Phenyl organic silicon modified polyurethane resin, preparation method and application thereof

A phenyl silicone and polyurethane resin technology, applied in the field of polyurethane resin, can solve the problems of single curing form, poor weather resistance, insufficient water resistance, etc., and achieves improved microphase separation, small differences in solubility parameters, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

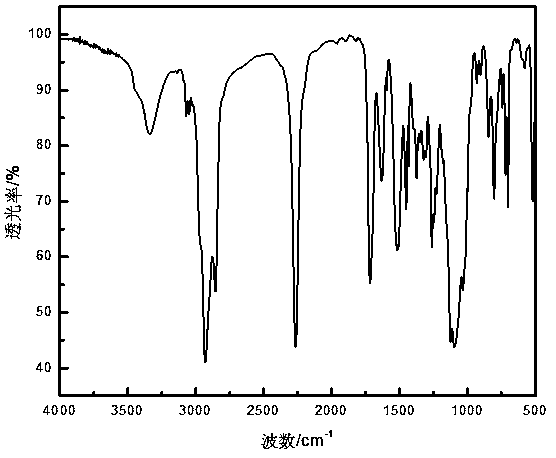

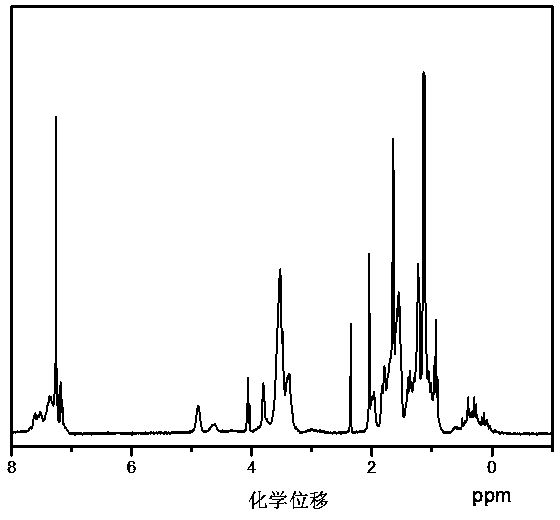

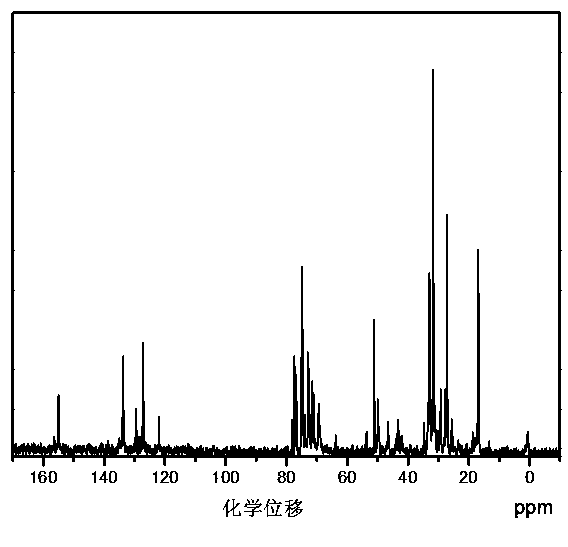

Image

Examples

Embodiment 1

[0060] 1. Preparation of phenyl silicone modified polyurethane resin

[0061] Preparation of amomethylphenyl polysiloxane

[0062] Dissolve 7.8g (0.06mol) dimethyl dichlorosilane in 70.2g toluene, then add dropwise to a solution containing 17.28g (0.08mol) diphenylsilanediol, 146.0g tetrahydrofuran (THF) and 9.5g (0.12 mol) in a reaction flask of pyridine. After reacting at 20°C for 5h, cool to room temperature, and filter under reduced pressure. After removing the solvent under reduced pressure, at 20°C, the low boiling point substances in the product were removed under reduced pressure by an oil pump to obtain a transparent liquid.

[0063] Preparation of imino-terminated methylphenylpolysiloxane

[0064] 10.4 g (0.04 mol) of γ-cyclohexylaminopropyltrimethoxysilane and 0.1 g of tetrabutyl titanate were added and reacted at 70° C. for 7 hours to prepare imino-terminated methylphenylpolysiloxane.

[0065] Preparation of Phenyl Silicone Modified Polyurethane Resin

[0066]...

Embodiment 2

[0070] 1. Preparation of phenyl silicone modified polyurethane resin

[0071] Preparation of hydroxy-terminated methylphenylpolysiloxane

[0072] After dissolving 3.9g (0.03mol) dimethyldichlorosilane and 4.7g (0.03mol) methylpropyldichlorosilane in 9.4g toluene, they were added dropwise to 12.32g (0.08mol) methylphenylsilane Diol, 17.3g of tetrahydrofuran (THF) solution and 9.5g (0.12mol) of pyridine in a reaction flask were reacted at 80°C for 2h. After cooling to room temperature, filter under reduced pressure. After removing the solvent under reduced pressure, the low boiling point substances in the product were removed under reduced pressure by an oil pump at 40°C to obtain a transparent liquid.

[0073] Preparation of amino-terminated methylphenylpolysiloxane

[0074] Add 7.2g (0.04mol) of γ-aminopropyltrimethoxysilane and 0.2g of tert-butyl titanate to hydroxyl-terminated methylphenylpolysiloxane, and react at 100°C for 10h to prepare amino-terminated terminal methy...

Embodiment 3

[0080] 1. Preparation of phenyl silicone modified polyurethane resin

[0081] Preparation of hydroxy-terminated methylphenylpolysiloxane

[0082] After dissolving 21.2g (0.06mol) methylcyclohexyl dichlorosilane in 42.4g toluene, add dropwise to a solution containing 17.28g (0.08mol) diphenylsilanediol, 7.8g tetrahydrofuran (THF) and 9.5g ( 0.12mol) of pyridine in a reaction flask, reacted at 50°C for 5h. After cooling to room temperature, filter under reduced pressure. After removing the solvent under reduced pressure, the low boiling point substances in the product were removed under reduced pressure by an oil pump at 40°C to obtain a transparent liquid.

[0083] Preparation of amino-terminated methylphenylpolysiloxane

[0084]Add 7.6g (0.04mol) of γ-aminopropylmethyldiethoxysilane and 0.01g of isopropyl titanate to hydroxyl-terminated methylphenyl polysiloxane, react at 80°C for 8h, and prepare amino end-blocked polysiloxane.

[0085] Preparation of Phenyl Silicone Modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com