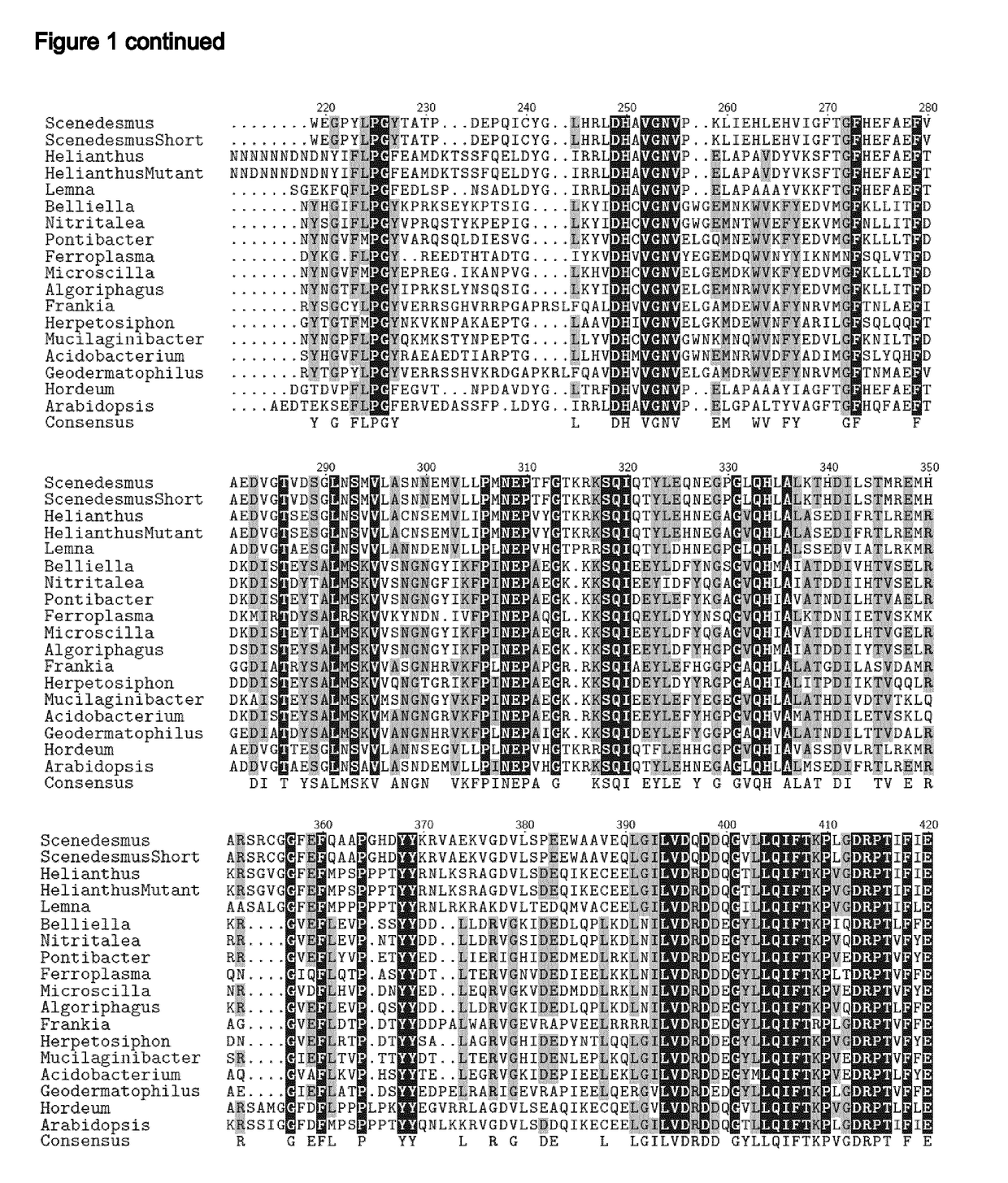

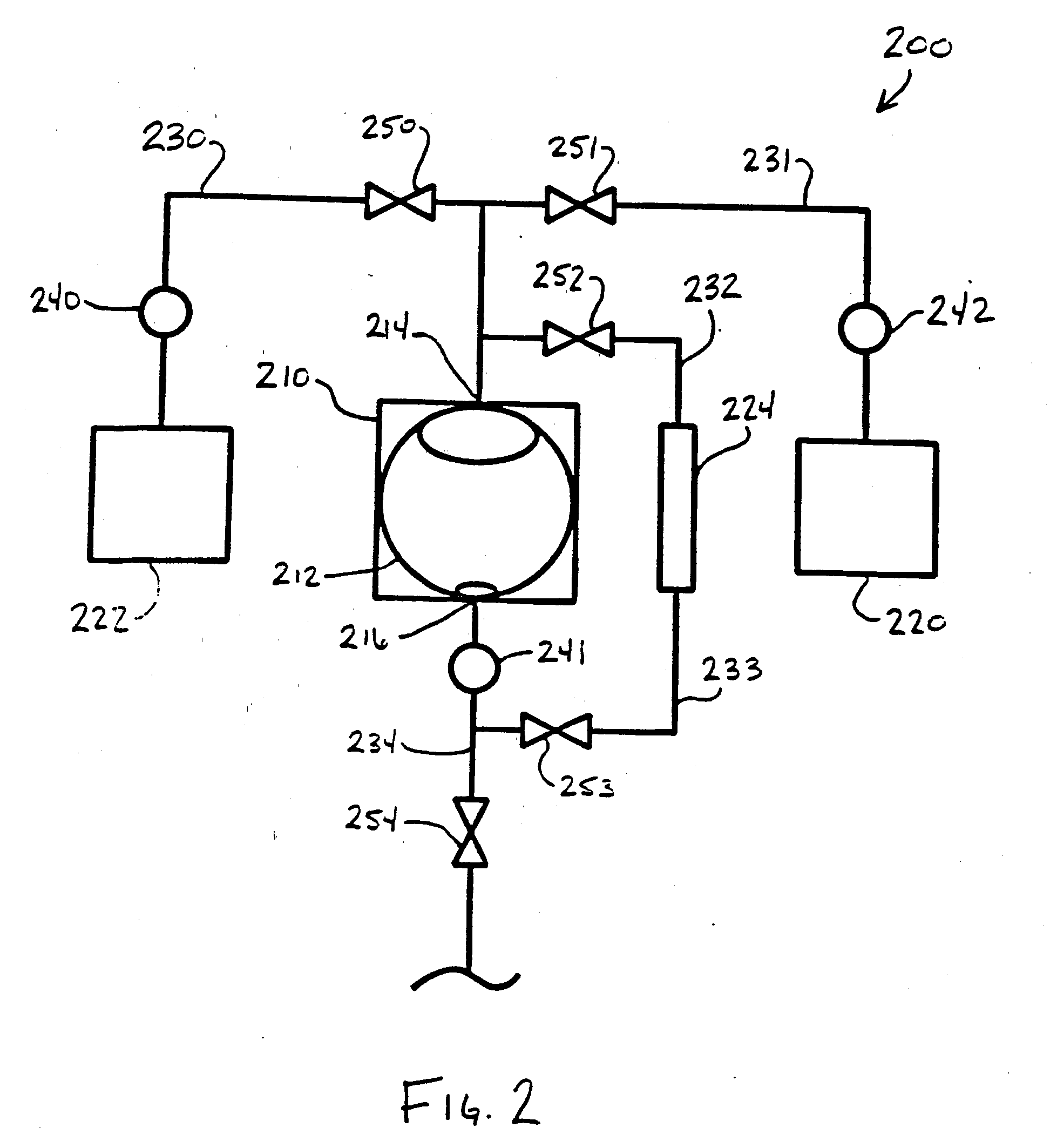

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

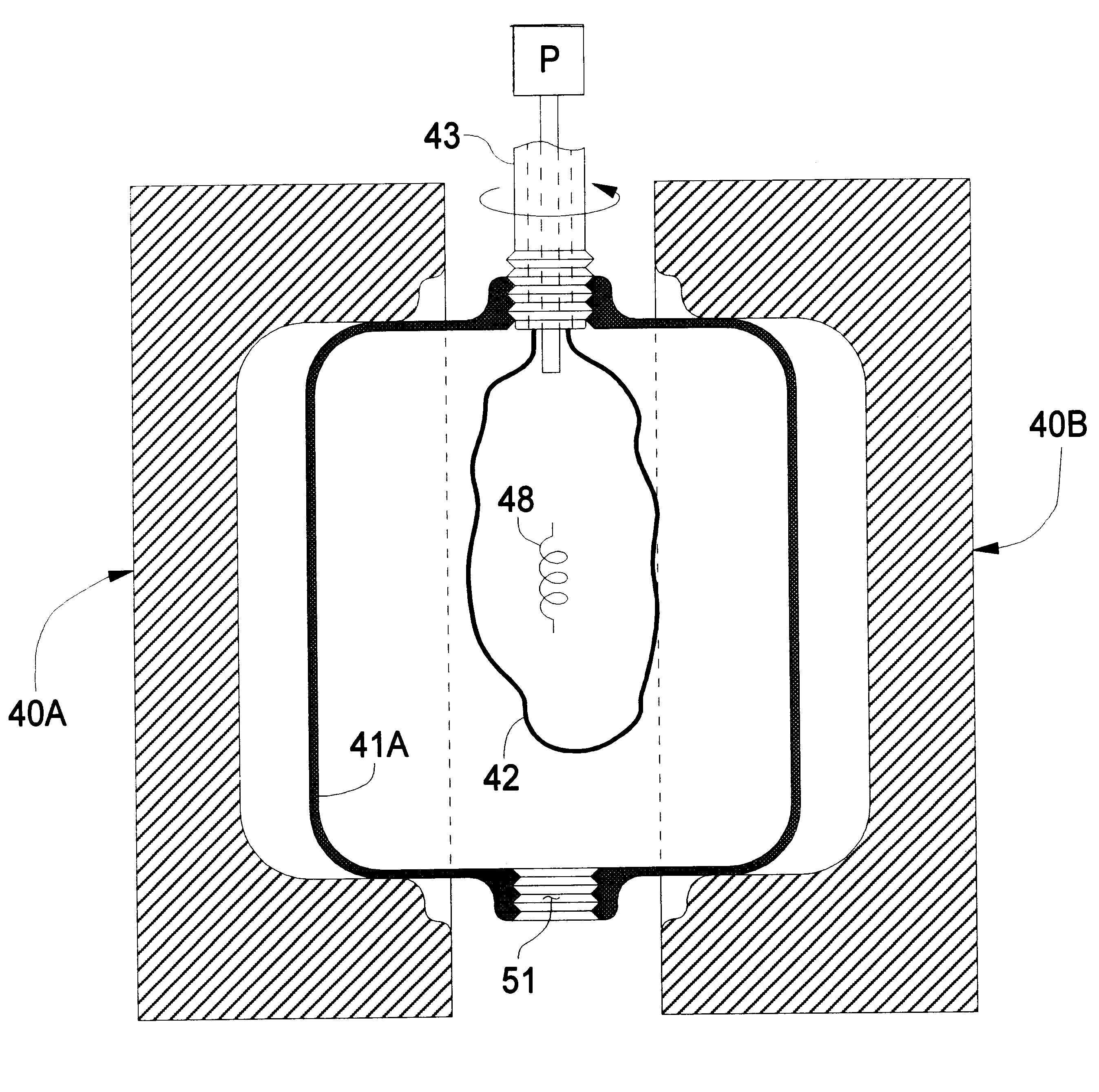

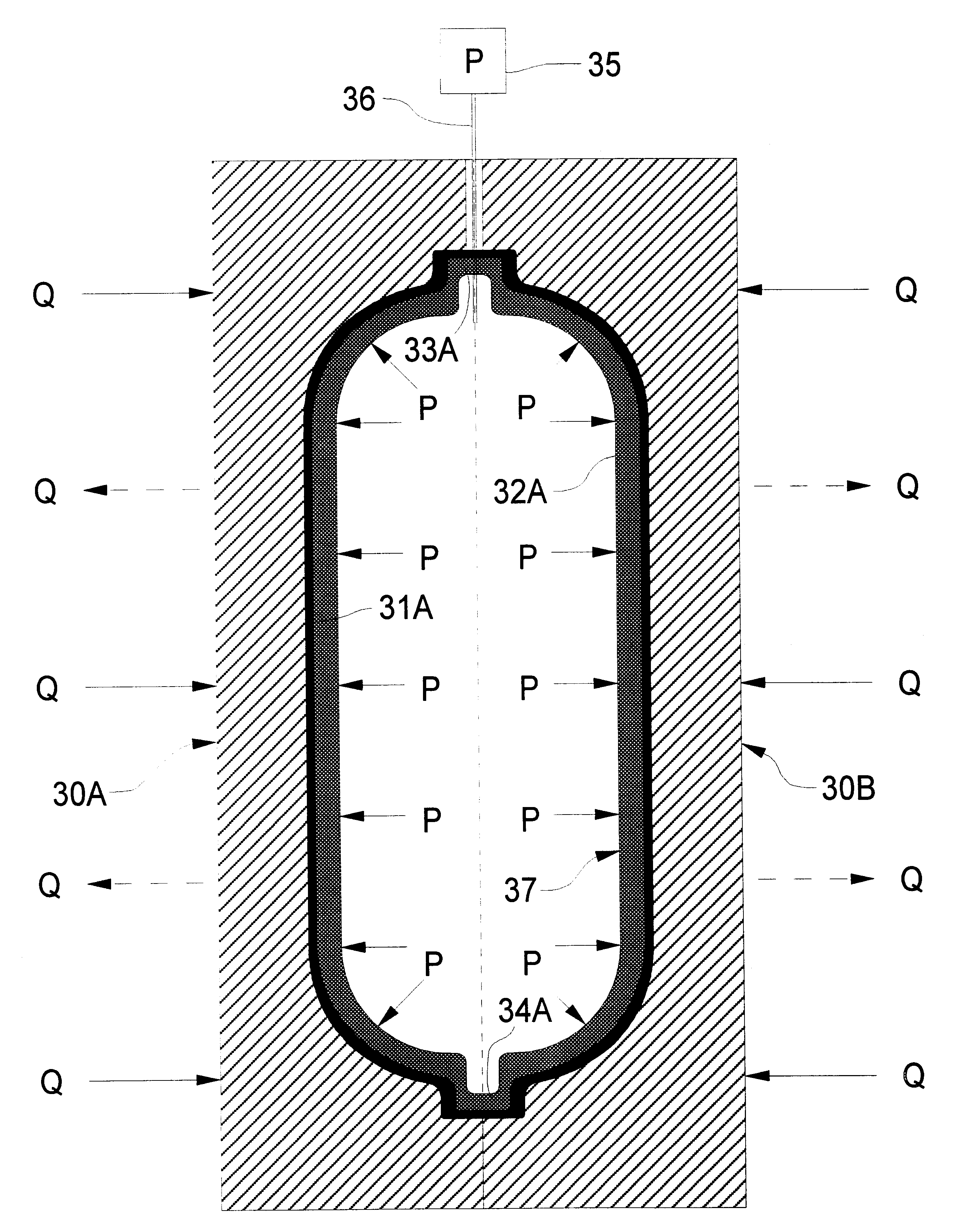

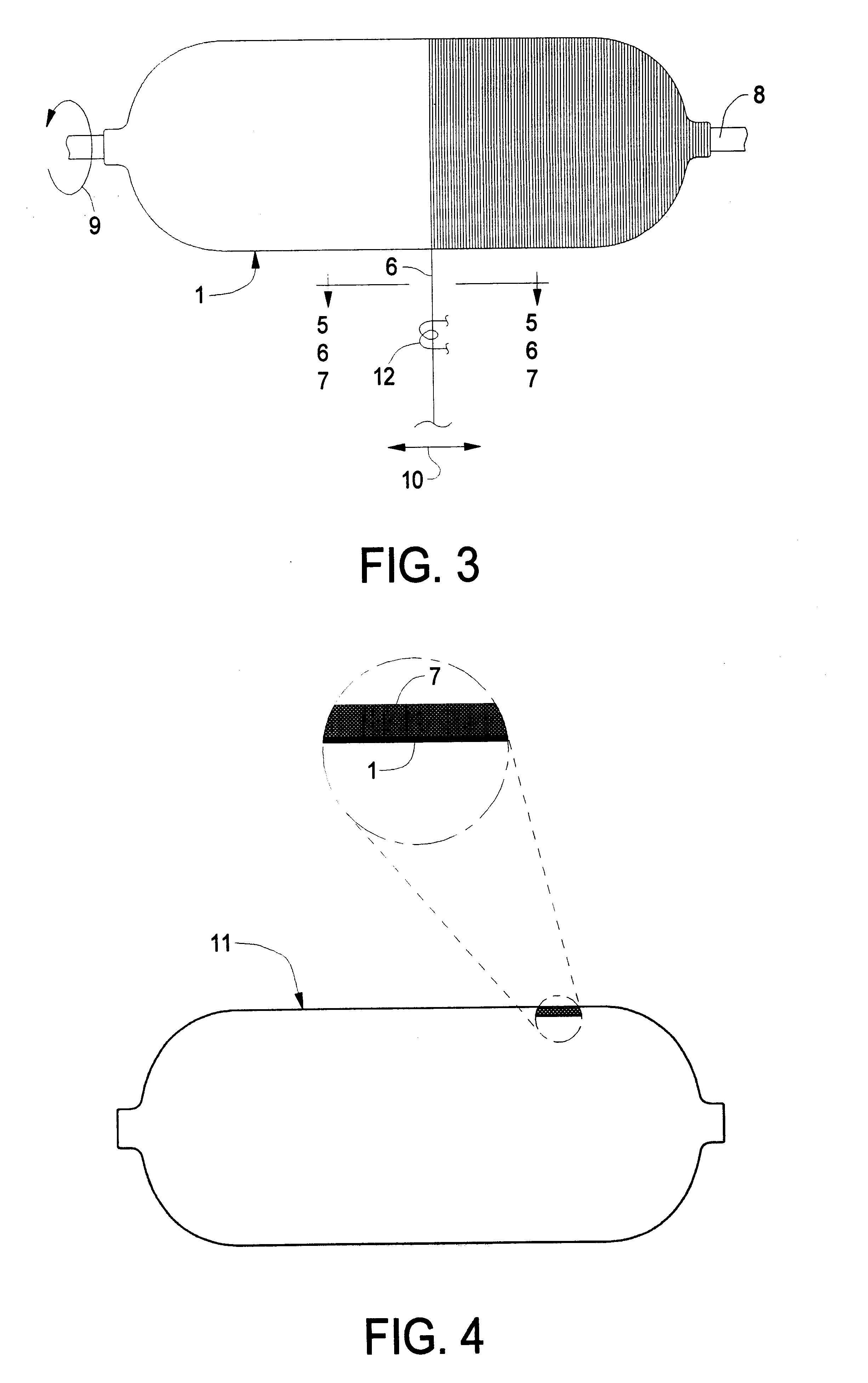

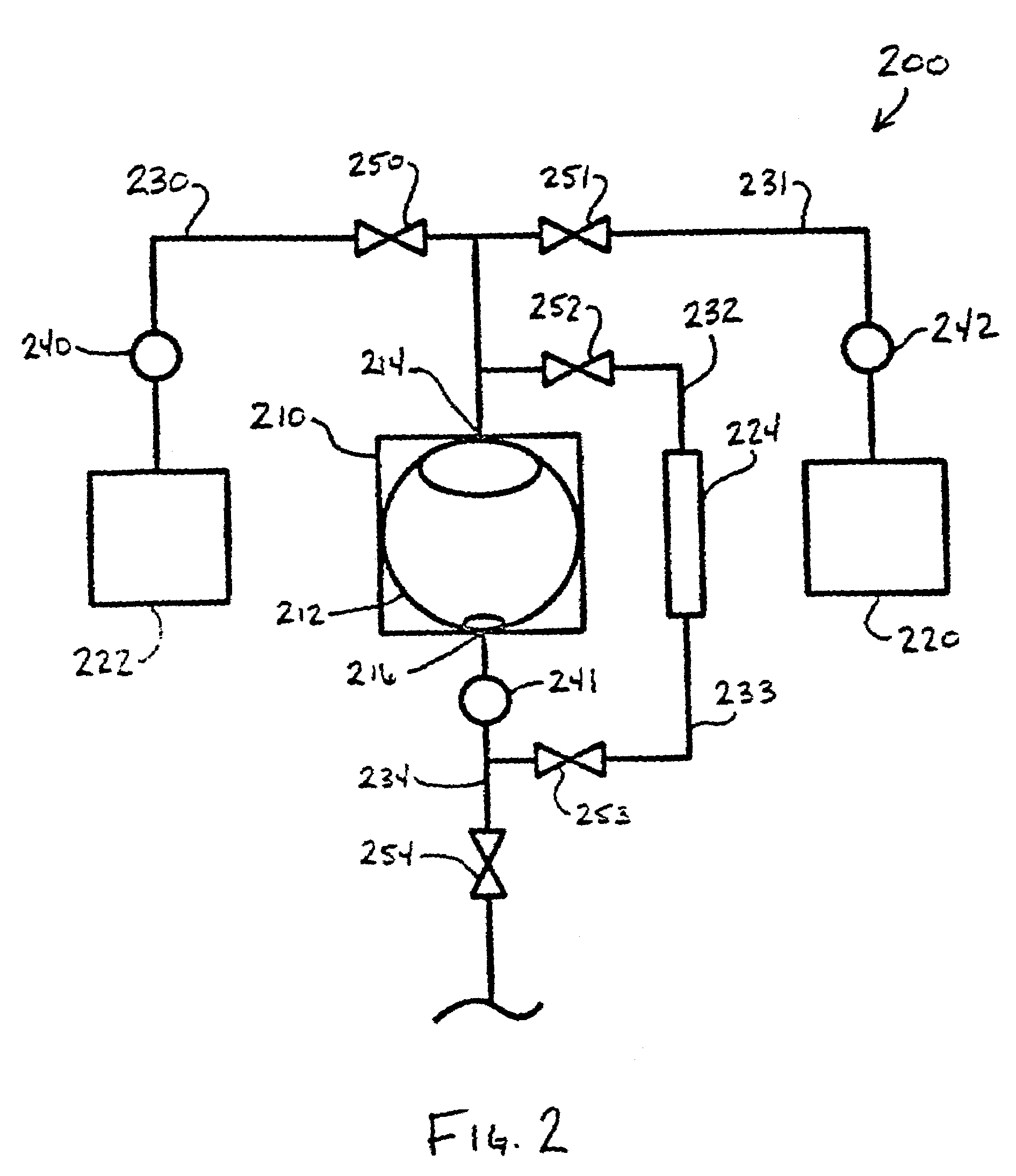

Method for making thermoplastic composite pressure vessels

InactiveUS6190598B1Speed up the processRatio is limitedLayered productsDomestic articlesGlass fiberEngineering

A process of making a composite vessel with superior mechanical and aesthetic characteristics includes the steps of: A) preforming a composite thermoplastic shell (e.g., by winding a commingled roving of fiberglass and a thermoplastic material onto a thermoplastic liner) having an opening for access to the interior; B) placing the shell (which may optionally be preheated) into a mold (which itself may optionally be preheated); C) introducing an inflatable bag containing a heater into the shell through the opening; D) heating the inflatable bag to a temperature which is sufficient to render the shell fluid while pressurizing the interior of the inflatable bag; E) continuing step D) until the shell forms against the interior walls of the mold; F) allowing the formed composite vessel to cool; G) removing the inflatable bag; and H) removing the formed composite vessel from the mold. Prior to step C), an insert having an opening may be juxtaposed in alignment with the opening in the shell such that, during step C), the inflatable bag is inserted through the opening in the insert. If desired for the intended purpose of the composite vessel, a portion of the exterior surface of the insert may be threaded such that threads are formed in the opening of the shell whereby the insert can be unscrewed leaving a threaded port into the vessel.

Owner:FLECK CONTROLS +1

Method for fabricating composite pressure vessels

InactiveUS6171423B1Speed up the processRatio is limitedVessel manufacturingCylinder headsPolytetramethylene terephthalateFiber

A process for fabricating a composite vessel includes the steps of: A) preforming (e.g., by winding fiber and at least one thermoplastic substance onto a thermoplastic liner) a thermoplastic shell which has at least one opening for access to the interior; B) extruding a circular cross section of a fluid parison of thermoplastic material (which preferably is chosen to have a melting point lower than that of the thermoplastic shell) into the interior of the thermoplastic shell through the opening; C) in a mold, applying at least one force (such as gas under pressure) which tends to urge the fluid parison toward the interior walls of the thermoplastic shell (which may be preheated prior to introduction into the mold) such that the fluid parison imparts heat to the thermoplastic shell; D) continuing step C) until the thermoplastic shell and the fluid parison consolidate to form a composite vessel; E) cooling the vessel until it is solidified; and F) removing the vessel from the mold. For some composite vessels, prior to step C), an insert may be introduced into the interior of the parison and positioned in alignment with the opening in the thermoplastic shell such that the insert is rendered integral with the composite vessel during step D). Suitable thermoplastic materials include polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

Electric stimilator for alpha-wave derivation

InactiveUS7386347B2Efficient implementationMaximize the effect of treatmentInternal electrodesMedical devicesHuman bodyDisease

Owner:CHUNG JONG PIL

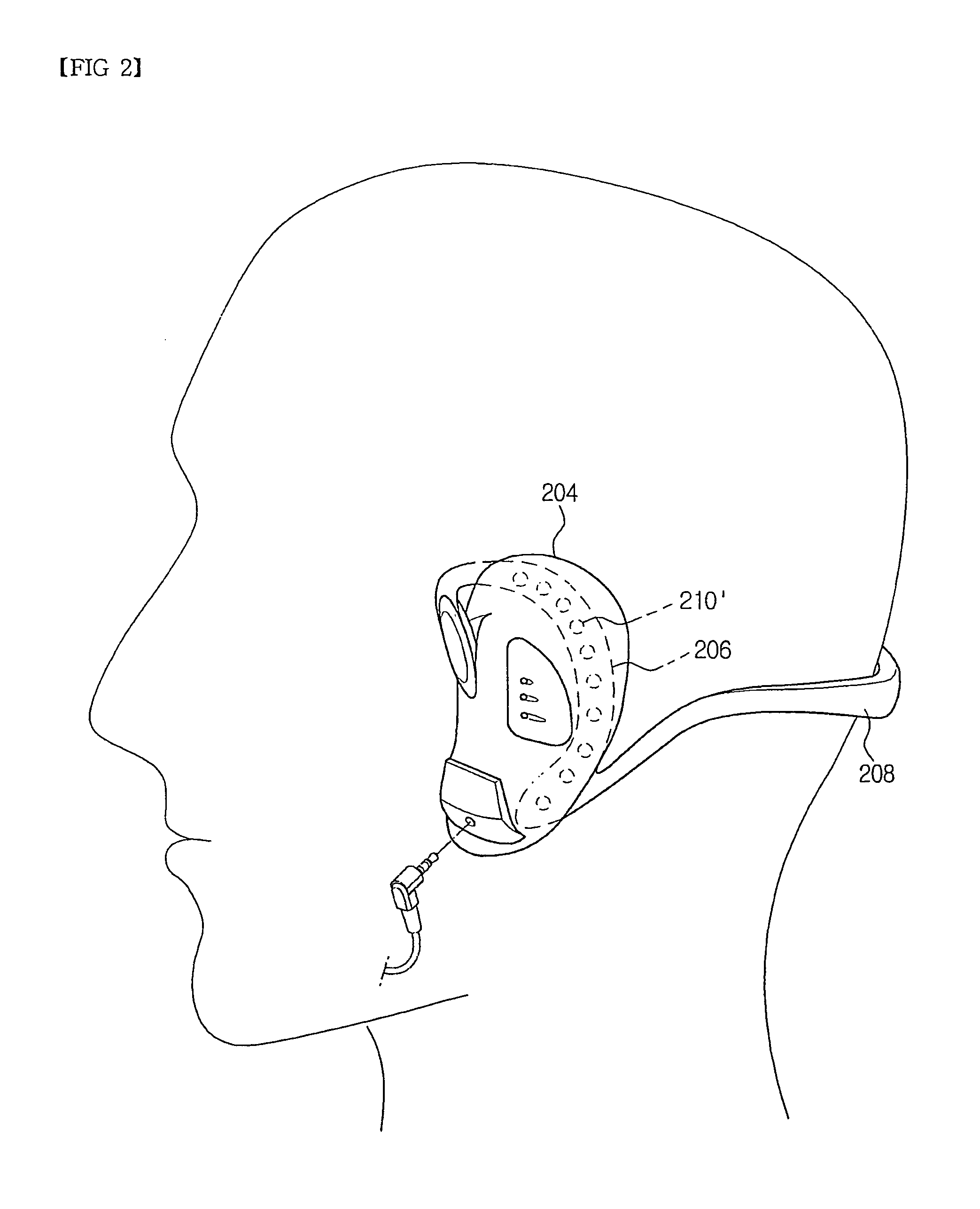

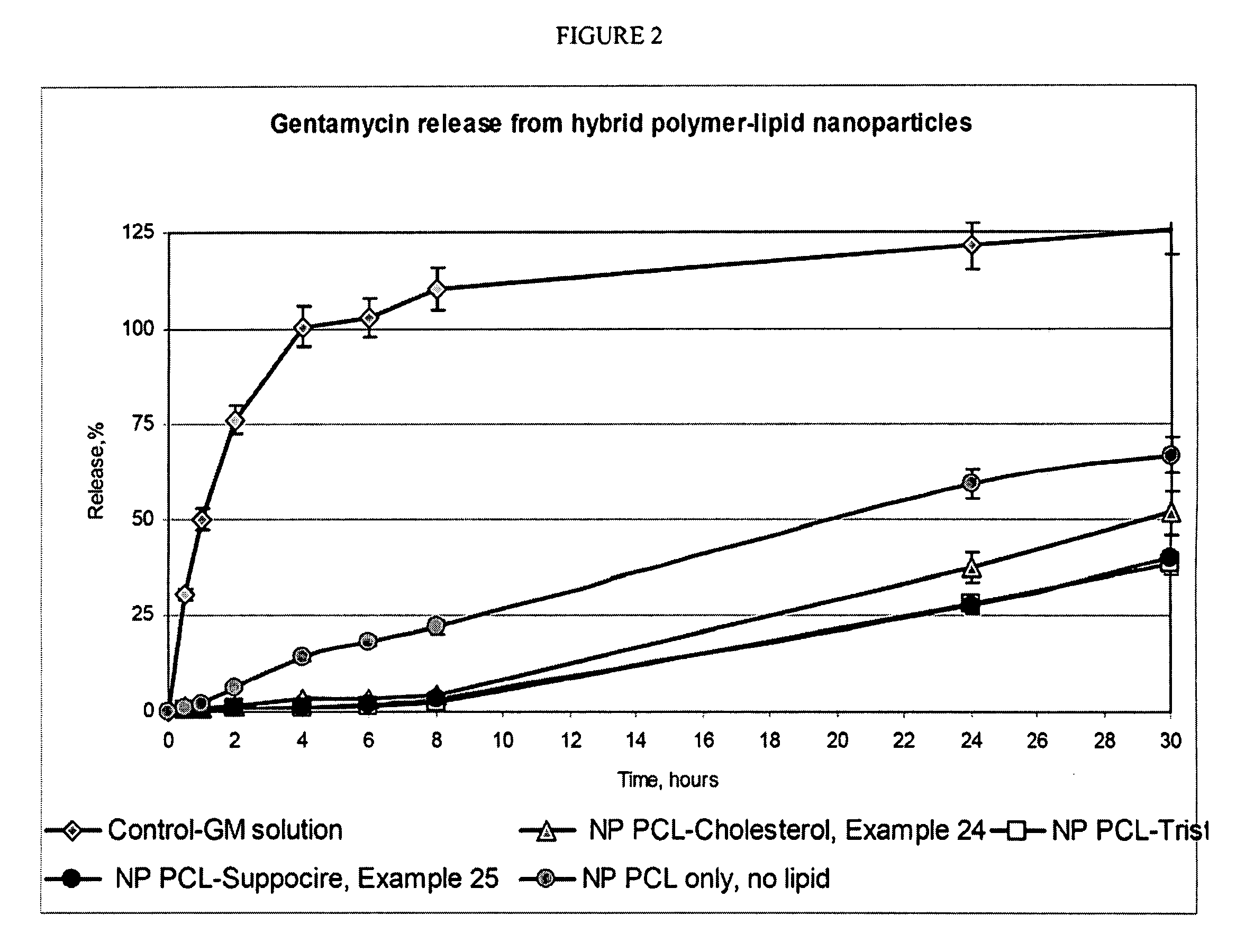

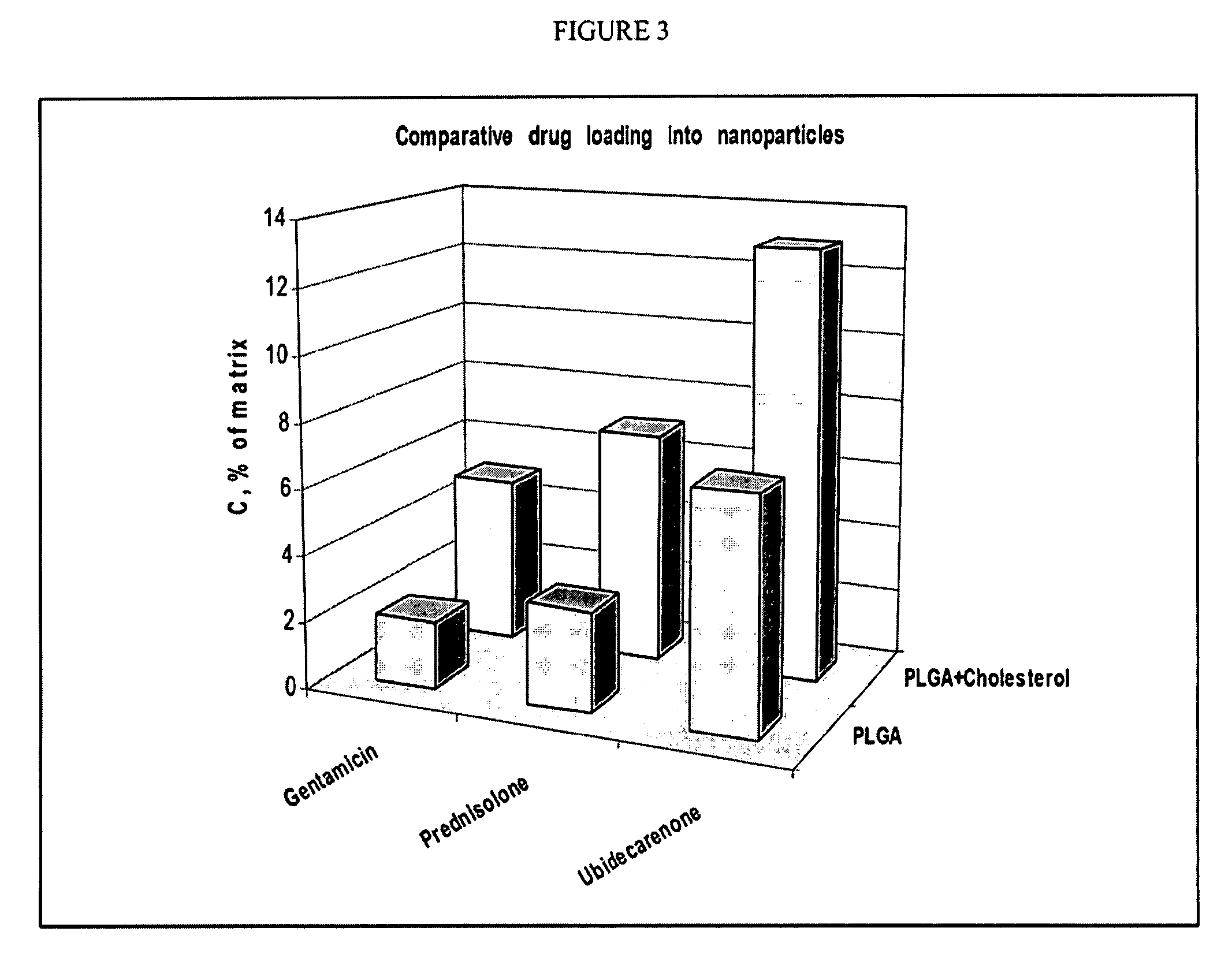

Hybrid lipid-polymer nanoparticulate delivery composition

The invention relates to a nanoparticulate colloidal delivery vehicle comprising a biodegradable polymer in combination with a hydrophobic lipid component. Variation of the lipid and polymer types and variation in the ratio between the polymer and lipid components allows regulation of drug loading and release rate.

Owner:ALPHARX

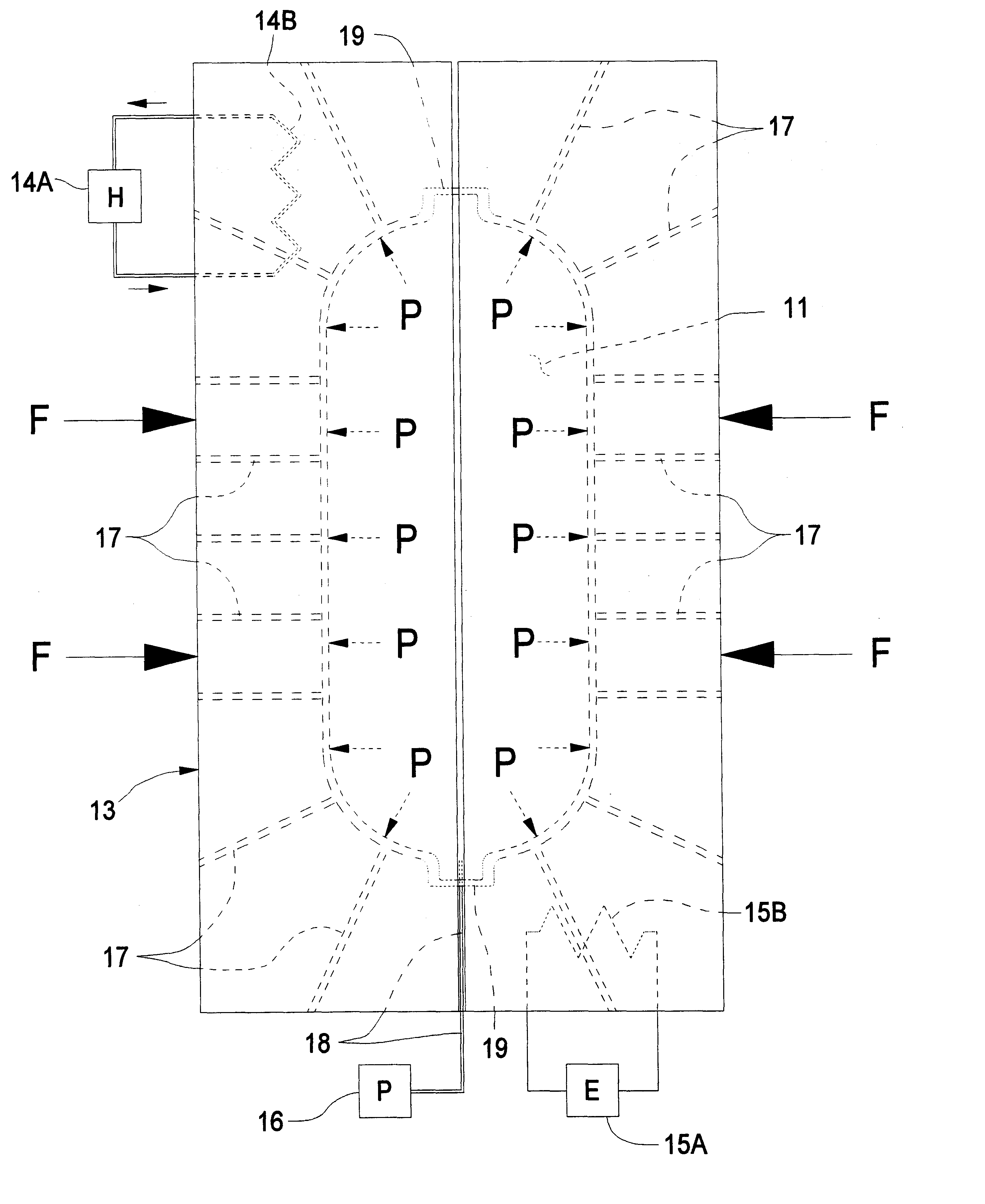

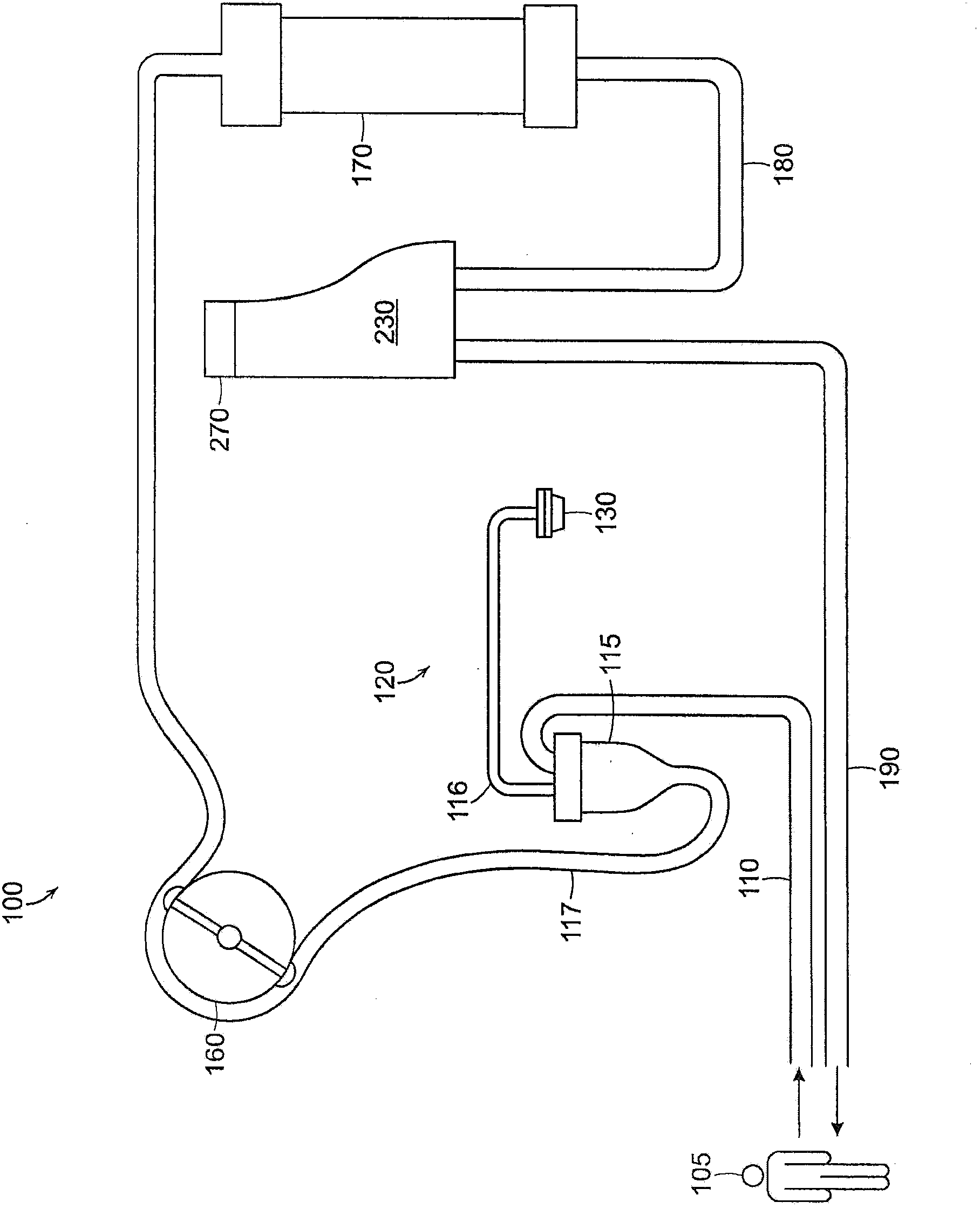

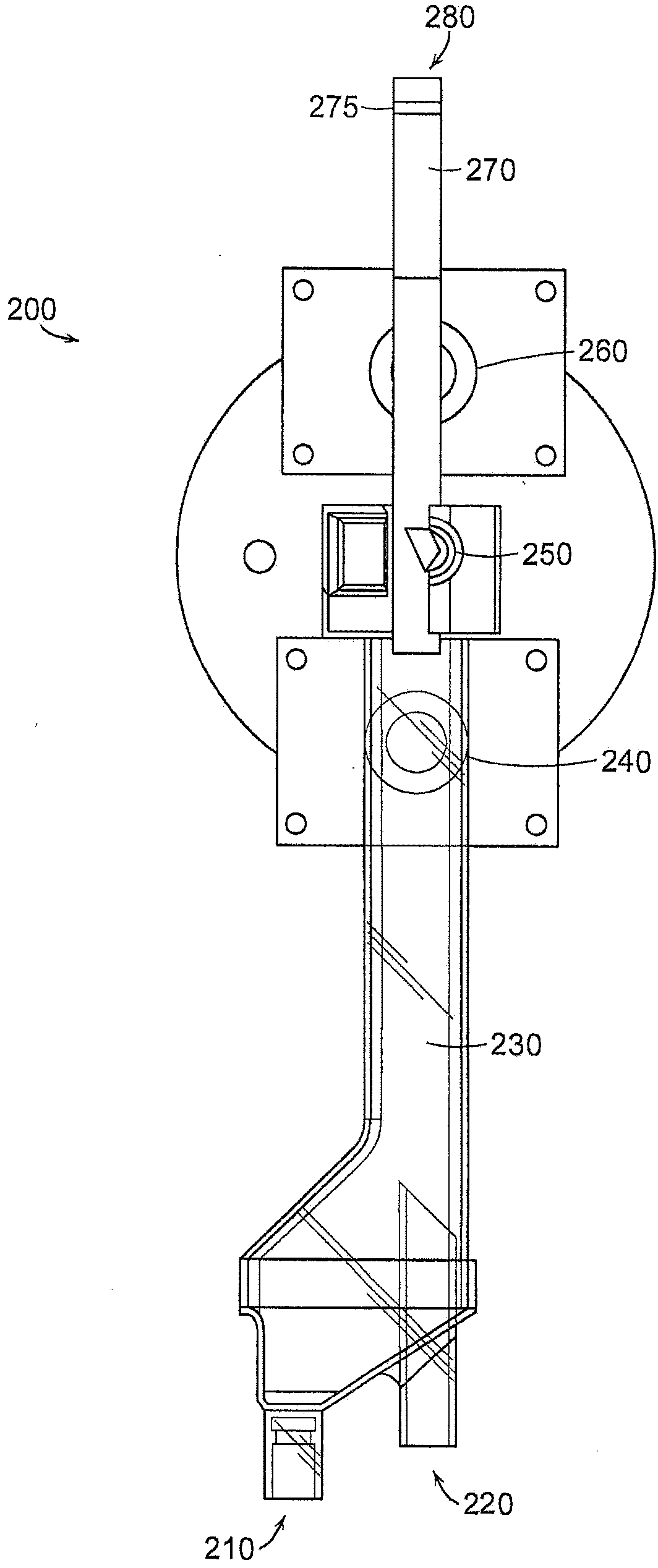

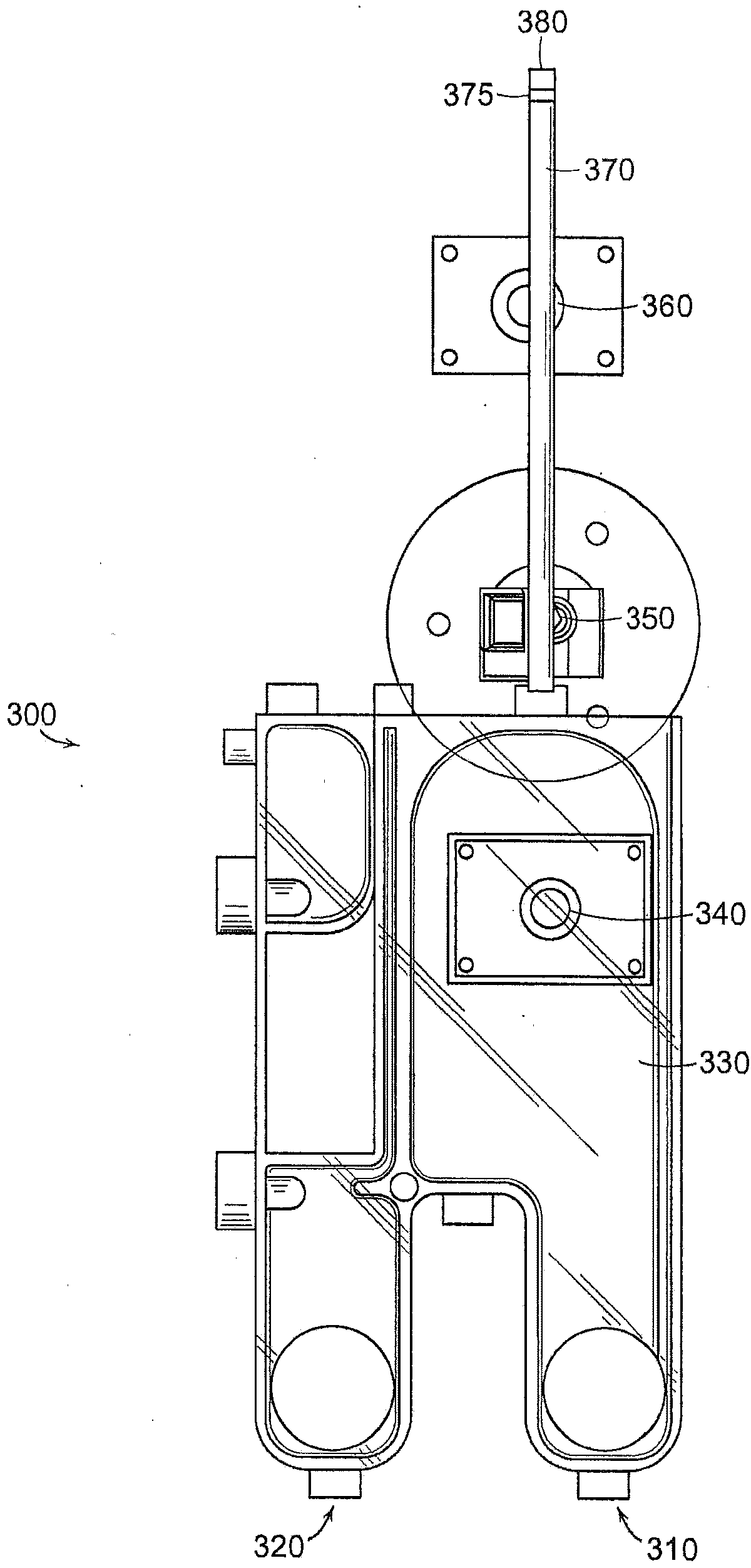

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7097715B1Machine and operating cost be reduceLess regulatedDry-cleaning apparatusTextile treatment machine partsSolventOrganic solvent

The present invention relates generally to cleaning systems, and more specifically to substrate cleaning systems, such as textile cleaning systems, utilizing an organic cleaning solvent and a pressurized fluid solvent. However, unlike conventional cleaning systems, a conventional drying cycle is not necessary. Particularly, the present invention provides a process for cleaning substrates by cleaning the substrates with an organic solvent in absence of liquid carbon dioxide, and removing the organic solvent from the substrates using a pressurized fluid solvent.

Owner:EMINENT TECHNOLOGY

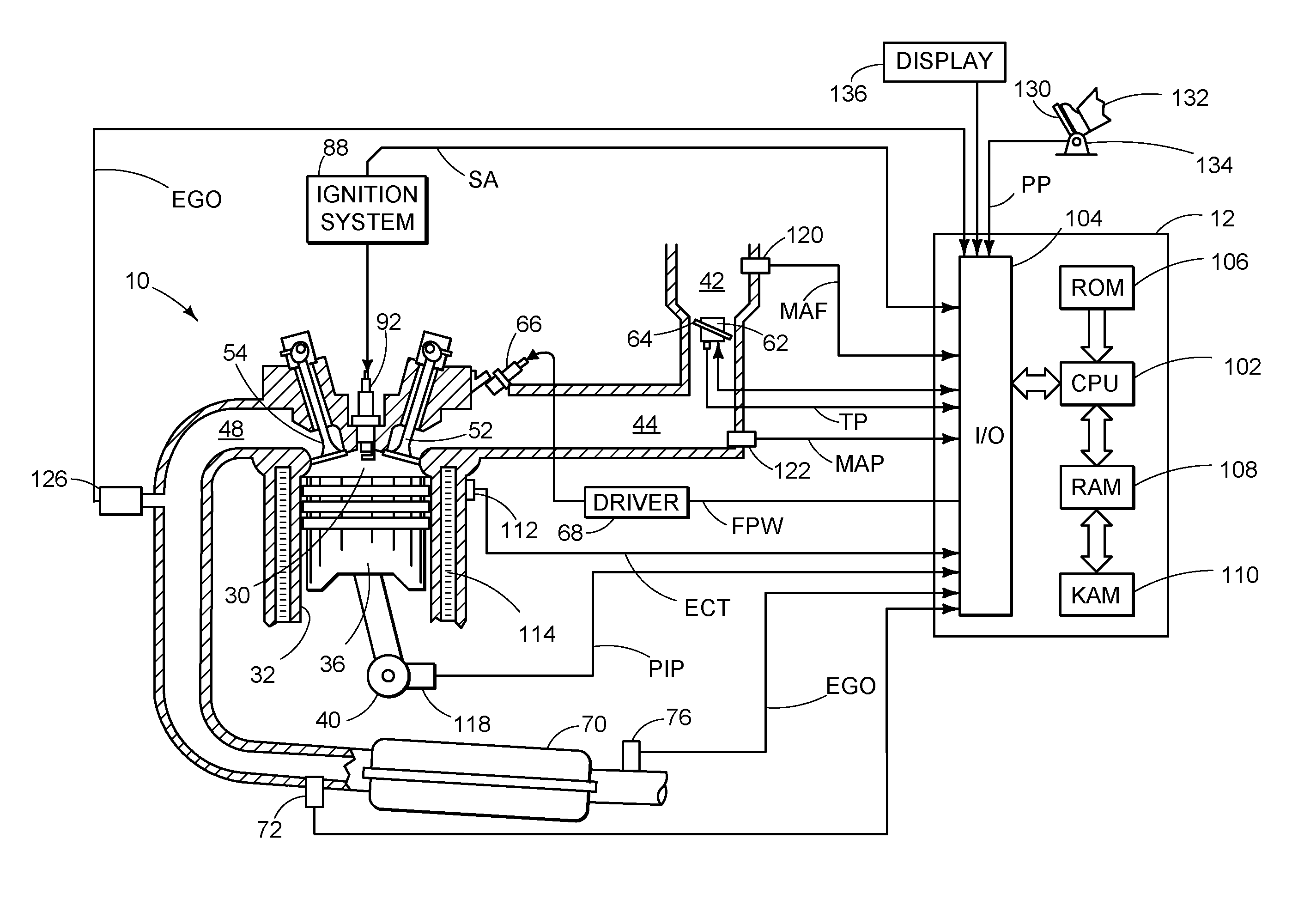

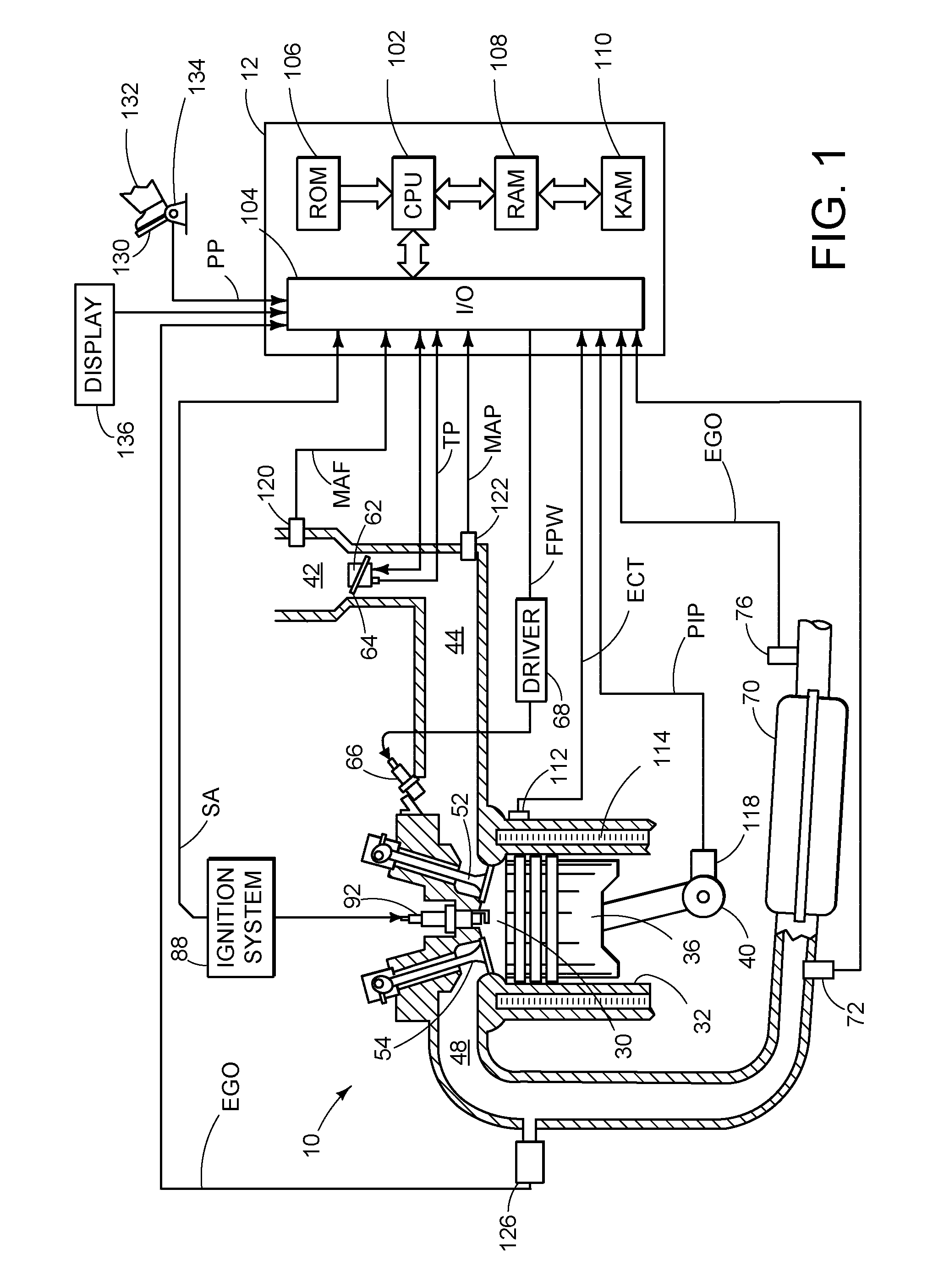

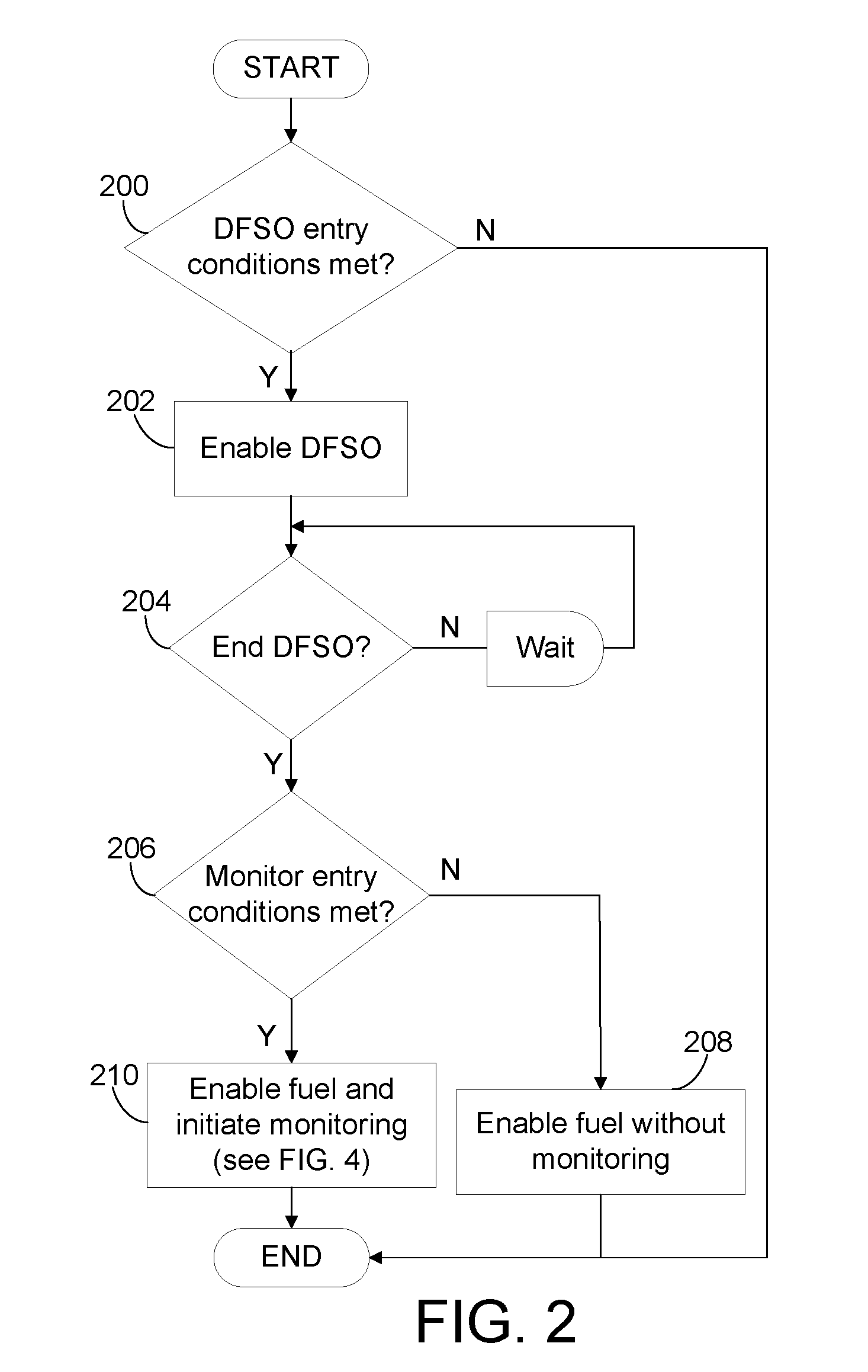

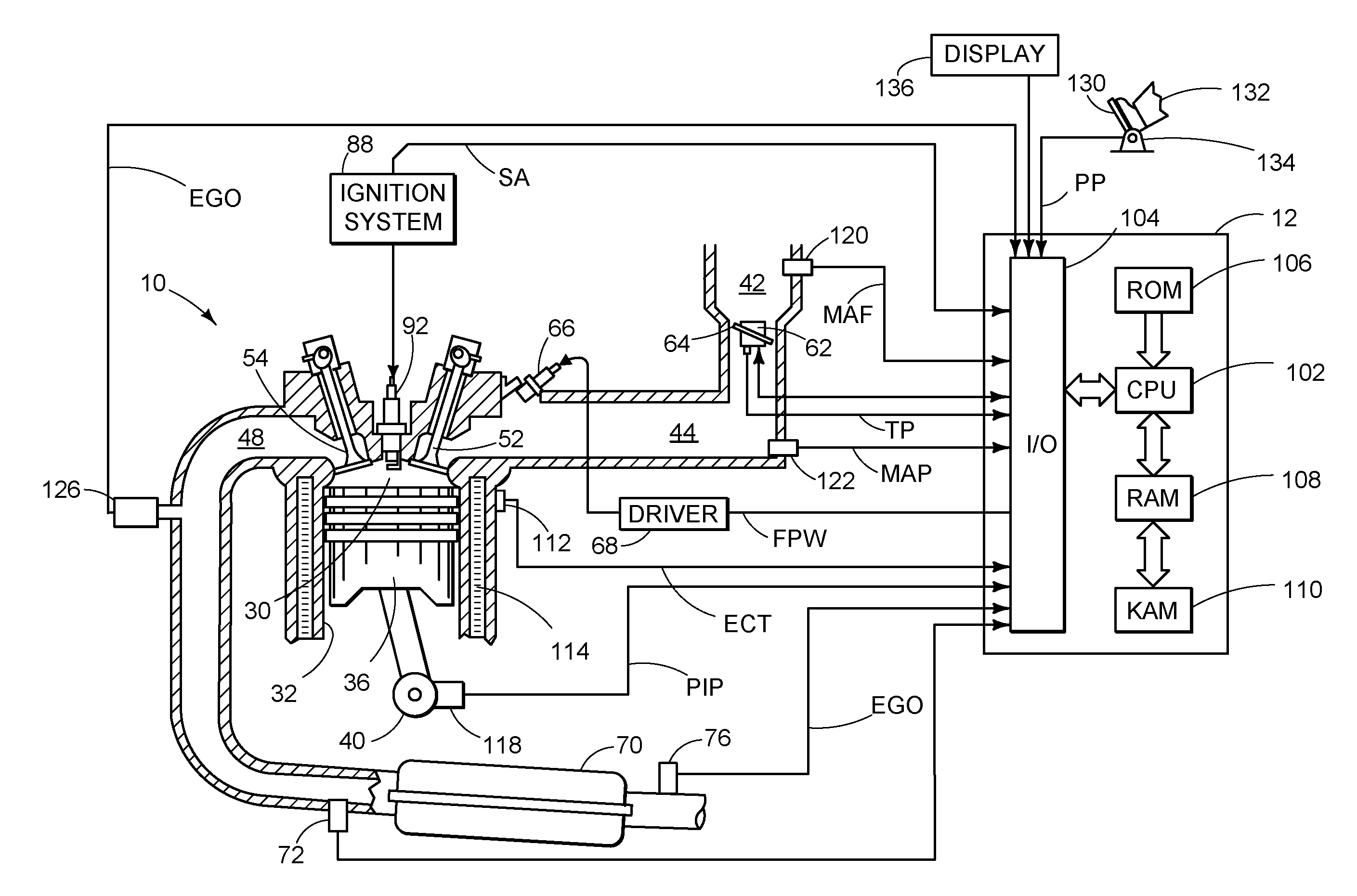

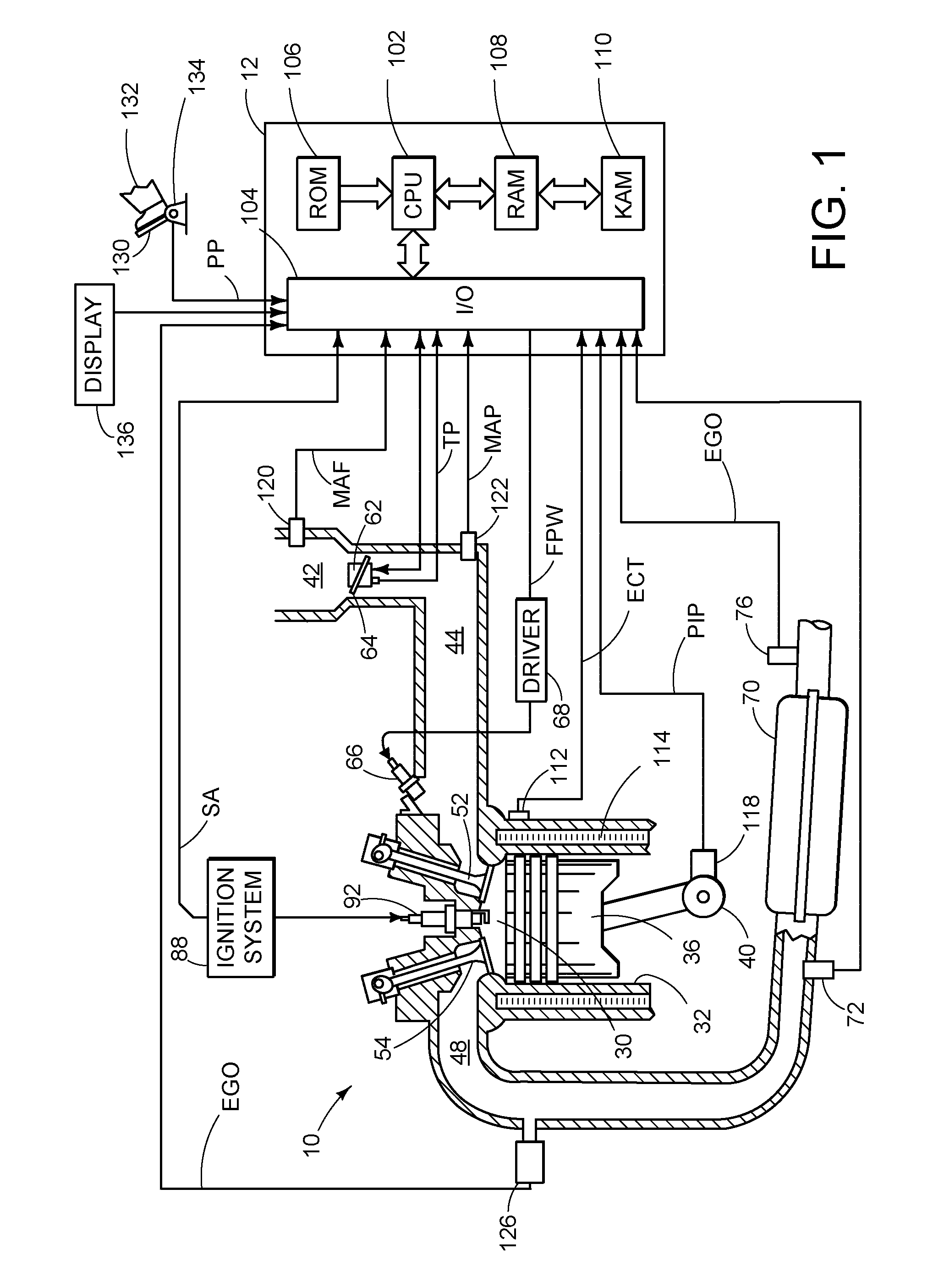

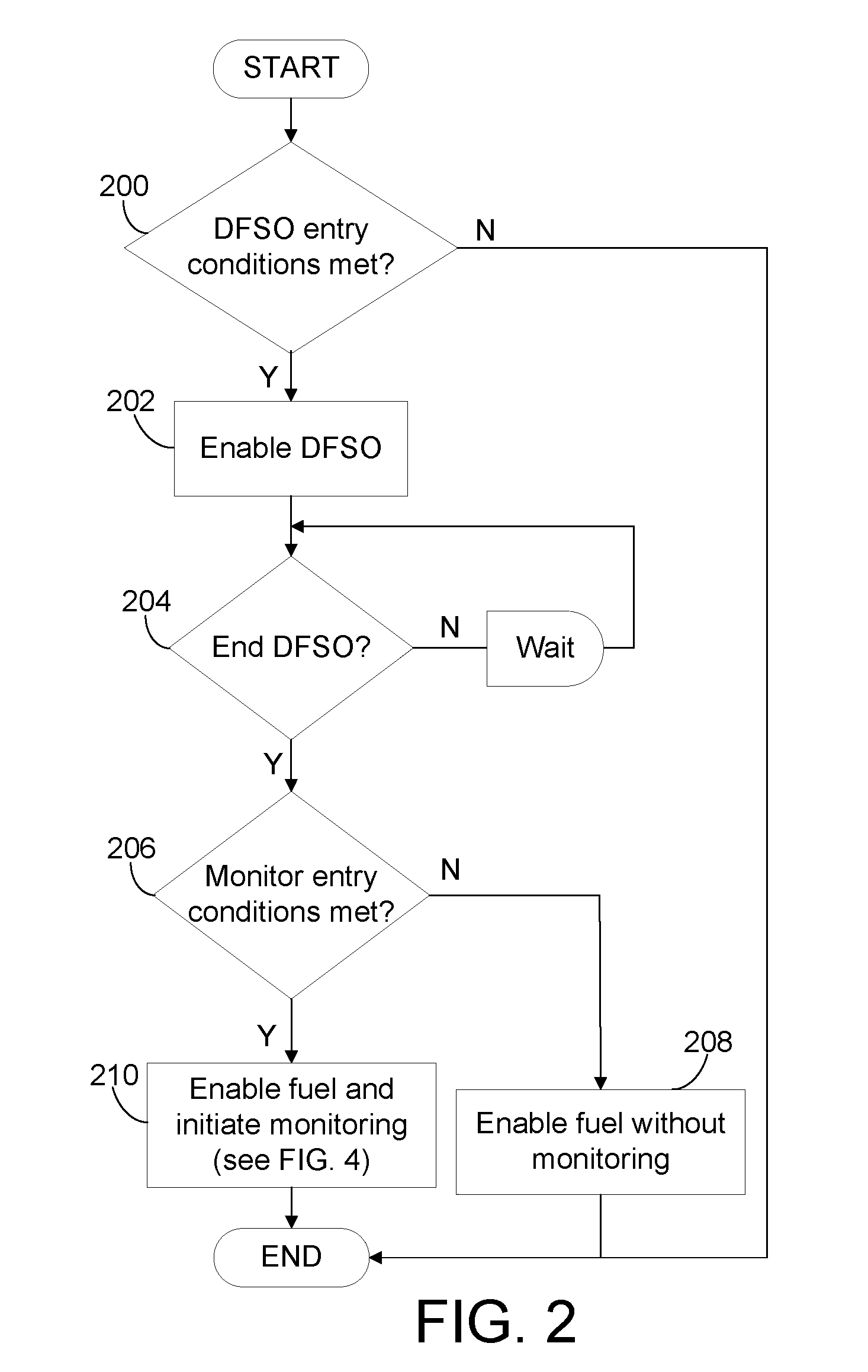

Integrated fuel catalyst monitor

ActiveUS20110083425A1Reduce capacityLow efficiencyElectrical controlInternal combustion piston enginesProcess engineeringOxygen

A method is provided for monitoring an emission device coupled to an engine. In one example approach, the method comprises: following a deceleration fuel shut-off duration, indicating degradation of the emission device based on an amount of rich products required to cause a sensor to become richer than a threshold. The amount of rich products required may be correlated to an amount of oxygen stored in the emission device. The indication of emission device degradation may be further based on air mass and temperature during delivery of the required rich products.

Owner:FORD GLOBAL TECH LLC

Method for fabricating composite pressure vessels

InactiveUS6565793B1Speed up the processRatio is limitedLabelling non-rigid containersLaminationFiberPolytetramethylene terephthalate

A process of fabricating a composite vessel includes the steps of: A) fabricating a thermoplastic liner for the vessel; B) overlaying a layer comprising fiber and a thermoplastic material (preferably by winding commingled filaments, rovings or yarns) onto the thermoplastic liner to obtain a composite intermediate structure (the fiber and thermoplastic material can be heated if desired during the overlaying, e.g. winding, step); C) heating the composite intermediate structure in a mold while applying at least one force thereto tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold; D) continuing step C) until the thermoplastic liner and the overlaid layer consolidate to form a composite vessel; E) cooling the mold and composite vessel until the composite vessel is solidified; and F) removing the formed composite vessel from the mold. The at least one force applied during step C) may be obtained by introducing gas pressure into the interior of the composite intermediate structure. Suitable materials for the thermoplastic material include: polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

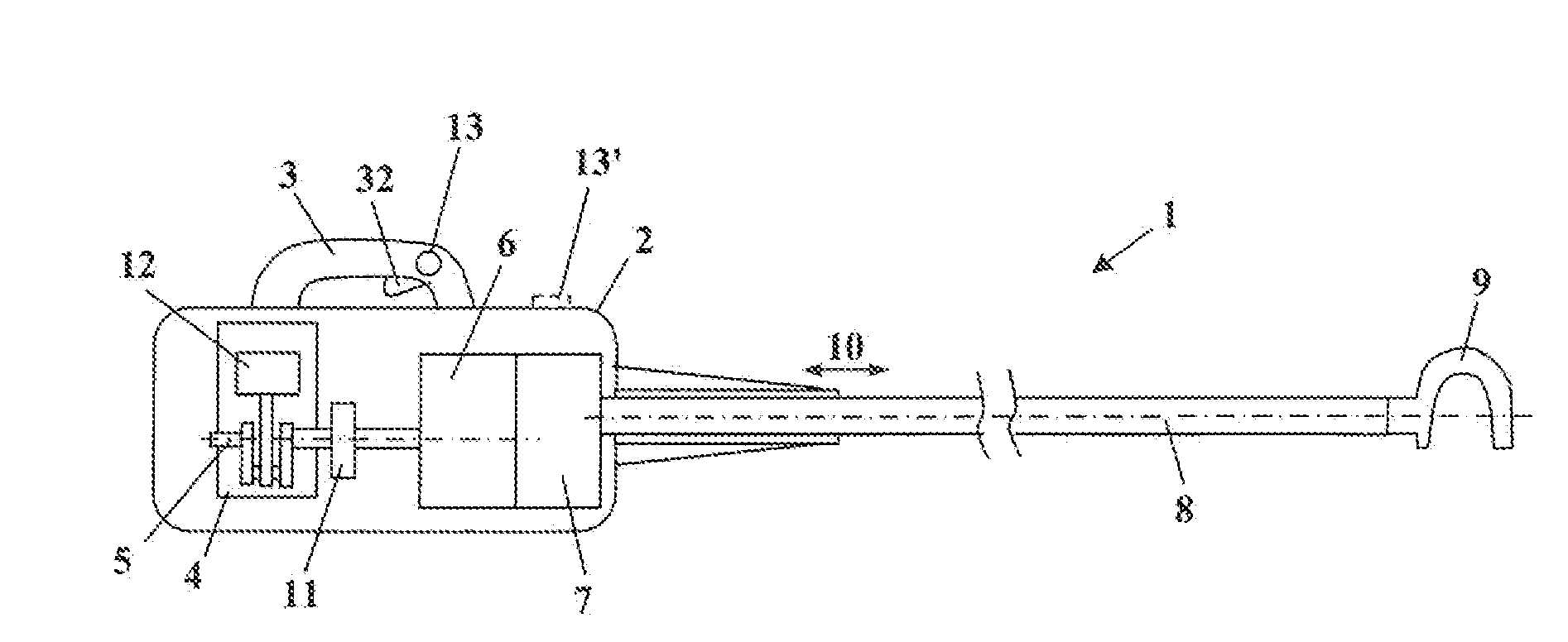

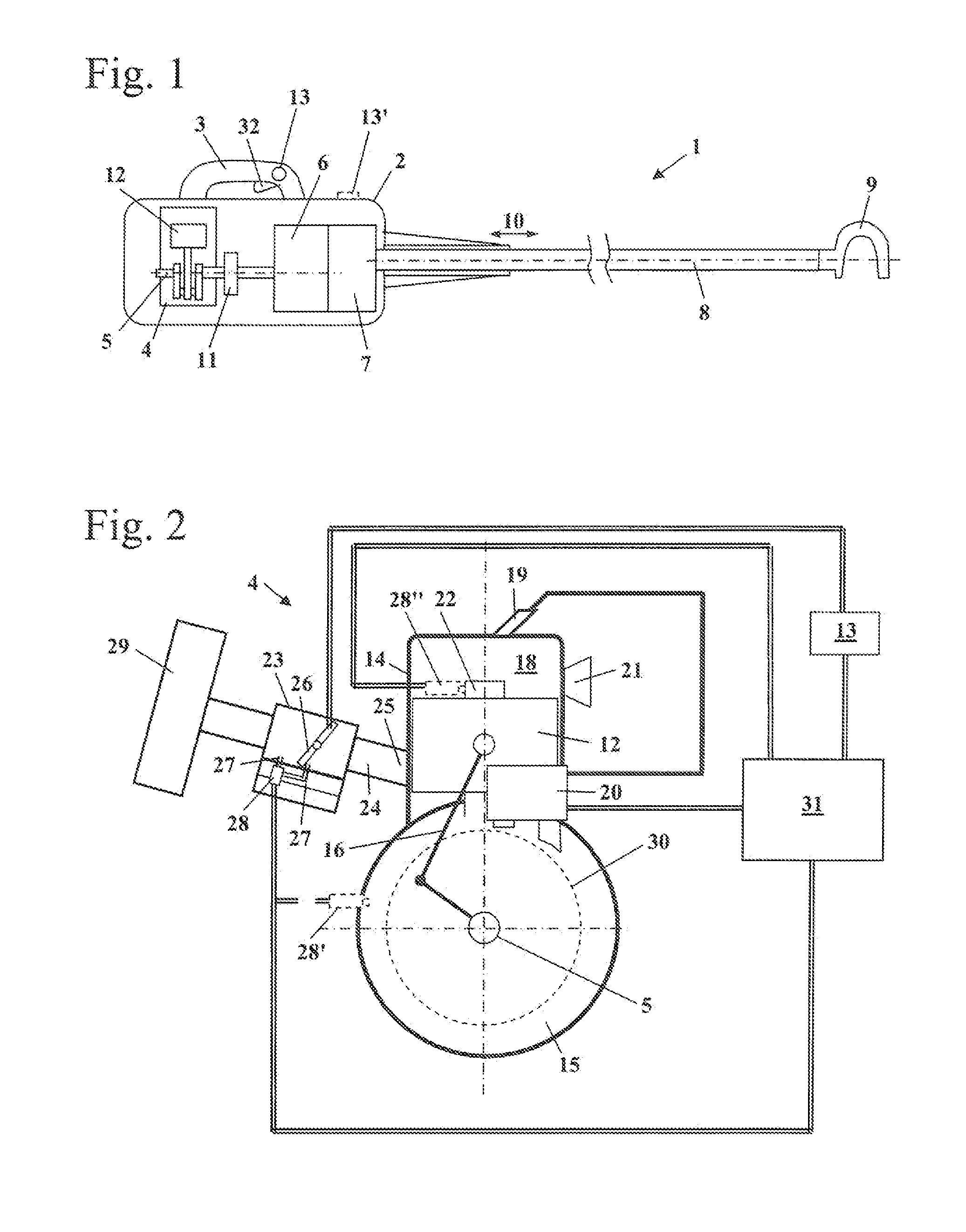

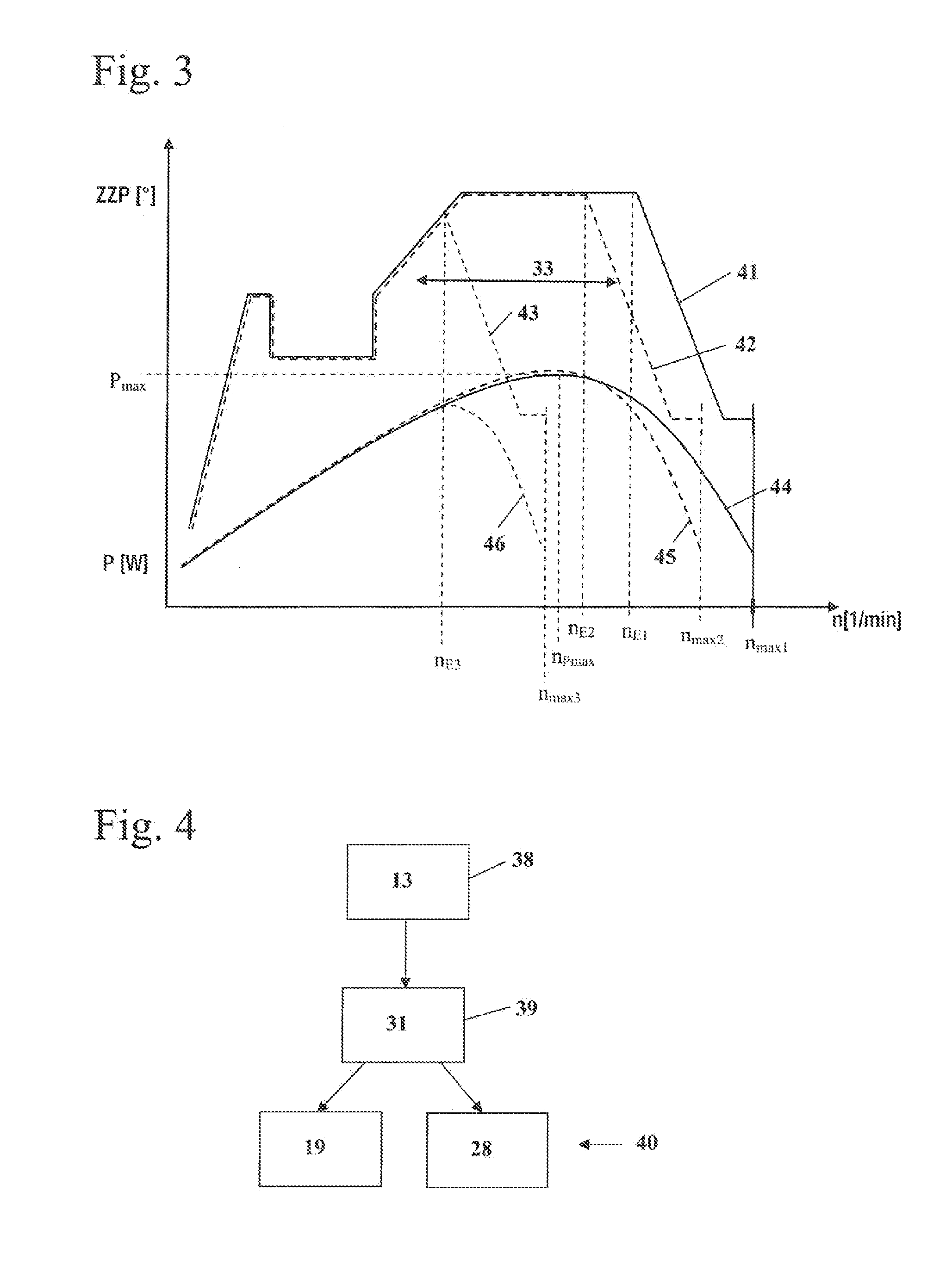

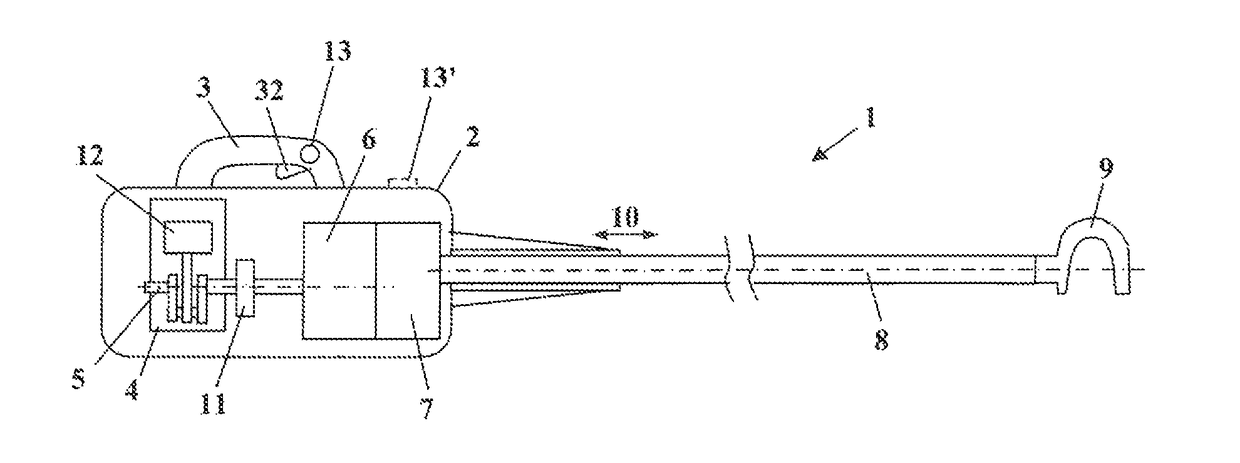

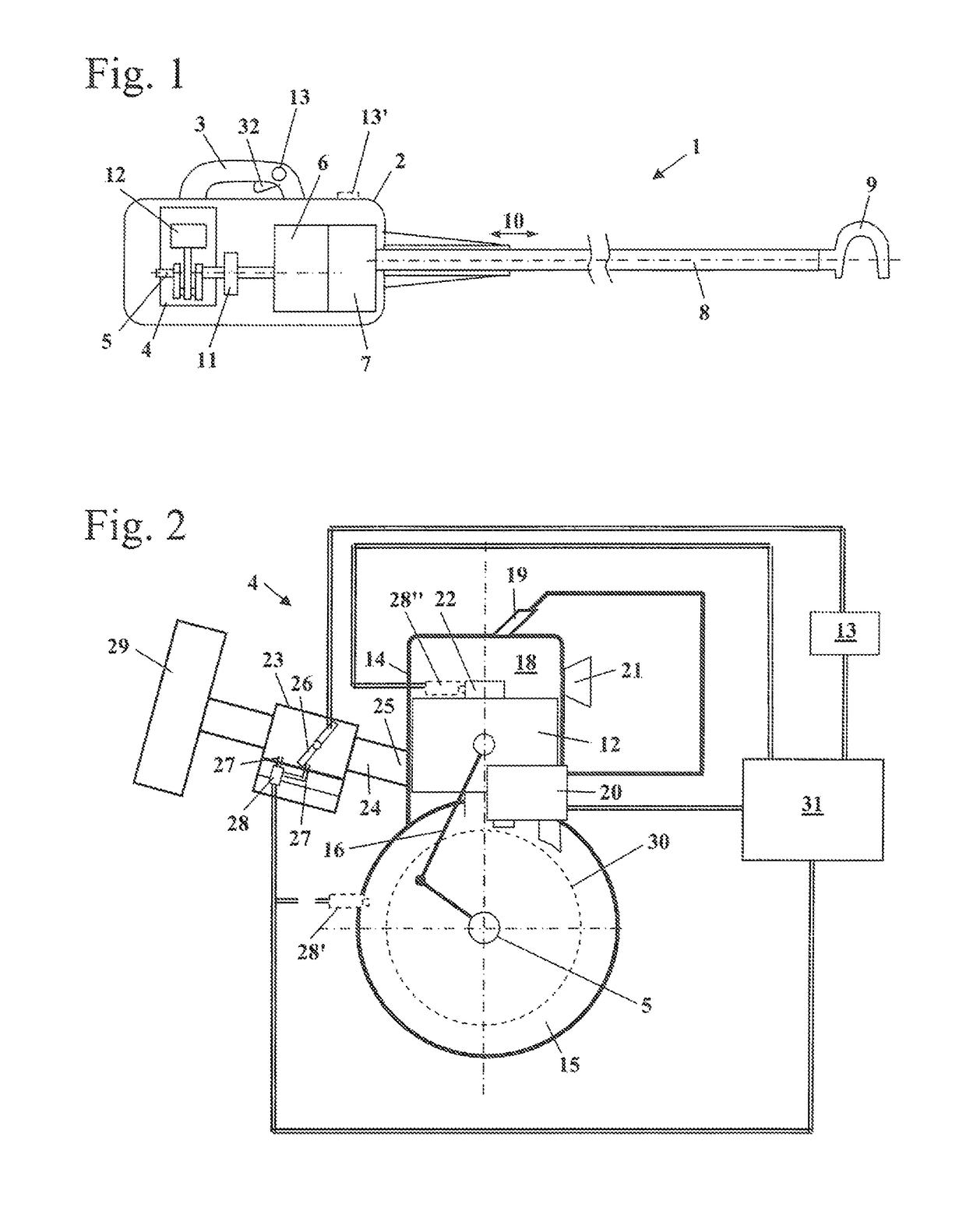

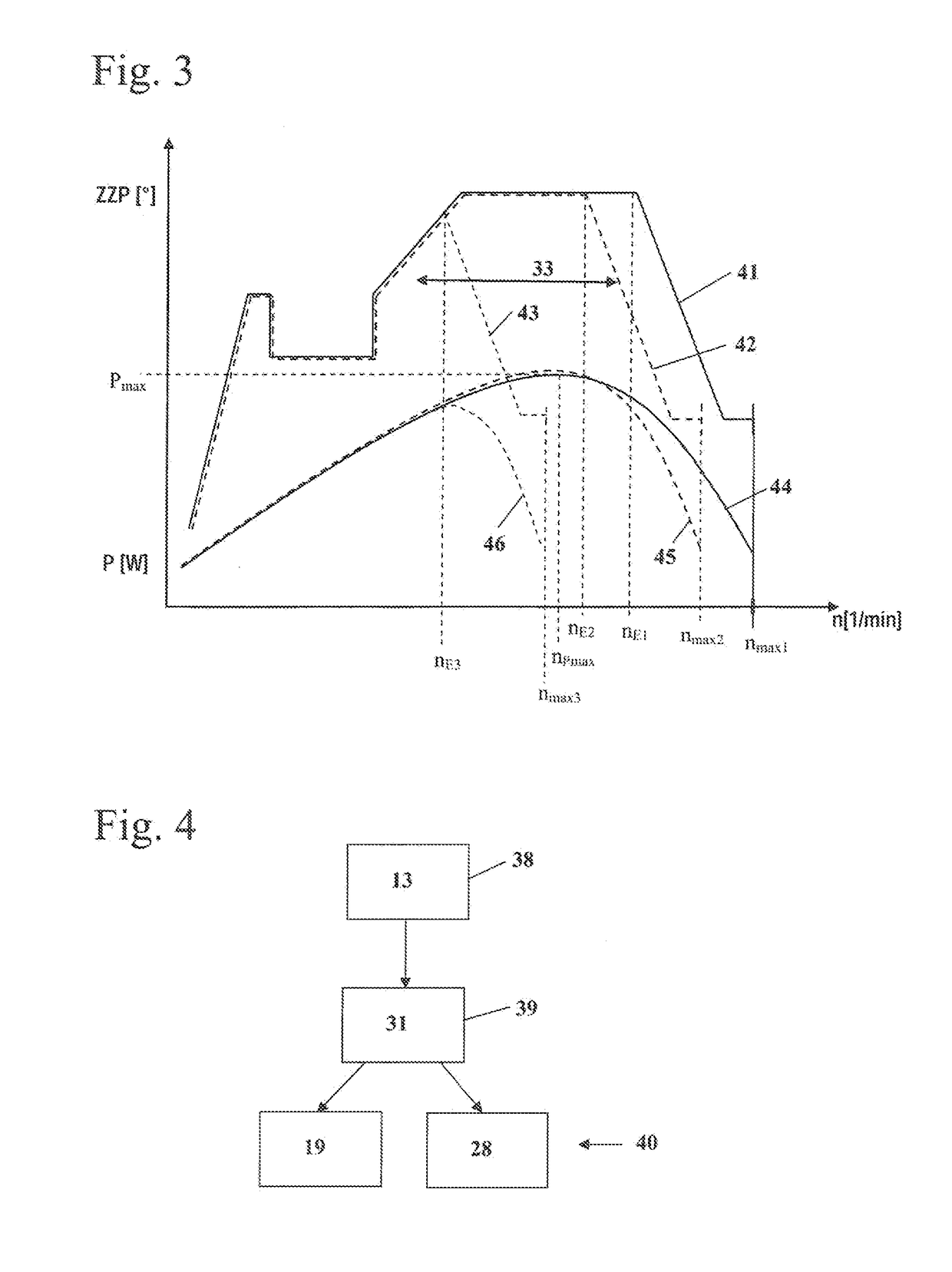

Handheld work apparatus

ActiveUS20130199812A1Set speed in easyEasily set speedElectrical controlInternal combustion piston enginesCombustionHand held

A handheld work apparatus has a combustion engine (4) for driving a tool. The combustion engine (4) has an ignition device, a device for metering fuel and a control device (31). The control device (31) engages when an engagement speed (nE1, nE2) is reached, in order to limit the speed (n) of the combustion engine (4). In order to allow the speed (n) to be set in an easy manner at full throttle, the work apparatus has a device for setting the engagement speed (nE2) by the user.

Owner:ANDREAS STIHL AG & CO KG

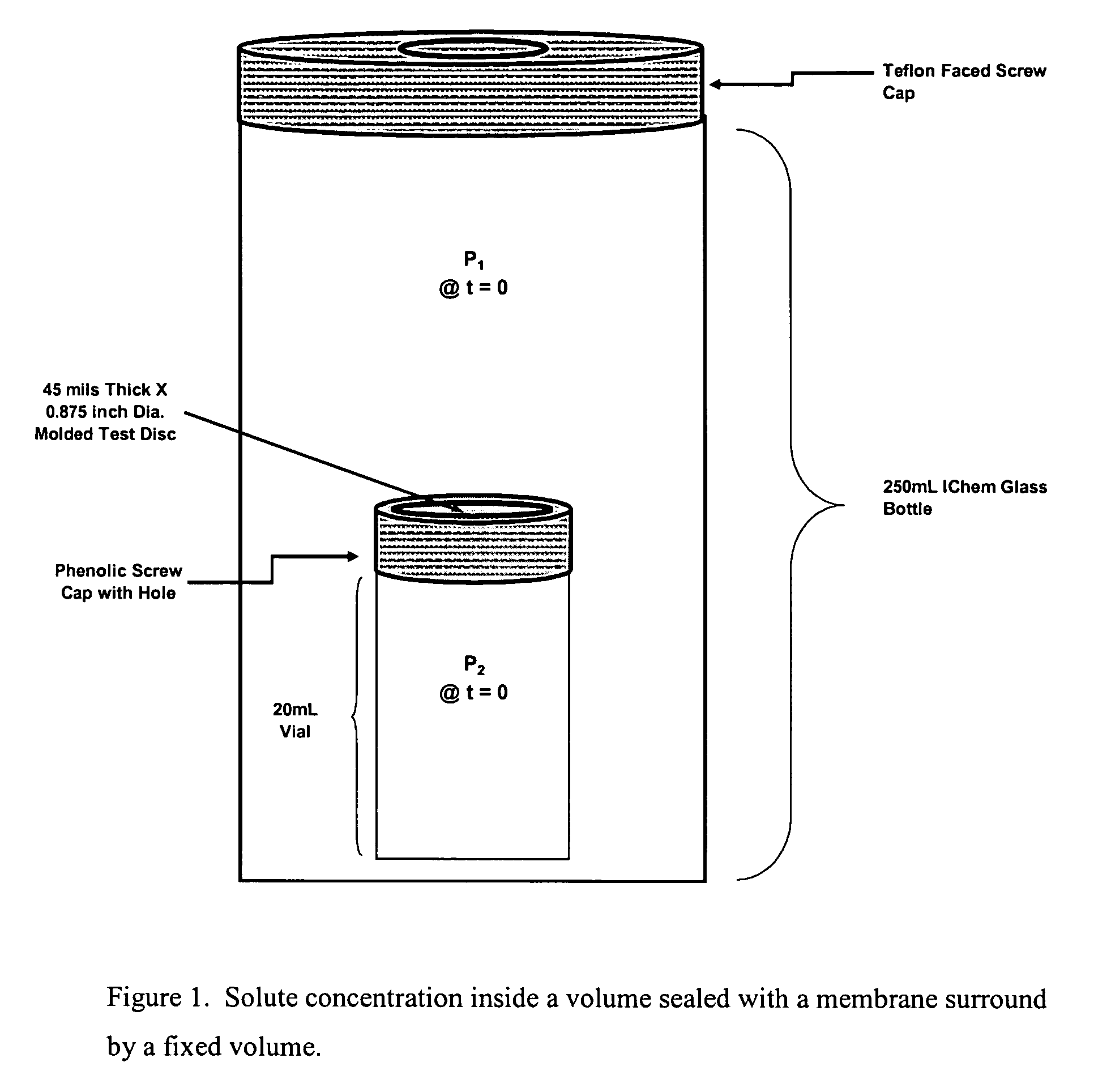

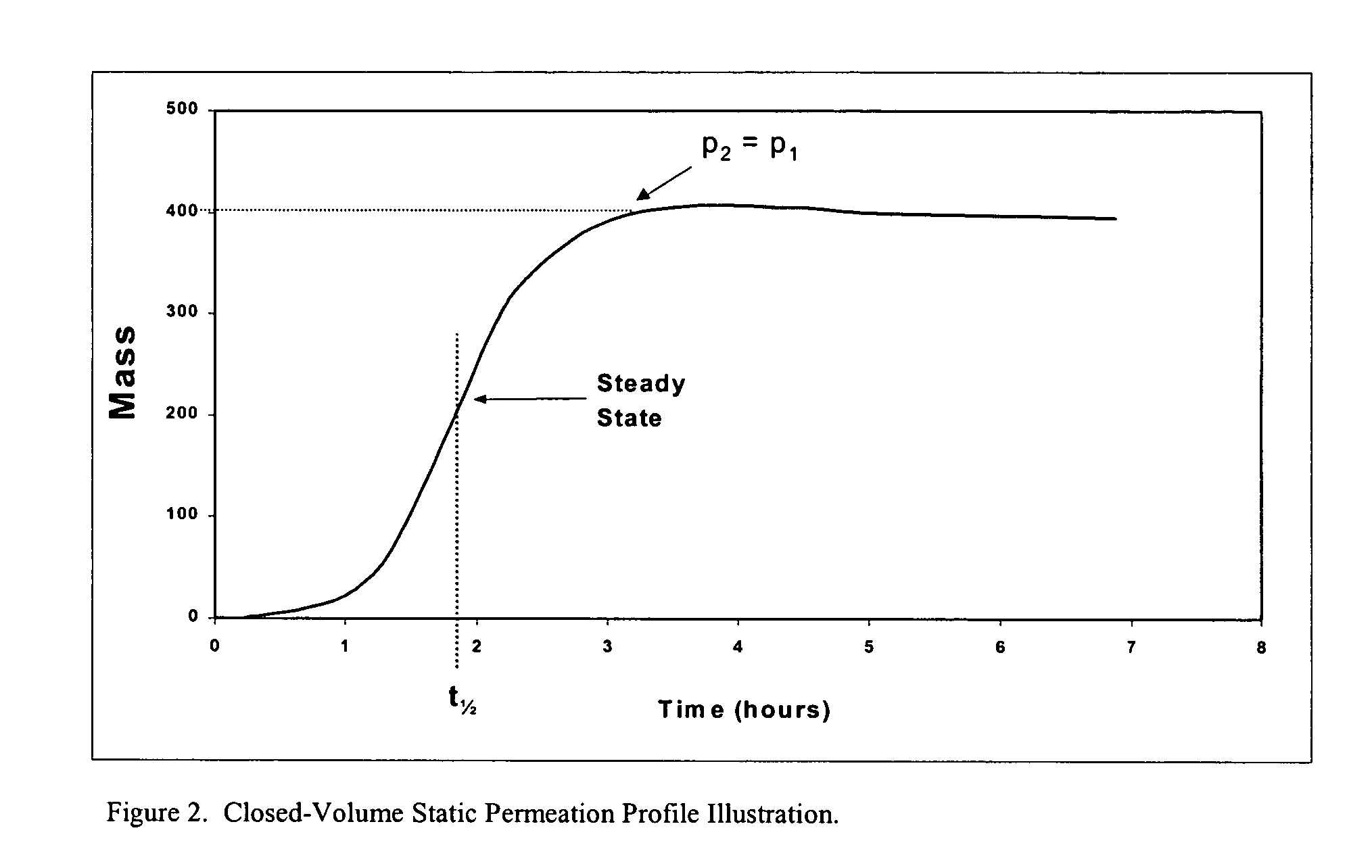

Amphoteric grafted barrier materials

Thermoplastic polymer compositions, films, containers, laminates and fibers can comprise a modified polymer. The said modified polymer having a moiety comprising a half-ester reaction product of cyclodextrin and metal and / or organic group covalently bonded to some portion of the half-acid moieties. The cyclodextrin compound, grafted to the polymer structure, can scavenge impurities, permeants, or other undesirable volatile contaminants. The cooperation between the modified polymer's carboxylic acidic groups, basic groups and grafted cyclodextrin can provide active barrier properties to a film, web, fiber or other polymer structure. A permeant or a contaminant can be complexed or trapped within the polymer and held within the film, web or fiber preventing the permeant from passing into the interior of a container, or the contaminant can be scavenged from the enclosed headspace or surrounding environment.

Owner:VERDANT TECH LLC

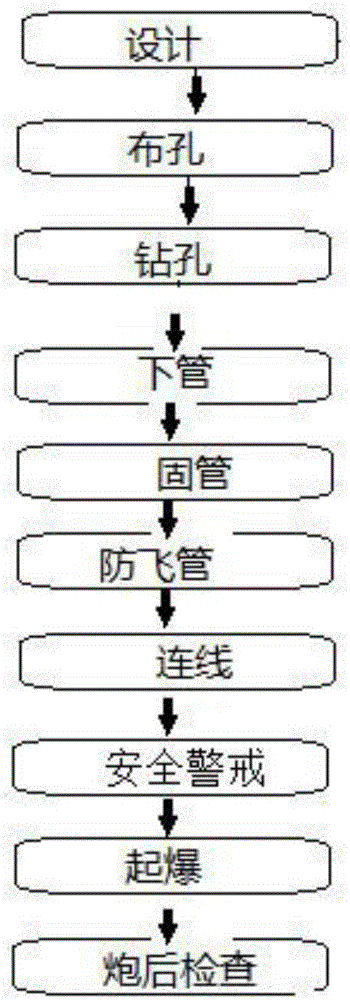

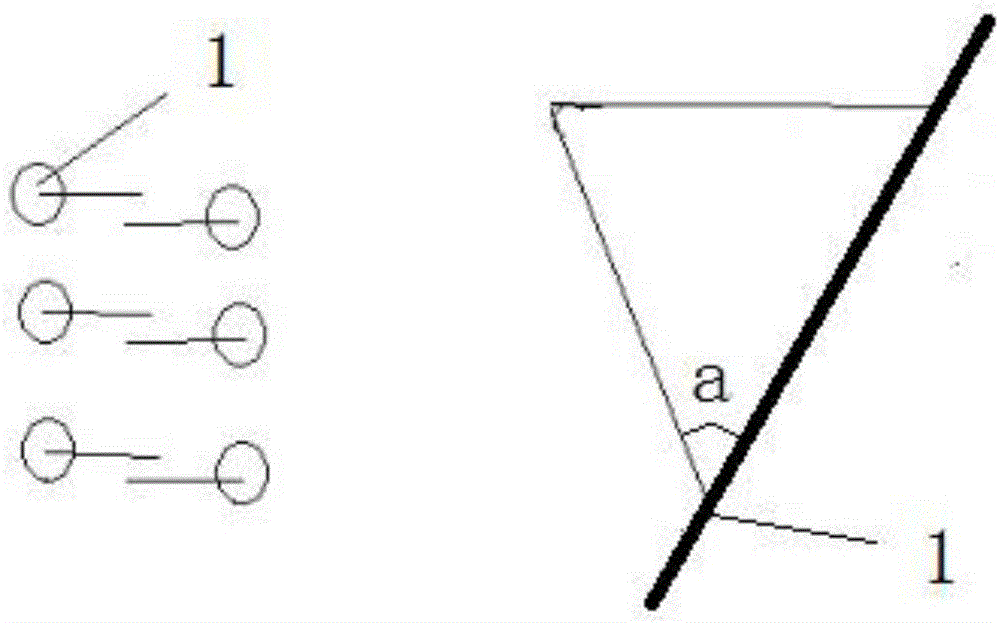

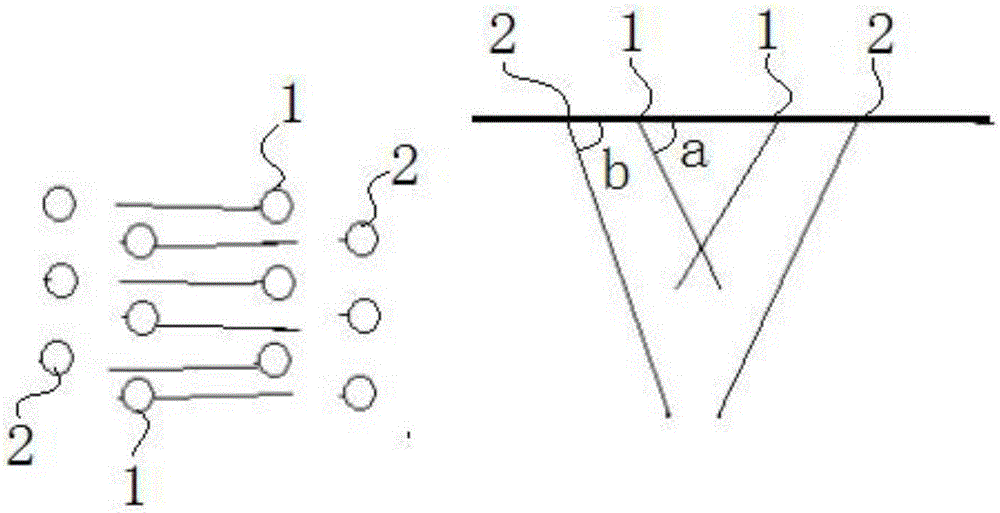

Intelligent carbon dioxide explosion technology method

ActiveCN106288988ALess regulationReduce use costBlasting cartridgesBlastingEngineeringArrangement number

The invention relates to an intelligent carbon dioxide explosion technology method, which comprises the following steps: a, explosion parameter design and calculation: comprising rock grade detection, carbon dioxide explosion pipe grade detection, hole arrangement number calculation, a hole arrangement manner, a pipe fixing manner, a fly pipe preventing manner, initiating network arrangement and safety alert distance calculation according to an explosion object; b, arrangement before explosion: comprising hole arrangement, hole drilling, formed hole inspecting, pipe blanking, pipe fixing, fly pipe preventing, wiring and safety alert; c, explosion and explosion effect inspection, wherein an initiating device in the explosion method is a carbon dioxide explosion pipe, two rows of inner drainage breaking-in holes are formed in the middle part of a tunnel cross-section, auxiliary holes and periphery holes are formed on the outer sides of the inner drainage breaking-in holes, and the inner drainage breaking-in holes are inclined holes inclined to a central line. According to the intelligent carbon dioxide explosion technology method provided by the invention, a corresponding-grade combined explosion pipe and explosion manner is used according to different tunnel cross-sections, and an ideal explosion effect is achieved.

Owner:BEIJING LONGDE SHIDAI TECH SERVICE

Stable ethylsilicate polymers and method of making the same

ActiveUS20160137841A1Reduce VOCsEliminates and reduces solventSemiconductor/solid-state device manufacturingVolatile organic compoundPolymer

Ethylsilicate polymers and a method of making, specifically ethylsilicate polymer binders with reduced levels of regulated volatile organic compounds (VOCs) for use in the coatings industry and casting industry, and more specifically to stable, fast cure ethylsilicate polymer binders with low levels of regulated VOCs.

Owner:SILBOND CORP

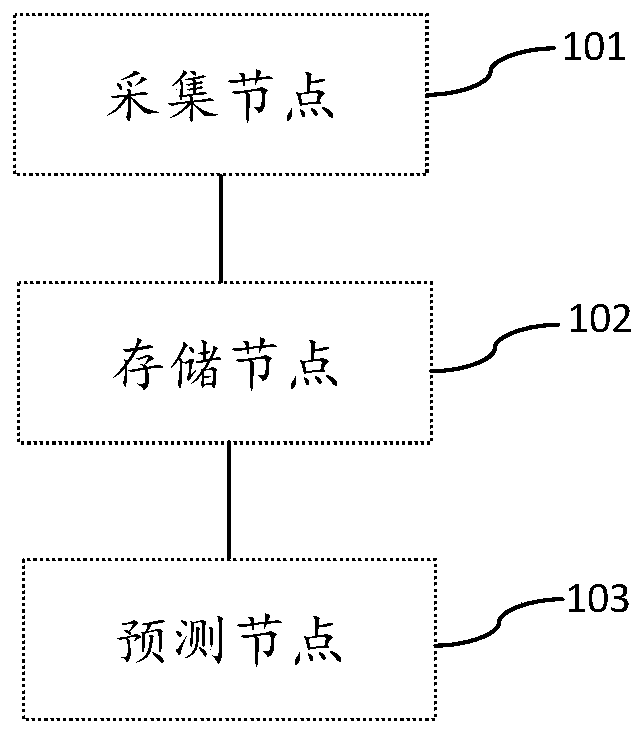

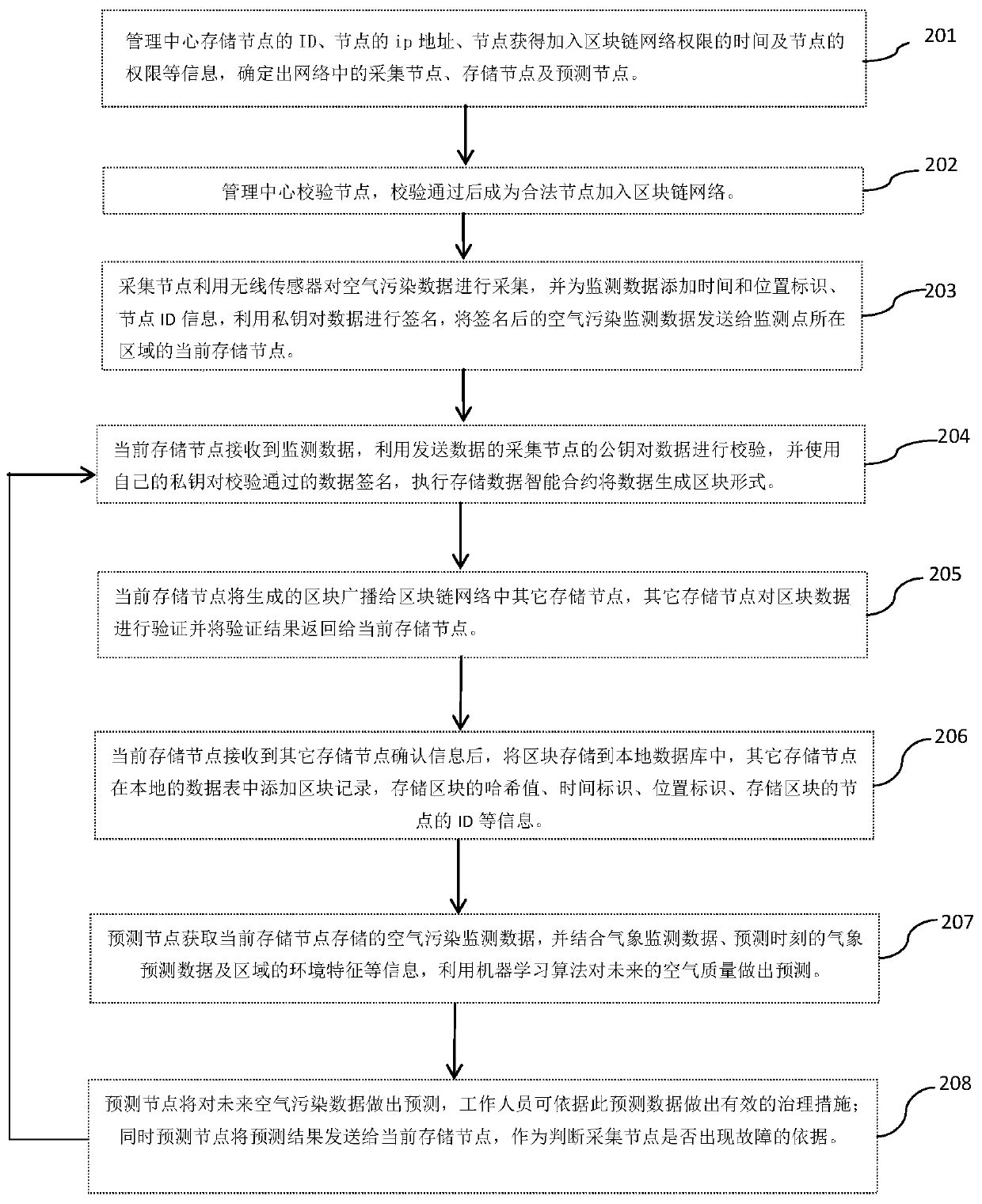

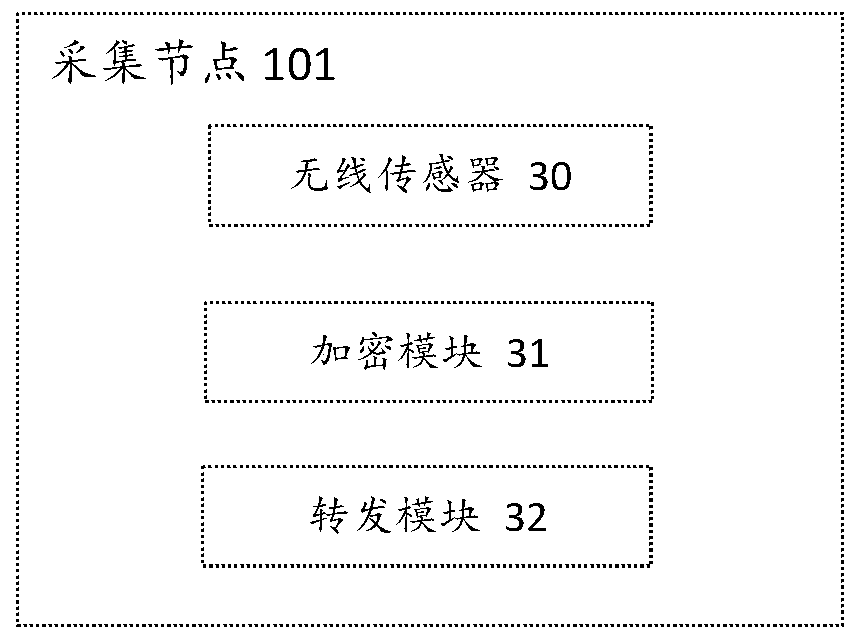

Air quality monitoring and predicting system and method

PendingCN111157682APrevent forgeryPrevent tamperingWeather condition predictionMaterial analysisMonitoring sitePrediction system

The invention provides an air quality monitoring and prediction system and method, and the system comprises a collection node, a storage node, and a prediction node, and the collection node, the storage node, and the prediction node form a blockchain network. The collection nodes are used for acquiring air pollution monitoring data and sending the monitoring data to the storage nodes in the area where the monitoring points are located. After receiving the monitoring data, the storage node verifies the data, generates a block from the data after passing the verification, and broadcasts the block in the system. Other storage nodes verify the blocks, and after the blocks pass the verification, the current storage node receives verification information of the other storage nodes and stores theblocks locally according to a time sequence to form a chain structure. Other storage nodes store the hash value, the time identifier and the position identifier of the block and the information of the storage node of the block locally for monitoring and querying the monitoring data, and the prediction nodes acquire monitoring data and predict future air quality in combination with a machine learning algorithm.

Owner:SHANGHAI INST OF TECH

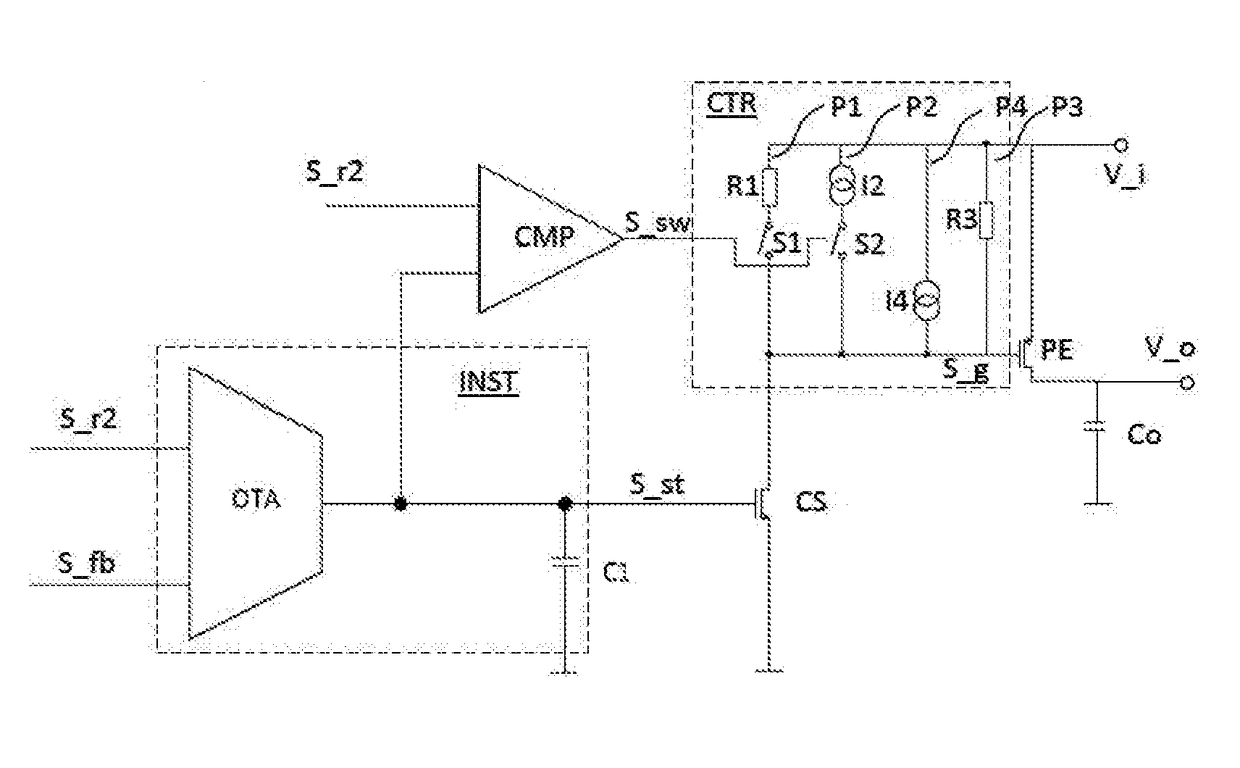

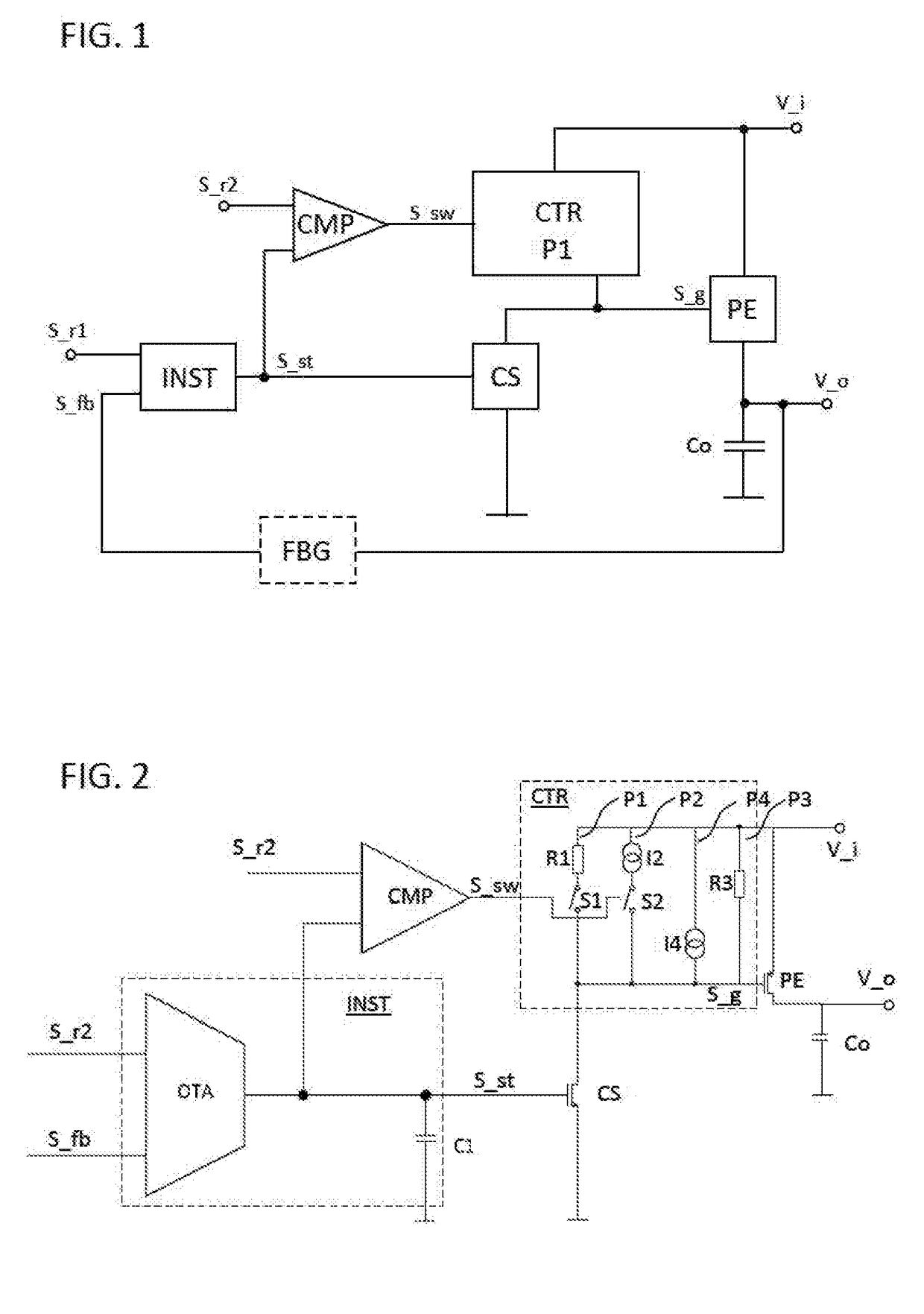

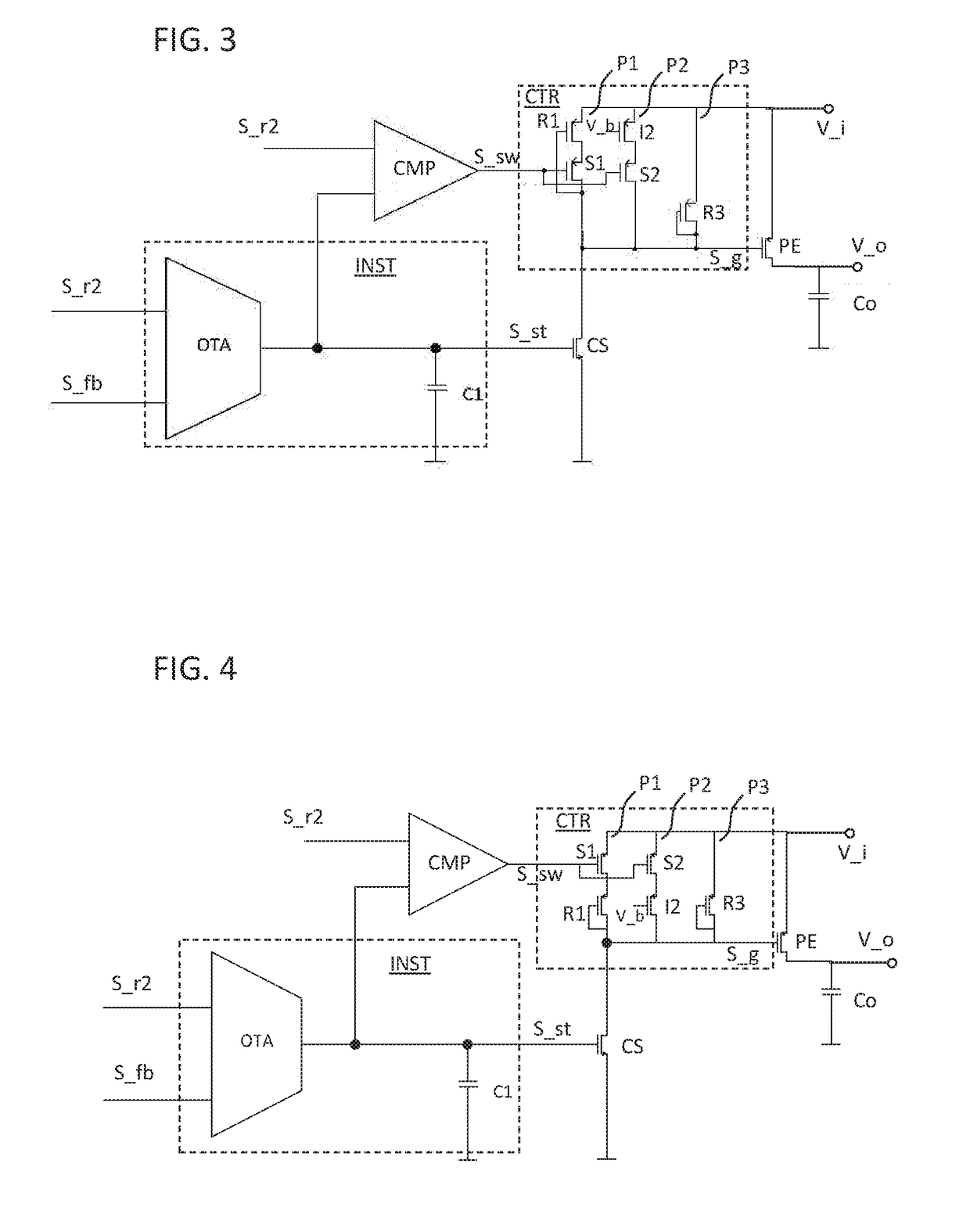

Low dropout regulator circuit and method for controlling a voltage of a low dropout regulator circuit

ActiveUS20180017984A1Total current dropLess regulationElectric variable regulationSwitching signalEngineering

An LDO circuit comprises a pass element, and input stage, a current sink, a comparator and a control circuit. The pass element is configured to generate an output voltage depending on a gate signal and on an input voltage. The input stage is configured to generate a steering signal based on a deviation between a first reference signal and a feedback signal, the feedback signal being based on the output voltage. The current sink is controlled by a steering signal and connected between the gate control terminal and a reference terminal. The comparator is configured to compare the steering signal to a second reference signal and to generate a switch signal based on the comparison. The control circuit comprises a first current path and is configured to suspend, in particular temporarily suspend, the first current path depending on the switch signal.

Owner:AMS AG

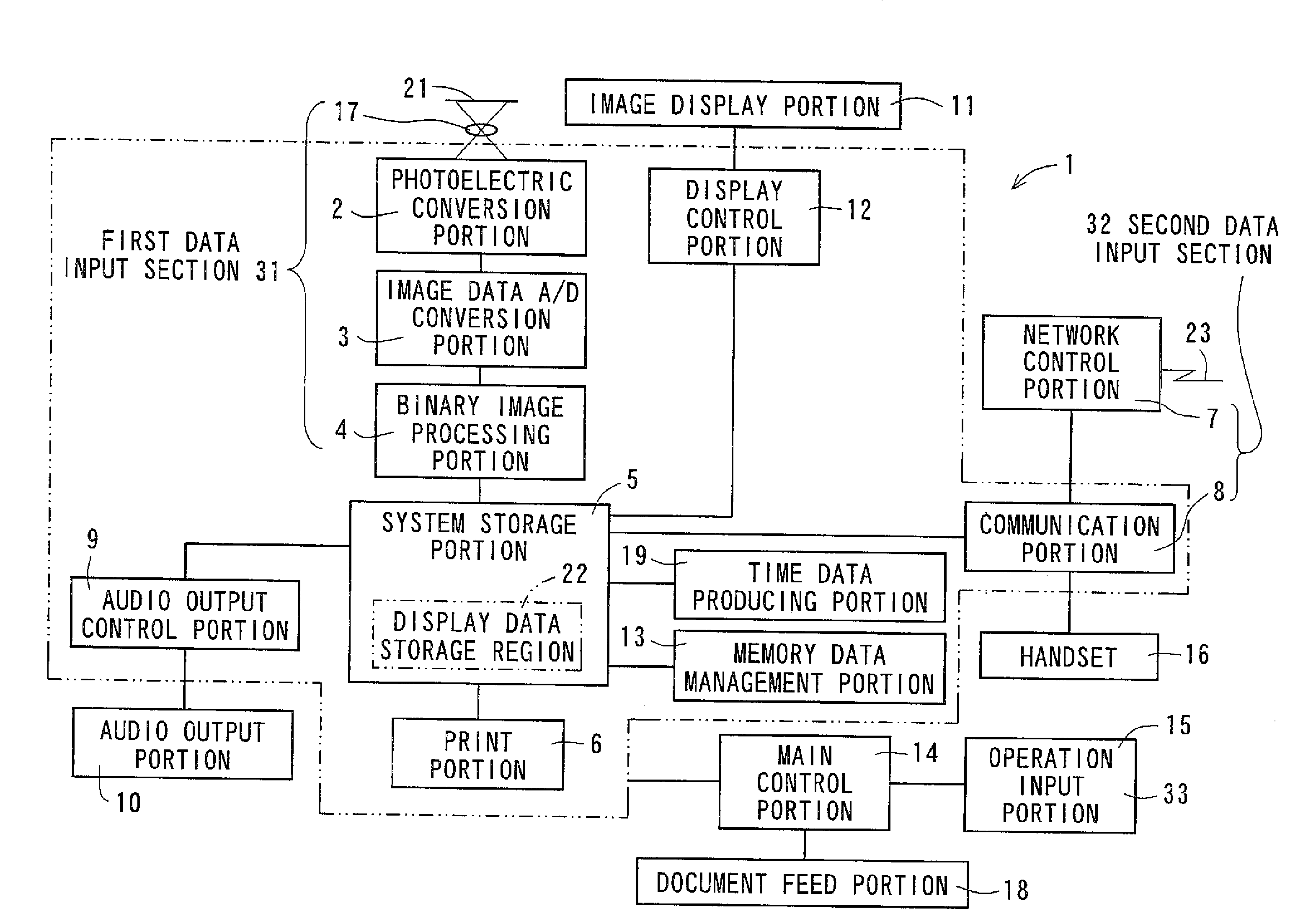

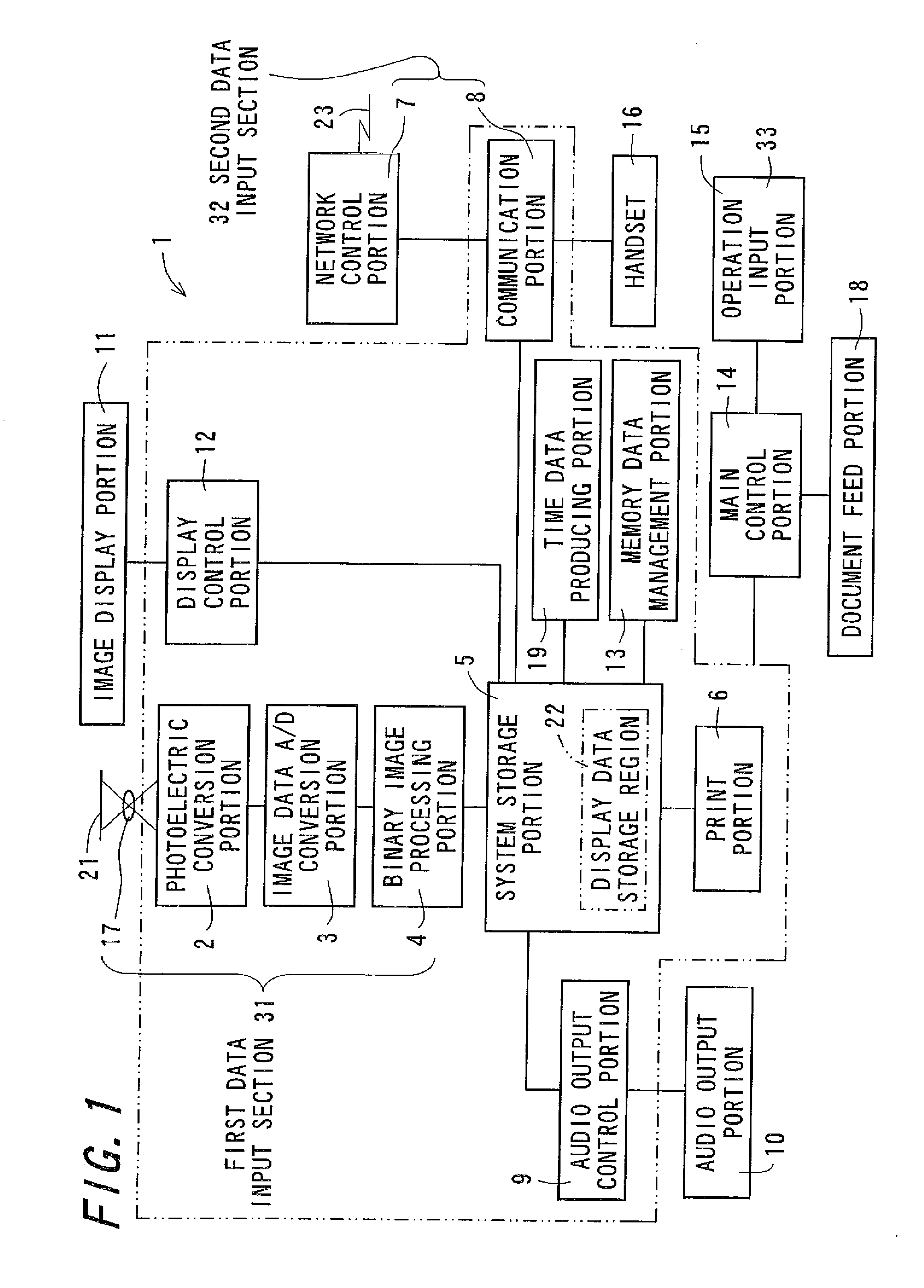

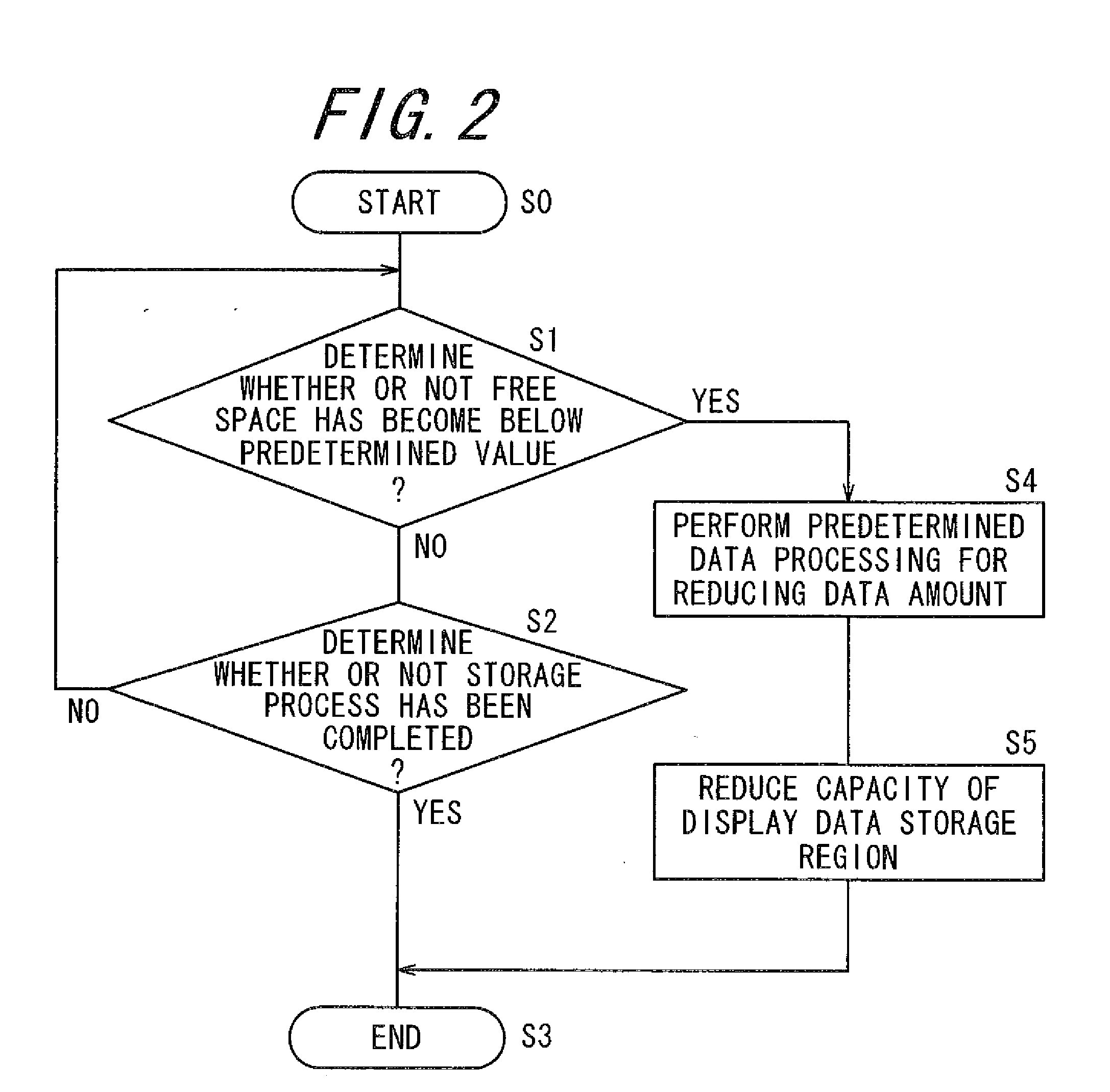

Information Processing Apparatus

InactiveUS20090167781A1Reduce decreaseLess regulationCathode-ray tube indicatorsStill video camerasInformation processingComputer graphics (images)

An information processing apparatus capable of storing more data to a remaining region of a storage portion excluding a frame buffer region while displaying an image by an image display portion, is provided. When free space of a system storage portion has become below a predetermined value, a reduction in number of gray scales of the image results in a reduction in a data amount of image data stored in a display data storage region and a reduction in capacity of the display data storage region. This makes it possible to reduce the data amount of image data and increase the free space of the system storage portion while keeping the size of the image displayed by an image display portion.

Owner:SHARP KK

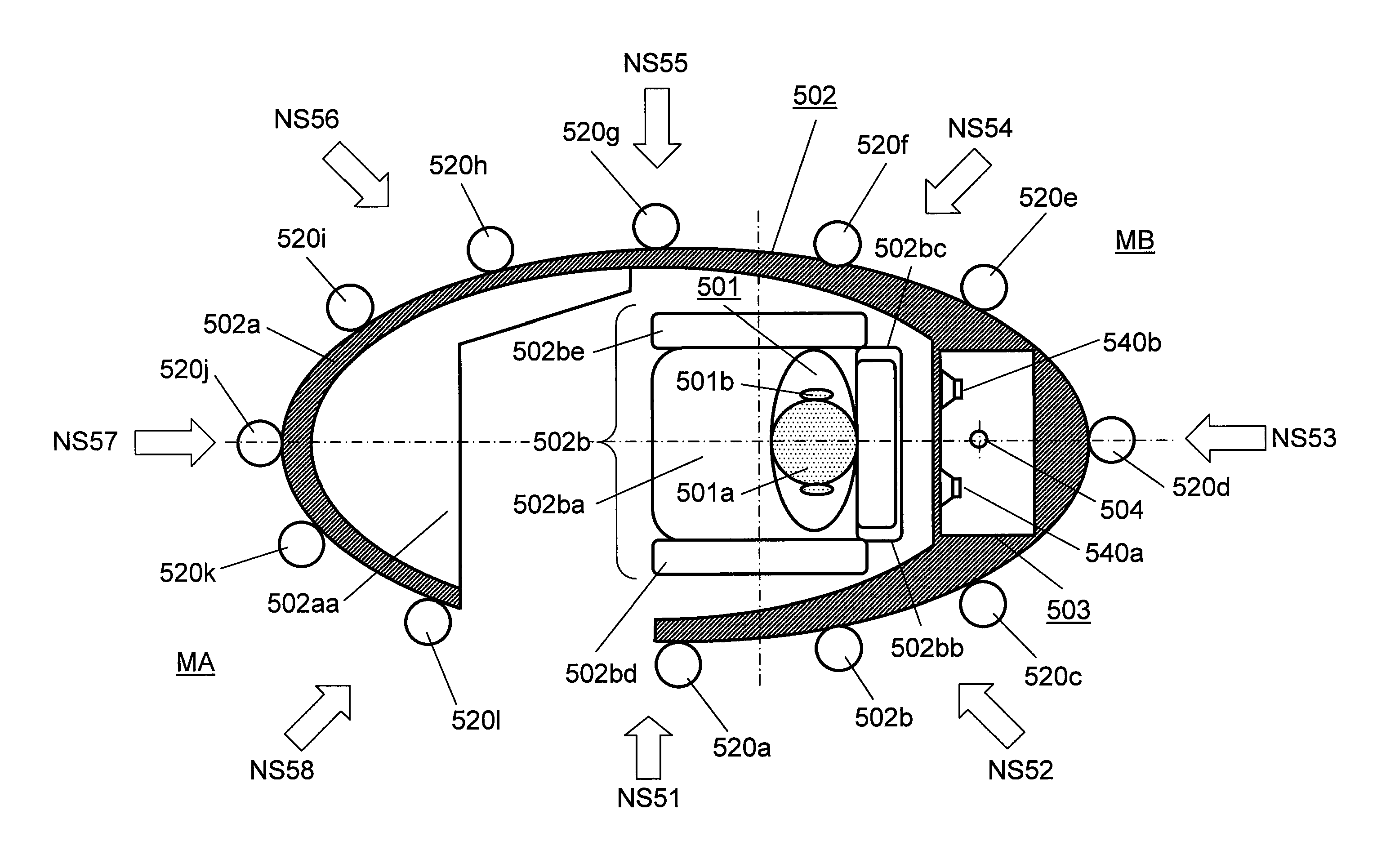

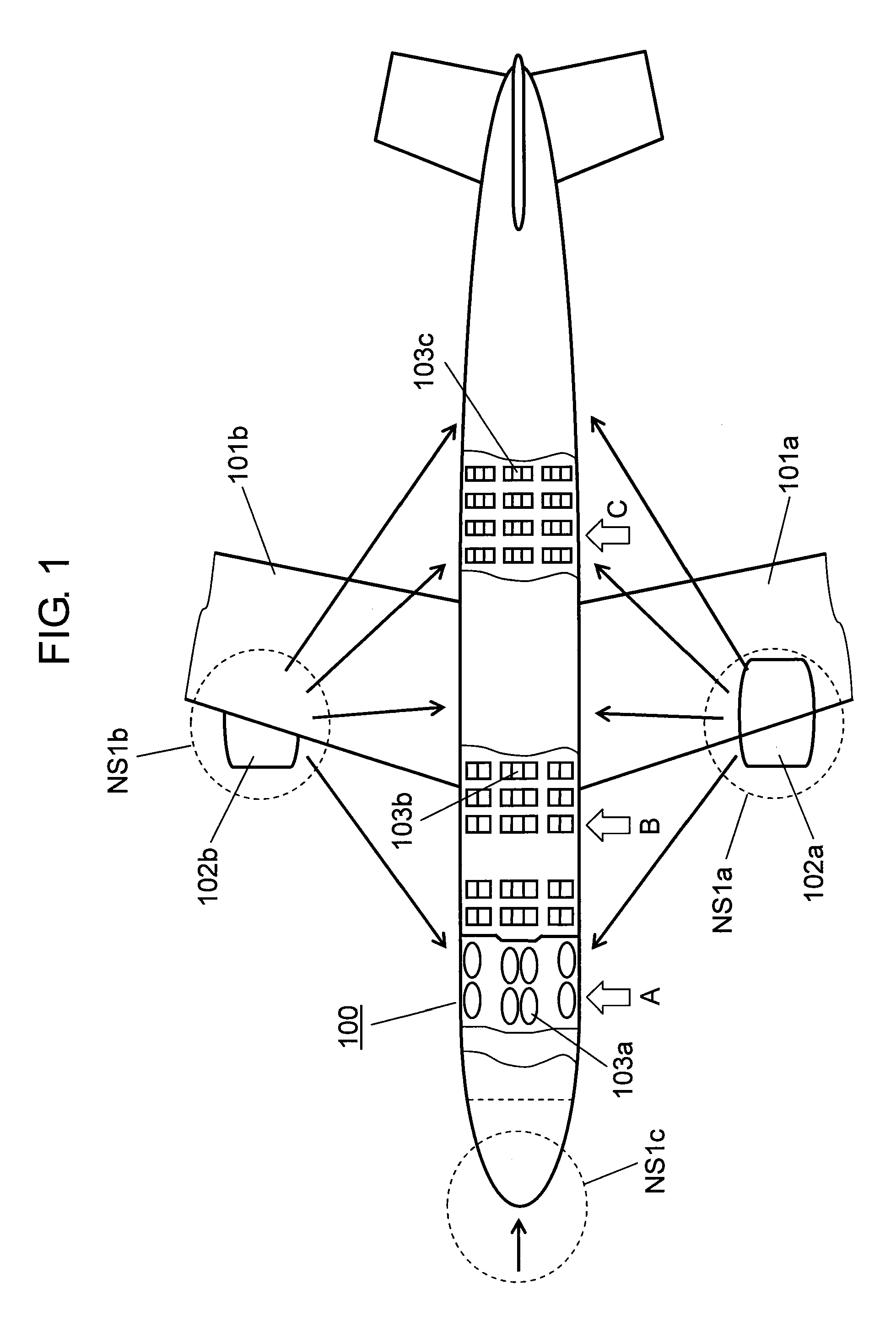

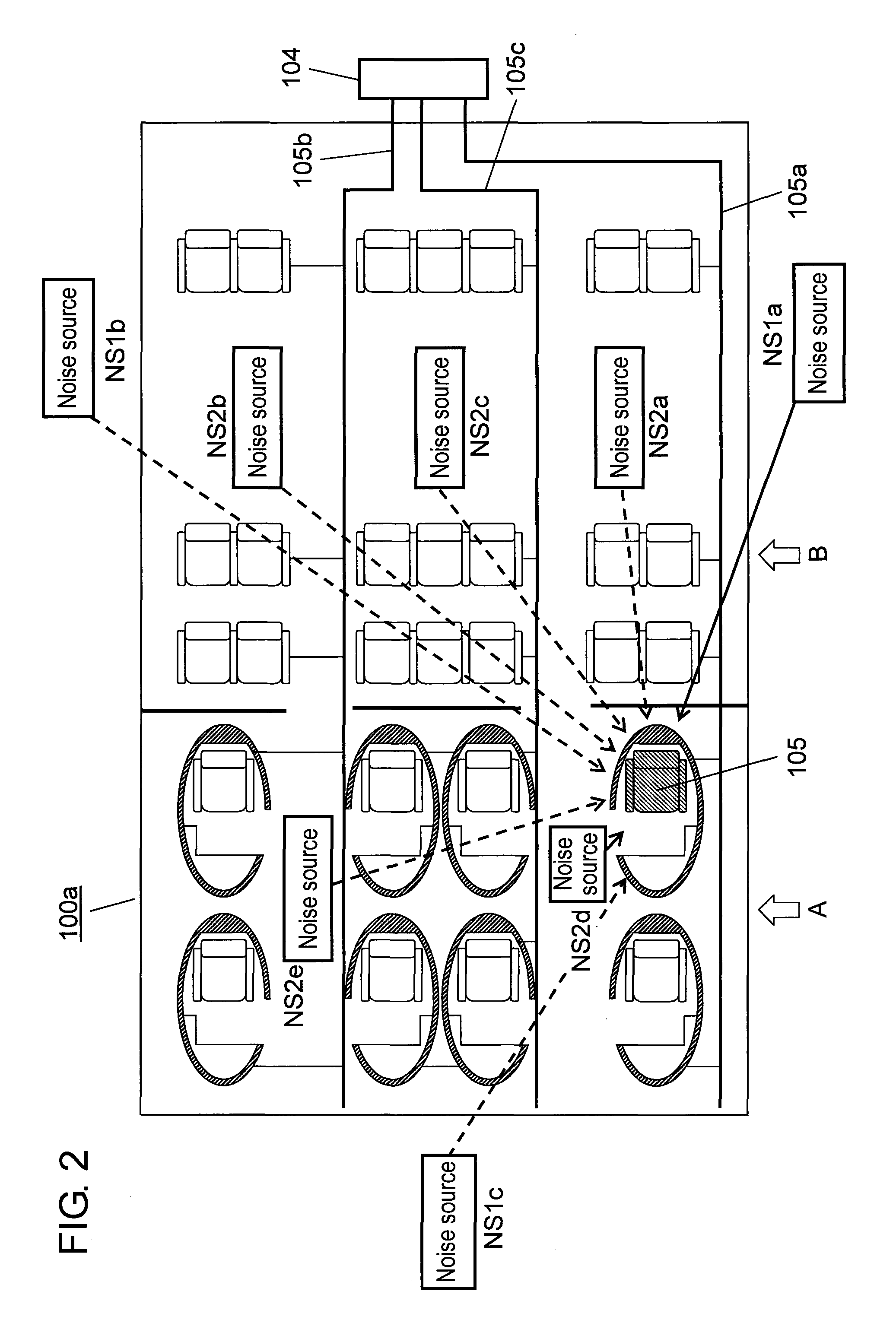

Noise reduction device

ActiveUS9090332B2Increase volumeHigh in capacity of reproducing low-frequency soundVehicle seatsEar treatmentNoise controlEngineering

A noise reduction device, including a microphone for detecting noise, a noise controller for reversing the phase of noise detected by the microphone based on information outputted from the microphone, and a speaker for outputting sound based on information outputted from the noise controller, is arranged at a seat surrounded by a shell portion having a cavity, wherein a speaker is disposed in the cavity of the shell portion.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

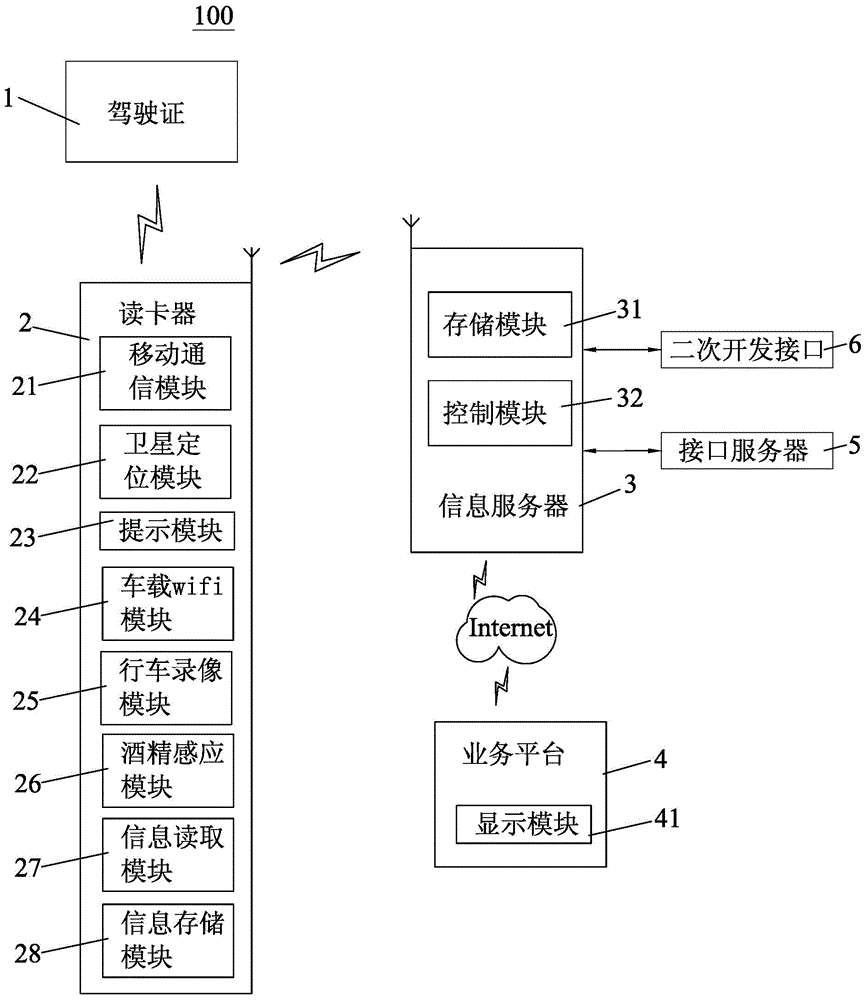

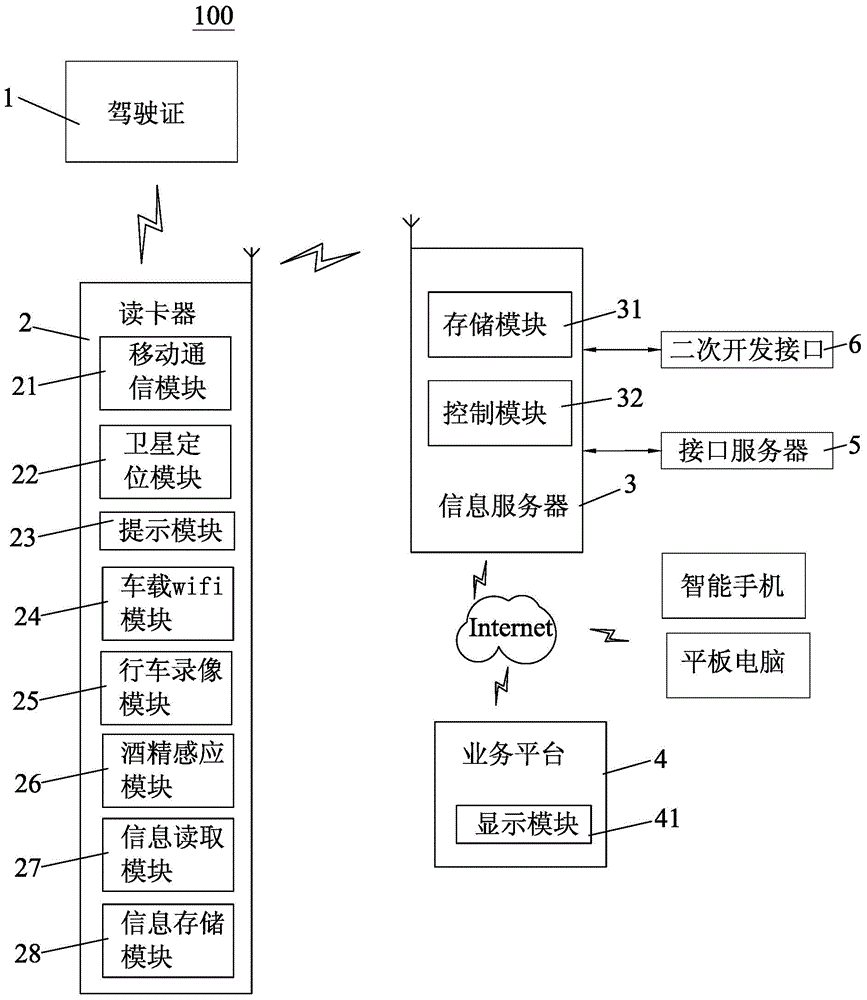

Car driving license intelligent management system

InactiveCN104134114ARealize network intelligent monitoringEffective supervisionSensing record carriersResourcesTime conditionDriver/operator

The invention discloses a car driving license intelligent management system, which comprises a driving license, a card reader, an information server and a service platform, wherein a contact type IC (Integrated Circuit) or an induction type IC is built in the driving license, and driver information is stored in the driving license; the card reader is arranged in a proper position in a car and is used for reading and analyzing the driving license information; if the reading passes, the car is allowed to start, if the reading does not pass, the car is not allowed to start, and the car information and the driving license information are sent to the information server and a car owner; the information server takes charge of collecting and storing the car information and the driving license information, and provides a function of inquiring the car information and the driving license information for the outside; the service platform is connected with the information server, and sends real-time conditions of the car to the car owner or gives an alarm; and the car owner or the traffic control department can send an instruction to the card reader through the service platform, and the card reader receives and executes the instruction. The car driving license intelligent management system belongs to a networking intelligent management system capable of realizing the trinity of the traffic control department, the car owner and the driver.

Owner:钟华

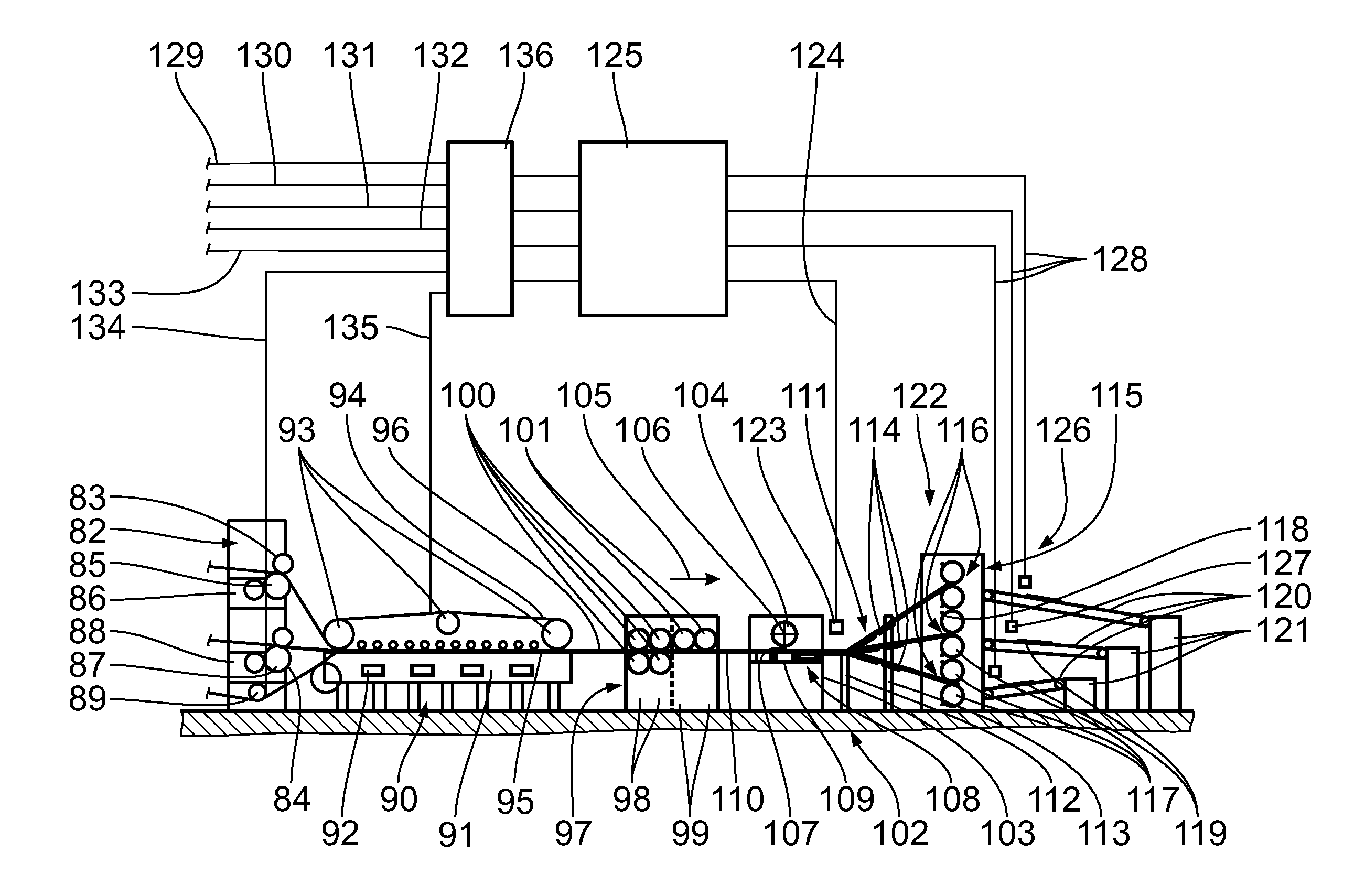

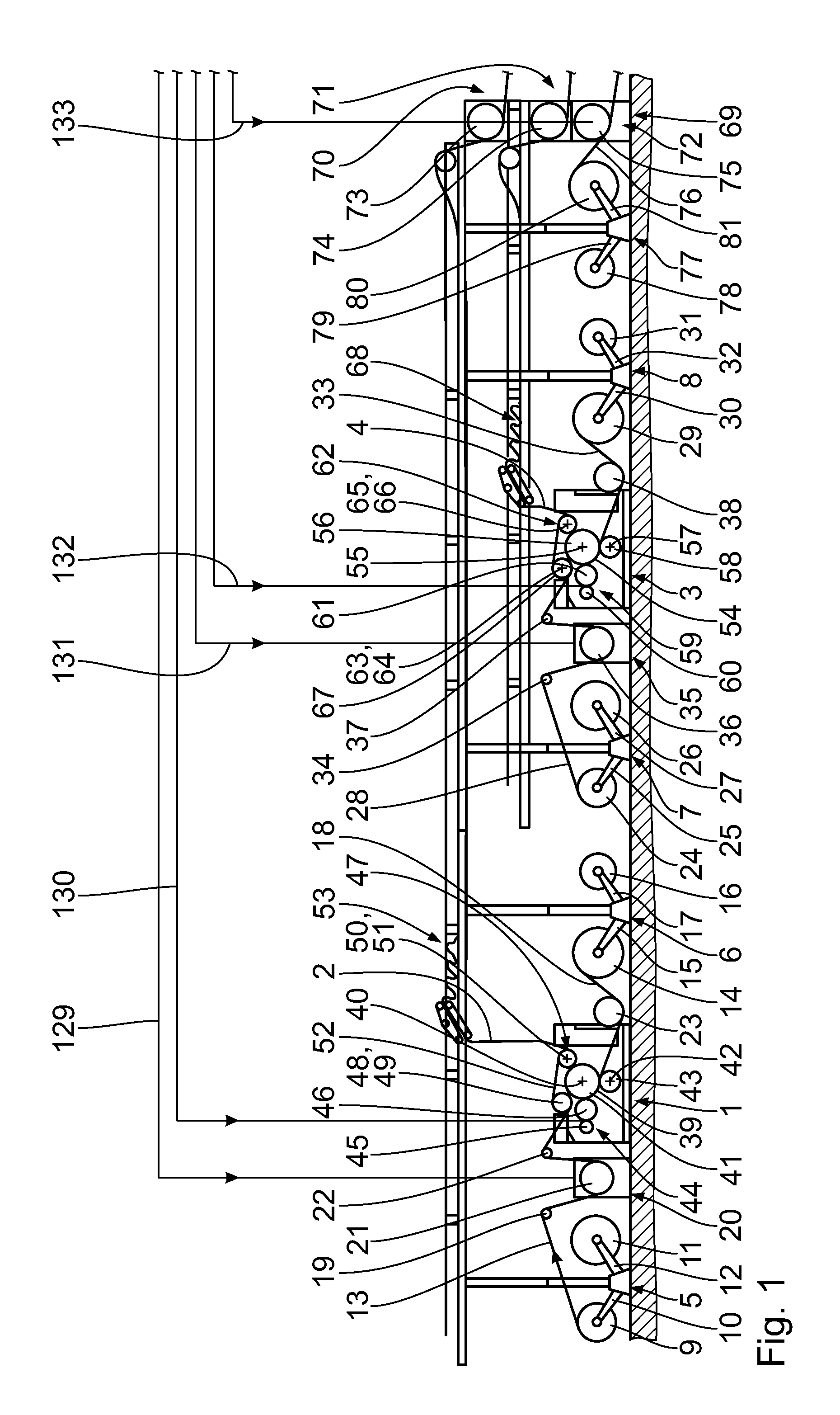

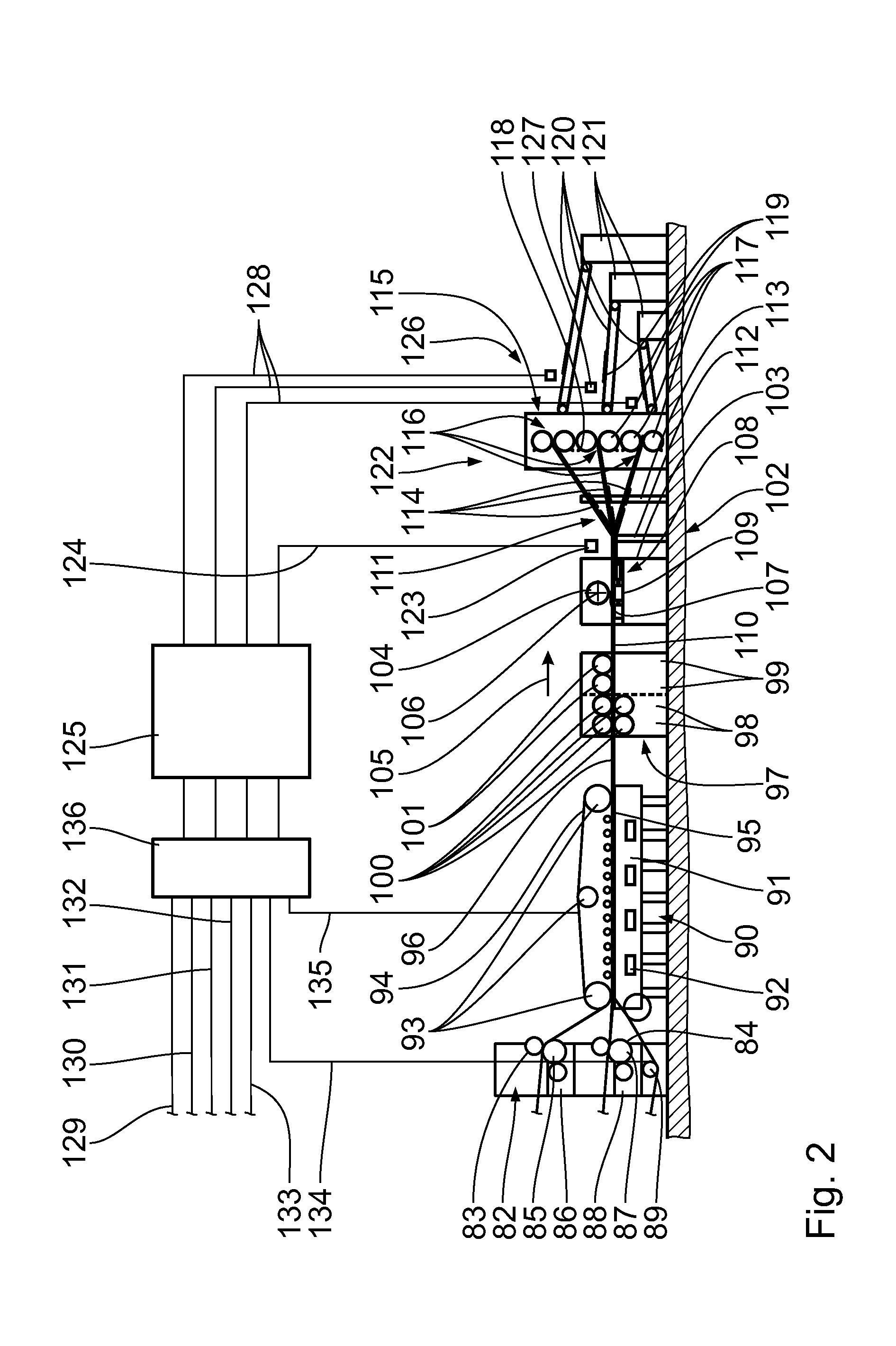

Corrugated cardboard installation

InactiveUS20150224733A1Overcomes drawbackLess regulationMechanical working/deformationLamination ancillary operationsInformation processingCardboard

The invention relates to a corrugated cardboard installation. The corrugated cardboard installation comprises a first material supply device for dispensing a first material web, a second material supply device for dispensing a second material web, a first corrugated cardboard production assembly for producing a first corrugated cardboard web from the first material web and the second material web, a cross-cutting assembly for producing corrugated cardboard sheets from the first corrugated cardboard web, a warp detection assembly for detecting the warp of corrugated cardboard sheets or partial corrugated cardboard webs, an information processing device receiving warp information from the warp detection assembly relating to the corrugated cardboard sheets or the partial corrugated cardboard webs, and at least one corrugated cardboard sheet warp influencing assembly (actuable depending on signals received from the information processing device for influencing the warp of the corrugated cardboard sheets.

Owner:BHS CORRUGATED MASCHEN & ANLAGENBAU

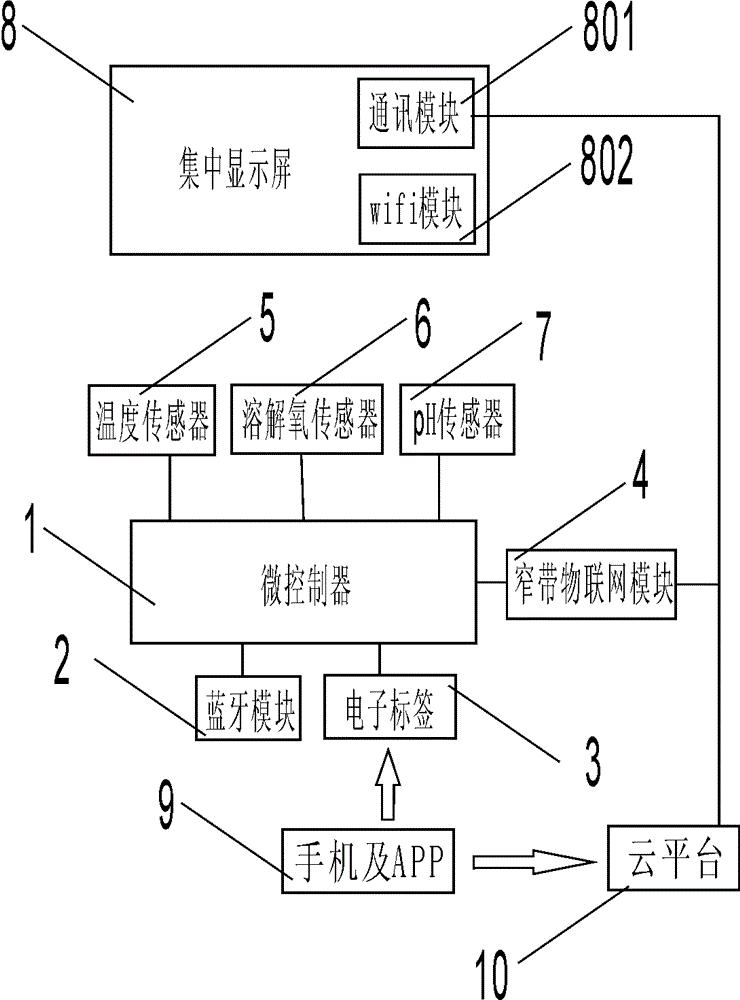

Aquaculture pond inspection sign-in and water quality detection device and system and realization method

PendingCN106657404AReduce the chance of occurrenceReduce lossesRegistering/indicating time of eventsTesting waterMicrocontrollerOxygen sensor

The invention provides an aquaculture pond inspection sign-in and water quality detection device and system and a realization method. The device and system comprises a microcontroller, a Bluetooth module, an electronic tag, a narrowband Internet of things module, a temperature sensor, a dissolved oxygen sensor, a pH sensor, a centralized display screen, a mobile phone and APP and a cloud platform. According to the system, through combination of periodic online detection for water quality and periodic pond inspection of aquaculture workers, the occurrence probability of an aquaculture event is reduced; worker confirmation is carried out by holding the mobile phone and APP to inspection points; the condition that the pond inspection workers slack off is effectively avoided; and dynamic pond inspection paths, pond inspection time and related monitoring information are automatically recorded, thereby facilitating trace confirmation after the event. According to the device, the system and the method, the pond inspection efficiency can be improved; the supervision force of a boss for the workers can be reduced; the boss does not need to supervise the workers all the time; the technical realization is convenient; and the market prospect is wide.

Owner:FUJIAN QIANGMIN INFORMATION TECH CO LTD

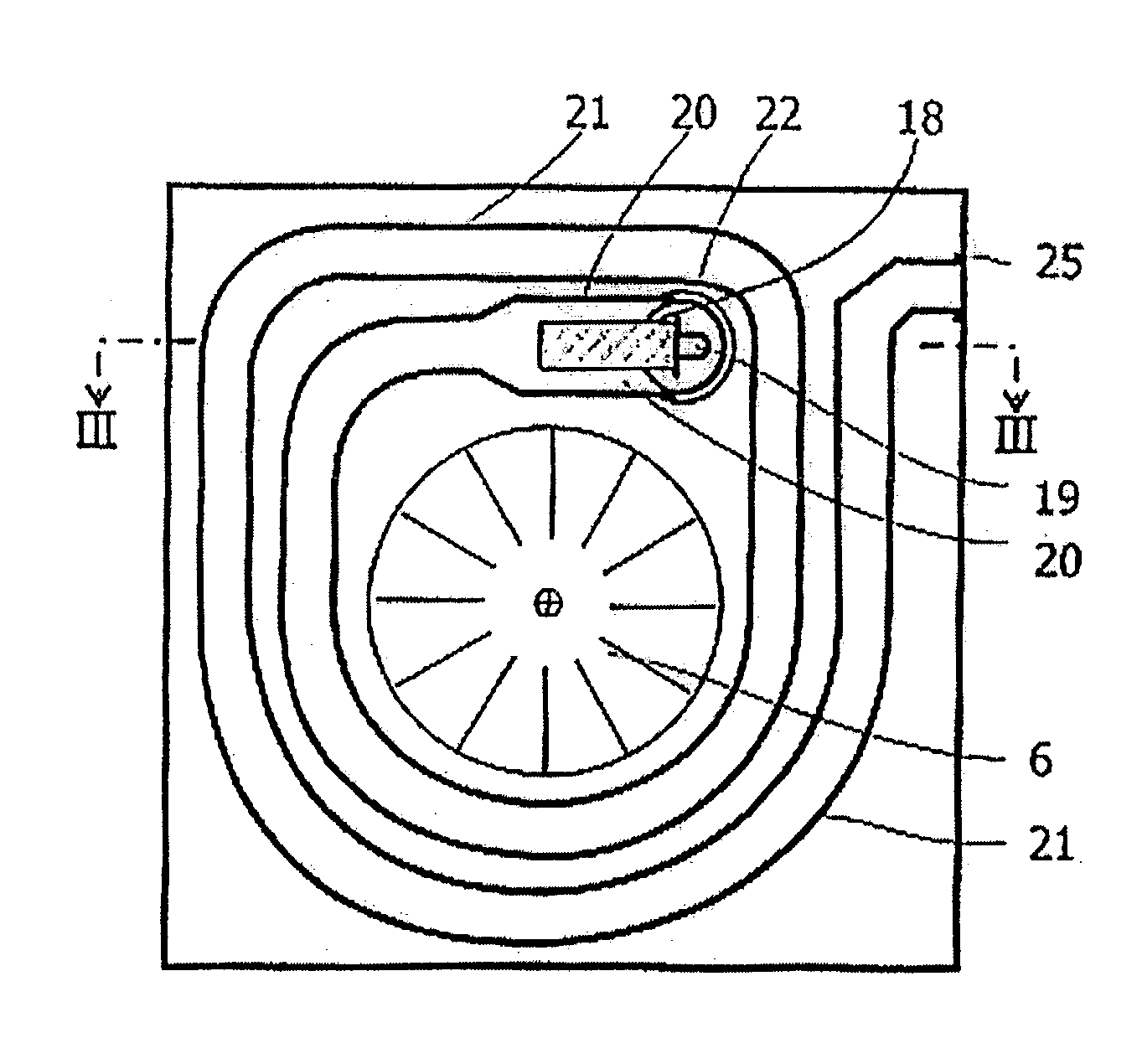

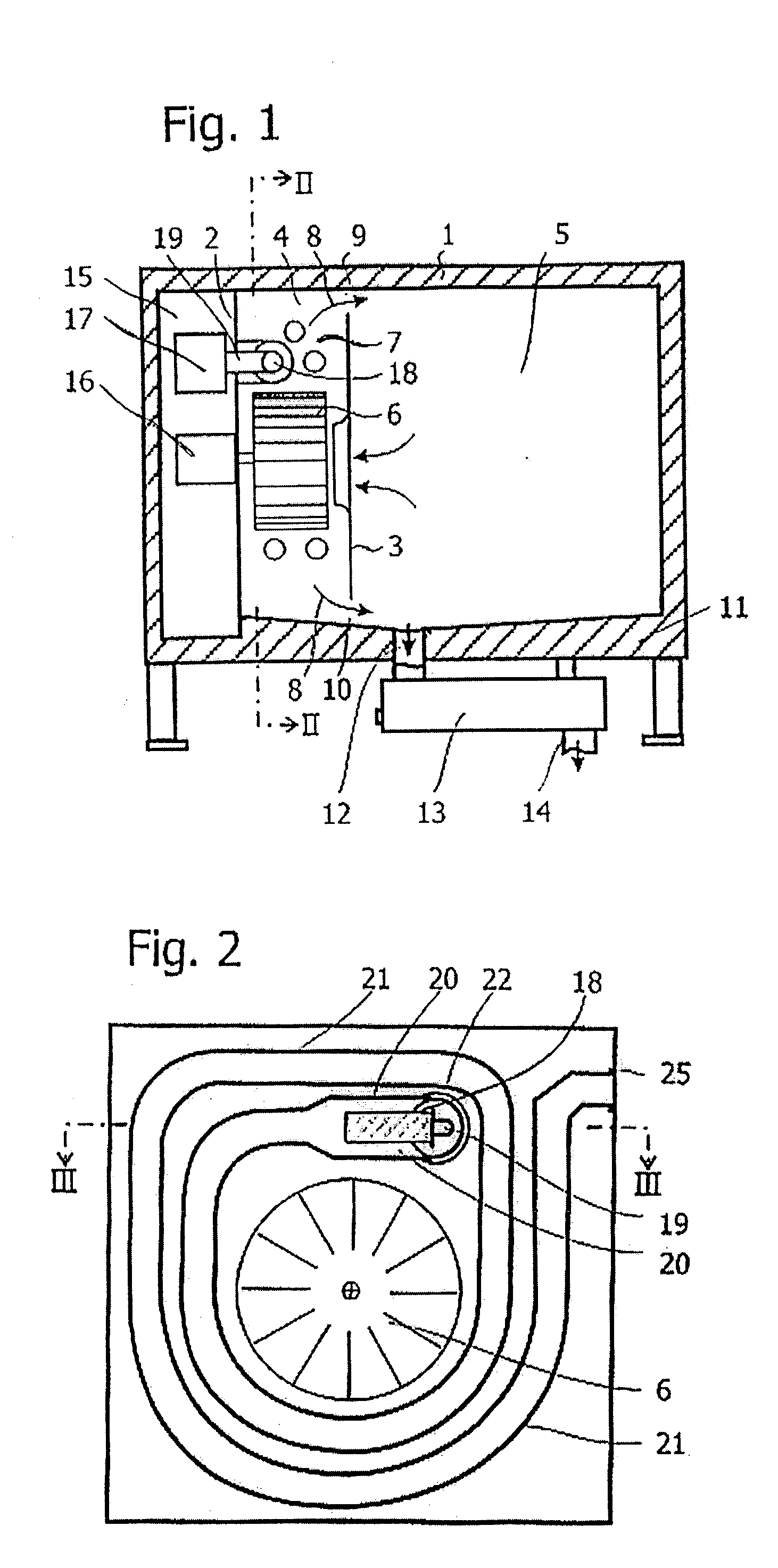

Heat exchanger device

InactiveUS20040255925A1Inhibit productionDamp productionAir-treating devicesDomestic stoves or rangesCombustion chamberCombustor

A heat exchanger device for a cooking appliance includes a burner arranged in a combustion chamber. The burner is connected by a feeding pipe to a mixing device which prepares a gas / air mixture necessary for the combustion and feeds it to the burner. The mixing device is connected to the burner in a gastight manner additional air is prevented from flowing in. The combustion chamber is formed by an enlargement of a heat exchanger pipe which, starting from the combustion chamber, spirally surrounds the fan wheel which provides forced circulation of the treatment medium. The heat exchanger pipe is also wound around the combustion chamber.

Owner:CONVOTHERM ELEKTROGERATE

Integrated fuel catalyst monitor

ActiveUS8756915B2Reduce capacityLow efficiencyElectrical controlInternal combustion piston enginesProcess engineeringOxygen

Owner:FORD GLOBAL TECH LLC

Apparatus and method for venting gas from a liquid

ActiveCN104168933AAvoid contactExtend your lifeDialysis systemsMedical devicesSemipermeable membraneEngineering

The present invention relates to an apparatus and method for venting a gas from a liquid, which are applicable to a wide variety of medical liquid delivery systems. The apparatus includes level detectors, a clamp, and a control apparatus operably connected to the level detectors and the clamp. The method includes detecting whether liquid or gas is present at the level detectors, and opening and closing a clamp to vent gas. The present invention also relates to an apparatus and method for controlling pressure differential across a semipermeable membrane by using a pressure sensor, a gas source, a valve, and a membrane.

Owner:FRESENIUS MEDICAL CARE HLDG INC

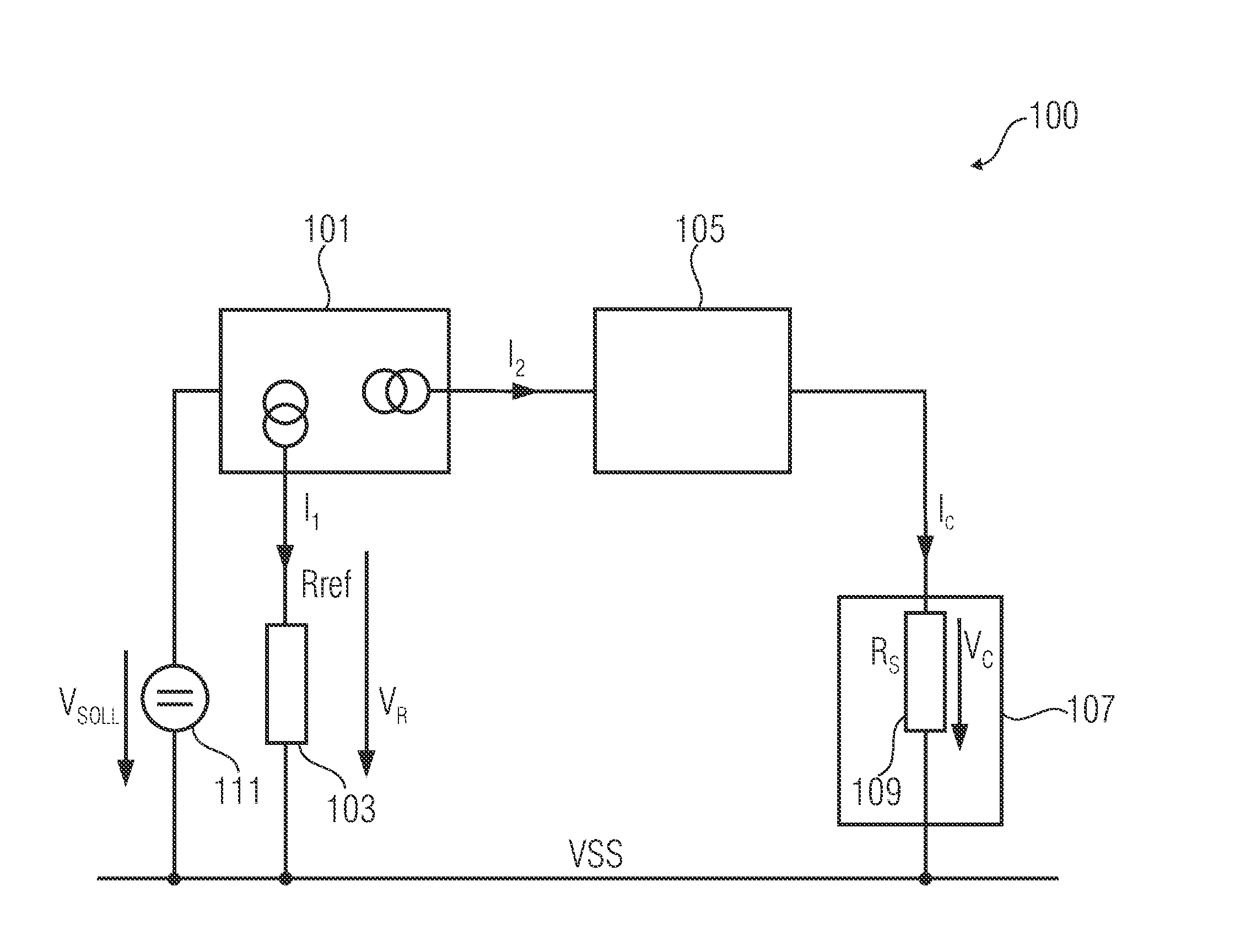

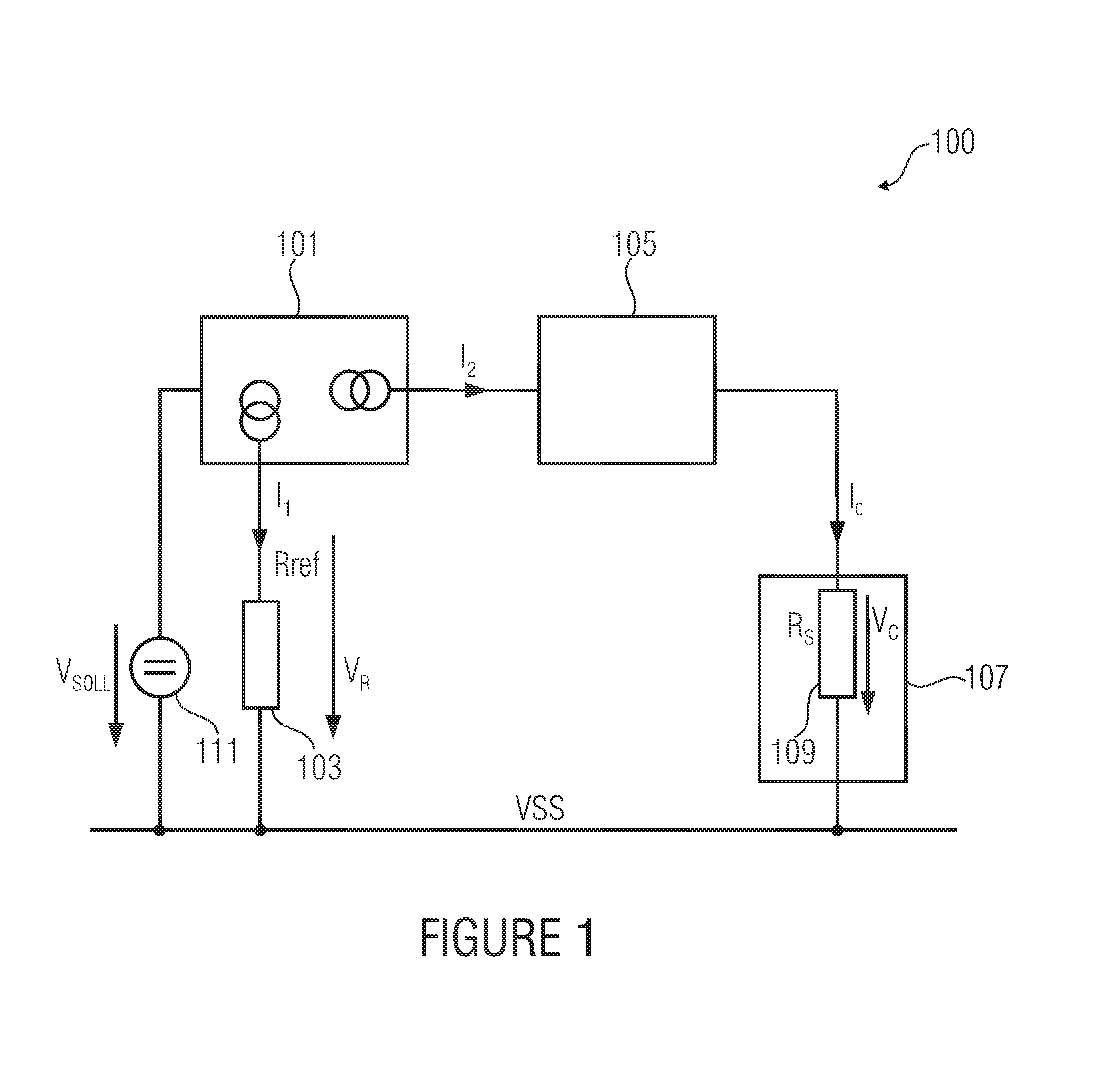

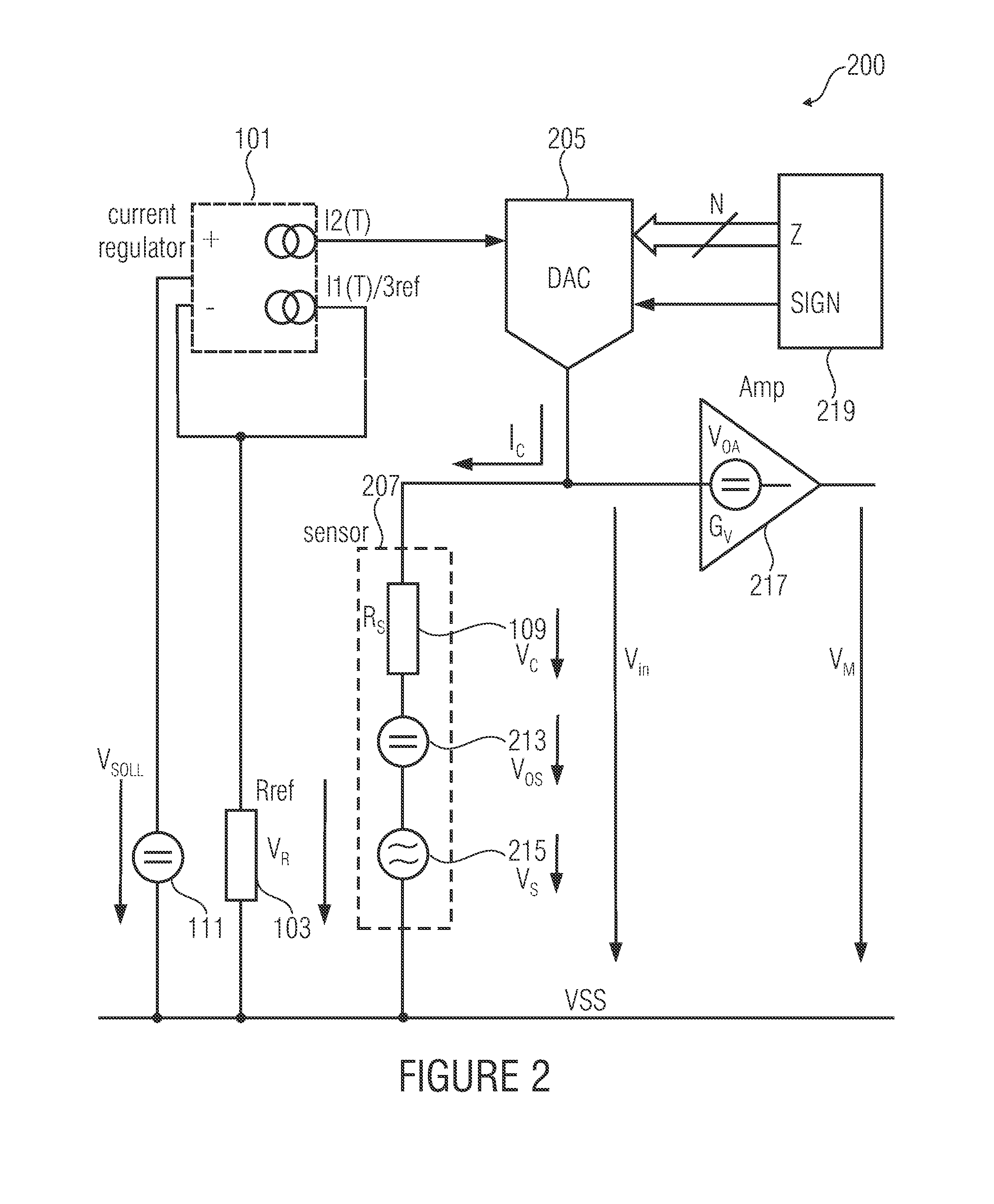

Sensor arrangement and method

ActiveUS20140055146A1Reduce offsetAccurate settingElectrical measurementsMitigation of undesired influencesElectricityElectrical resistance and conductance

A sensor arrangement has a current regulator, a reference resistance a feed current scaler and a sensor element having an internal resistance, the internal resistance of the sensor element and the reference resistance having a predetermined ratio. The current regulator is implemented to provide a reference current by the reference resistance and to change the reference current in response to an interference influence-conditioned change of the reference resistance such that the voltage decreasing across the reference resistance remains in a predetermined range around an applied set voltage. The current regulator is implemented to provide a feed current to the feed current scaler and to change a magnitude of the feed current depending on a magnitude of the reference current. The feed current scaler is implemented to feed a scaled feed current into the sensor element to scale a voltage according to the scaling of the feed current.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

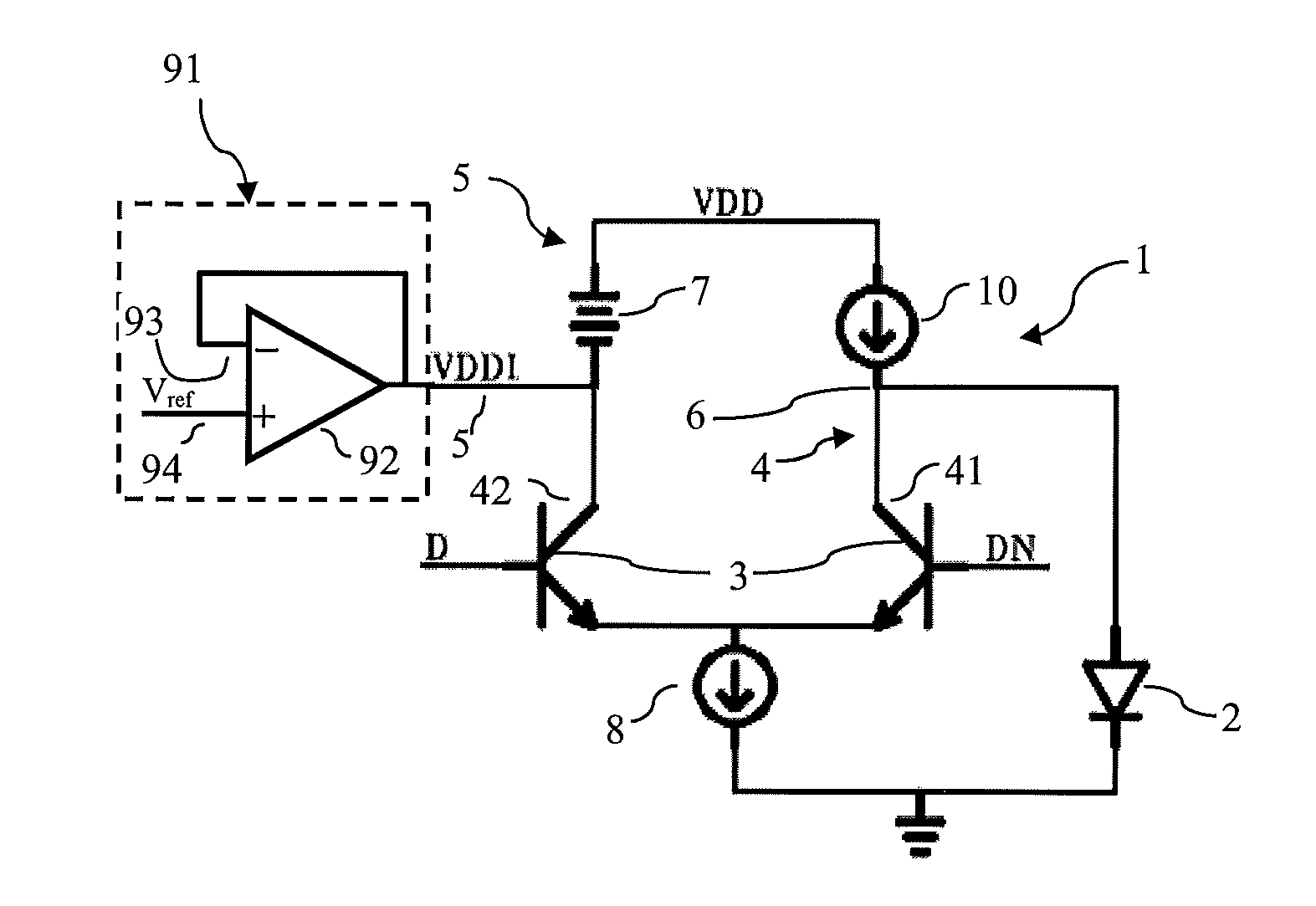

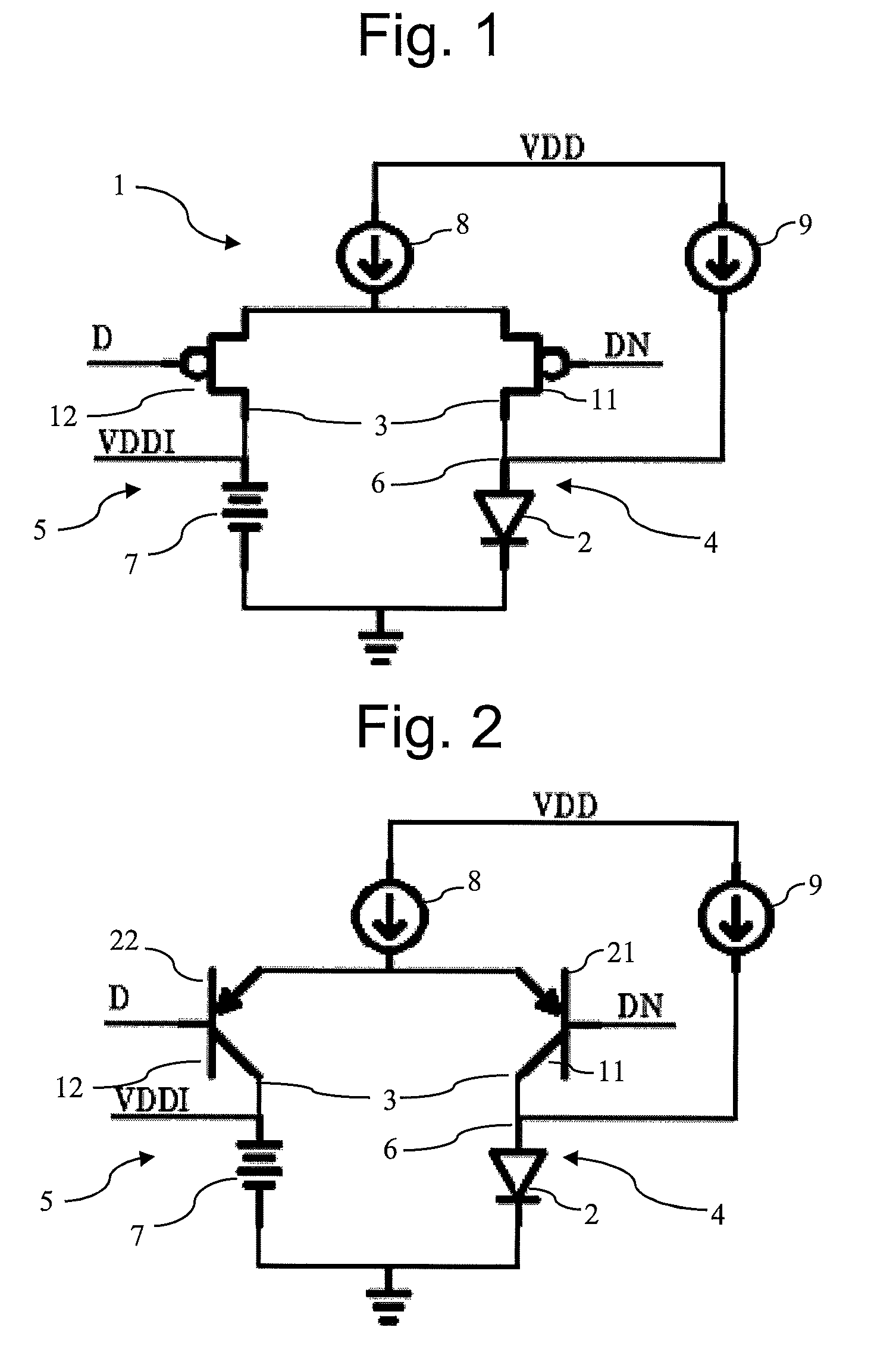

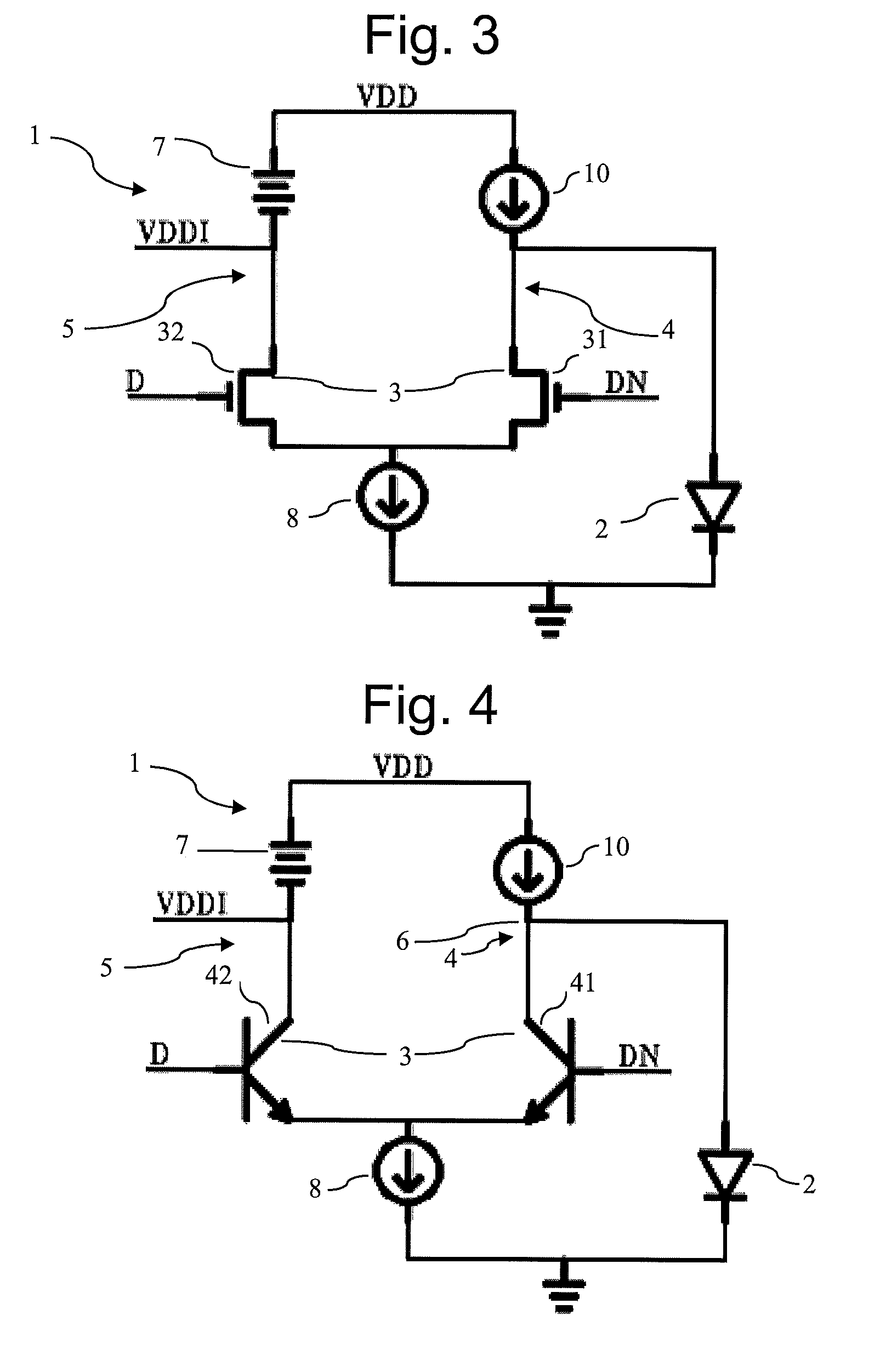

Low power drive circuit

ActiveUS8228962B2Easy to integrateLong lastingLaser detailsElectroluminescent light sourcesDriver circuitCurrent consumption

The invention relates to an integrated driver circuit suitable for driving a light emitter with a signal current I(time) based on a received signal said circuit comprising a differential pair of transistors having a first transistor and a second transistor each respectively forming part of a first branch and a second branch, said first branch comprises a node suitable for connecting to said light emitter and / or said first branch comprises said light emitter, wherein said second branch comprise at least one charge storage device. This charge storage device may be arranged to collect current otherwise wasted in the process of driving the light emitter. This current may be utilized to drive circuitry thereby reduce current consumption.

Owner:NVIDIA DENMARK APS

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7435265B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

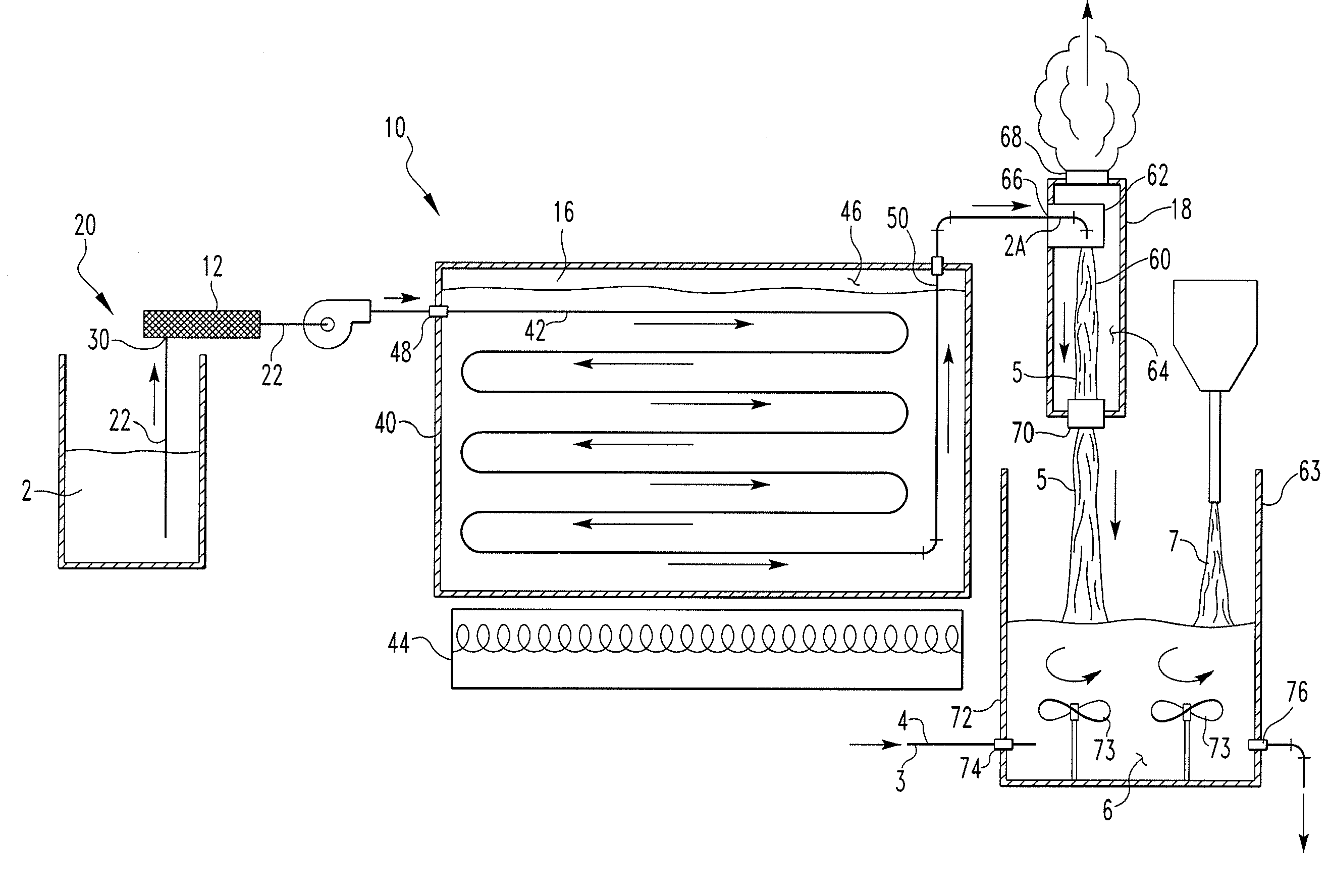

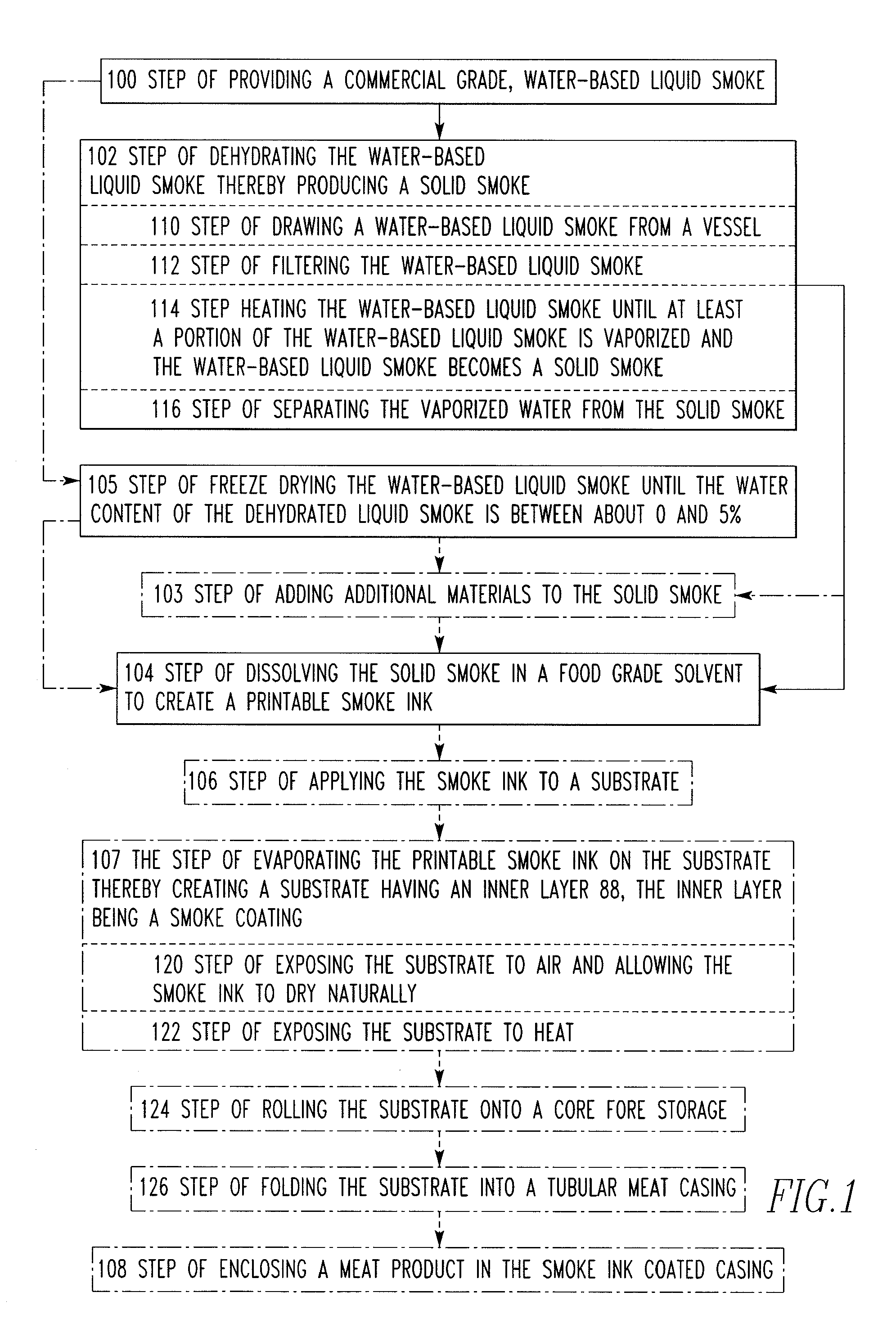

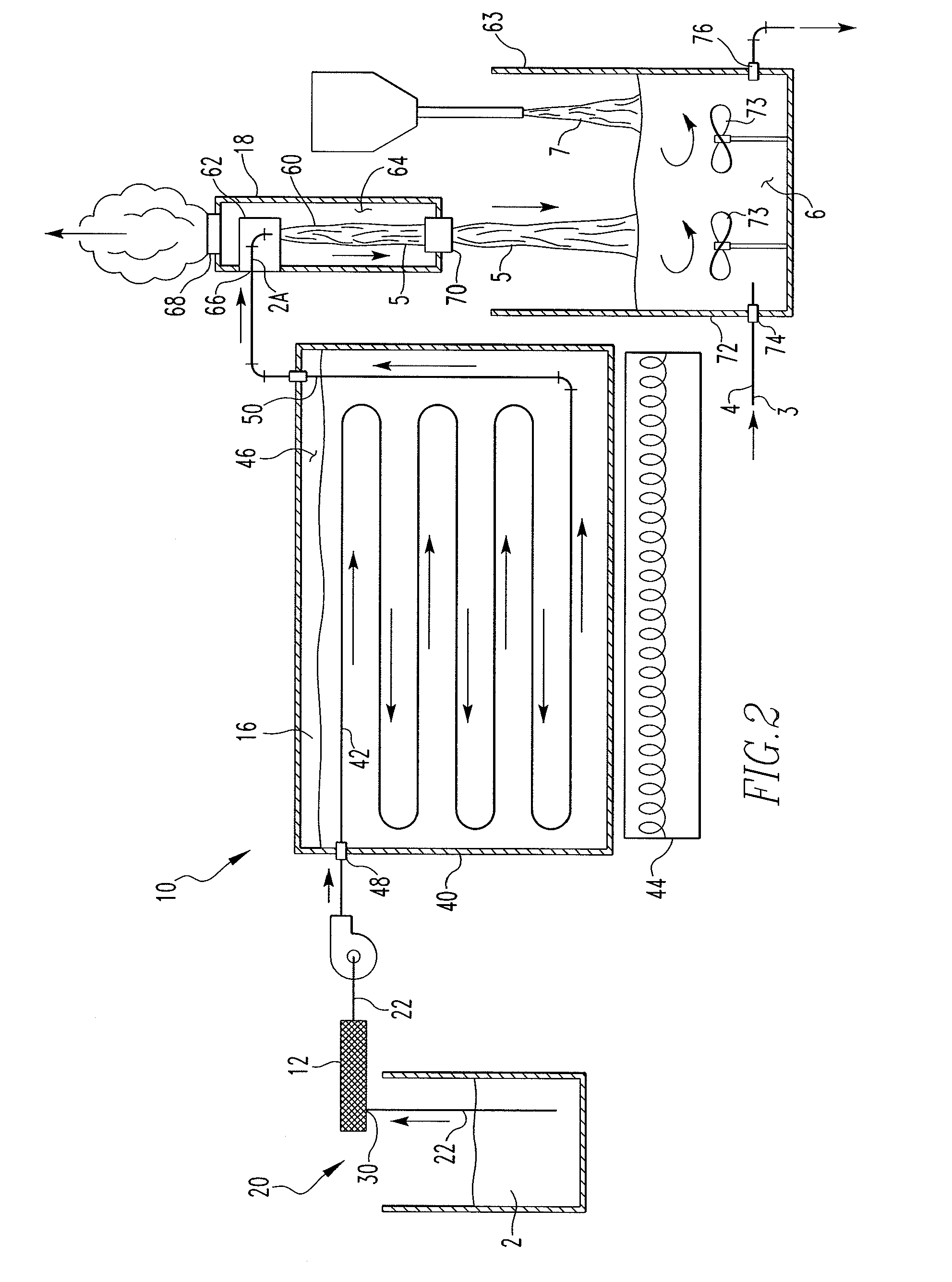

Smoke ink and method of manufacture

InactiveUS20120093984A1Reduce moistureGood colorContainers for flexible articlesMeat/fish preservationLiquid smokeEngineering

A liquid smoke ink and a method of making the smoke ink is provided. The smoke ink may be applied to a substrate and dried. The substrate may be used as a food, primarily a meat, casing. Liquid smoke is made from a dehydrated liquid smoke, which is a solid smoke. The solid smoke is dissolved in a food grade solvent to create the smoke ink. The smoke ink is applied to a substrate wherein the solvent evaporates. This leaves the smoke flavor on the substrate in an, essentially, fixed position.

Owner:DISPOSE ALL +1

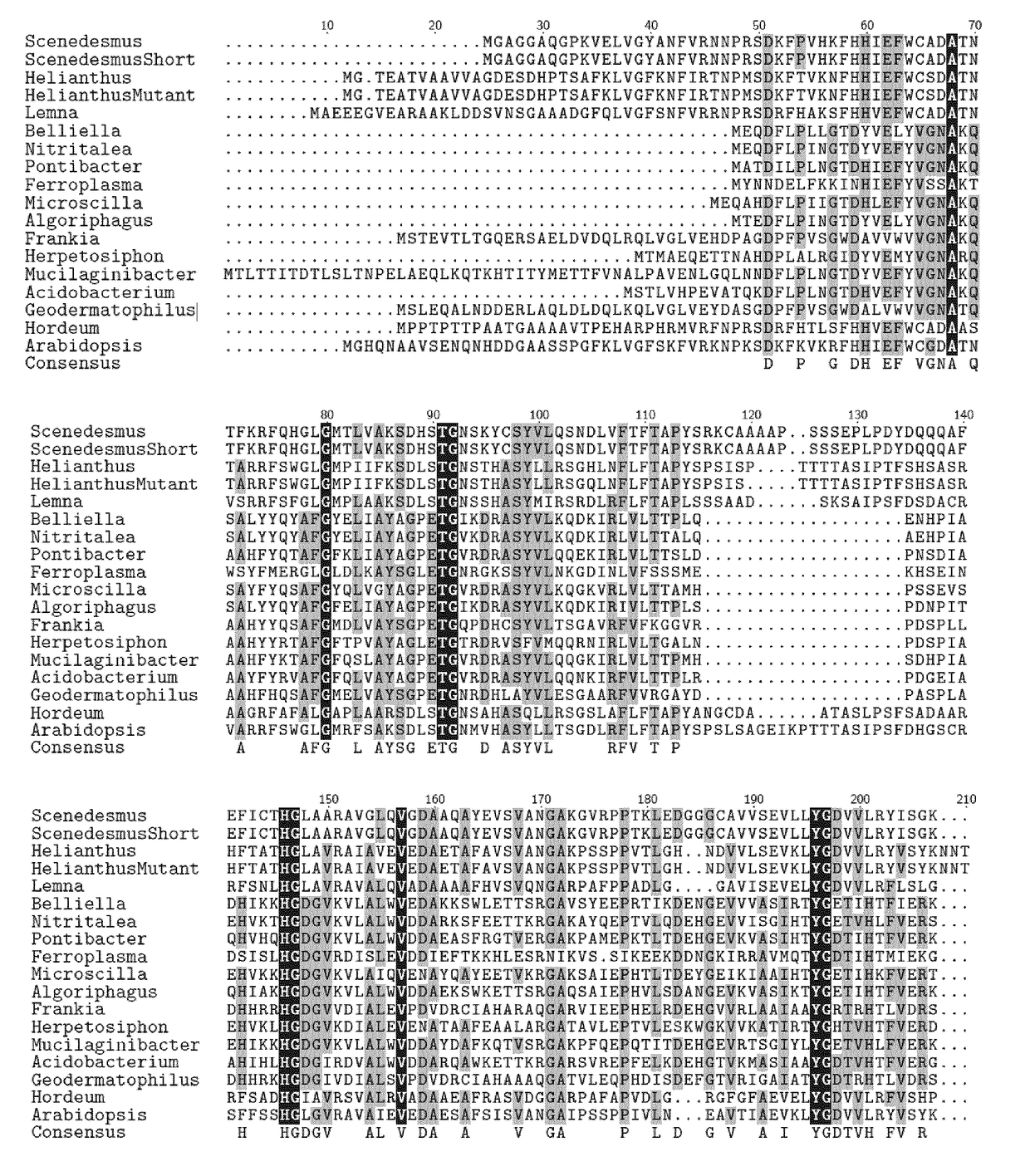

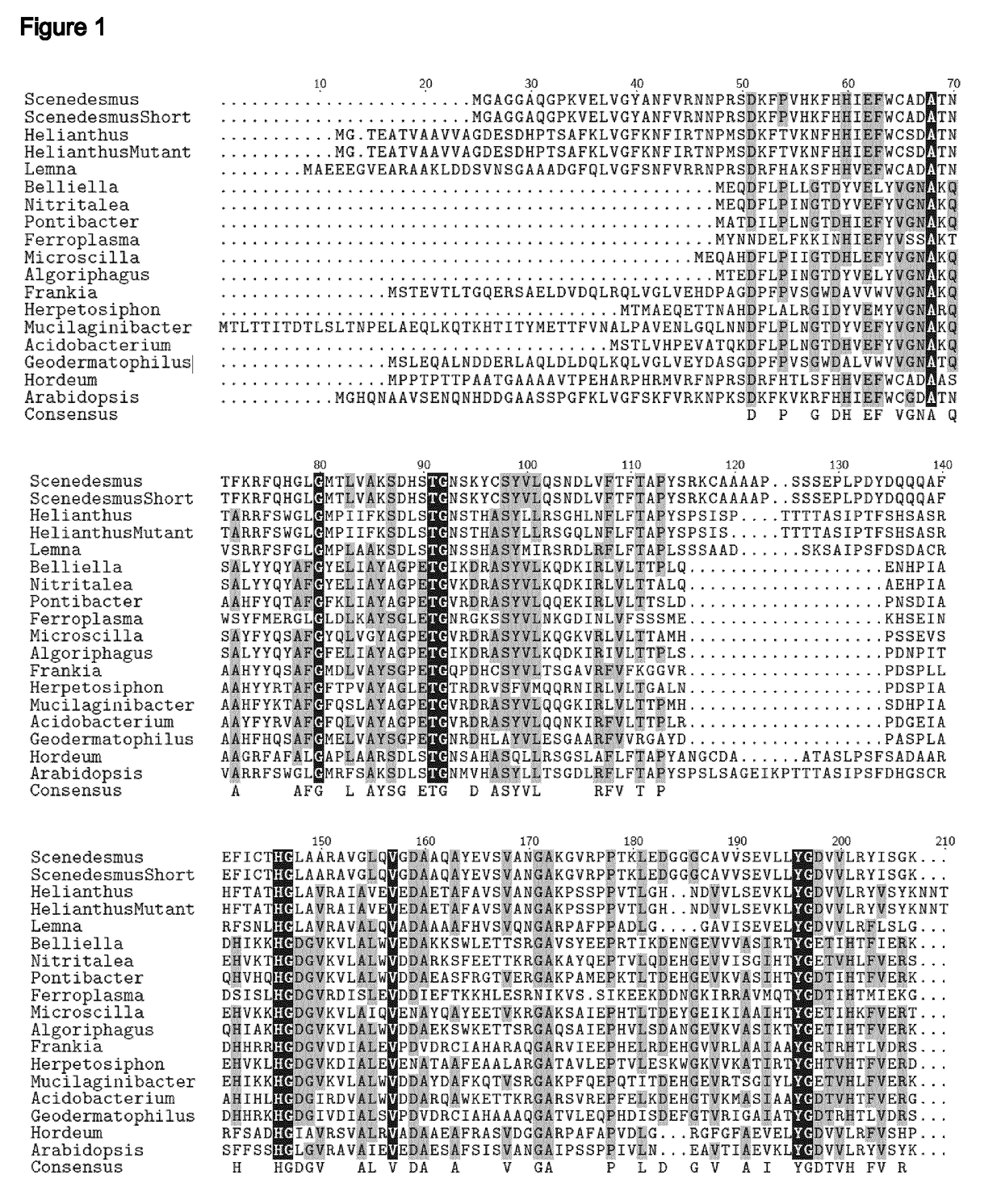

Herbicide-resistant hydroxyphenylpyruvate dioxygenases

ActiveUS20180023060A1Increased herbicide toleranceIncrease resistanceOxidoreductasesVector-based foreign material introductionPlant tissuePlant cell

The present invention refers to method for producing a transgenic plant with increased herbicide tolerance or resistance as compared to a corresponding non-transformed wild type plant, comprising transforming a plant cell or a plant cell nucleus or a plant tissue with a nucleic acid molecule encoding a mutated HPPD polypeptide, as well as to the nucleic acid, and plants with increased HPPD-inhibiting herbicide tolerance or resistance comprising the nucleic acid of the invention.

Owner:BASF AG

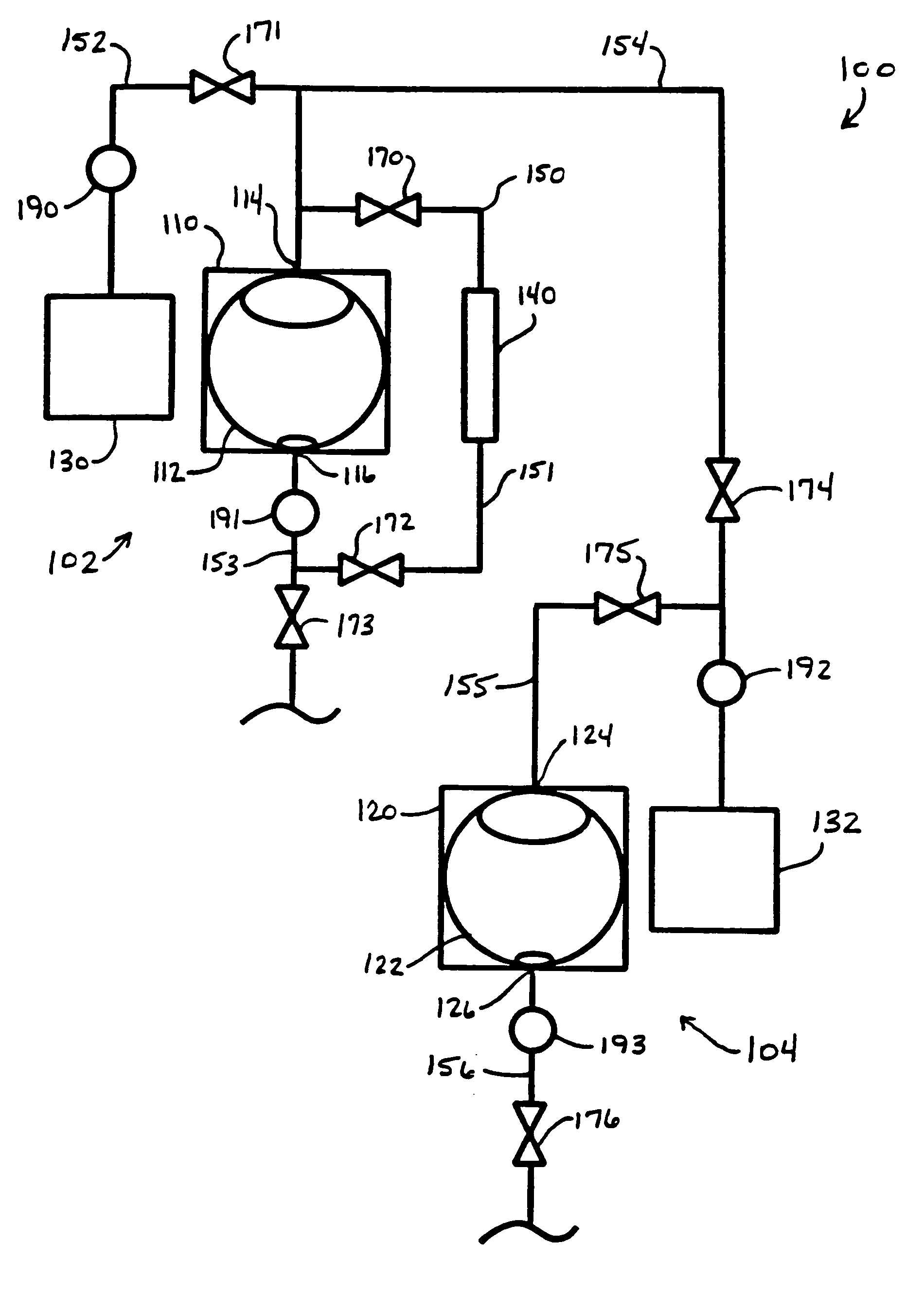

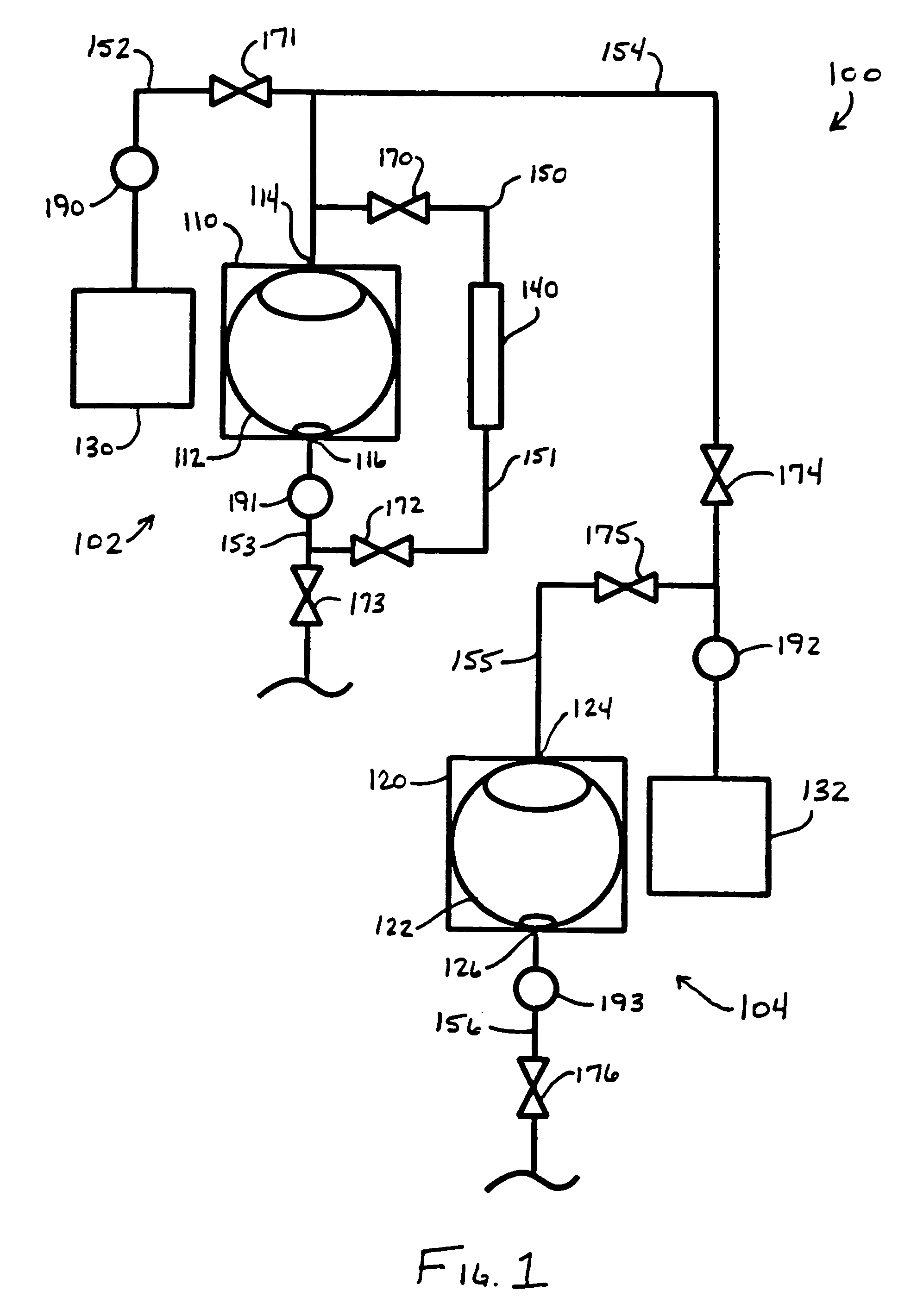

Cleaning system utilizing an organic and a pressurized fluid solvent

InactiveUS20070017036A1Efficient removalLess regulationDry-cleaning apparatusDry-cleaning apparatus for textilesSolubilitySolvent free

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably dipropylene glycol n-butyl ether, tripropylene glycol n-butyl ether or tripropylene glycol methyl ether, a mixture thereof, or a similar solvent and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:RACETTE TIMOTHY L +2

Handheld work apparatus

ActiveUS9797319B2Easily set speedControl speedElectrical controlInternal combustion piston enginesCombustionEngineering

A handheld work apparatus has a combustion engine (4) for driving a tool. The combustion engine (4) has an ignition device, a device for metering fuel and a control device (31). The control device (31) engages when an engagement speed (nE1, nE2) is reached, in order to limit the speed (n) of the combustion engine (4). In order to allow the speed (n) to be set in an easy manner at full throttle, the work apparatus has a device for setting the engagement speed (nE2) by the user.

Owner:ANDREAS STIHL AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com