Patents

Literature

56 results about "Methyl phenyl polysiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-component addition-type silicone rubber and preparation method thereof

The invention provides a single-component addition-type silicone rubber which is prepared by vulcanizing the following raw materials in parts by mass: 20-50 parts of vinyl polysiloxane, 3-18 parts of vinyl methyl phenyl polysiloxane, 4-20 parts of hydrogen-containing polysiloxane, 0.01-0.1 part of platinum catalyst, 0.3-2.5 parts of inhibitor, 40-60 parts of filler, 2.0-10 parts of additive and 0.5-3 parts of tackifier. The single-component addition-type silicone rubber comprises the heat-resistant additive and the filler, so that the single-component addition-type silicone rubber prepared by vulcanizing has good high temperature resistance and low temperature aging resistance. The single-component addition-type silicone rubber comprises the catalytic inhibitor, so that the single-component addition-type silicone rubber has a higher inhibitory effect, and the storage life of the single-component addition-type silicone rubber is prolonged. When the addition-type silicone rubber is vulcanized, small molecular substances are not produced, and packaging components are not corroded.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

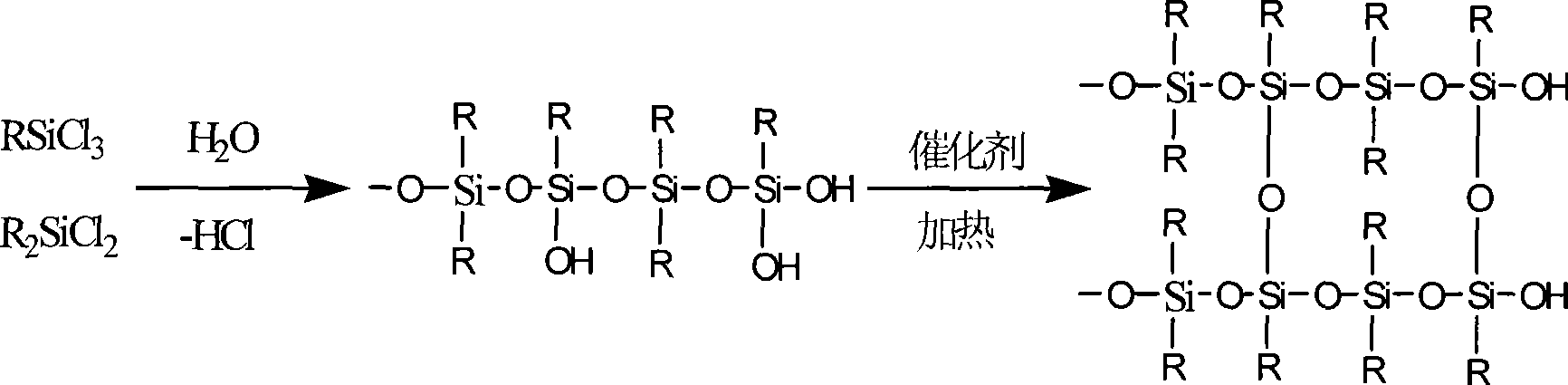

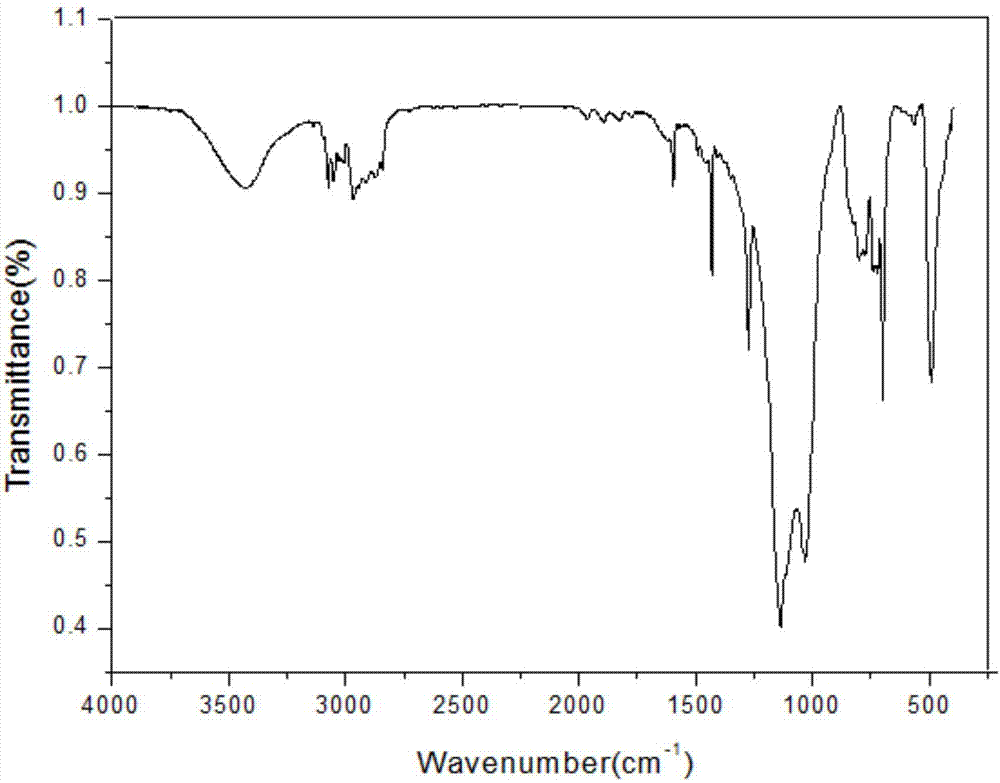

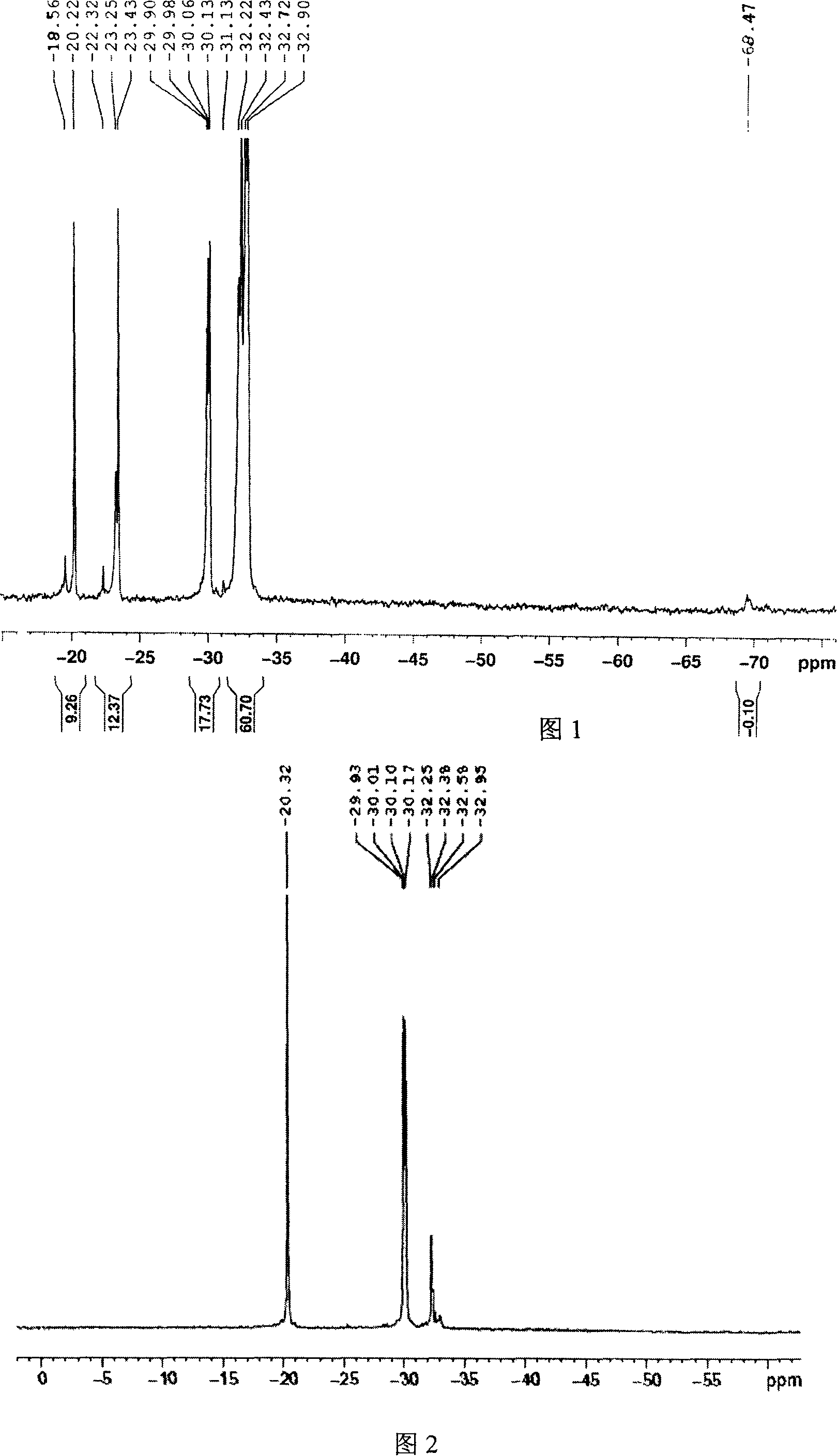

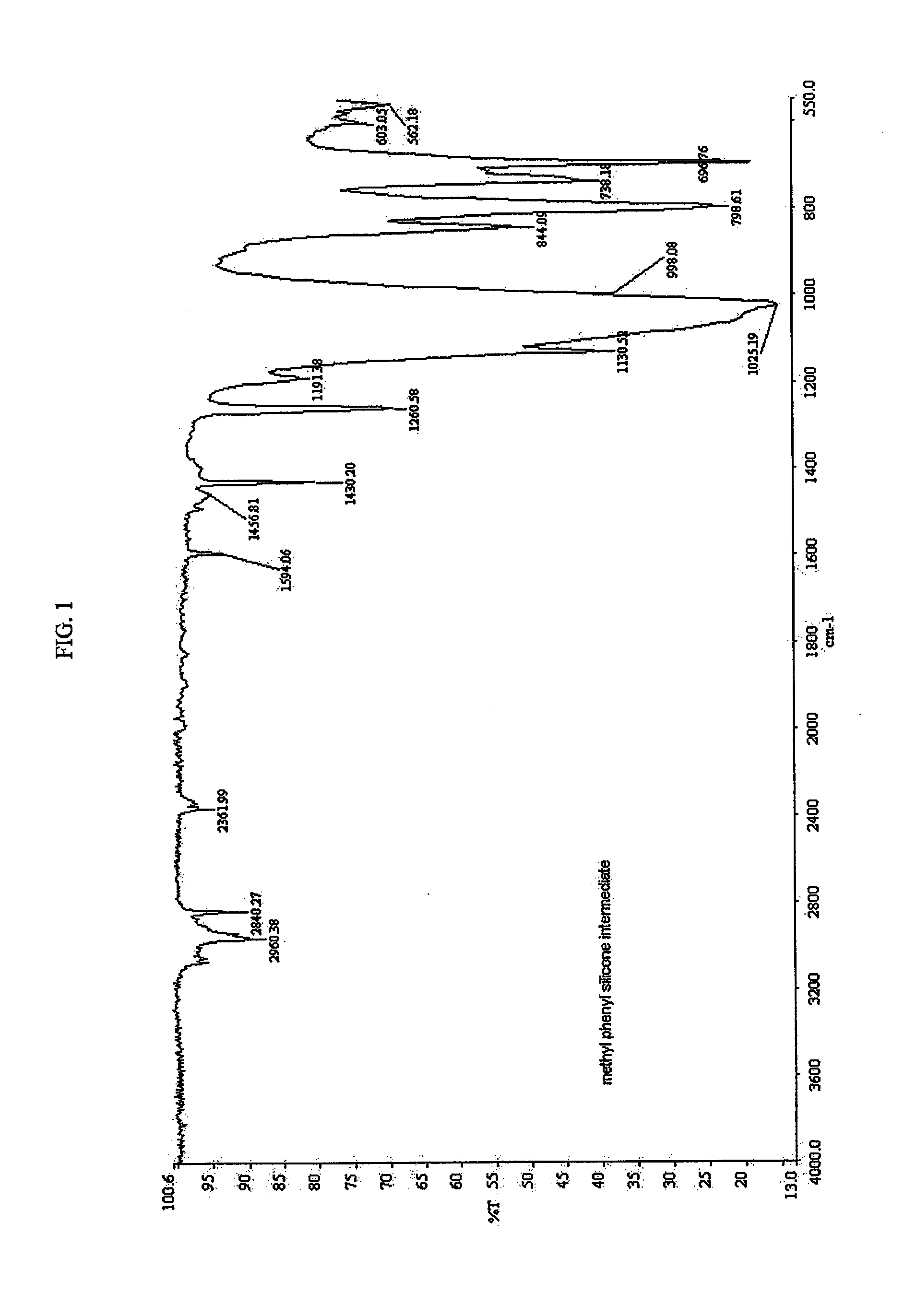

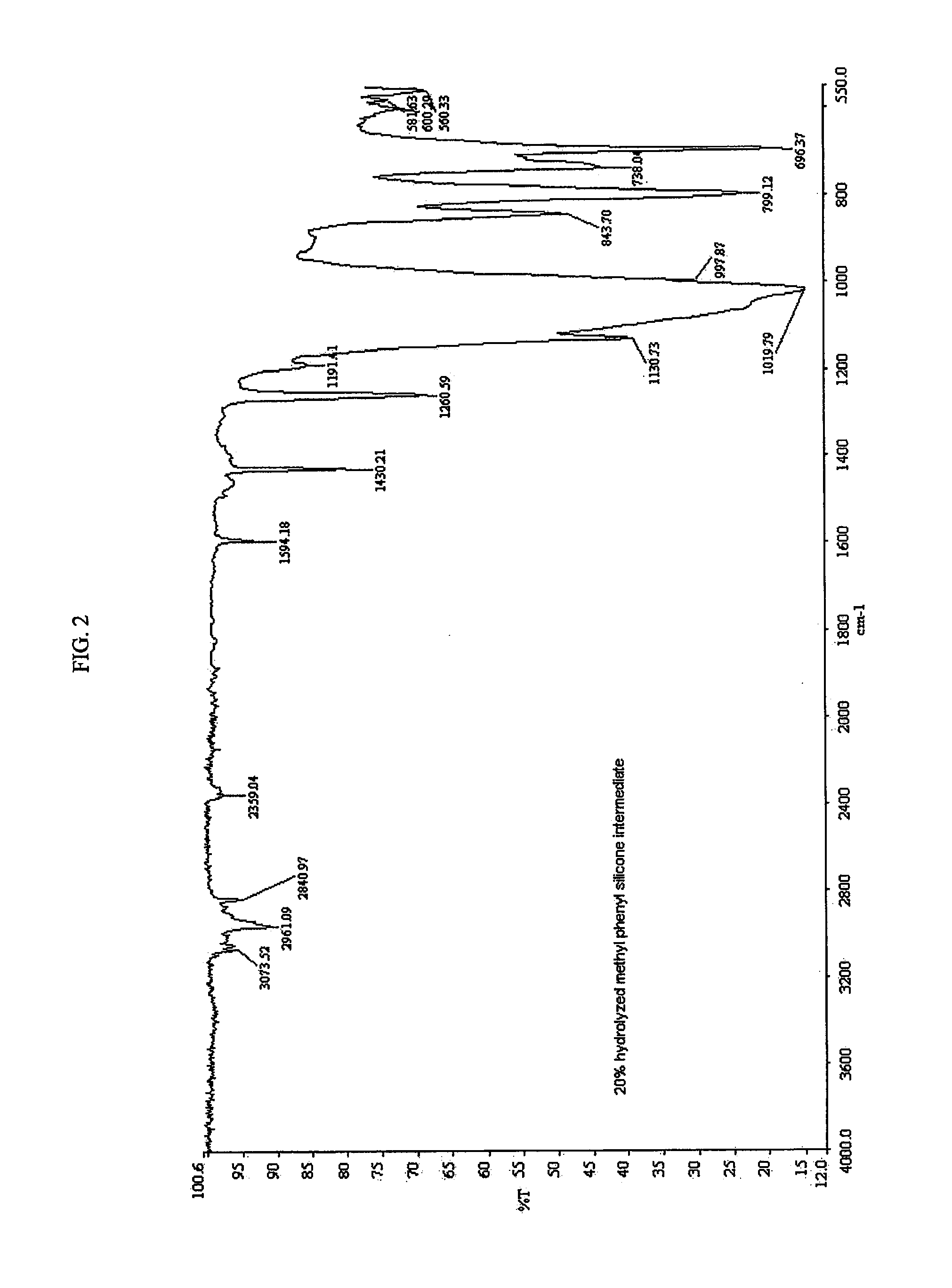

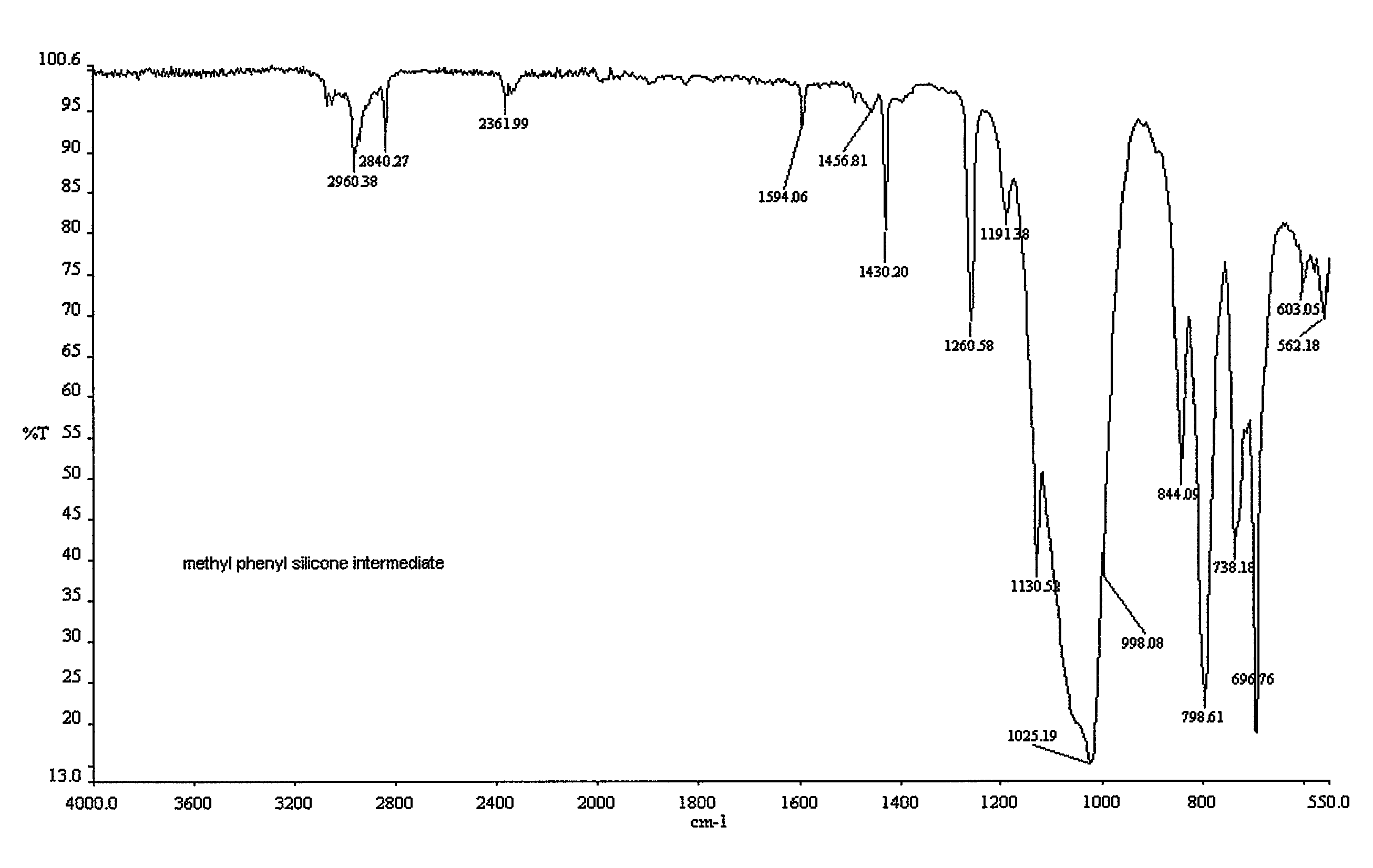

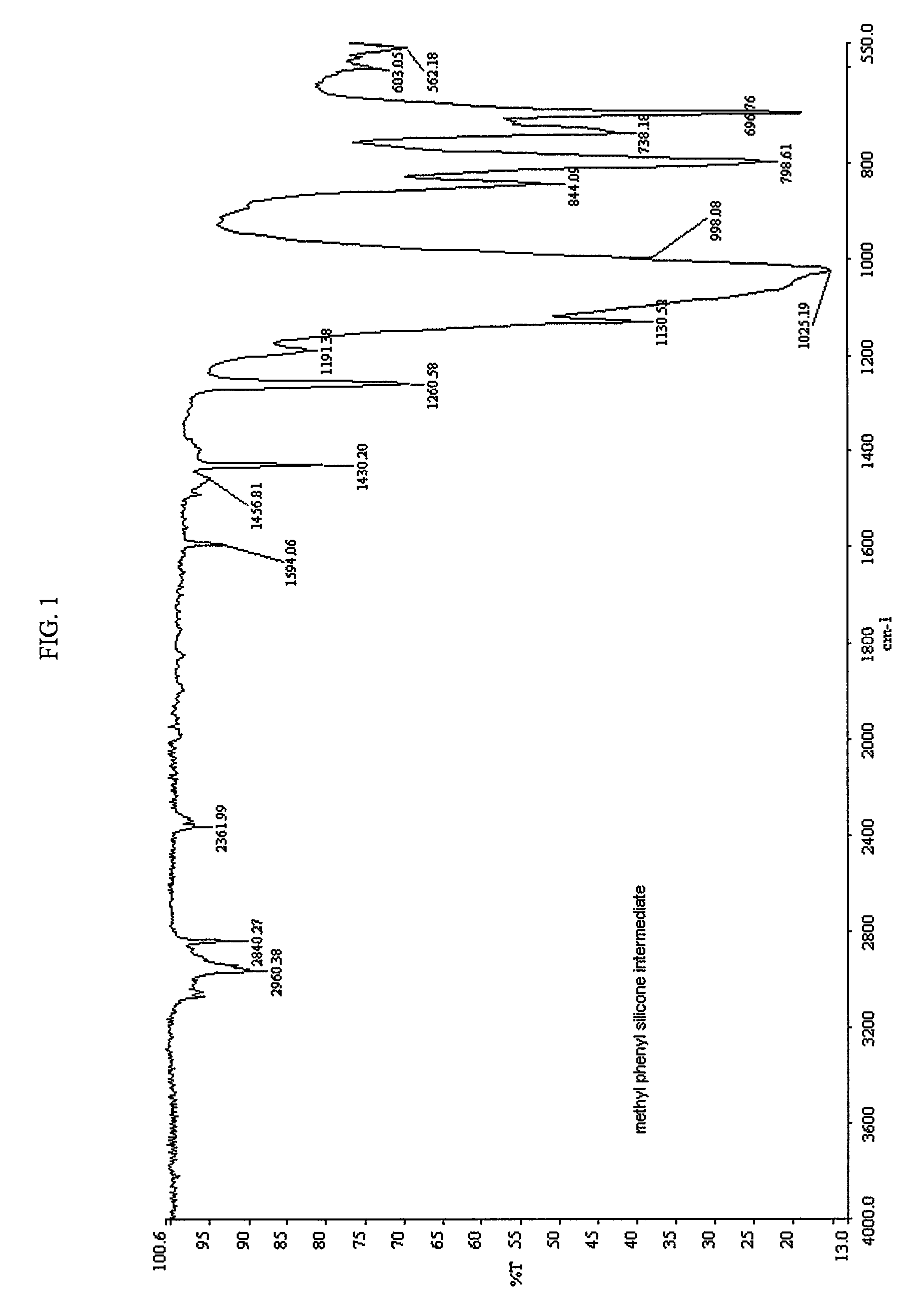

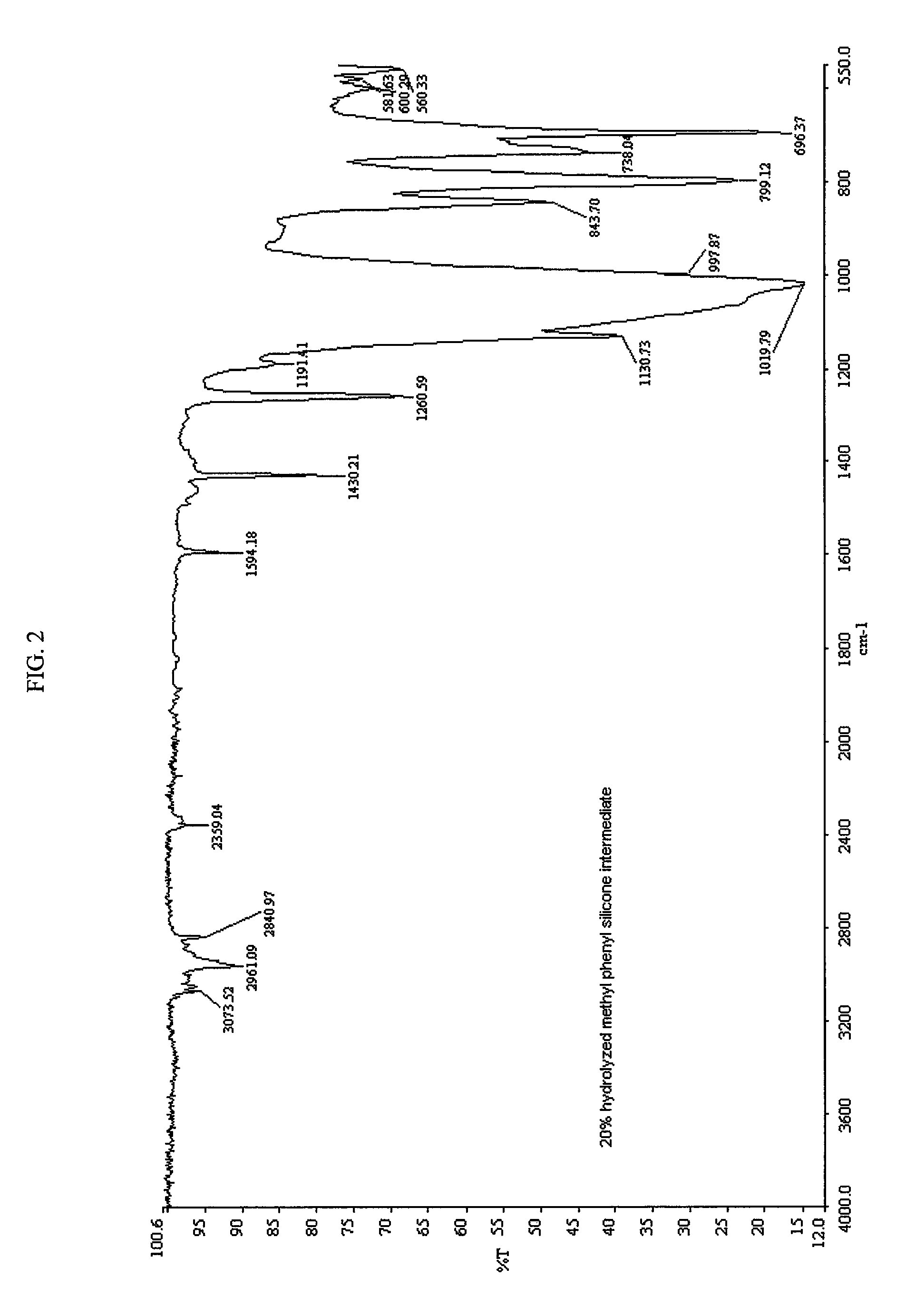

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

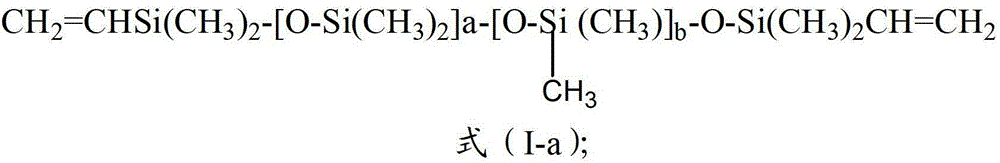

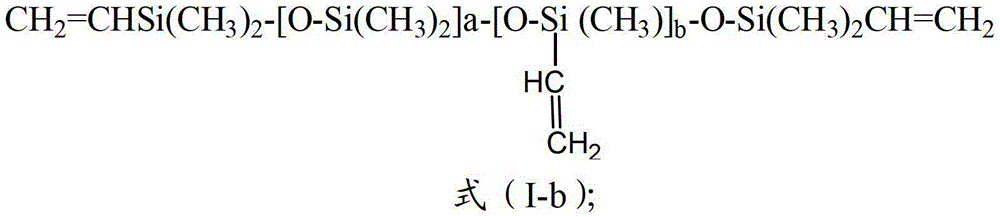

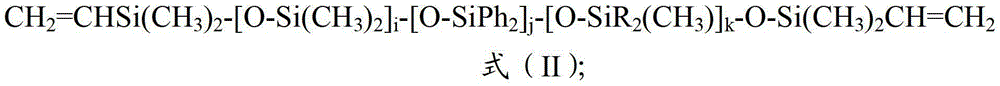

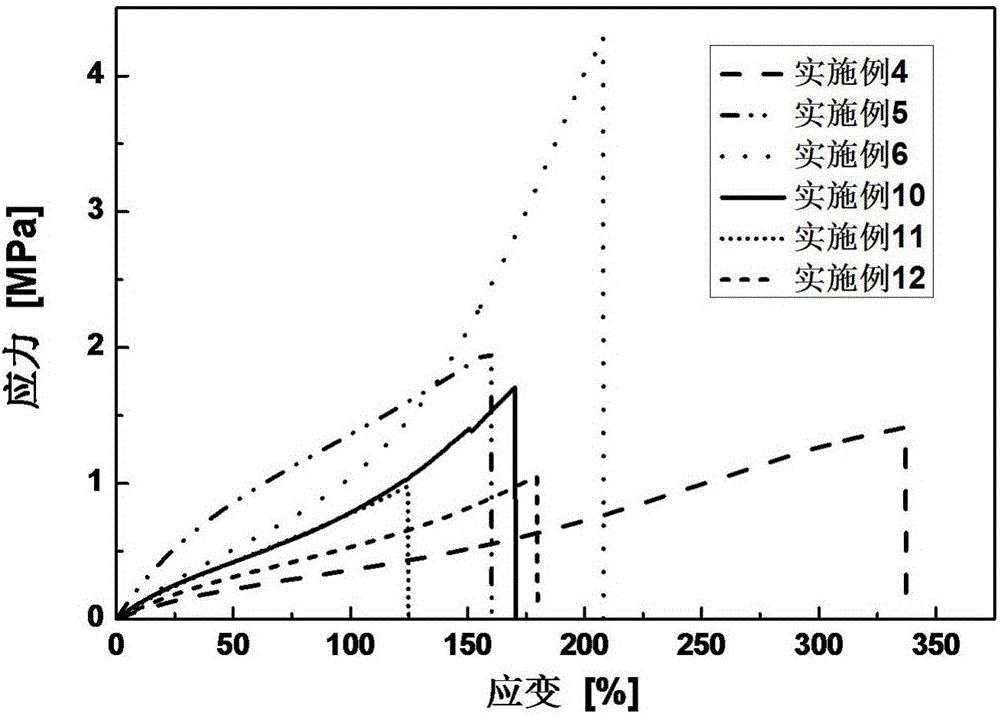

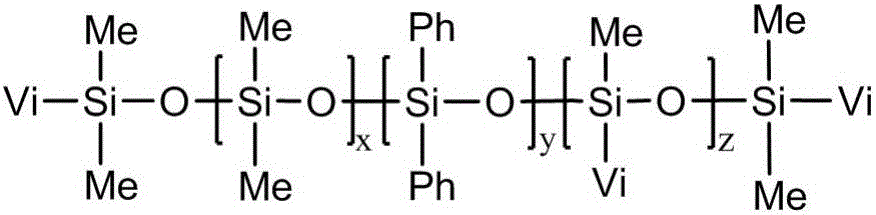

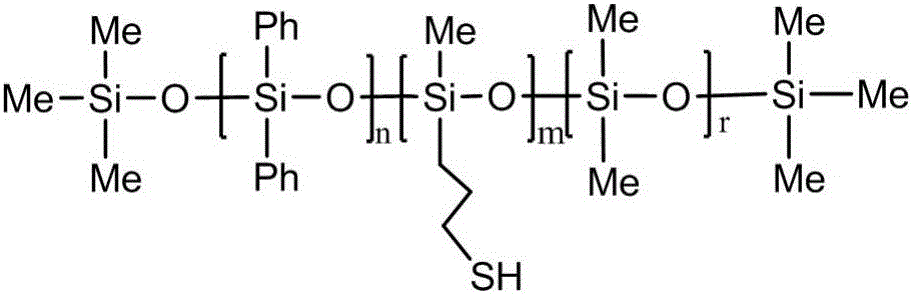

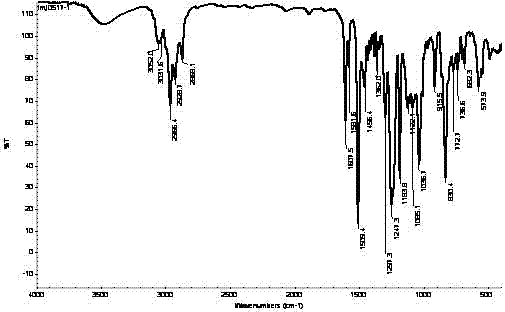

Photocured organosilicone elastomer and preparation method and application thereof

InactiveCN106317898AEffective adjustment of mechanical propertiesImprove mechanical propertiesAdditive manufacturing apparatusSemiconductor/solid-state device detailsCross-linkElastomer

The invention discloses a photocured organosilicone elastomer and a preparation method thereof. The photocured organosilicone elastomer is prepared from, by weight, 50-80 parts of vinyl methyl phenyl polysiloxane, 10-30 parts of mercaptopropyl methyl phenyl polysiloxane, 5-20 parts of mercaptopropyl silicon resin, 0-3 parts of photoinitiator and 0.1-1 part of auxiliary. Vinyl methyl phenyl polysiloxane, mercaptopropyl methyl phenyl polysiloxane, mercaptopropyl silicon resin and the photoinitiator are used as raw materials and mixed and stirred to be uniform, and the photocured organosilicone elastomer is prepared. By adjusting the quantity ratio of methyl segmers and phenyl segmers in polysiloxane and introducing mercaptopropyl silicon resin to serve as a macromolecular cross-linking agent, photocured organosilicone elastomers different in toughness, mechanical strength and refractive index can be prepared, and rapid curing molding is realized within 5-20 s under ultraviolet illumination; the process is simple, efficient and environmentally friendly and saves energy; the photocured organosilicone elastomer can be applied to the fields of electronic packaging materials, optical materials, 3D printing materials and the like.

Owner:GUANGDONG UNIV OF TECH

Chemical method for preparing organic silicon modified epoxy resin

InactiveCN102532556AGood compatibilitySimple preparation processAdhesivesBoiling pointCompound (substance)

The invention relates to a chemical method for preparing organic silicon modified epoxy resin, aiming to solve the technical problems that the compatibility is not good and the efficiency is low in a modification process of organic silicon epoxy resin. The chemical method comprises the following steps of: adding epoxy resin (one of bisphenol A epoxy resin and bisphenol F epoxy resin), hydroxyl-terminated methyl phenyl polysiloxane (with the use amount of 20-50% of the mass of the epoxy resin) and a catalyst (which is 1-5% of the total mass of two components including the epoxy resin and the hydroxyl-terminated methyl phenyl polysiloxane) into a reactor; uniformly agitating and gradually raising the temperature to 60-140 DEG C, and reacting for 4-6 hours; after the reaction, lasting under the condition of 120-130 DEG C / 5-10 mmHg for 0.5 hours; and desorbing low-boiling-point compounds, which are generated in the reaction, in vacuum to obtain the organic silicon modified epoxy resin.

Owner:HANGZHOU NORMAL UNIVERSITY

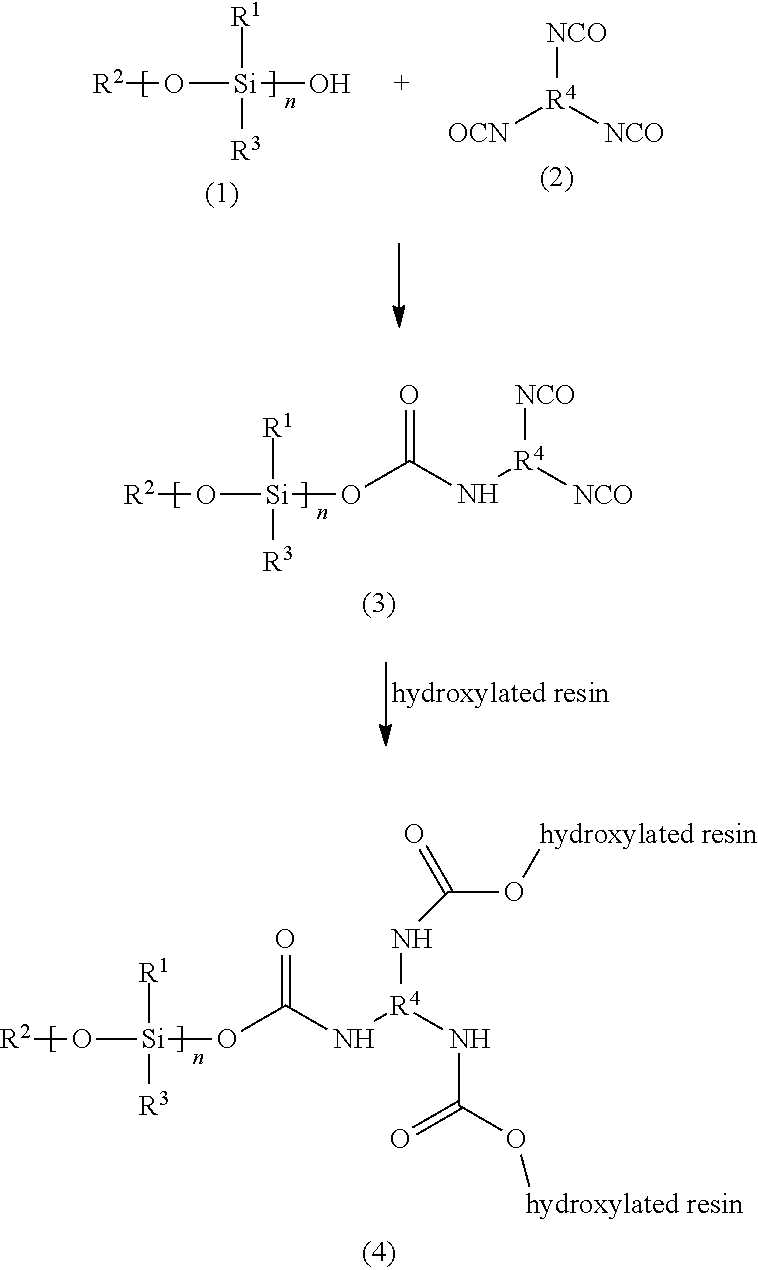

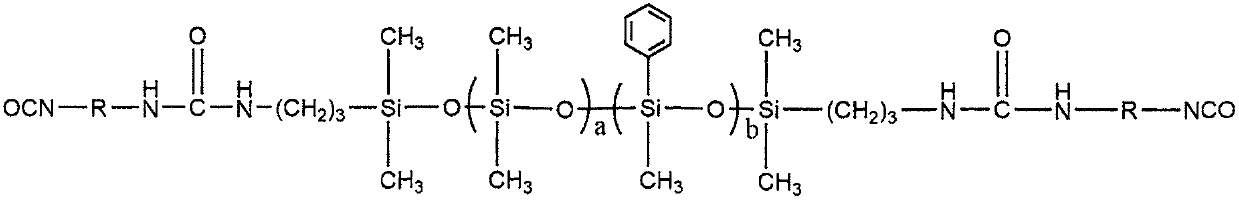

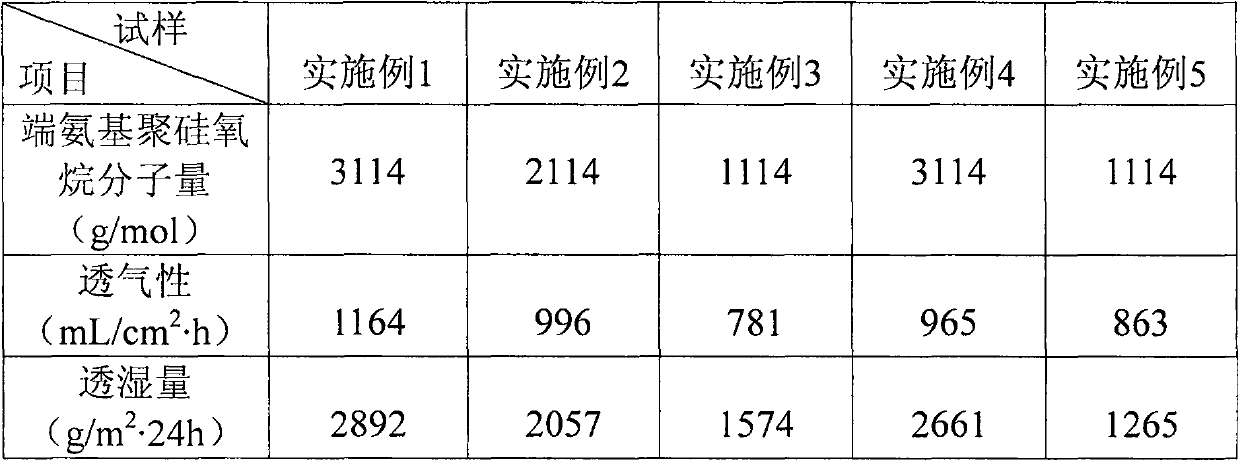

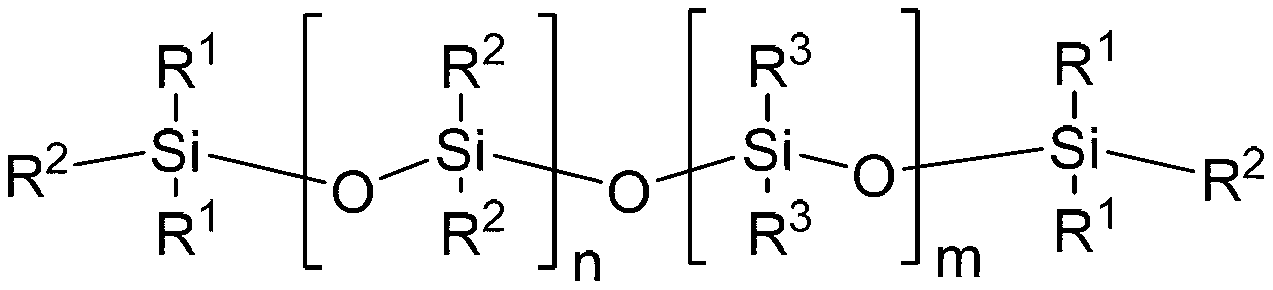

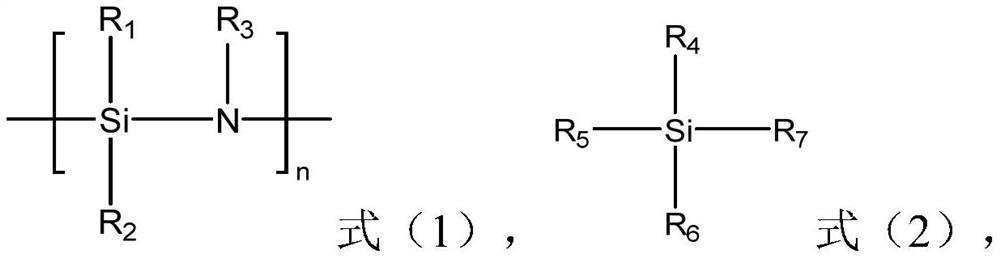

Phenyl organic silicon modified polyurethane resin, preparation method and application thereof

ActiveCN104387546AImprove surface propertiesSmall water absorptionPolyethylene glycolMethyl phenyl polysiloxane

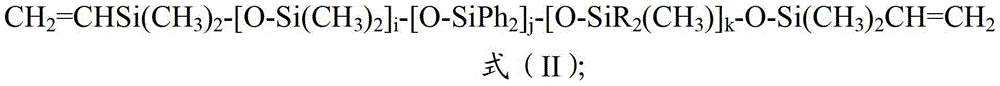

The invention discloses a phenyl organic silicon modified polyurethane resin, a preparation method and application thereof, and belongs to the field of polyurethane resin. The structural formula of the phenyl organic silicon modified polyurethane resin is as shown in the description; the preparation method of the phenyl organic silicon modified polyurethane resin comprises the following steps: dissolving phenylsilanediol into an organic solvent, taking a reaction with chlorosilane (R<2>SiCH3Cl2) to prepare hydroxyl-terminated methyphenyl polysiloxane, under the action of a catalyst, mixing the hydroxyl-terminated methyphenyl polysiloxane with a silane compound to obtain amino or imino terminated methyphenyl polysiloxane, then in the atmosphere of argon, mixing diisocyanate, amino or imino terminated methyphenyl polysiloxane, polyethylene glycol or polyol with a mixed solvent, and taking a reaction to obtain the phenyl organic silicon modified polyurethane resin. The phenyl organic silicon modified polyurethane resin has the advantages of being capable of reducing the water absorption, improving the hydrophobicity, and improving the compatibility of organic silicon and polyurethane, and can be prepared to thin film with good properties; the preparation method is simple and feasible.

Owner:WUHAN UNIV

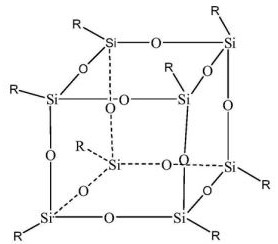

Organic silicon potting adhesive containing POSS group and preparation method of organic silicon potting adhesive

The invention relates to an organic silicon potting adhesive containing a POSS (polysilsesquioxane) group and a preparation method of the organic silicon potting adhesive. The organic silicon potting adhesive comprises a component A and a component B and is characterized in that the component A is formed by a POSS-phenyl organosilicon polymer and excessive hydrogen-terminated methyl phenyl polysiloxane which is not involved in the reaction, wherein the POSS-phenyl organosilicon polymer is formed by hydrosilylation to graft hydrogen-terminated methyl phenyl polysiloxane by taking polysiloxane cage octavinyl polysilsesquioxane as a main chain; the component B is methyl phenyl vinyl polysiloxane. By virtue of the phenyl of phenyl vinyl polysiloxane in the component A of the potting adhesive, the high refractive index of the material is ensured; by virtue of an introduced organic polysiloxane system, the heat resistance of the material is improved, the number of cross-linking points is increased and the refractive index of the material is increased; meanwhile, by virtue of phenyl polysiloxane matrix, the high refractive index of the material is ensured; the transparent organic silicon material with high heat resistance and high refractive index can be applied to encapsulation of HB-LED.

Owner:SHANGHAI UNIV

Preparation method and application of polyhedral oligomeric silsesquioxane skeleton containing vinyl silicone oil

ActiveCN103289096AEasy to prepareMeet packaging requirementsSemiconductor devicesMethyl phenyl polysiloxaneMechanical property

The invention relates to an organic silicon rubber for LED packaging. In order to solve the problems that during direct physical blending of POSS (polyhedral oligomeric silsesquioxane) with vinyl silicone oil and hydrogen containing silicone oil, POSS has poor compatibility with vinyl silicone oil and hydrogen containing silicone oil and is very easy to precipitate, so that the light transmittance and mechanical properties of the product can be affected, the invention provides a preparation method of a POSS skeleton containing vinyl silicone oil. The method includes: mixing POSS with one or two of dimethyl polysiloxane and methylphenyl polysiloxane at any proportion to obtain a mixture, in the presence of a catalyst, carrying out end-capping with a vinyl end-capping reagent, and performing a polymerization reaction to obtain the POSS skeleton containing vinyl silicone oil. The preparation method is simple. The invention also provides application of the POSS skeleton containing vinyl silicone oil in LED packaging materials.

Owner:HANGZHOU NORMAL UNIVERSITY

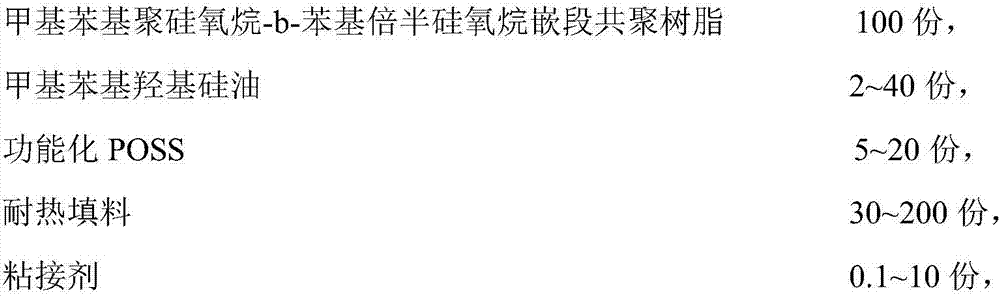

High-temperature resisting bonding sealed silicone resin and preparation method thereof

ActiveCN107353871AImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesOther chemical processesCross-linkPolymer science

The invention relates to high-temperature resisting bonding sealed silicone resin and a preparation method thereof. The high-temperature resisting bonding sealed silicone resin is prepared from the following raw materials: methyl phenyl polysiloxane-b-polyphenylsilsesquioxane block copolymer resin, methyl phenyl hydroxy silicone oil, functional POSS (Polyhedral Oligomeric Silsesquioxane), heat-resisting filler, an adhesive, a cross-linking agent and a catalyst. The preparation method comprises the following steps: firstly, mixing the methyl phenyl polysiloxane-b-polyphenylsilsesquioxane block copolymer resin, the methyl phenyl hydroxy silicone oil and the functional POSS, and then carrying out vacuum stirring and dehydrating at the temperature of 100 to 120 DEG C for 1 to 2 hours; secondly, adding the heat-resisting filler and the cross-linking agent for carrying out vacuum stirring for 30 to 60 minutes, then adding the adhesive and the catalyst for carrying out vacuum stirring for 30 to 60 minutes, discharging and sealing to obtain the high-temperature resisting bonding sealed silicone resin. The resin has the advantages of better heat-resisting property and mechanical property, and no need of white carbon black for reinforcing and priming; in addition, the retention rate of shear strength is more than 90 percent after the resin is subjected to 400 DEG C*1 hour high-temperature treatment, and tensile strength, shear strength and peel strength are still more than 80 percent after the resin is subjected to 330 DEG C*24 hour treatment.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

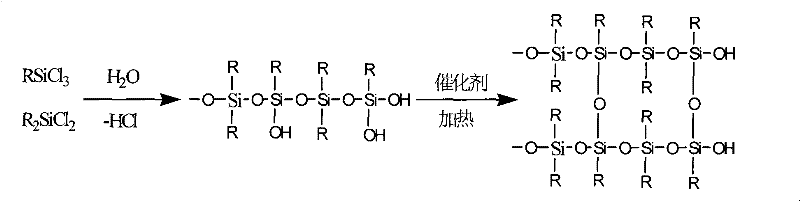

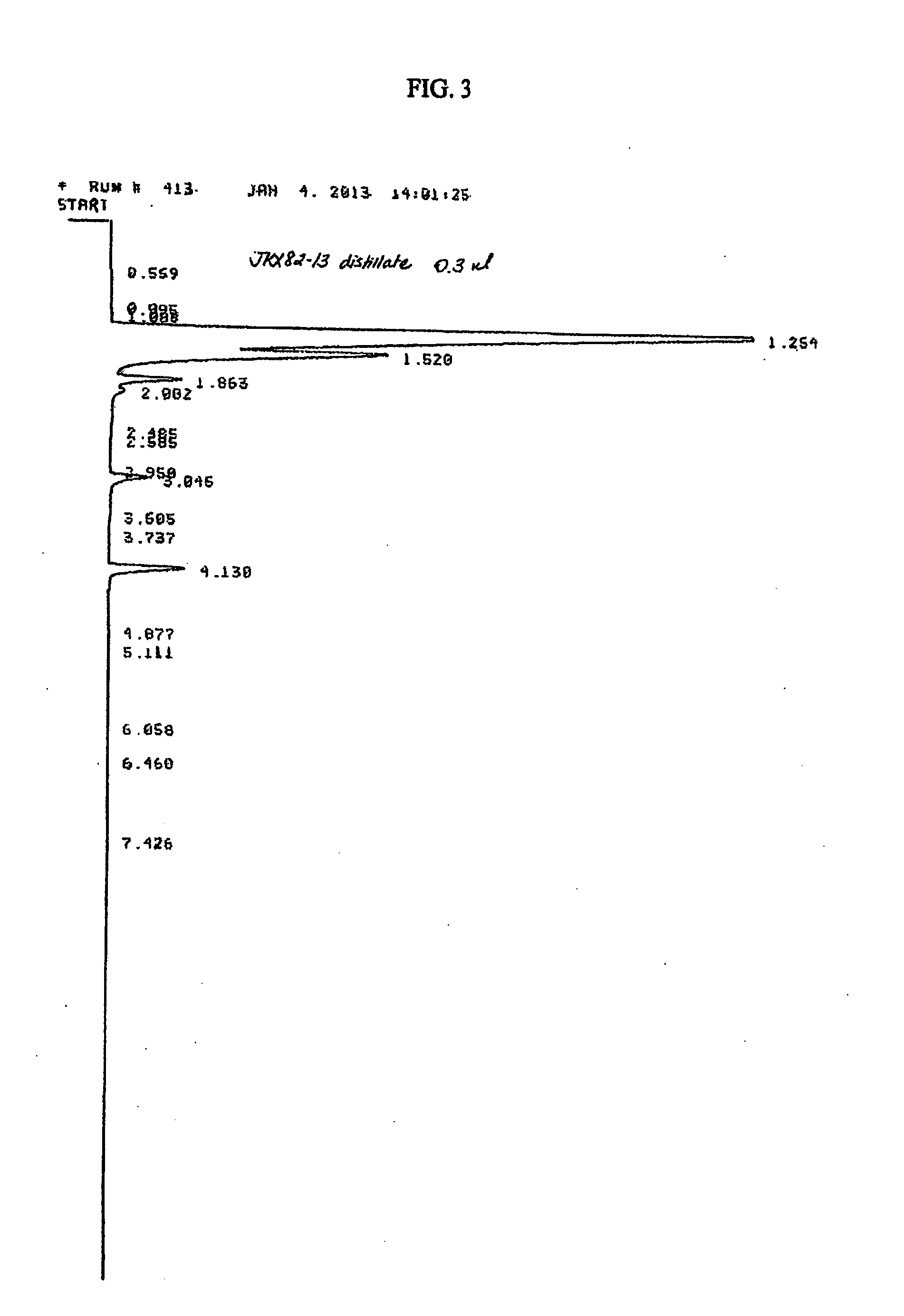

Method for preparing methylphenylcyclosiloxane

InactiveCN101125860AHigh molecular weightNo need to separateSilicon organic compoundsDistillationLithium hydroxide

The invention relates to a preparation method of methyl phyenyl cyclosiloxane, aiming at solving the technical problem that the invention provides the preparation method of the methyl phenyl polysiloxane containing SiPhO1.5, namely TP under catalysis of alkali through thermal cracking. The particular steps are that: 1) polymethylphenyl sioxane containing TP is mixed evenly with catalysts (lithium hydroxide, potassium carbonate or sodium carbonate), and catalyst dosage is 0.1 to 10 percent of the polymethylphenyl sioxane dosage; 2) a low-boiling material condensed by the polymethylphenyl sioxane containing TP is removed under the vacuum and heating-up temperature of 200 to 250 DEG C; 3) the polymethylphenyl sioxane containing TP is cracked under high vacuum and highly heating-up temperature of 300 to 350 DEG C, thereby obtaining the product by collecting 250 to 290 DEG C / 2mmHg distillations.

Owner:HANGZHOU NORMAL UNIVERSITY

Direct-to-metal and exterior durable non-skid coating

ActiveUS20120071582A1Good color retentionImproved external durabilityOther chemical processesEpoxy resin coatingsEpoxyMethyl phenyl polysiloxane

A non-skid coating described herein attempts to overcome the deficiencies of the conventional coatings with improved external durability and color retention, a reduced level of VOCs, and direct-to-metal (DTM) adhesion using organo-siloxane chemistry. The non-skid coating has a first component having an amino-functional siloxane resin; a second component having a non-aromatic epoxy resin; a spherical filler for lowering viscosity; a pigment; a coarse aggregate; and a thixotropic agent. The amino-functional siloxane resin can be an amino-functional methyl phenyl polysiloxane, diphenyl polysiloxane or silsesquioxane-based resin. The non-aromatic epoxy resin can be cycloaliphatic or aliphatic. The first component is about 5% to 20% weight of the coating, and the second component is about 80% to 95% weight of the coating.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

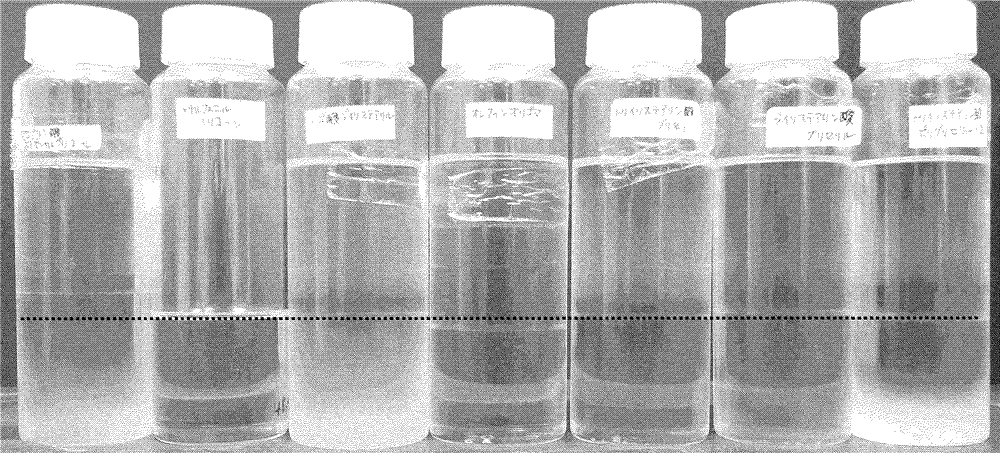

Leather cleaning, nourishing and care cream and production method thereof

The invention discloses leather cleaning, nourishing and care cream, which comprises the following components in percentage by weight: 1 to 5 percent of molecular distilled monoglyceride, 1 to 5 percent of stearic acid, 8 to 15 percent of medical white vaseline, 1 to 5 percent of methyl phenyl polysiloxane, 2 to 6 percent of alcohol 16-18, 1 to 5 percent of coconut water oil-fatty acid-diethanol amide, 0.5 to 2.5 percent of lanolin, 0.2 to 1 percent of diazolidinyl urea, 0.2 to 1 percent of plant essence, 0.2 to 1 percent of aloe liquid, 0.5 to 3 percent of vegetable wax, 0.1 to 0.5 percent of natural zeolite, and 50 to 85 percent of deionized water. The invention also provides a production method for the cream. The cream integrates maintenance and care into a whole, is environment-friendly, has the properties of cleaning and polishing leather and resisting water, cracking, mildew and bacteria, is safe, healthy and natural, does not contain paraffin, is not greasy or sticky, keeps the natural color of the leather, is anti-fouling and clean, and is applied widely.

Owner:广州市美可生物科技有限公司

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776BWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

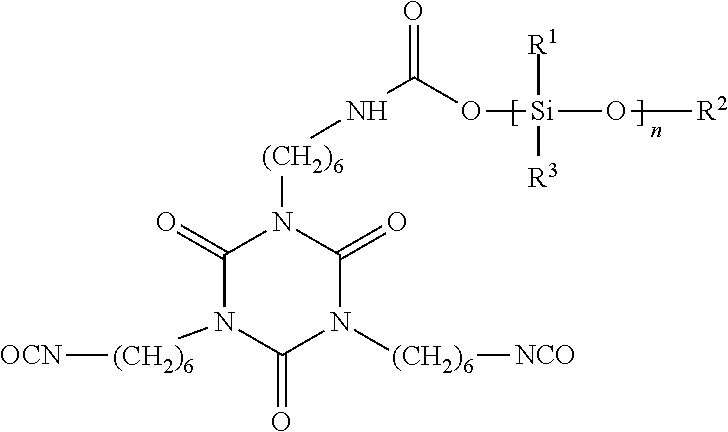

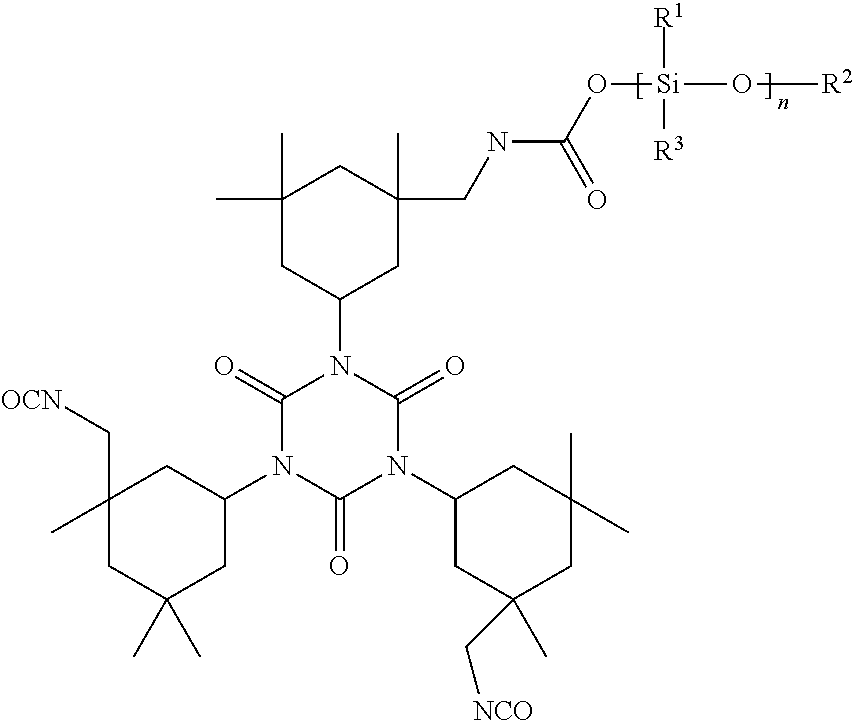

Polysiloxane Modified Polyisocyanates for Use in Coatings

InactiveUS20140275410A1Group 4/14 element organic compoundsPolyurea/polyurethane coatingsPolyesterEpoxy

The invention relates to an isocyanate-terminated polysiloxane material that can preferably be used as a curing agent, hardener or co-reactant in coatings. The invention further relates to a method of manufacturing the isocyanate-terminated polysiloxane material by partially hydrolyzing a methoxy-functional polysiloxane such as a methyl phenyl polysiloxane, and reacting it with a polyisocyanate to yield the isocyanate-terminated polysiloxane hardener. The hardener can preferably be used with any isocyanate-reactive functional group of another component to form coating systems, including acrylics, polyesters, epoxies and urethanes.

Owner:HEMPEL AS

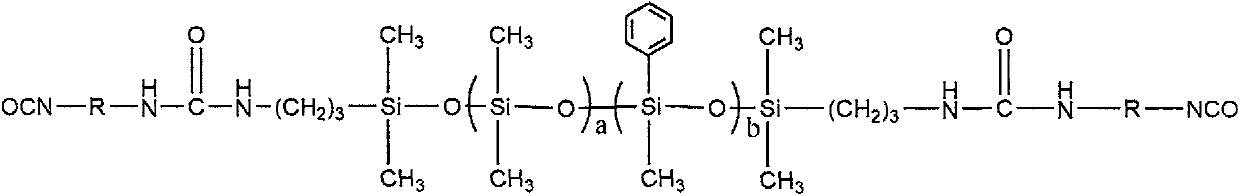

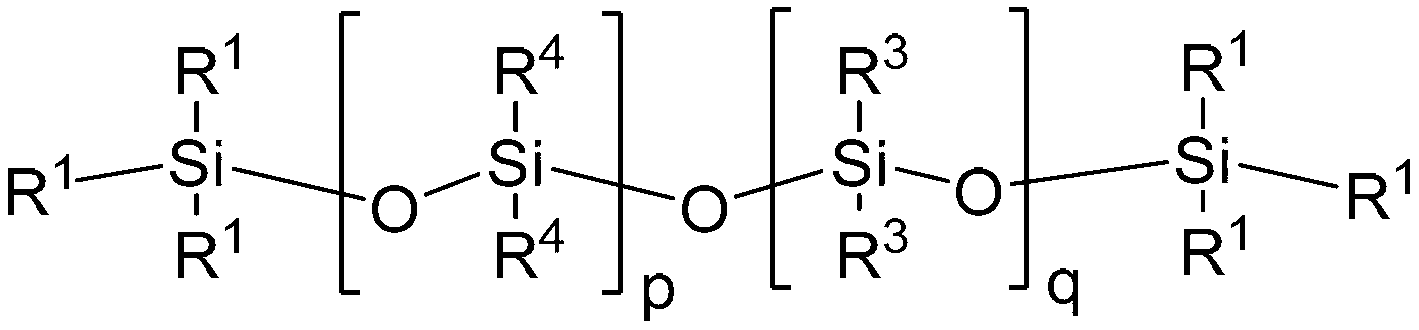

Organosilicone modified isocyanate prepolymer for solvent-free type synthetic leather and preparation method thereof

The invention discloses an organosilicone modified isocyanate prepolymer for solvent-free type synthetic leather and a preparation method thereof. The prepolymer contains a compound in the structure shown in the description, wherein R is aryl or fatty group; a and b are natural numbers. The preparation method comprises the following steps that (1) octamethylcyclotetrasiloxane, 2,4,6,8-tetramethyl-2,4,6,8-tetraphenylcyclotetrasiloxane and acid catalysts are added into a reactor; then, tetramethyl dihydrodisiloxane is added; ring-opening polymerization reaction is performed for 4 to 6h at 60 to80 DEG C; temperature reduction, neutralization, water washing, filtering and micromolecule by-product removal are performed to obtain hydrogen-terminated blocking methyl phenyl polysiloxane; (2) thehydrogen-terminated methyl phenyl polysiloxane obtained in the step (1) and allyl amine react under H2PtCl6 catalysts to prepare hydrogen-terminated blocking methyl phenyl polysiloxane; (3) the product in the step (2) is dehydrated and then reacts with isocyanate monomers to generate the prepolymer with the terminal group being NCO.

Owner:LIMING RES INST OF CHEM IND

Polysiloxane modified polyisocyanates for use in coatings

The invention relates to an isocyanate-terminated polysiloxane material that can preferably be used as a curing agent, hardener or co-reactant in coatings. The invention further relates to a method of manufacturing the isocyanate-terminated polysiloxane material by partially hydrolyzing a methoxy-functional polysiloxane such as a methyl phenyl polysiloxane, and reacting it with a polyisocyanate to yield the isocyanate-terminated polysiloxane hardener. The hardener can preferably be used with any isocyanate-reactive functional group of another component to form coating systems, including acrylics, polyesters, epoxies and urethanes.

Owner:HEMPEL AS

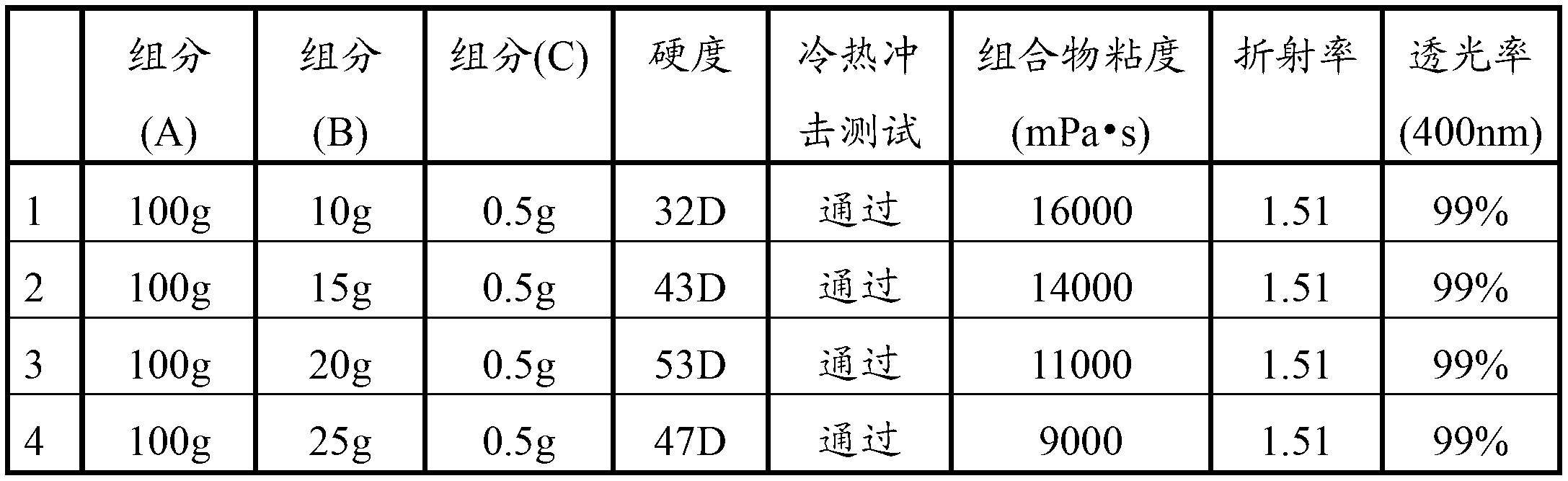

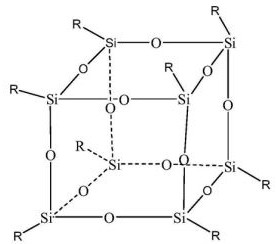

Curable silicon rubber composition as well as cured product and coating curing method thereof

InactiveCN103232707AHigh refractive indexImproved performance characteristicsCoatingsPlatinumPolymer science

The invention aims to provide a curable silicon rubber composition which is high in refractive index, is good in rubber-like performance and strength characteristics and hardly has surface viscosity after curing. A coating agent is developed based on the composition. The curable silicon rubber composition comprises a component A, a component B and a component C, wherein the component A contains methyl phenyl polysiloxane with unsaturated bonds in aliphatic series, and the viscosity of the component A at 25 DEG C is 2000-20000 mPa.s; the component B is methyl phenyl polysiloxane of which each molecule contains a plurality of silicon-hydrogen bonds, and the viscosity of the component B at 25 DEG C is 2000-20000 mPa.s; the component C is a platinum family metal catalyst; and the mass of the component B occupies 10-90% of the total mass of the component A and the component B.

Owner:SHENZHEN CAPCHEM TECH CO LTD +1

Direct-To-Metal and Exterior Durable Non-Skid Coating

ActiveUS20120238666A1Lower Level RequirementsGood colorOther chemical processesEpoxy resin coatingsEpoxyMethyl phenyl polysiloxane

A non-skid coating described herein attempts to overcome the deficiencies of the conventional coatings with improved external durability and color retention, a reduced level of VOCs, and direct-to-metal (DTM) adhesion using organo-siloxane chemistry. The non-skid coating has a first component having an amino-functional siloxane resin; a second component having a non-aromatic epoxy resin; a spherical filler for lowering viscosity; a pigment; a coarse aggregate; and a thixotropic agent. The amino-functional siloxane resin can be an amino-functional methyl phenyl polysiloxane, diphenyl polysiloxane or silsesquioxane-based resin. The non-aromatic epoxy resin can be cycloaliphatic or aliphatic. The first component is about 5% to 20% weight of the coating, and the second component is about 80% to 95% weight of the coating.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

High-temperature resistance methyl phenyl polysiloxane resin powder coating and preparation method thereof

InactiveCN103333605AImprove moisture resistanceImprove waterproof performancePowdery paintsBrickSlag

The invention discloses a high-temperature resistance methyl phenyl polysiloxane resin powder coating and a preparation method thereof. The coating comprises following components, in parts by weight: 47 to 53 parts of methyl phenyl polysiloxane resin, 0.3 to 0.8 part of tert-butyl peroxide, 8 to 12 parts of methyltris(methylethylketoxime)silane, 1.1 to 1.3 parts of organic silicon levelling agent, 2.5 to 3.0 parts of polysiloxanes, 3.3 to 3.8 parts of triglycidyl isocyanurate, 9 to 10 parts of aluminium nitride powder, 5.5 to 7.5 parts of nano brick slag powder, 1.3 to 1.8 parts of 1-methyl amyl alcohol and 2 to 3 parts of propylene glycol methyl ether acetate. The methyl phenyl polysiloxane resin has the advantages of excellent damp-resistance, waterproofness, stainlessness, cold-resistance, ozone-resistance and weatherability. The methyl phenyl polysiloxane resin has a good high-temperature resistance performance, and the heat-resistance temperature arrives at 550 DEG C or more.

Owner:BENGBU HONGAN PRECISION MACHINERY

Polysiloxane modified polyisocyanates for use in coatings

The invention relates to an isocyanate-terminated polysiloxane material that can preferably be used as a curing agent, hardener or co-reactant in coatings. The invention further relates to a method of manufacturing the isocyanate-terminated polysiloxane material by partially hydrolyzing a methoxy-functional polysiloxane such as a methyl phenyl polysiloxane, and reacting it with a polyisocyanate to yield the isocyanate-terminated polysiloxane hardener. The hardener can preferably be used with any isocyanate-reactive functional group of another component to form coating systems, including acrylics, polyesters, epoxies and urethanes.

Owner:HEMPEL AS

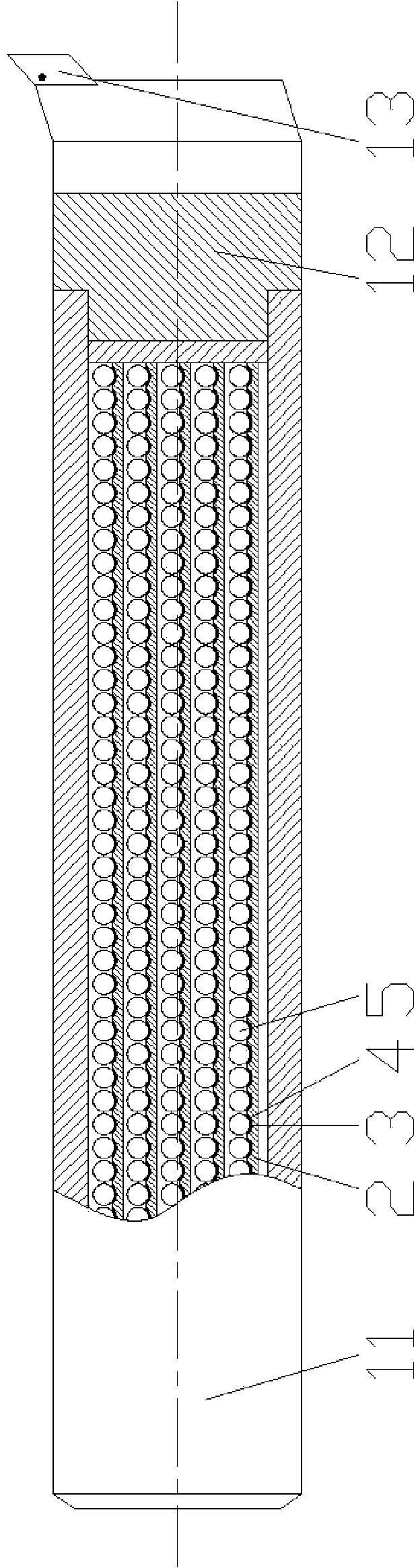

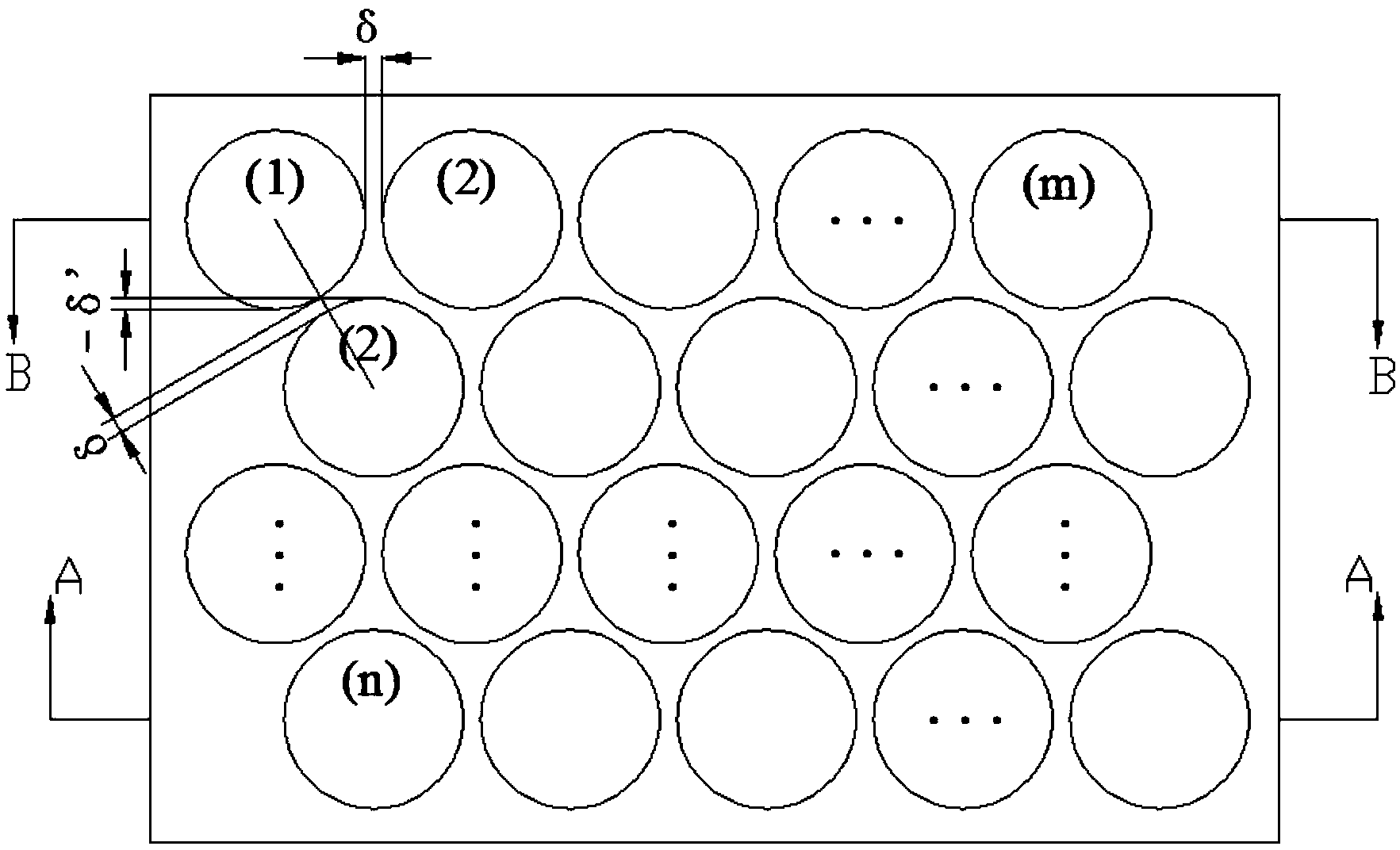

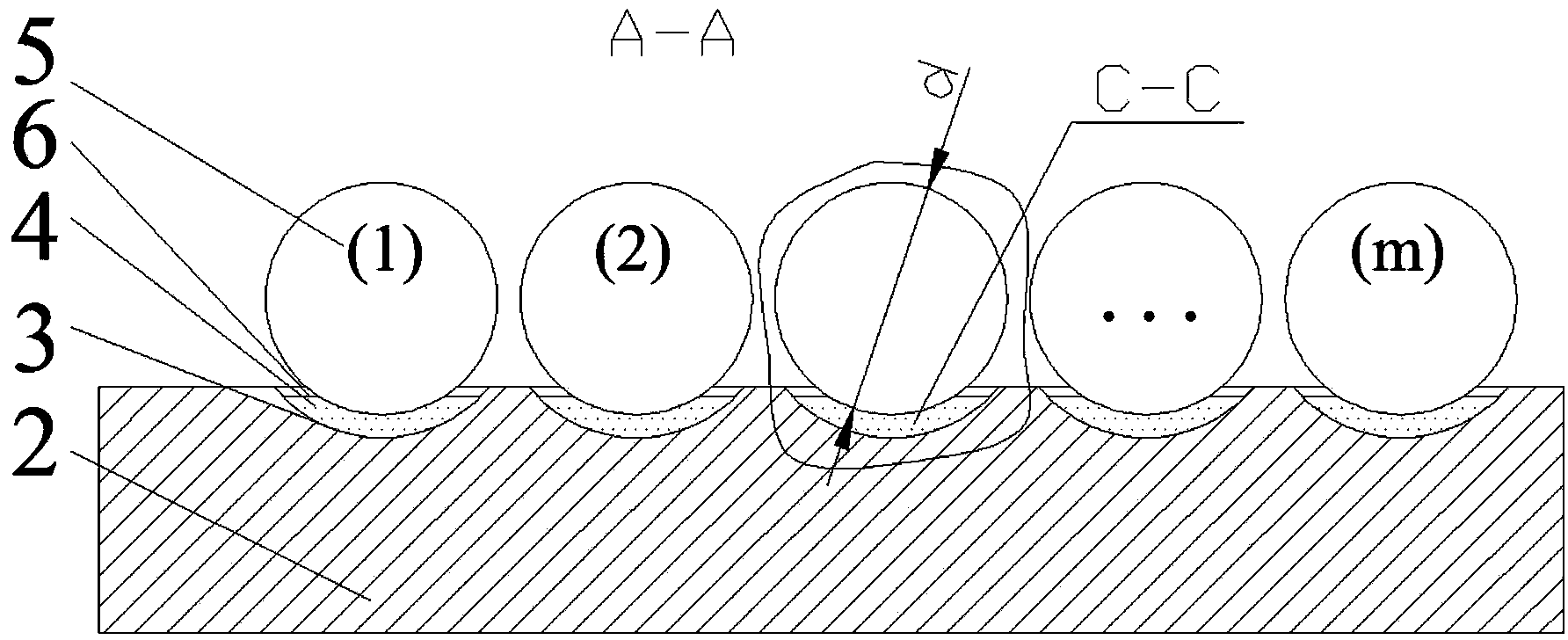

Inelastic collision and rolling viscous resistance particle coupling energy dissipation cutter rod

ActiveCN104096873AImprove stabilityHigh precisionBoring barsMetallic materialsMethyl phenyl polysiloxane

An inelastic collision and rolling viscous resistance particle coupling energy dissipation cutter rod relates to a cutting tool. The cutter rod comprises a cutter rod body, a cutter rod connection piece, a cutting head and coupling energy dissipation plates. A groove array is formed in each coupling energy dissipation plate. A surface low recovery coefficient particle and at least two high surface viscous resistance macromolecule particles are arranged in each groove, a high polymer film wraps the surface of each high surface viscous resistance macromolecule particle, and a fixed groove for installing the coupling energy dissipation plate is formed in each coupling energy dissipation plate. After multiple layers of coupling energy dissipation plates are installed in the cutter rod, vibration energy generated by cutting force can be dissipated quickly and gradually, energy dissipation factors are high, the vibration restraining effect is obvious, and boring stability and accuracy of parts with deep holes are effectively improved. The cutter rod is low in cost and easy to implement. The surface low recovery coefficient particles utilize a metal material as the base material, methyl phenyl polysiloxane and acrylate interpenetration polymer wraps the base material, and the surface low recovery coefficient particles are high in strength, not prone to corrosion, long in service life and capable of being used in a long term.

Owner:厦门粒资科技有限公司

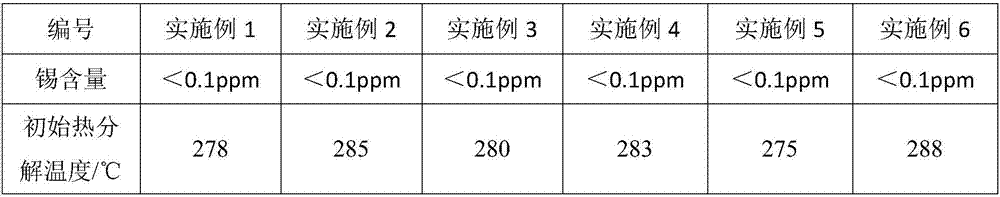

Water-borne polyurethane not containing organic tin and preparation method thereof

InactiveCN107446107AImprove hydrolysis resistanceImprove heat resistancePolyesterMethyl phenyl polysiloxane

The invention discloses a water-borne polyurethane not containing organic tin. The water-borne polyurethane is prepared from the following components in parts by weight: 25 to 80 parts of aromatic polyester polyol, 10 to 20 parts of diisocyanate, 10 to 40 parts of hydroxyalkyl-terminated methyl phenyl polysiloxane, 0.015 to 0.06 part of catalyst, 2 to 10 parts of hydrophilic chain-extending agent, 2 to 10 parts of amine chain-extending agent, 5 to 10 parts of solvent and 2 to 5 parts of salt forming agent, wherein the catalyst is selected from one or two of organic bismuth, organic zinc or organic zirconium. The water-borne polyurethane has the advantages that the hydrophilic chain-extending agent and the hydroxyalkyl-terminated methyl phenyl polysiloxane are used as main polymerizing monomers, so that the hydrolysis-resistant property and heat-resistant property are better; the water-borne polyurethane is more suitable for application environments with complicated water system; the water-borne polyurethane does not contain the organic tin catalyst, so that the more environment-friendly property is realized.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

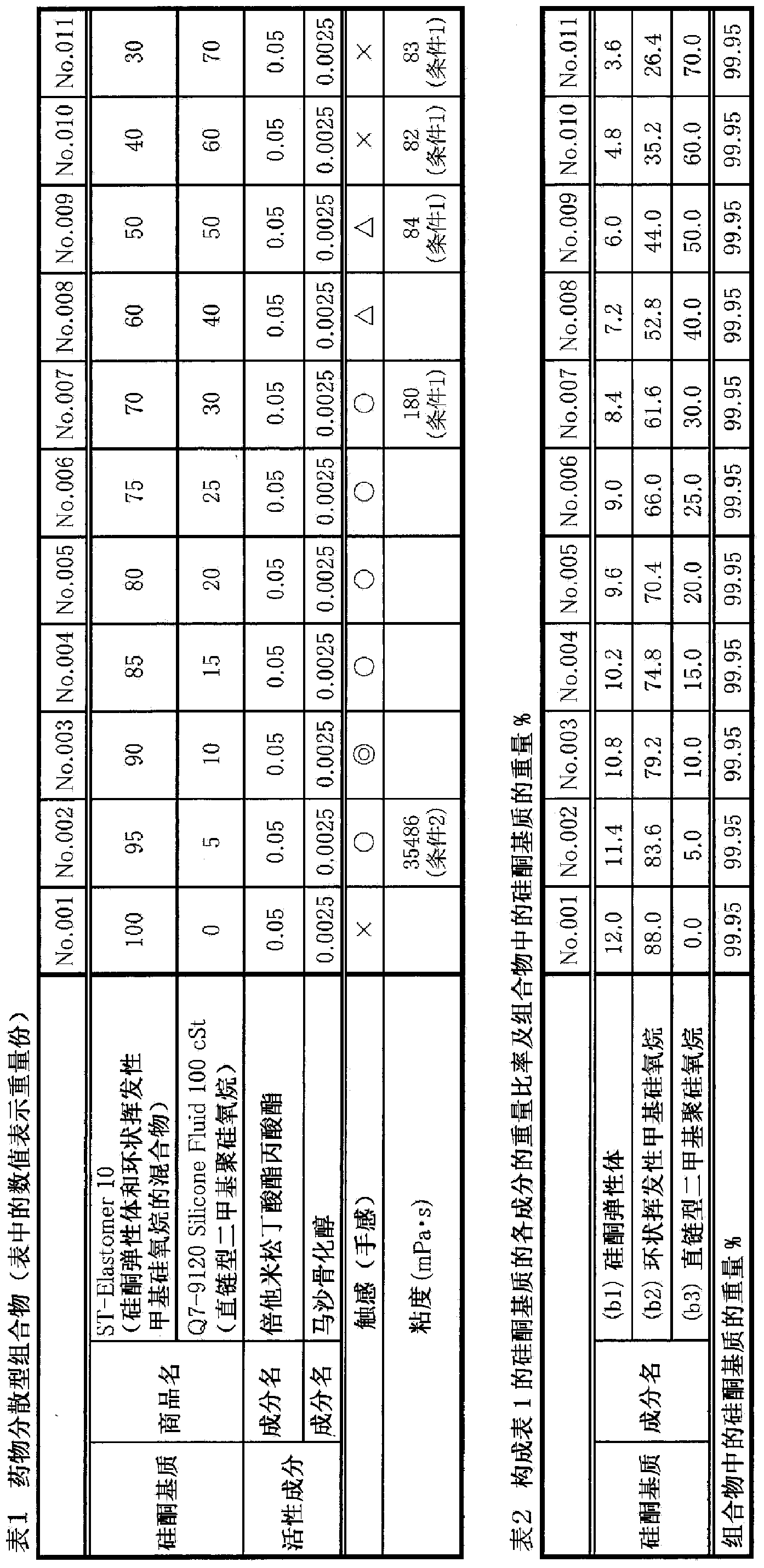

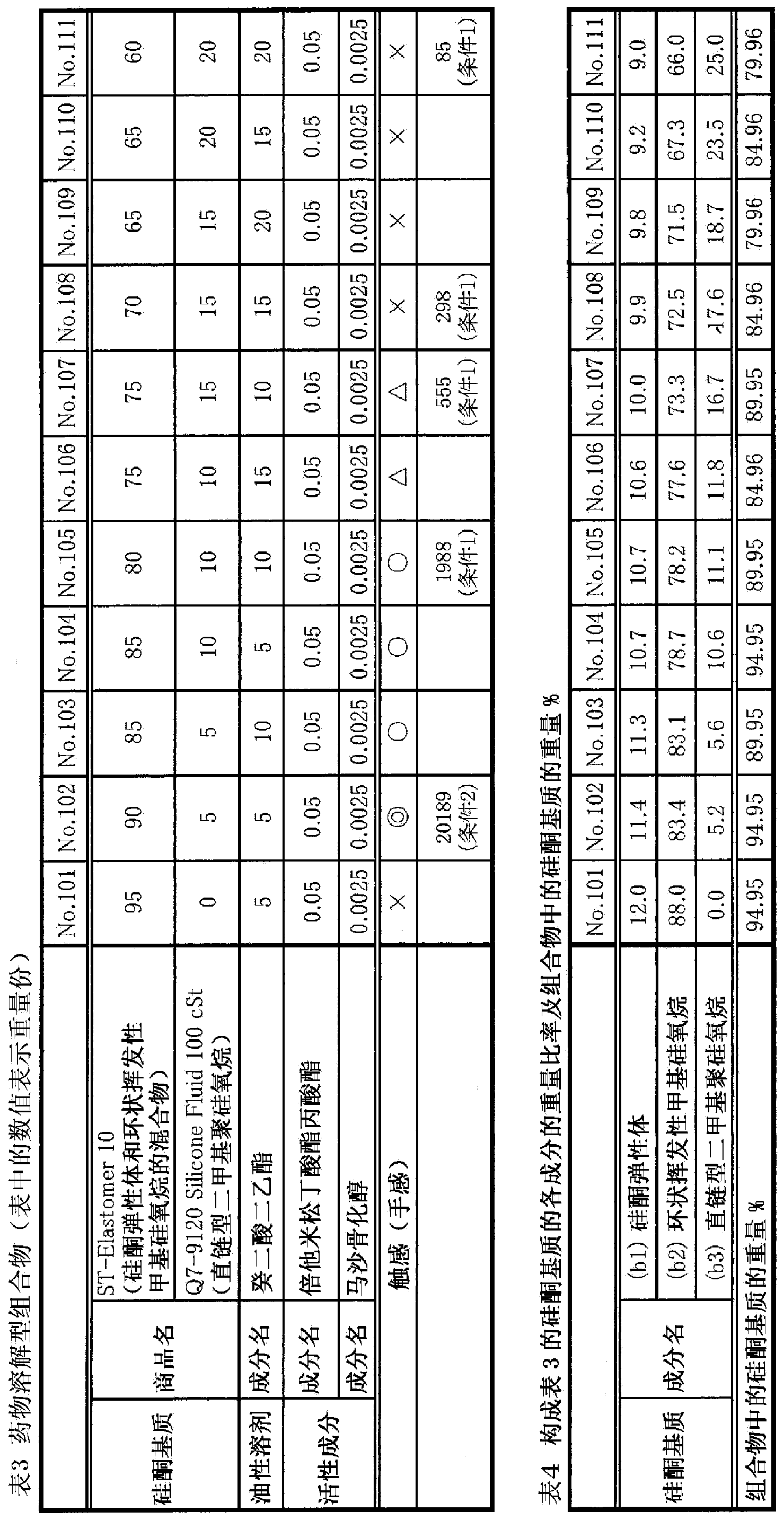

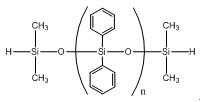

Composition for skin containing silicone base

InactiveCN103998062ARaise the ratioGood touchCosmetic preparationsToilet preparationsActive componentMethyl phenyl polysiloxane

The present invention addresses the problem of providing a composition for the skin, which has excellent texture and feeling of use. The present invention provides an anhydrous composition for the skin, which is characterized in that: (A) 80% by weight or more of the composition is composed of a silicone base; (B) the silicone base contains (b1) a silicone elastomer, (b2) a cyclic volatile methyl siloxane that has 3-6 silicon atoms and (b3) a linear dimethyl polysiloxane and / or a linear methylphenyl polysiloxane; (C) the composition contains an active component that is present in a dispersed or dissolved state; and (D) the composition does not contain a non-silicone thickener.

Owner:MARUHO

Phenyl polysiloxane containing hydrogen and preparation method thereof

The invention relates to phenyl polysiloxane containing hydrogen and a preparation method thereof, the phenyl polysiloxane containing hydrogen is prepared by using 60 to 80 parts of methyl phenyl polysiloxane, 20 to 35 parts of methylhydracyclosiloxane, 5 to 8 parts of end-capping reagent tetramethyl dihydro disiloxane, and taking cation exchange resin as a catalyst. The process route is simple and convenient, economic and environment friendly and raw materials are easy to obtain. The prepared phenyl polysiloxane containing hydrogen by utilizing the technology has the usability of high phenyl content, good transparency, high refraction coefficient and excellent usability.

Owner:上海爱世博有机硅材料有限公司

High-temperature-resistant paint composition, high-temperature-resistant paint, preparation method and application of high-temperature-resistant paint, and high-temperature-resistant coating

ActiveCN113174198AEasy to cleanEasy to withstand high temperatureFireproof paintsPolymer scienceMethyl phenyl polysiloxane

The invention relates to the technical field of coatings, and discloses a high-temperature-resistant paint composition, a high-temperature-resistant paint, a preparation method and application of the high-temperature-resistant paint, and a high-temperature-resistant coating. The paint composition is obtained by compounding methyl phenyl polysiloxane resin, polysilazane, alkylsilane, a silane coupling agent and a solvent with specific content; the coating prepared from the paint composition has the advantages of being easy to clean, resistant to high temperature and good in adhesiveness; and meanwhile, when the coating is applied to kitchen appliances, the electric appliances can be endowed with hydrophobic and oleophobic effects.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

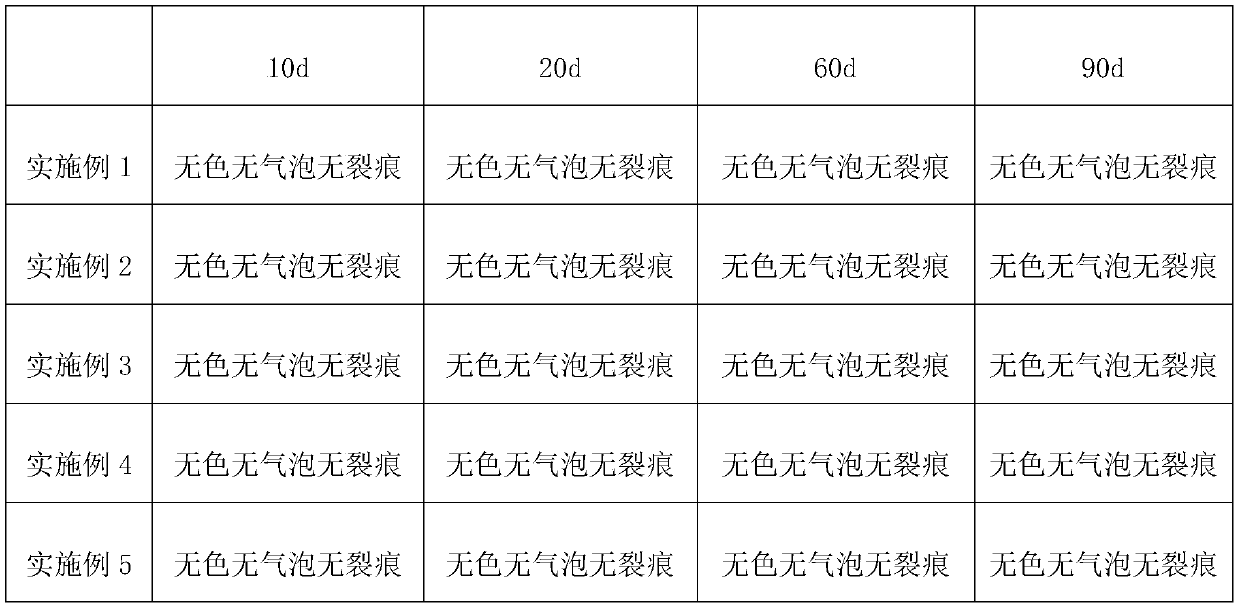

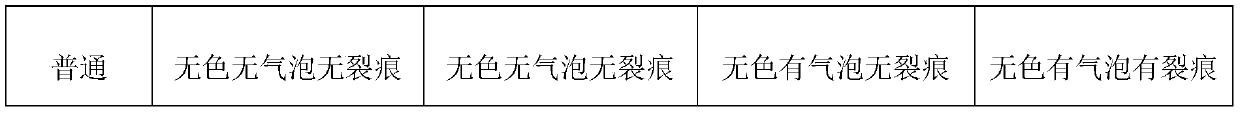

RTV single component hydrophobic long-acting antifouling flashing paint

InactiveCN1128192CImprove hydrophobicityIncrease pollution flashover voltageAntifouling/underwater paintsPaints with biocidesElectric power systemMethyl phenyl polysiloxane

The present invention provides a RTV monocomponent hydrophobic long-acting antifouling flashing paint for porcelain insulator for high-voltage transmission line of power system and its production method. It is formed from the following components (by weight %): 20-40% of terminal hydroxy polysiloxane, 2-10% of basic fire-resisting agent, 3-20% of reinforcing agent, 1-5% of additive, 0.2-0.4% of catalyst, 1-5% of cross-linking agent and 30-60% of diluting agent.

Owner:CHENGDU TALY TECH CO LTD

Hot-melt OCA optical adhesive film and preparation method thereof

InactiveCN111808539AOvercome limitationsOvercome defectsNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermoplasticPolymer science

The invention discloses a hot-melt OCA optical adhesive film and a preparation method thereof. The hot-melt OCA optical adhesive film is a novel optical-grade material taking hot-melt resin and organic silicon resin as the main body, wherein the hot-melt resin comprises thermosetting resin and thermoplastic resin, and the organic silicon resin comprises: reactive methyl phenyl polysiloxane, methylphenyl T resin, methyl phenyl silicon resin, a phenyl cross-linking agent, a phenyl chain extender and an additive. Compared with the traditional OCA, the OCA provided by the invention has the advantages of excellent light transmission, bonding strength, cold and hot impact resistance and weather resistance.

Owner:SUZHOU TONGLI PHOTOELECTRIC CO LTD

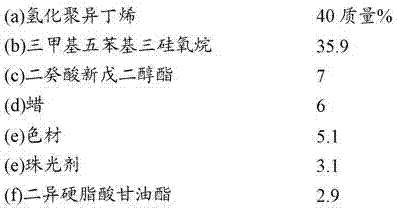

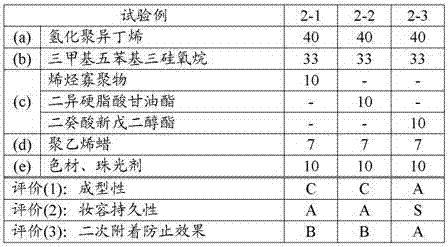

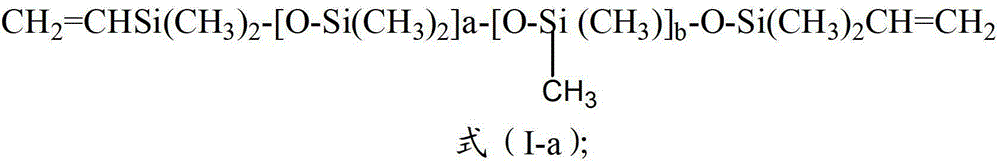

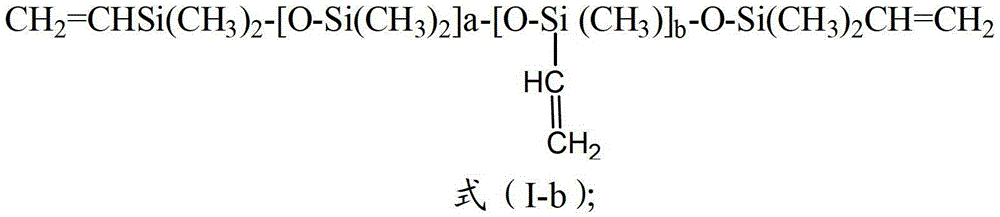

Solid lip cosmetic

ActiveCN106999369AExcellent secondary adhesion prevention effectGood formabilityCosmetic preparationsMake-upWaxMethylphenylsilicone

Owner:SHISEIDO CO LTD

Single-component addition-type silicone rubber and preparation method thereof

The invention provides a single-component addition-type silicone rubber which is prepared by vulcanizing the following raw materials in parts by mass: 20-50 parts of vinyl polysiloxane, 3-18 parts of vinyl methyl phenyl polysiloxane, 4-20 parts of hydrogen-containing polysiloxane, 0.01-0.1 part of platinum catalyst, 0.3-2.5 parts of inhibitor, 40-60 parts of filler, 2.0-10 parts of additive and 0.5-3 parts of tackifier. The single-component addition-type silicone rubber comprises the heat-resistant additive and the filler, so that the single-component addition-type silicone rubber prepared by vulcanizing has good high temperature resistance and low temperature aging resistance. The single-component addition-type silicone rubber comprises the catalytic inhibitor, so that the single-component addition-type silicone rubber has a higher inhibitory effect, and the storage life of the single-component addition-type silicone rubber is prolonged. When the addition-type silicone rubber is vulcanized, small molecular substances are not produced, and packaging components are not corroded.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

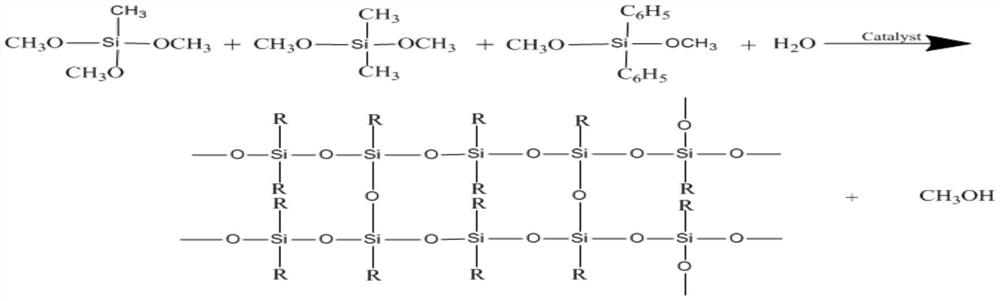

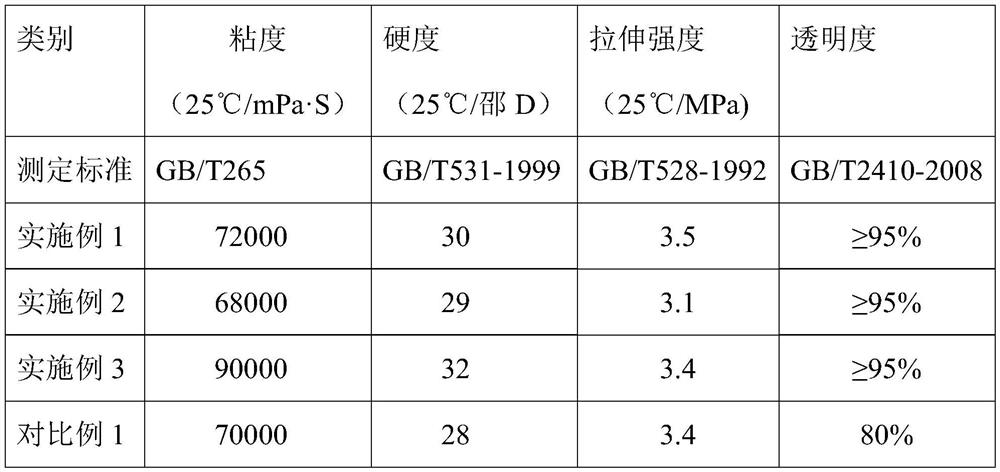

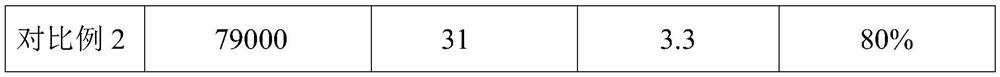

Methoxy-terminated methylphenyl polysiloxane resin, silicone coating glue, preparation method and application

The invention relates to a methoxy-terminated methylphenyl polysiloxane resin, a silicone coating glue, a preparation method and an application thereof, and the silicone material for preparing the methoxy-terminated methylphenyl polysiloxane resin is Oxygen monomers include: 19-30 parts of diphenyldimethoxysilane, 20-30 parts of dimethyldimethoxysilane and 40-60 parts of methyltrimethoxysilane; The mass content of phenyl groups in the group-terminated methylphenyl polysiloxane resin is 23% to 25%. The above-mentioned methoxy-terminated methylphenyl polysiloxane resin is terminated with methoxy groups and has a suitable content of phenyl groups, so that its refractive index is very close to that of fumed silica and has a suitable viscosity . Using this polysiloxane resin to replace the base material in the traditional organic coating adhesive, and adding fumed silica as a reinforcing agent can significantly improve the mechanical properties such as hardness and tensile strength on the basis of ensuring high transparency , Adhesive performance and air tightness.

Owner:广州天宸高新材料有限公司

Organic silicone adhesive containing nano-silver material and preparation method thereof

PendingCN111303830AHigh refractive indexHigh light transmittanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceMethyl phenyl polysiloxane

The invention relates to the technical field of high polymer materials, in particular to an organic silicone adhesive containing a nano-silver material and a preparation method thereof. The organic silicone adhesive is prepared from the following components: vinyl-terminated methyl phenyl polysiloxane, an amine compound, terminal group hydrogen-containing polysiloxane, o-hydroxybenzophenone, nano-silver, a toughening agent, heat-resistant filler, a curing agent and a platinum catalyst, and has an antibacterial function, and is better in durability and long in service life. The preparation method comprises the following steps of weighing vinyl-terminated methyl phenyl polysiloxane, the amine compound, the terminal group hydrogen-containing polysiloxane, the toughening agent and the platinumcatalyst, and adding the materials into a sealed reaction device for heating under the protection of inert gas, adding the nano-silver and the heat-resistant filler, and stirring, then adding o-hydroxybenzophenone and the curing agent, and continuously stirring, decompressing to remove bubbles, and heating and curing to obtain an organic silicone adhesive. The preparation process is simple, the obtained organic silicone adhesive is good in antibacterial effect, and the durability of the organic silicone adhesive is improved.

Owner:深圳市先进连接科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com