Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

A technology of an olefin copolymer and a manufacturing method, which is applied in the field of ethylene copolymer and can solve the problems of poor processing performance and small application range of ultra-high molecular weight polyethylene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

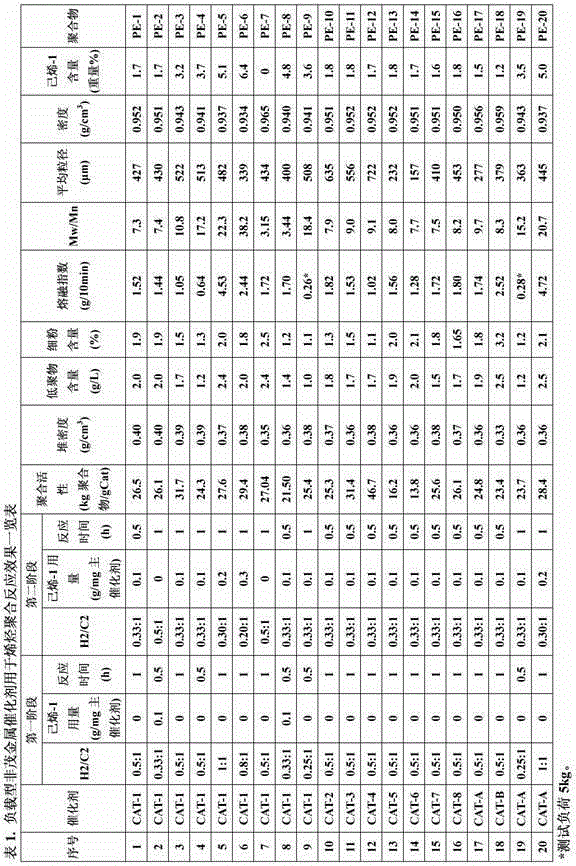

Examples

preparation example Construction

[0144] According to the present invention, the preparation method of the supported non-metallocene catalyst comprises the following steps: dissolving the magnesium compound and the non-metallocene ligand in a solvent in the presence of alcohol to obtain a solution of the magnesium compound; Adding a precipitant to the solution or drying the magnesium compound solution to obtain a magnesium compound carrier; and contacting the magnesium compound carrier with a chemical treatment agent selected from Group IVB metal compounds to obtain the supported non-metallocene catalyst step.

[0145] The steps for obtaining the magnesium compound solution are specifically described below.

[0146] According to this procedure, the magnesium compound and the non-metallocene ligand are dissolved in an appropriate solvent (also referred to as a solvent for dissolving the magnesium compound) in the presence of alcohol, thereby obtaining the magnesium compound solution.

[0147] As the solvent, f...

Embodiment 1

[0447] The magnesium compound adopts anhydrous magnesium chloride, the solvent adopts tetrahydrofuran, the alcohol adopts n-butanol, the chemical treatment agent of IVB group metal compound adopts titanium tetrachloride, the precipitating agent adopts hexane, and the non-metallocene ligand adopts the structure compound of.

[0448] Weigh 5g of anhydrous magnesium chloride, add solvent, non-metallocene ligand and alcohol, and dissolve completely at normal temperature to obtain a magnesium compound solution, add a precipitating agent to the magnesium compound solution to make it completely precipitate, filter, and wash 3 times with a precipitating agent. The amount of the secondary precipitating agent is 60ml, and it is uniformly heated to 60° C. and vacuum-dried to obtain a magnesium compound carrier.

[0449] Add the prepared magnesium compound carrier into the hexane solvent, add the IVB group chemical treatment agent dropwise within 30 minutes at room temperature, and then...

Embodiment 2

[0453] Basically the same as Example 1, but with the following changes:

[0454] Before the magnesium compound carrier is in contact with the chemical treatment agent, the magnesium compound carrier is treated with triethylaluminum, an auxiliary chemical treatment agent.

[0455] That is, add the magnesium compound carrier to the hexane solvent, then slowly add the auxiliary chemical treatment agent triethylaluminum (concentration: 0.88mol / L, hexane solution), stir at 60°C for 2 hours, filter, wash with hexane 3 times, each time with the same amount of solvent added before, and finally vacuum-dried at 60° C. to obtain a pretreated magnesium compound carrier. The molar ratio of the magnesium compound carrier calculated as Mg element to the auxiliary chemical treatment agent calculated as Al element is 1:0.2.

[0456] Supported non-metallocene catalysts are designated CAT-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com