High-temperature resisting bonding sealed silicone resin and preparation method thereof

A technology of bonding and sealing, silicone resin, applied in chemical instruments and methods, non-polymer adhesive additives, adhesives, etc., can solve the problem of adhesive tensile strength and tensile shear strength less than 2MPa, less than 0.6 MPa, performance degradation and other problems, to achieve the effect of improving heat resistance, improving adhesive properties, and improving resin mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

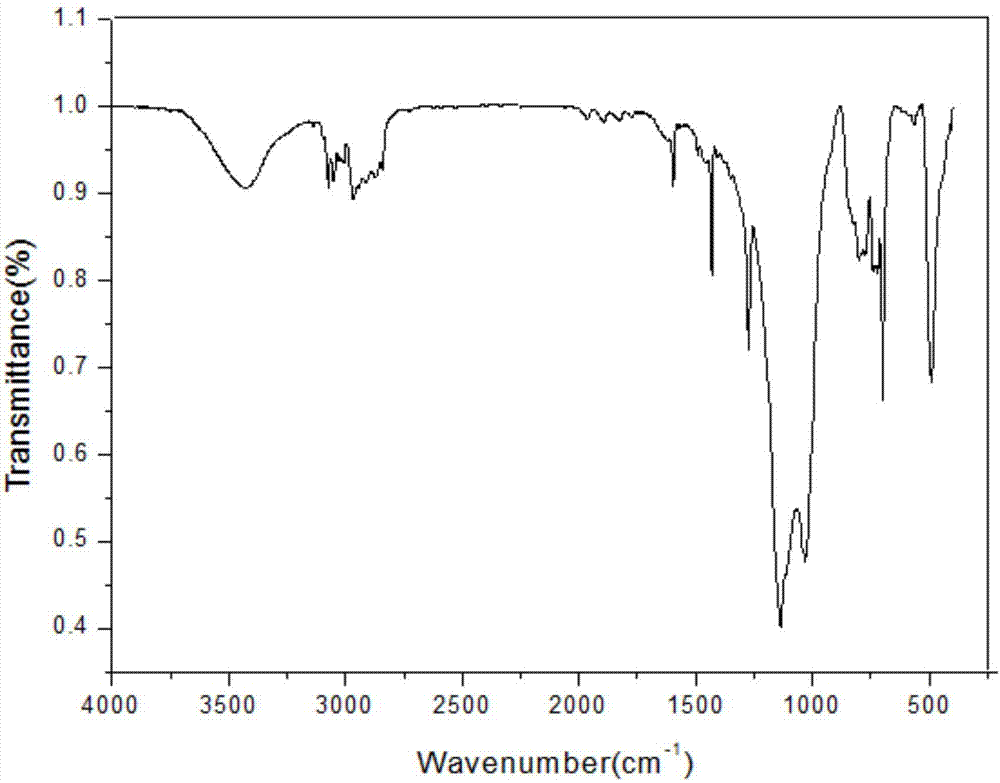

Image

Examples

Embodiment 1

[0027] A high-temperature-resistant adhesive and sealing silicone resin is made of the following raw materials in parts by weight:

[0028]

[0029] The Ph / R of the methylphenyl hydroxy silicone oil described therein is 20%, the viscosity (25°C) is 40000mpa·s, and the low volatile content is 0.14wt%.

[0030] The functionalized POSS is eight [(trialkoxysilyl) propyl]-POSS, its preparation reference (Polymer, 2010, 51 (17) p3867-3878.), the specific preparation process is as follows: anhydrous Diethyl ether 500ml, octavinyl POSS 10g (provided by Beijing Huawei Raycus Chemical Co., Ltd., purity 98%) and trimethoxysilane 73.2g were mixed, and 0.2g chloroplatinic acid isopropanol solution (0.1mol / L) was added to catalyze the reflux reaction After 24 hours, the solvent and unreacted raw materials were distilled off under reduced pressure to obtain 124.1 g of the product with a yield of 97.5%.

[0031]The heat-resistant filler is obtained by mixing iron oxide, aluminum oxide, ce...

Embodiment 2

[0035] A high-temperature-resistant adhesive and sealing silicone resin is made of the following raw materials in parts by weight:

[0036]

[0037] Among them, the methylphenyl hydroxy silicone oil Ph / R is 28%, the viscosity (25°C) is 10000mpa s, and the low volatile content is 0.12wt%. The functionalized POSS is octa[(trialkoxysilyl)propyl]-POSS, The preparation process is consistent with the description in Example 1; the heat-resistant filler is obtained by mixing iron oxide, aluminum oxide, cerium oxide, titanium dioxide, and graphite powder in a mass ratio of 1:5:1:0.2:1; the adhesive is KH560 and silanol sealant The terminal methyl phenyl siloxane oligomer is condensed at 120°C for 1 hour; the crosslinking agent is methyltrimethoxysilane; the catalyst is dibutyltin dilaurate. The preparation of methylphenylpolysiloxane-b-phenylsilsesquioxane block copolymer resin is consistent with that described in Example 1;

[0038] The preparation method of the high-temperature-r...

Embodiment 3

[0040] A high-temperature-resistant adhesive and sealing silicone resin is made of the following raw materials in parts by weight:

[0041]

[0042]

[0043] Among them, the Ph / R of methylphenyl hydroxy silicone oil is 20%, the viscosity (25°C) is 6000mpa·s, and the low volatile content is 0.14wt%.

[0044] Described functionalized POSS is octaglycidyl ether oxypropyl POSS, preparation reference (fine and specialty chemicals, 2011,19 (1), p21-23), concrete preparation process is as follows: the 100ml xylene and 60gKH560 Drop the mixed solution into a mixture of 200ml of isopropanol and 13g of 4% tetramethylammonium hydroxide aqueous solution for 1 hour, continue to stir at room temperature for 7 hours to carry out hydrolysis reaction, then condense at 80°C for 1 hour, and adjust the pH of the solution with saturated saline To neutrality, stirred at room temperature for 1 h, distilled off the solvent under reduced pressure, washed with acetone three times, removed the ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com