Silane-modified polyether adhesive for single-component tile seam decoration industry

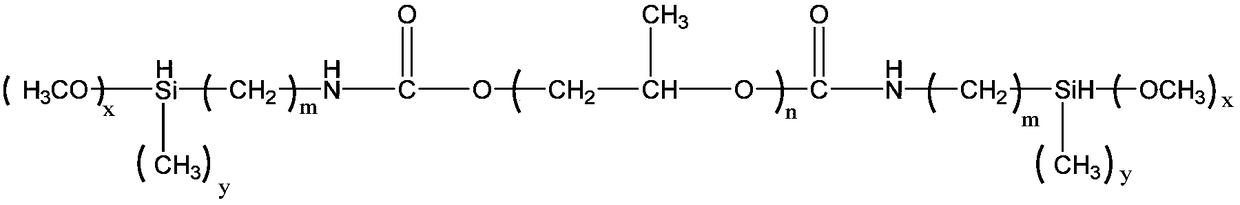

A technology of silane-modified polyether and silane-terminated polyether, which is applied in the field of silane-modified polyether adhesive for single-component ceramic tile beauty seam industry, which can solve the problem of time-consuming two-component mixing, whitening of material surface, restricted application, etc. problem, to achieve the effect of excellent yellowing resistance, no whitening after curing, and low material toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

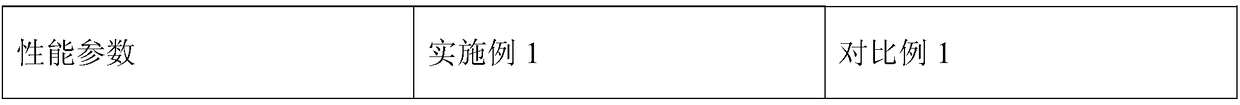

[0026] Example 1: Preparation method of silane-modified polyether adhesive for single-component ceramic tile beauty seam industry

[0027] The method includes the following steps:

[0028] (1) 10 parts of 60 micron pearl powder and a specific surface area of 200m 2 / g 5 parts of fumed silica thixotropic agent can be put into use after baking at 110℃ for 4 hours until the moisture content is lower than 3000ppm;

[0029] (2) 5 parts of polypropylene glycol plasticizers with a number average molecular weight of 2000, 35 parts of silicone resins, 0.5 parts of 2-(2-hydroxyl-5-methylphenyl) benzotriazole ultraviolet absorbers and bis(1 , 0.25 parts of 2,2,6,6-pentamethyl-4-piperidinyl) sebacate hindered amine-based light stabilizer were added to the stirring tank in turn, and the machine was started to scrape and stir, and the rotation and dispersion speeds were slow Modulate 20HZ, raise the temperature to 100-119°C, vacuumize and dehydrate for 2 hours, and control the vacuum de...

Embodiment 2

[0037] (1) 5 parts of rutile titanium dioxide filler and a specific surface area of 200m 2 Bake 6 parts of fumed silica thixotropic agent per g, and put it into use when the moisture content is lower than 3000ppm;

[0038] (2) 1 part of polypropylene glycol plasticizer with a number average molecular weight of 4000, 35 parts of silicone resin, 1 part of 2-(2-hydroxy-5-methylphenyl) benzotriazole ultraviolet absorber and bis(1 , 1 part of 2,2,6,6-pentamethyl-4-piperidinyl) sebacate hindered amine-based light stabilizer was added to the stirring tank in turn, and the machine was started to scrape and stir, and the frequency conversion self-rotation and frequency conversion dispersion speed Slowly modulate 20HZ, heat up to 100-119°C, vacuumize, control the vacuum degree below -0.095MPa for dehydration for 2 hours, during which the temperature should not exceed 120°C, if the temperature is too high, the speed can be appropriately reduced; cool down to 50°C, and step (1 ) to the...

Embodiment 3

[0041] (1) 5 parts of rutile titanium dioxide filler, 0.5 parts of carbon black filler and a specific surface area of 200m 2 Bake 6 parts of fumed silica thixotropic agent per g, and put it into use when the moisture content is lower than 3000ppm;

[0042] (2) 1 part of polypropylene glycol plasticizer with a number average molecular weight of 4000, 35 parts of silicone resin, 0.5 part of 2-(2-hydroxy-5-methylphenyl) benzotriazole ultraviolet absorber and bis(1 , 0.25 parts of 2,2,6,6-pentamethyl-4-piperidinyl) sebacate hindered amine-based light stabilizer were added to the stirring tank in turn, and the machine was started to scrape and stir, and the rotation and dispersion speeds were slow Modulate 20HZ, heat up to 100-119°C, vacuumize, control the vacuum degree below -0.095MPa for dehydration for 2 hours, during which the temperature must not exceed 120°C, if the temperature is too high, the speed can be appropriately reduced; cool down to 50°C, and step (1) is obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com