Asphalt pavement paving method achieving quick construction and forming

A technology for asphalt pavement and asphalt surface layer, which is applied to roads, roads, and on-site coagulation pavement, etc., can solve the problems of large long-term performance impact of pavement, inability to achieve continuous construction, and increase construction costs, and achieve good long-term performance. The effect of using performance, saving waiting time and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A section of 4-lane 500-meter-long urban arterial road reconstruction project, due to the heavy traffic pressure of closed construction, the traffic management department requires that after the completion of underground pipelines and roadbed construction, the road surface construction and opening to traffic should be completed as quickly as possible.

[0030] The material type and thickness of subbase, lower base and upper base are determined by the method of the present invention, and the thickness and number of layers of asphalt are determined by known methods.

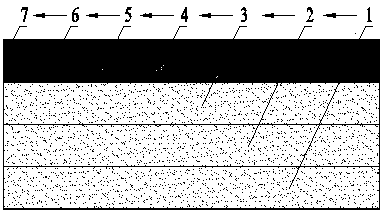

[0031] The pavement structure combination used is: 4cm asphalt mixture surface layer + 6cm asphalt mixture middle surface layer + 8cm asphalt mixture lower layer + 2×18cm lime fly ash macadam base (upper base + lower base) + 18cm lime powder Coal ash gravel subbase + soil foundation.

[0032] Through roadbed construction, the compacted roadbed modulus is greater than 80Mpa. The original subgrade soil is sof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com