Panel, method for manufacturing a panel and aircraft

A panel and insulator technology, applied in aircraft parts, air handling equipment, weight reduction, etc., can solve problems such as side panel replacement, achieve the effects of reducing weight, eliminating damage, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

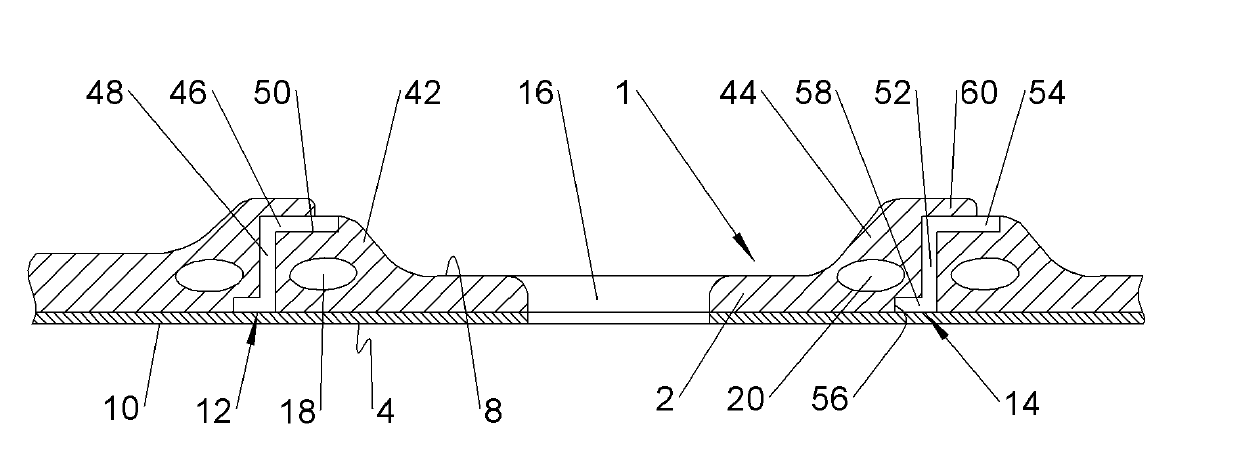

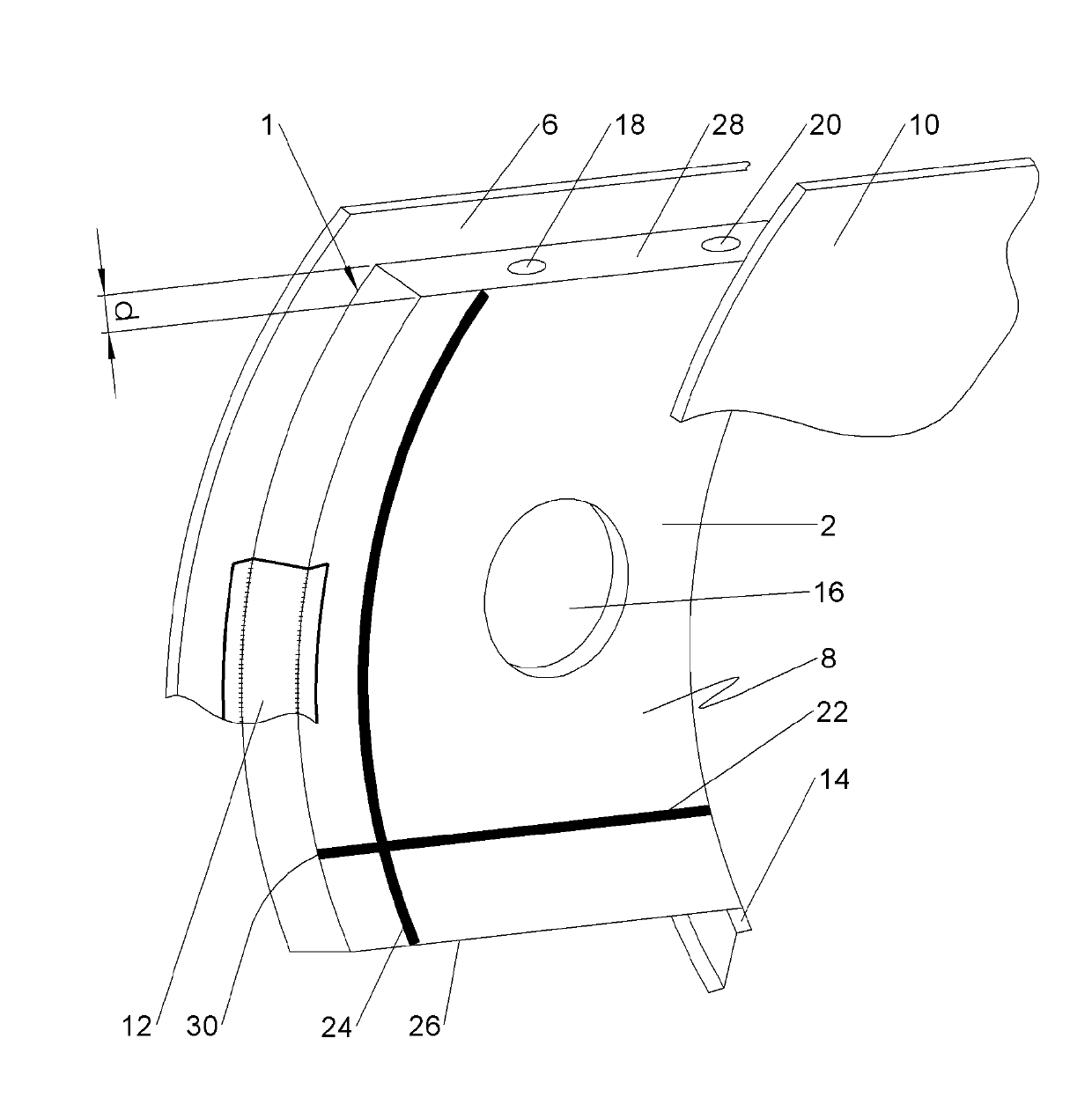

[0025] figure 1 A perspective view of a first exemplary embodiment of a panel 1 of the invention for detachable integration into an aircraft fuselage between a skin 2 and an inner lining 4 (inner trim 4 ) is shown.

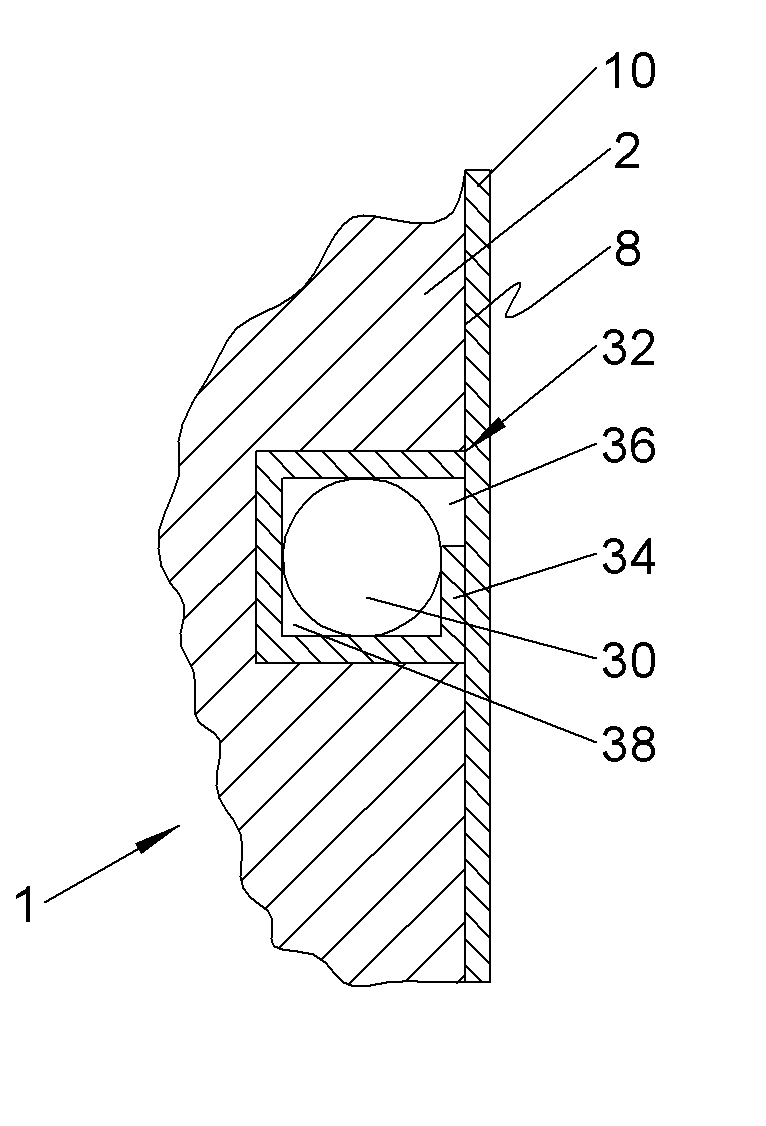

[0026] The panel 1 is characterized by a plate-like insulation or foam 6 of polymer having a constant thickness d. The polymer consists of a rigid foam with closed cells and has thermal, acoustic and fire-resistant properties. The foam 6 has an outer surface 8 in contact with the skin 2 (see image 3 ), and the inner surface 10 covered by the lining 4. It is actively clamped between two circumferential reinforcements such as frames 12 , 14 and follows the curved or spherical shape of the skin 2 . In order to ensure that the foam body 6 contacts the skin 2 flatly with its outer surface 8 , a plurality of not-shown notch-like recesses for receiving longitudinal reinforcements such as stringers are preferably created in the outer surface 8 .

[0027] Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com