Methoxy-terminated methylphenyl polysiloxane resin, silicone coating glue, preparation method and application

A technology of polysiloxane resin and terminal methyl phenyl group, applied in the field of coating protective materials, can solve the problems of reducing the transparency of organic coating glue, restricting the use of organic coating glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

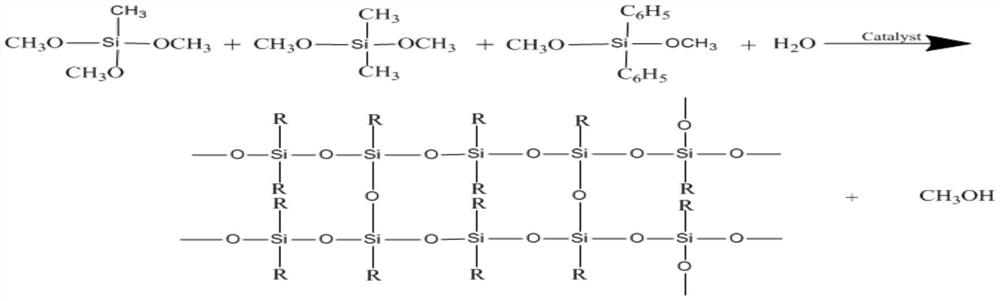

Method used

Image

Examples

preparation example Construction

[0028] The siloxane monomers for preparing methoxy-terminated methylphenyl polysiloxane resin include, by weight parts: 19-30 parts of diphenyldimethoxysilane, dimethyldimethoxysilane 20-30 parts and 40-60 parts of methyltrimethoxysilane; and the mass content of phenyl in the methoxy-terminated methylphenyl polysiloxane resin is 23%-25%. Wherein, the mass content of phenyl in the methoxy-terminated methylphenyl polysiloxane resin is the theoretical mass content of phenyl in the product calculated based on raw materials, the same below. The preparation method of the above-mentioned methoxy-terminated methylphenyl polysiloxane resin includes the following steps: reflux the above-mentioned siloxane monomer, acid catalyst and solvent at 70°C to 80°C for 2h to 6h, and filter to obtain the reaction solution, remove the solvent to obtain methoxy-terminated methylphenyl polysiloxane resin.

[0029] In one specific example, the acidic catalyst may be an acidic cation exchange resin, a...

Embodiment 1

[0052] The first step: the synthesis of methoxy-terminated phenylmethylpolysiloxane.

[0053] In a 2000mL four-necked flask equipped with a reflux condenser, a dryer, a dropping funnel and an electric stirrer, 193 parts of diphenyldimethoxysilane, dimethyldimethoxy 214 parts of silane, 450.6 parts of methyltrimethoxysilane, 18 parts of acidic cation exchange resin and 400 parts of methanol, slowly add 200 parts of measured deionized water at room temperature, and slowly continue to heat up to 75 ° C for reflux reaction for 4 hours after the addition is completed. After the reaction is over, filter out the cationic resin catalyst, continue to heat up to 110°C, and distill methanol under the condition of a vacuum of -0.09~-0.1MPa to obtain a colorless and transparent methoxy-terminated phenylmethyl group with a refractive index of 1.4602. Polysiloxane resin.

[0054] The second step: preparation of high-strength, high-transparency, high-airtight, high-friction-resistant silicon...

Embodiment 2

[0061] Example 2 is basically the same as Example 1, except that in the synthesis step of methoxy-terminated phenylmethylpolysiloxane, by weight, 300 parts of diphenyldimethoxysilane, two 220 parts of methyldimethoxysilane, 415 parts of methyltrimethoxysilane, 22 parts of acidic cation exchange resin and 400 parts of methanol, slowly add 200 parts of metered deionized water dropwise at room temperature, and slowly continue to heat up to 70 ° C reflux reaction for 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com