Cleaning system utilizing an organic and a pressurized fluid solvent

a technology of pressurized fluid and cleaning system, which is applied in the direction of dry cleaning apparatus for textiles, inorganic non-surface active detergent compositions, etc., can solve the problems of significant regulatory burden on solvents, increased costs for users, and doubts about the usefulness of employing these conventional methods and systems, etc., to achieve less combustible, less regulation, and efficient removal of different soil types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

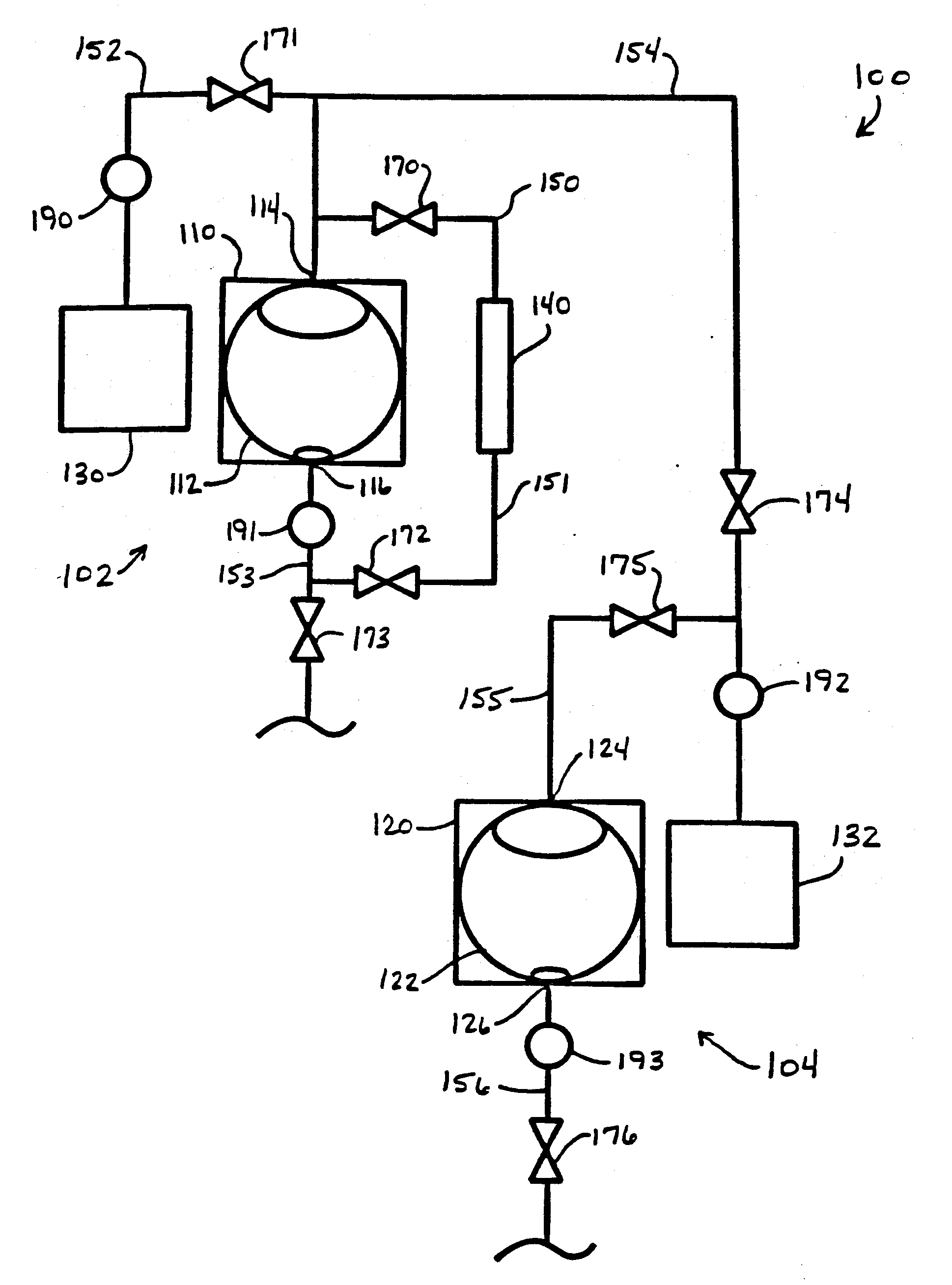

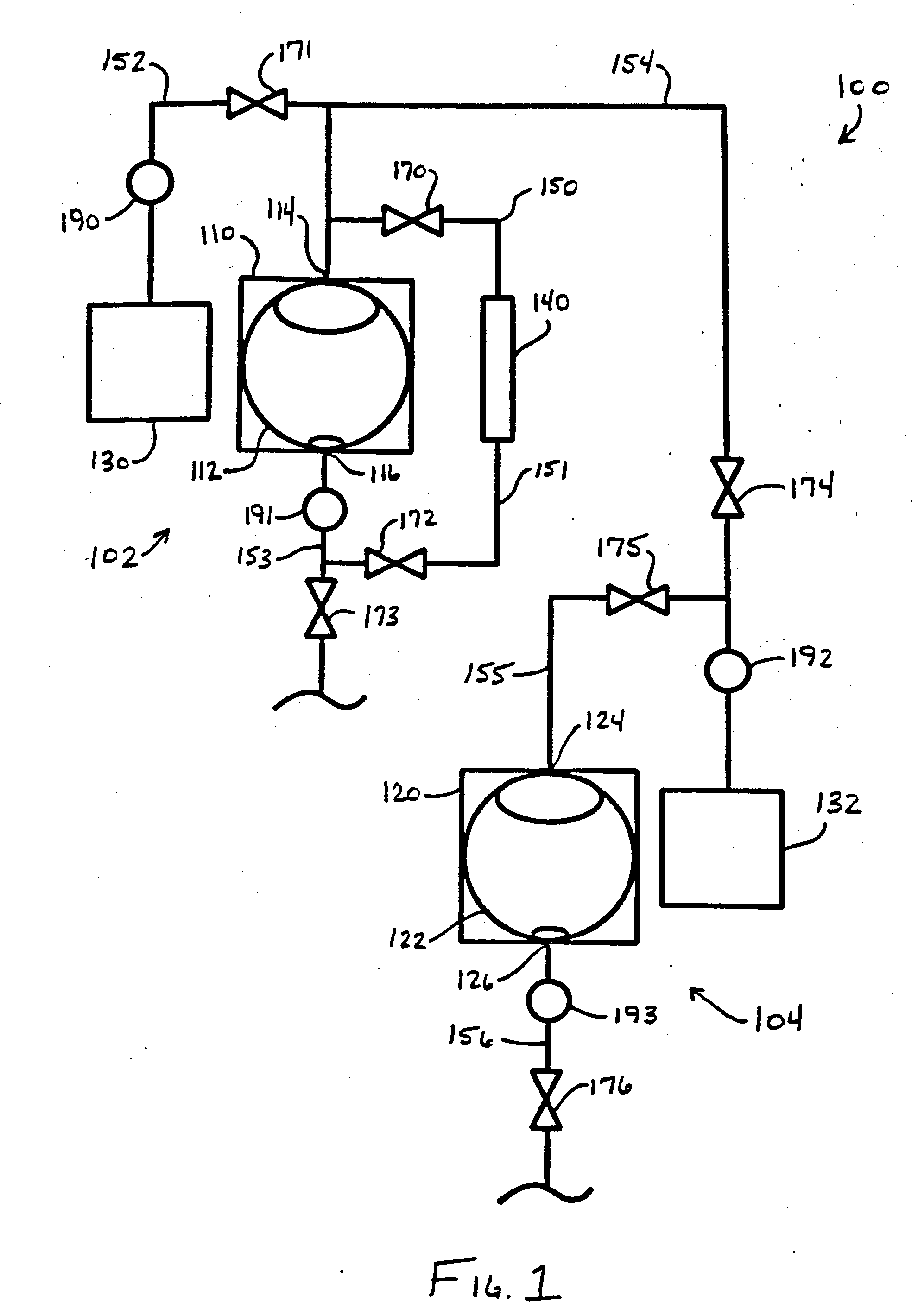

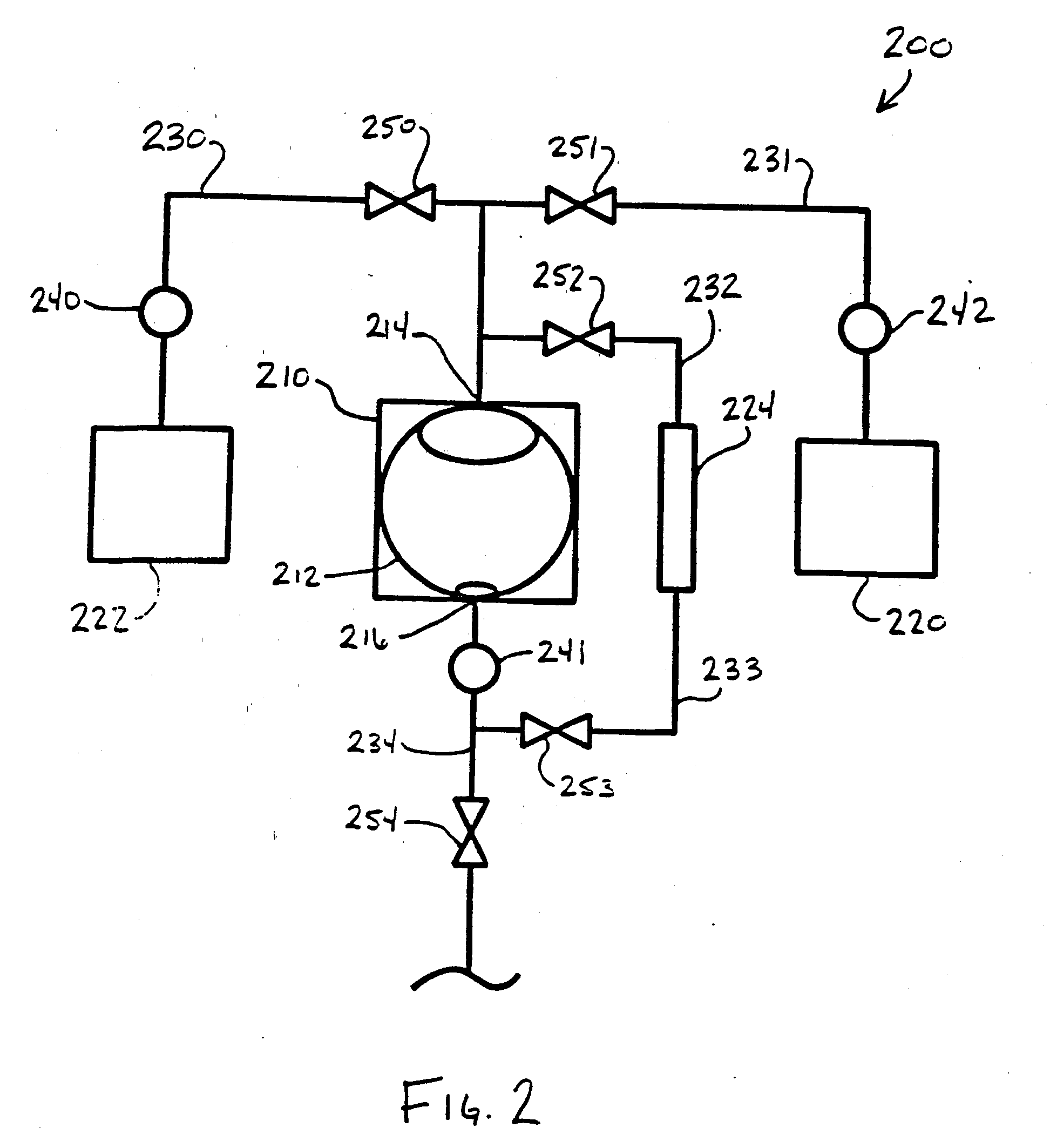

[0028] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. The steps of each method for cleaning and drying a substrate will be described in conjunction with the detailed description of the system.

[0029] The methods and systems presented herein may be used for cleaning a variety of substrates. The present invention is particularly suited for cleaning substrates such as textiles, as well as other flexible, precision, delicate, or porous structures that are sensitive to soluble and insoluble contaminants. The term “textile” is inclusive of, but not limited to, woven or non-woven materials, as well as articles therefrom. Textiles include, but are not limited to, fabrics, articles of clothing, protective covers, carpets, upholstery, furniture and window treatments. For purposes of explanation and illustration, and not limitation, exemplary embodiments of a system for cleaning textiles in accordance with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com