Curable silicon rubber composition as well as cured product and coating curing method thereof

A technology for curing silicone rubber and composition, applied in the direction of coating, etc., can solve the problems of unsatisfactory characteristics and indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

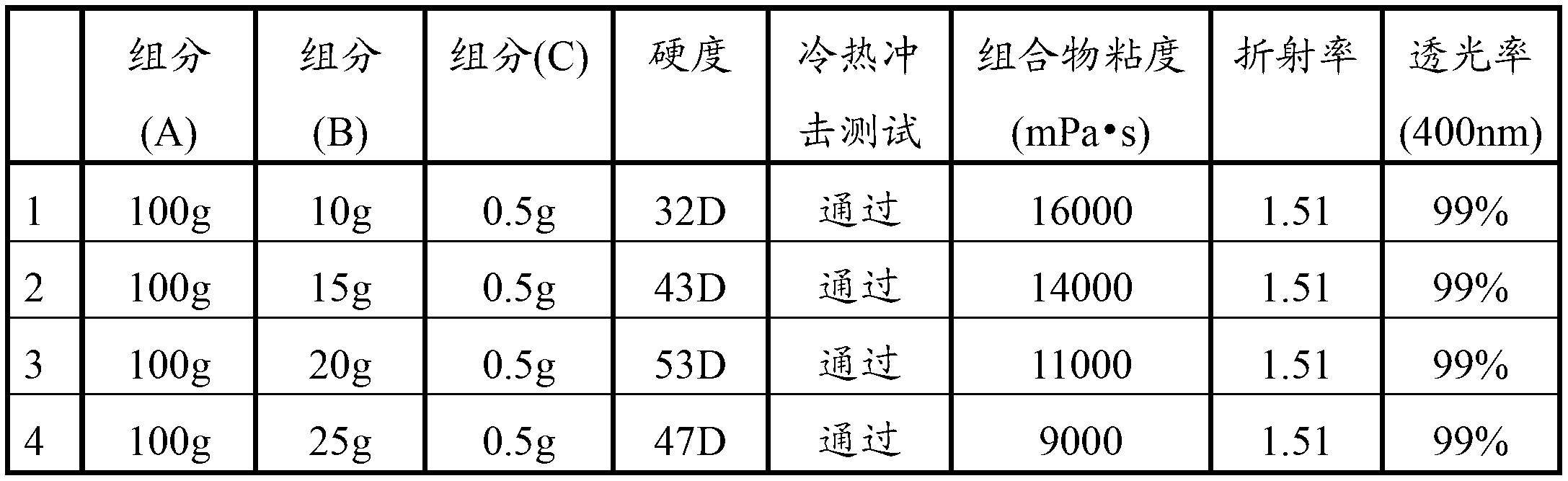

Examples

Embodiment 1

[0036] Add 150g octamethylcyclotetrasiloxane, 150g octaphenylcyclotetrasiloxane, 5g 1,1,3,3-tetramethyl-1,3-divinyldisiloxane to a 500ml dry one-necked bottle After dewatering the alkanes in vacuum at 50°C, add 2g of catalyst and raise the temperature to 160°C for 8 hours to react. After removing small molecules in vacuum, 250g of vinyl-modified linear methylphenyl polyorganosiloxane is obtained, with a viscosity of 20000mPa·s ( Component 1).

Embodiment 2

[0038] Add 150g octamethylcyclotetrasiloxane, 150g octaphenylcyclotetrasiloxane and 30g 1,1,3,3-tetramethyl-1,3-divinyldisiloxane to a 500ml dry one-necked bottle Alkanes, after removing water in vacuum at 50°C, add 4g of catalyst and raise the temperature to 160°C for 8 hours to react, and remove small molecules in vacuum to obtain 250g of vinyl-modified linear methylphenyl polyorganosiloxane with a viscosity of 2000mPa·s (component 2).

Embodiment 3

[0040] By mixing the linear methylphenyl polyorganosiloxane obtained in Example 1 and Example 2 according to a certain ratio, a linear methylphenyl polyorganosiloxane with any viscosity between 2000 and 20000 mPa·s can be obtained. alkanes mixture.

[0041] Component 1 mass (20000mPa·s)

Mass of component 2 (2000mPa·s)

Mixture viscosity

18g

2g

16000mPa·s

15g

5g

12000mPa·s

10g

10g

8000mPa·s

5g

15g

5000mPa·s

2g

18g

3000mPa·s

[0042] Table 1 Viscosities of the resulting polymethylphenylpolyorganosiloxane mixtures mixed in different proportions

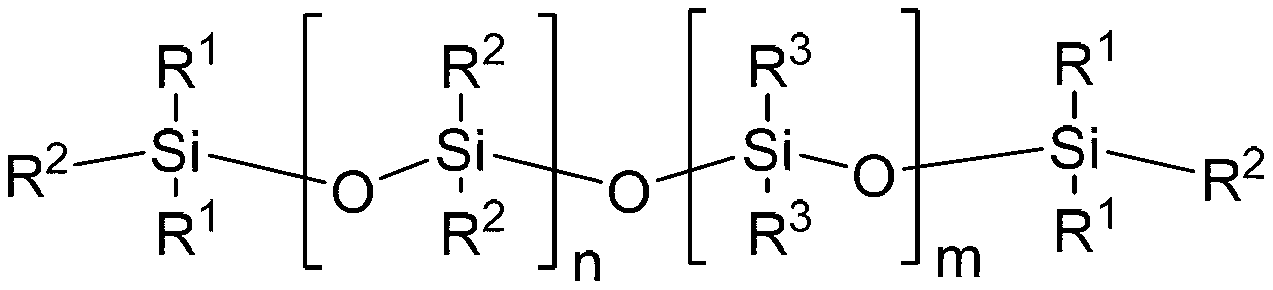

[0043] The product prepared by the above reaction can be used as component (A) which is the base component of the silicone rubber composition of the present invention. Each molecule contains more than two aliphatic unsaturated groups, the viscosity is 2000-20000mPa·s at 25°C, and organopolysiloxanes containing phenyl groups can replace the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com