Patents

Literature

36 results about "Inelastic collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An inelastic collision, in contrast to an elastic collision, is a collision in which kinetic energy is not conserved due to the action of internal friction. In collisions of macroscopic bodies, some kinetic energy is turned into vibrational energy of the atoms, causing a heating effect, and the bodies are deformed.

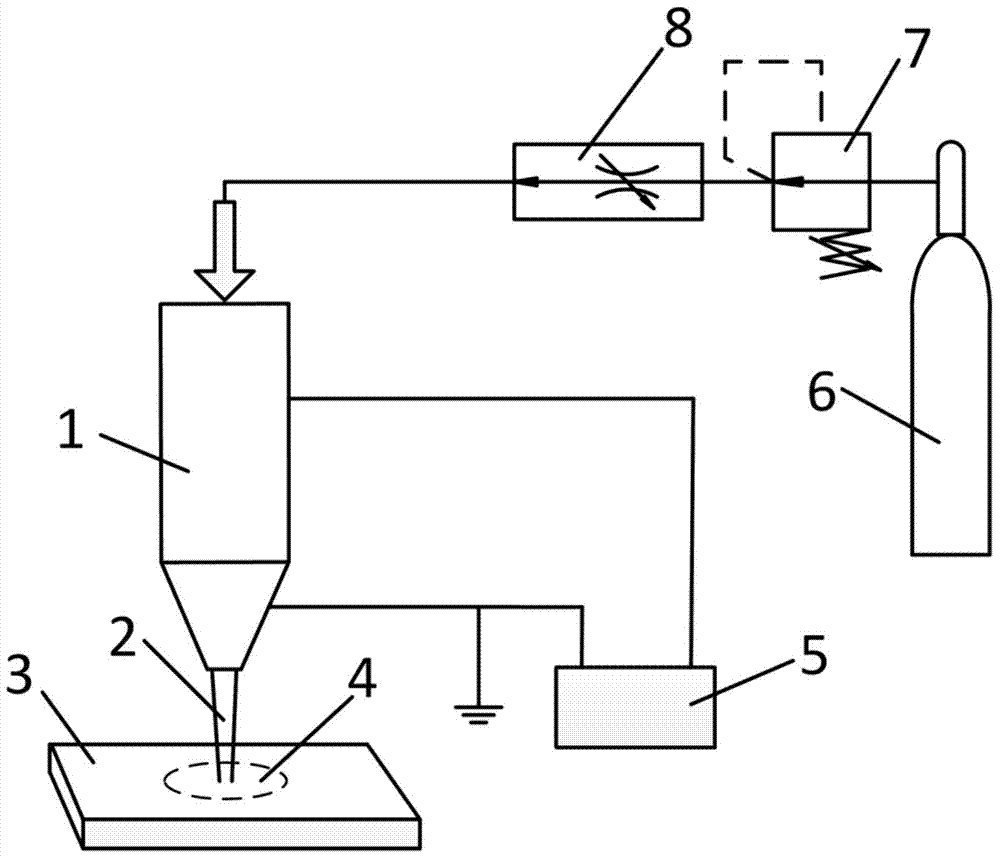

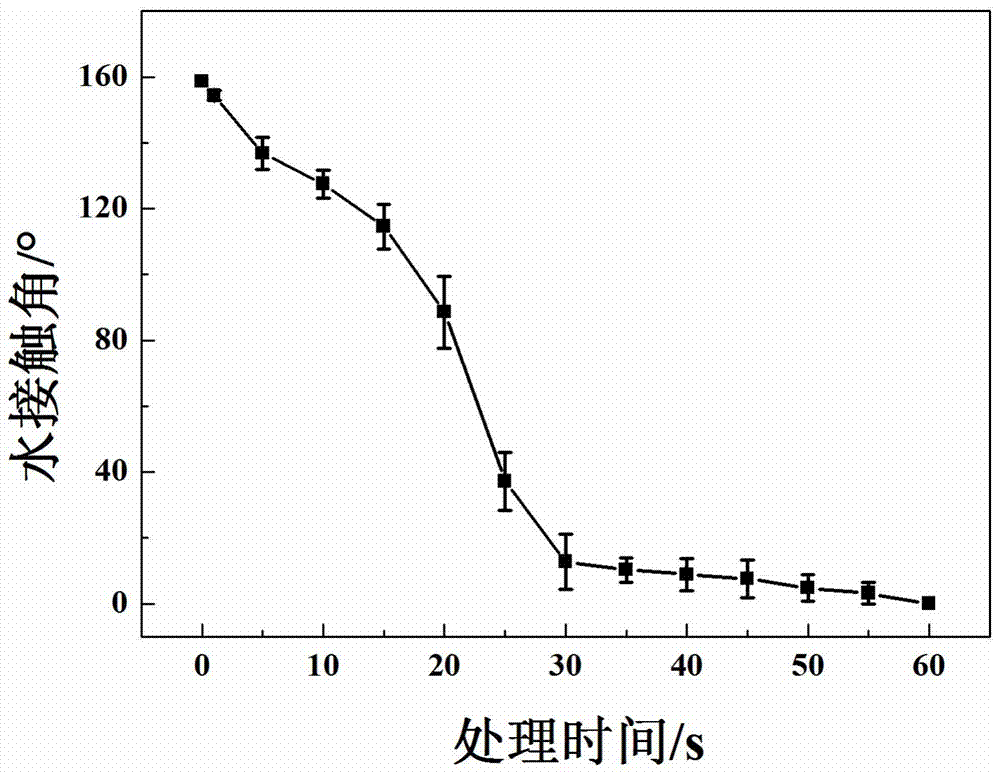

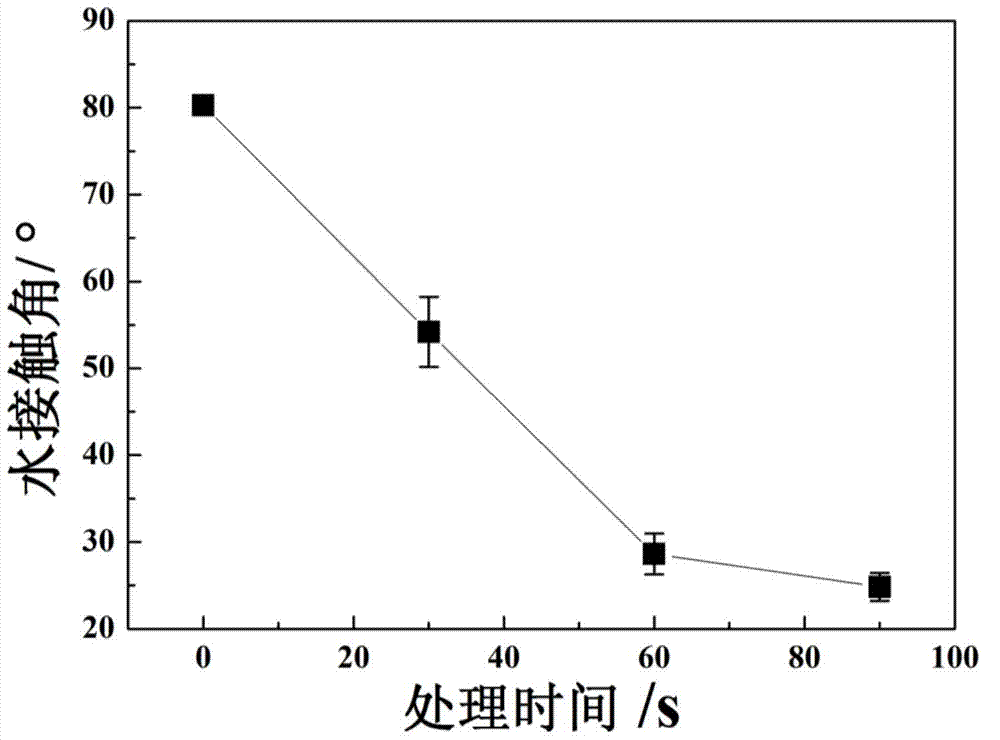

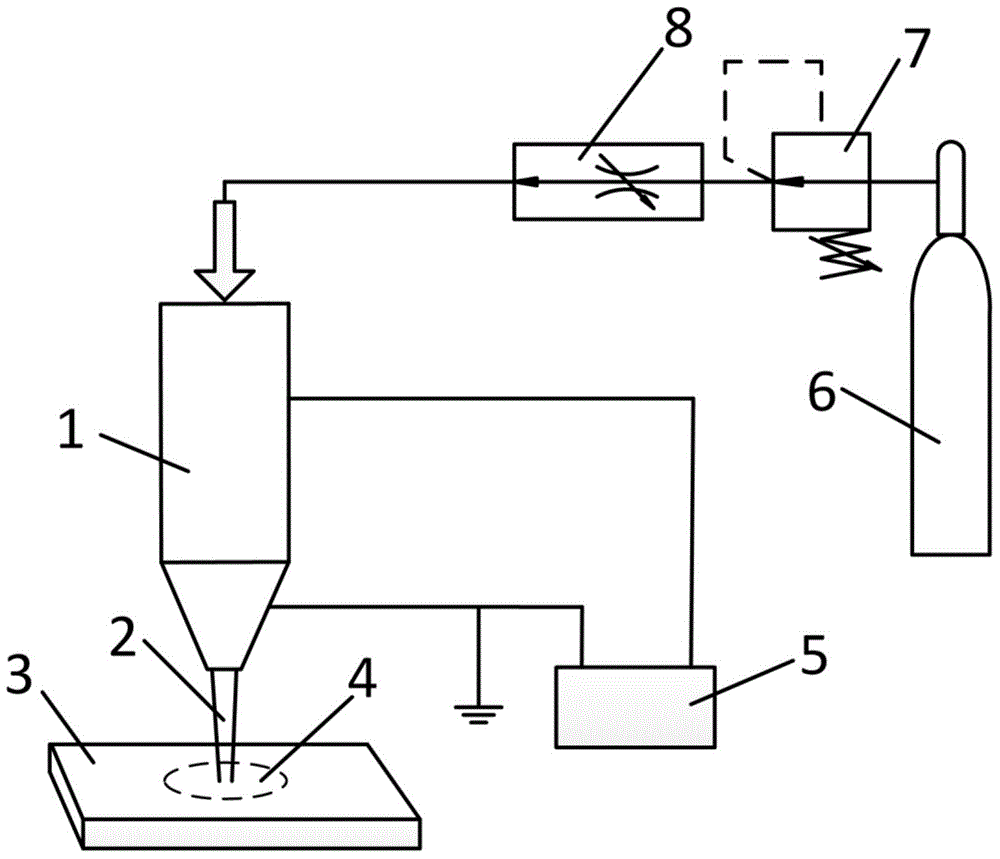

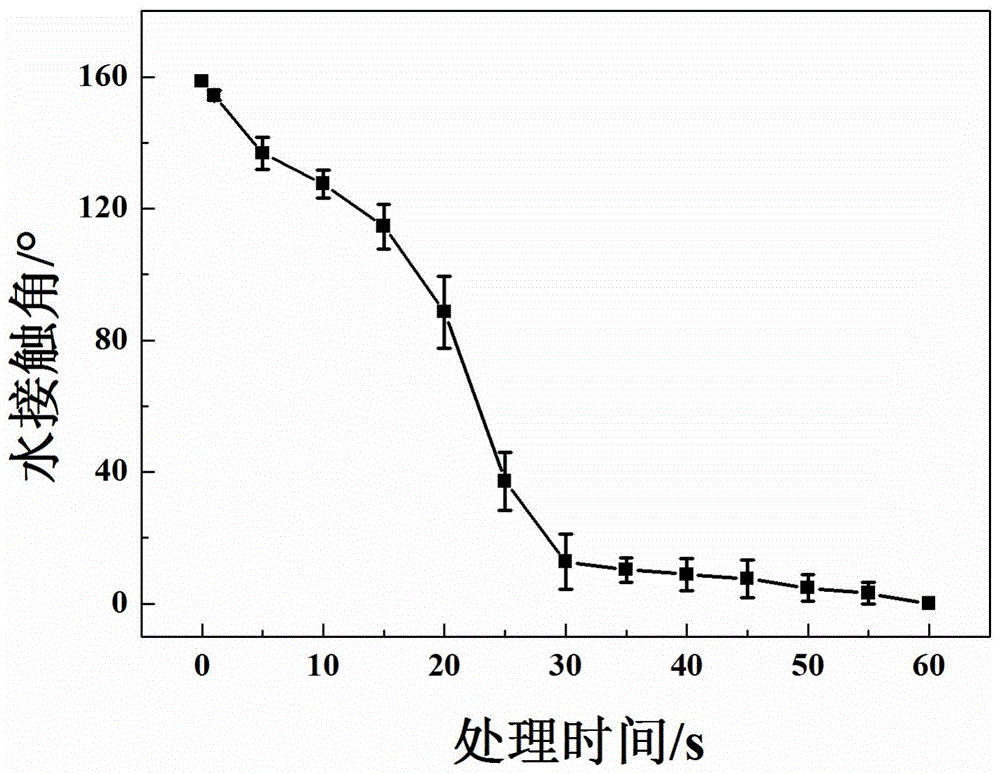

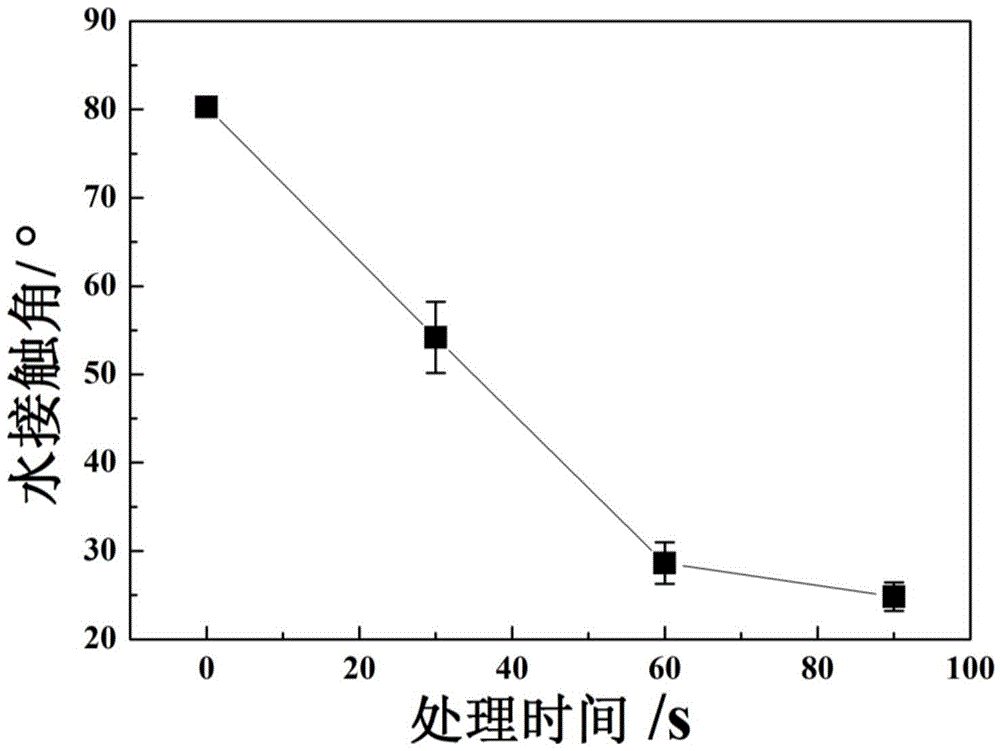

Method for modifying surface of metal material by adopting atmospheric-pressure cold plasma jet

ActiveCN103789716ANo heat damageAchieving surface modificationSolid state diffusion coatingPlasma jetChemical reaction

The invention provides a method for modifying the surface of a metal material by adopting atmospheric-pressure cold plasma jet, and belongs to the technical field of material surface treatment. The method comprises the following steps that: high-energy electrons and particles which are contained in the atmospheric-pressure cold plasma jet generate non-elastic collision with water molecules and oxygen molecules which are contained in an atmospheric environment to generate an oxygen-containing active particle; and the oxygen-containing active particle generates chemical reaction with the surface of the metal material to introduce an oxygen-containing functional group to the surface of the metal material, wherein the cold plasma jet is generated by a cold plasma jet generator with the discharge form of bare electrode corona discharge. The method provided by the invention can realize the modification of a designated-position and large-size metal surface by controlling the size or motion locus of the cold plasma jet without complex vacuum equipment, is low in cost and easily and flexibly operated without pollution on the environment, is a green surface modification method and can be applied to the surface modification of various non-metal materials.

Owner:DALIAN UNIV OF TECH

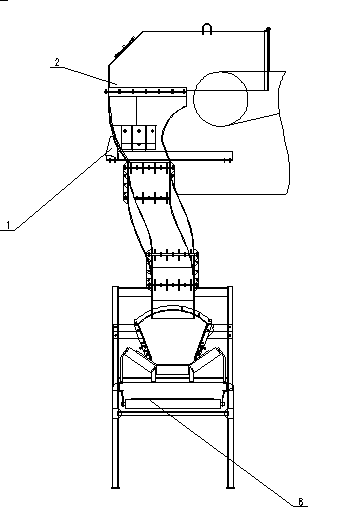

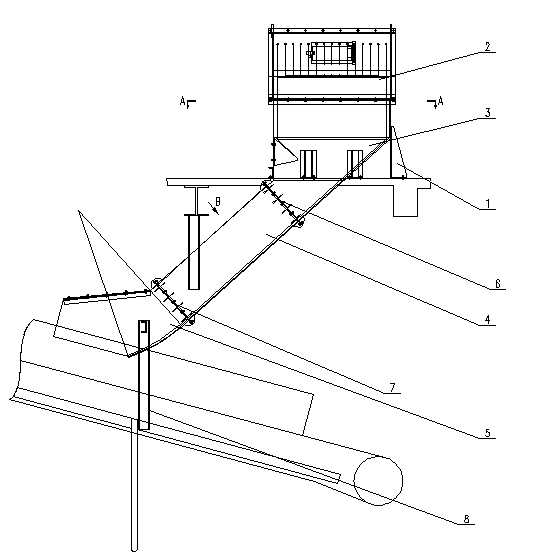

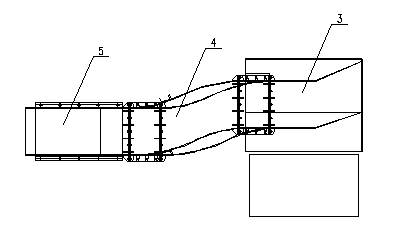

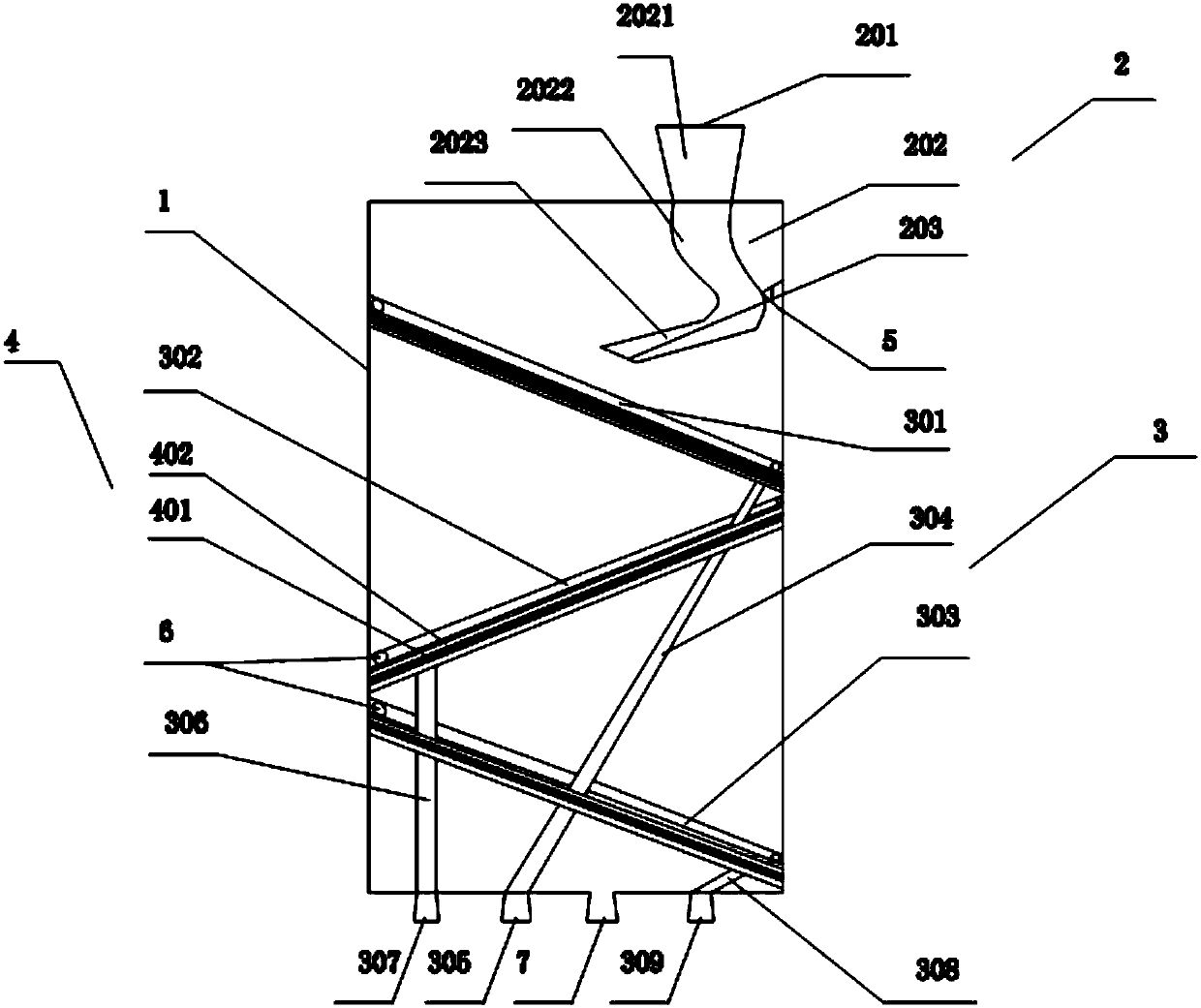

Breakage-proof buffering device for lump coal

The invention discloses a buffering device, and particularly discloses a breakage-proof buffering device for lump coal. The breakage-proof buffering device comprises a supporting seat, wherein a head shield is arranged on the supporting seat; a chute which is oblique downwards is formed below the head shield; and the chute is a circular-arc curved chute. The chute is the circular-arc curved chute, so that sufficient centrifugal force is generated by the lump coal through acceleration, and the lump coal can perform set curvilinear motion in a buffering device; meanwhile, a centripetal acceleration is generated under the action of composite force, so that the direction of the lump coal is changed, the friction surface of the lump coal along the buffering device is transferred, a free-fall motion is changed into a specific curvilinear motion, the moving speed of the lump coal is lowered greatly, and the collision time of particles is prolonged; and meanwhile, in a process when particles become static from moving, a tangential-velocity component is generated, full non-elastic collision is avoided, and the lump coal is effectively prevented from being broken.

Owner:SHANXI LU AN MINING GRP CO LTD

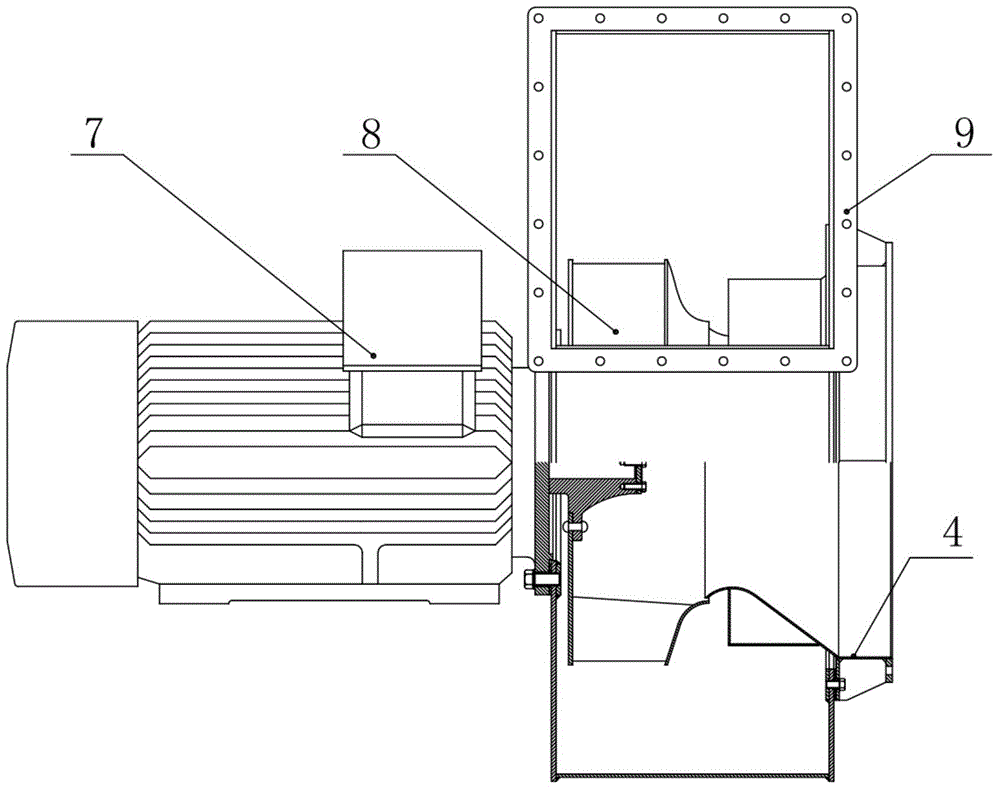

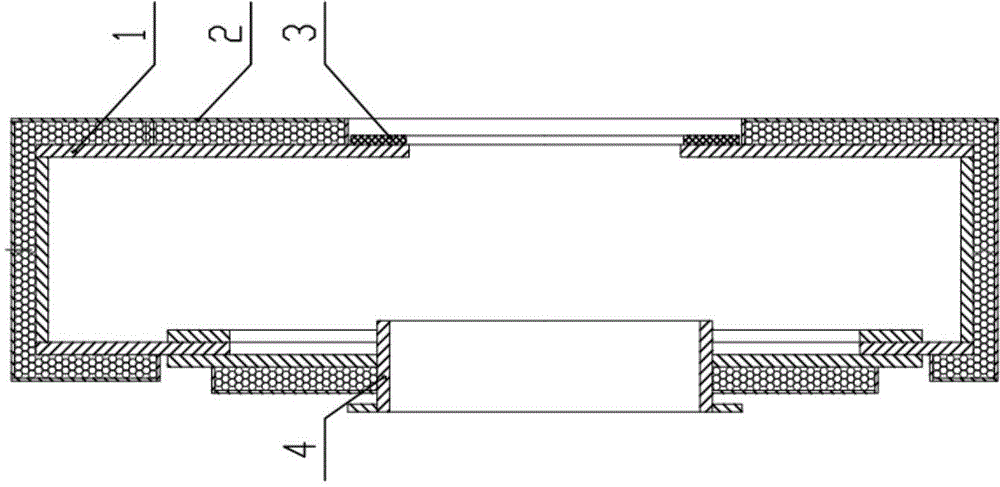

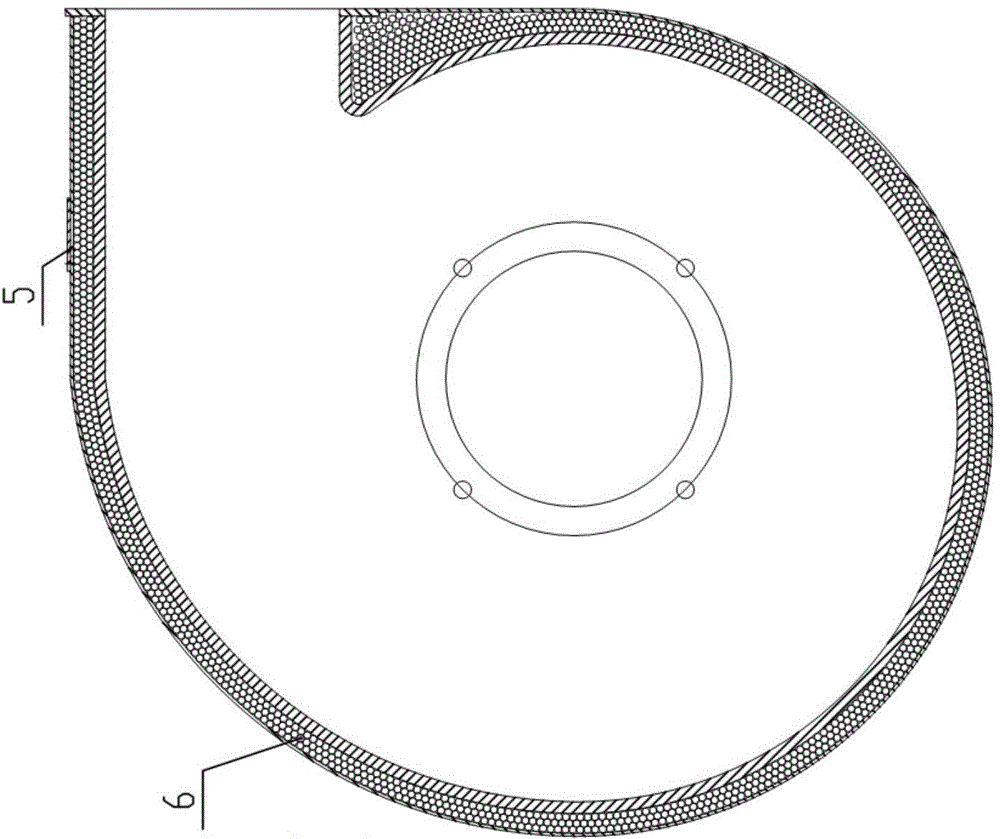

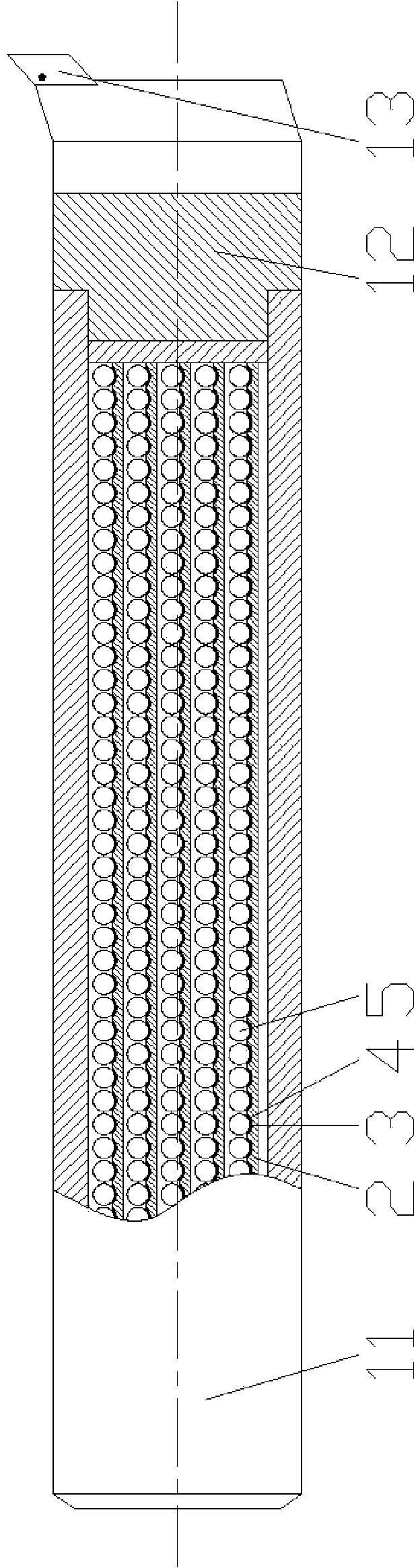

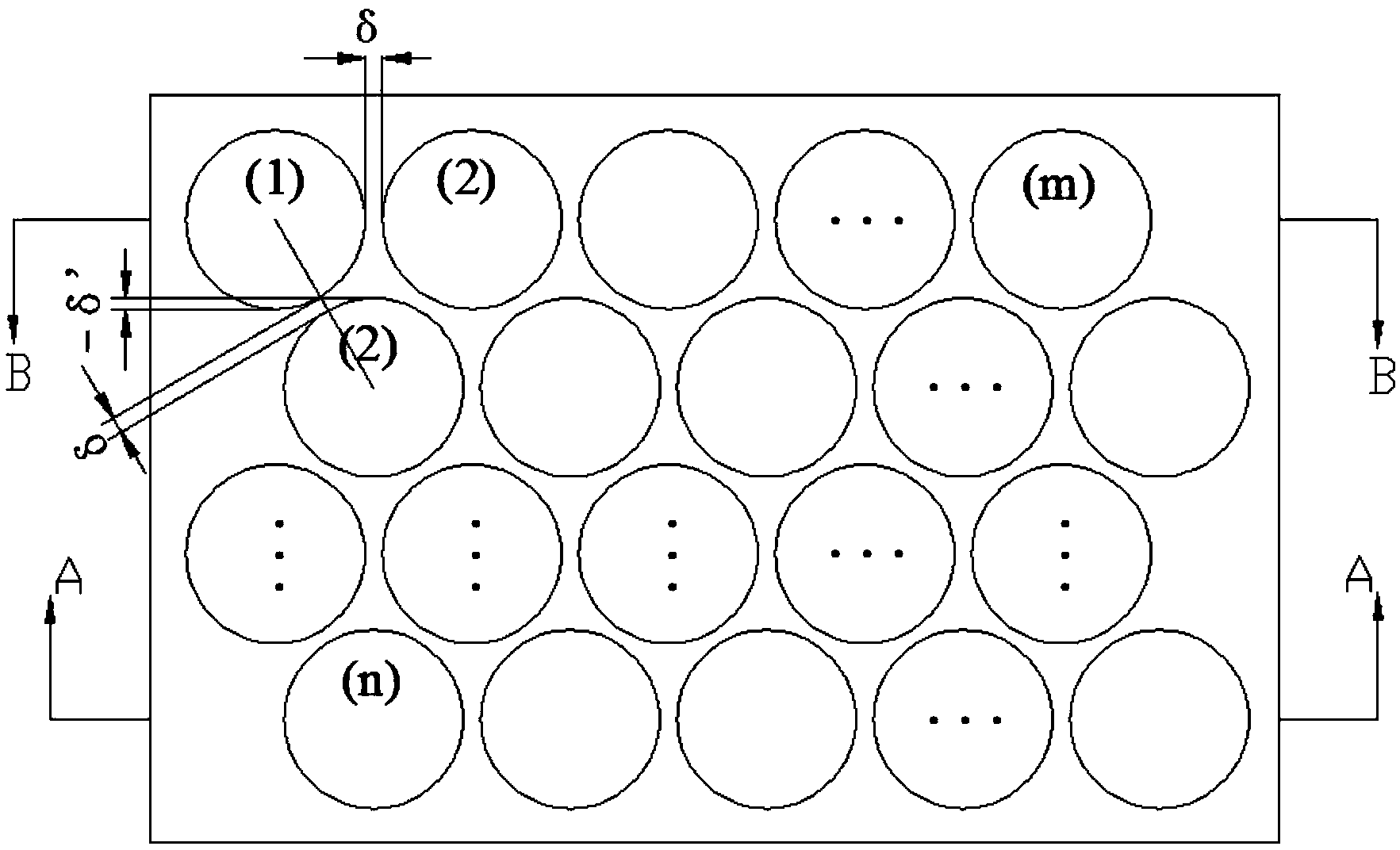

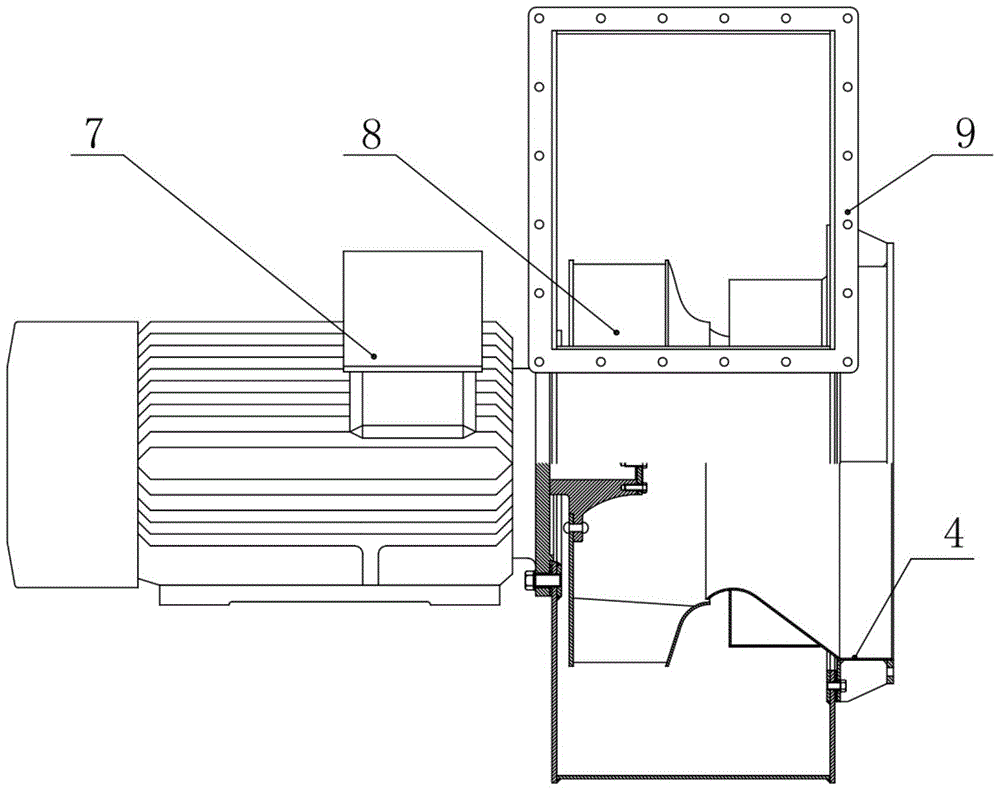

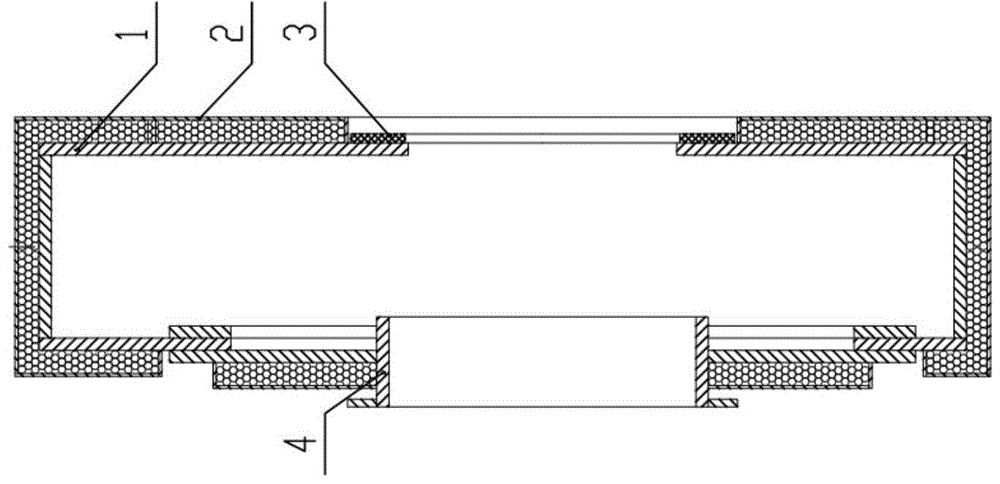

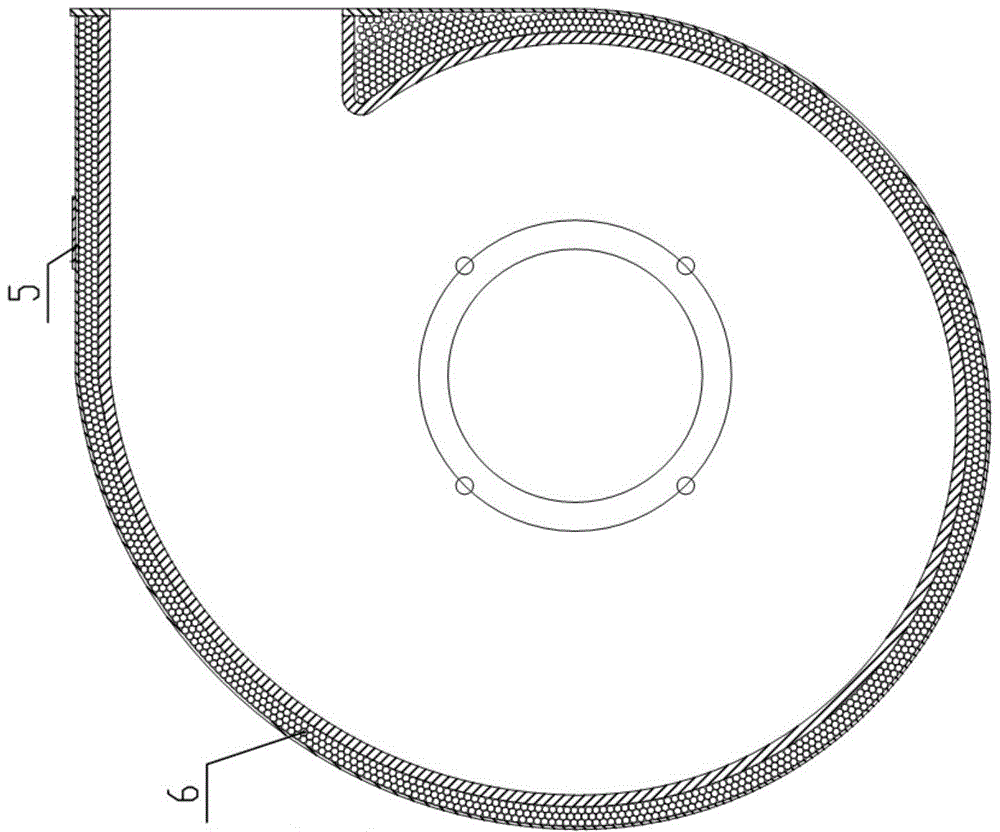

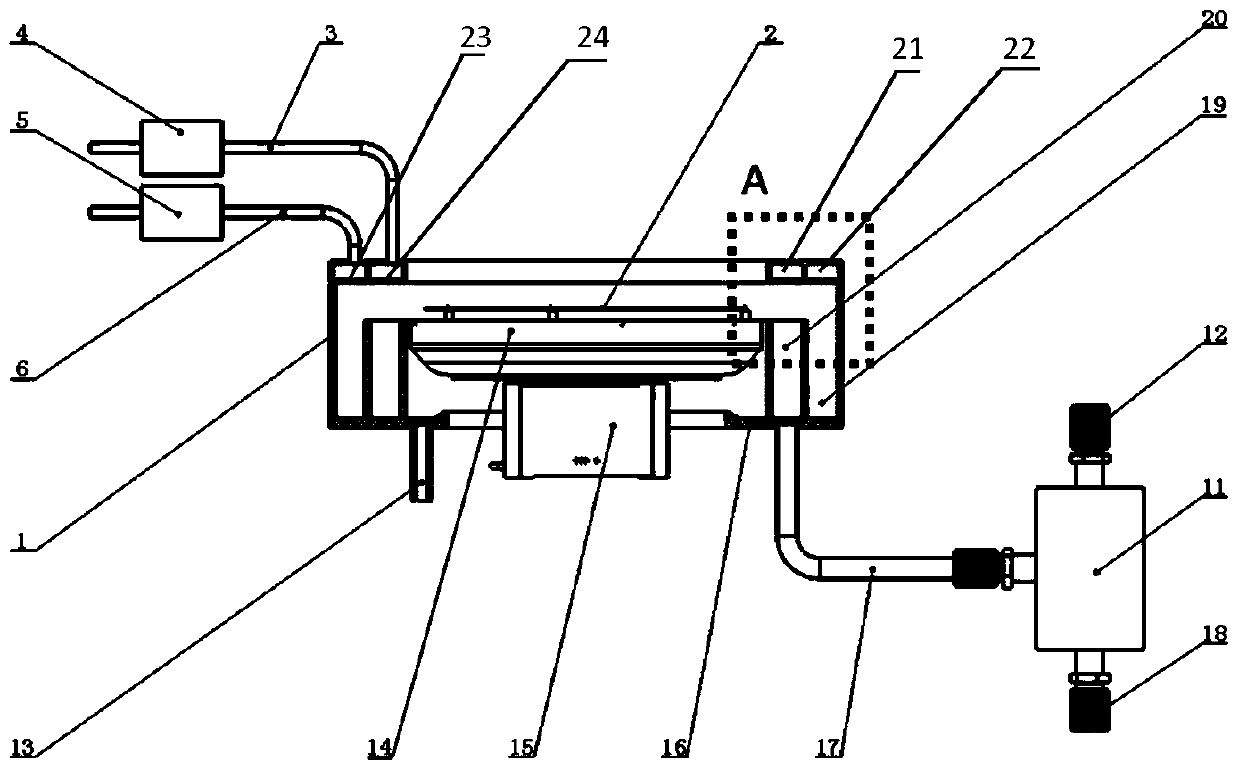

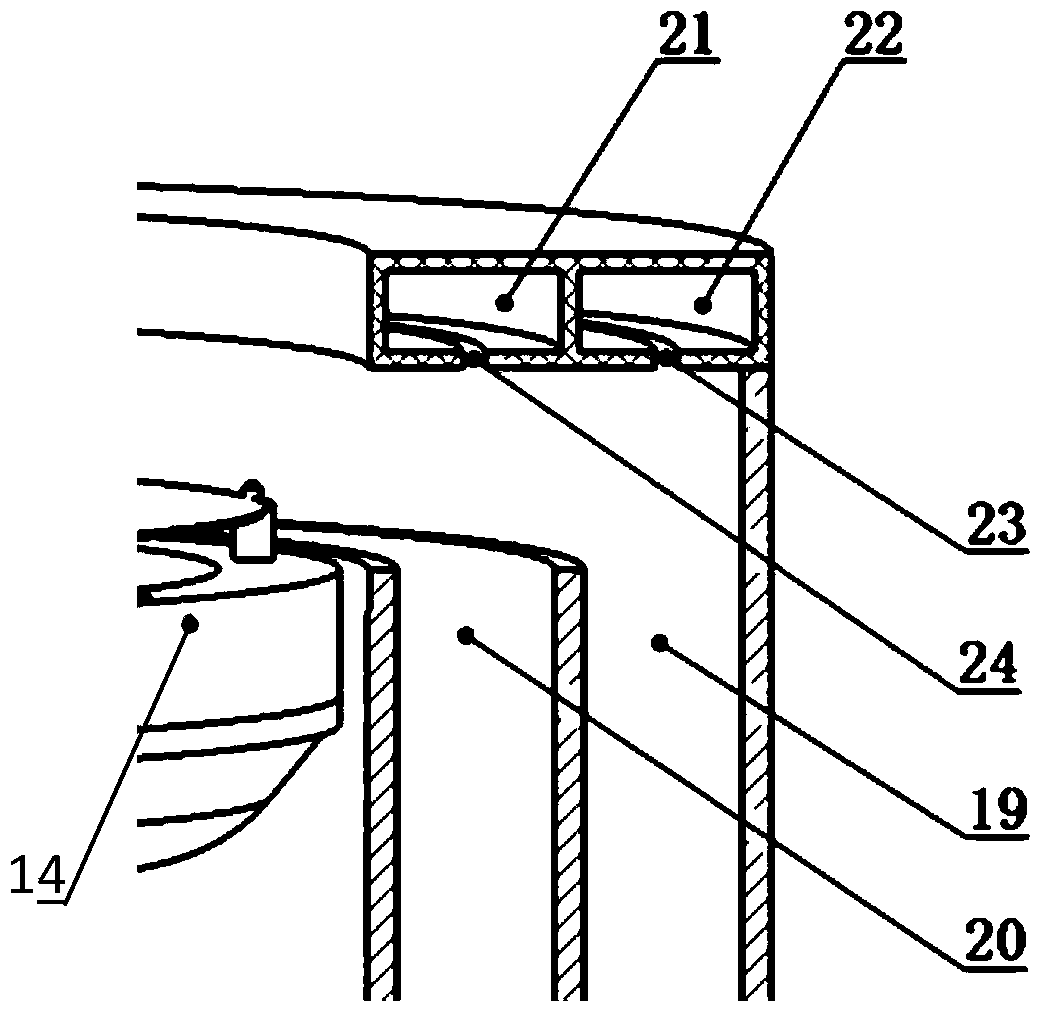

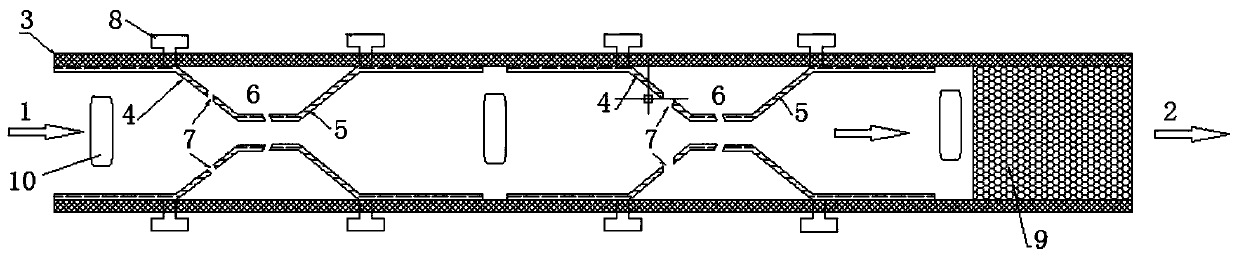

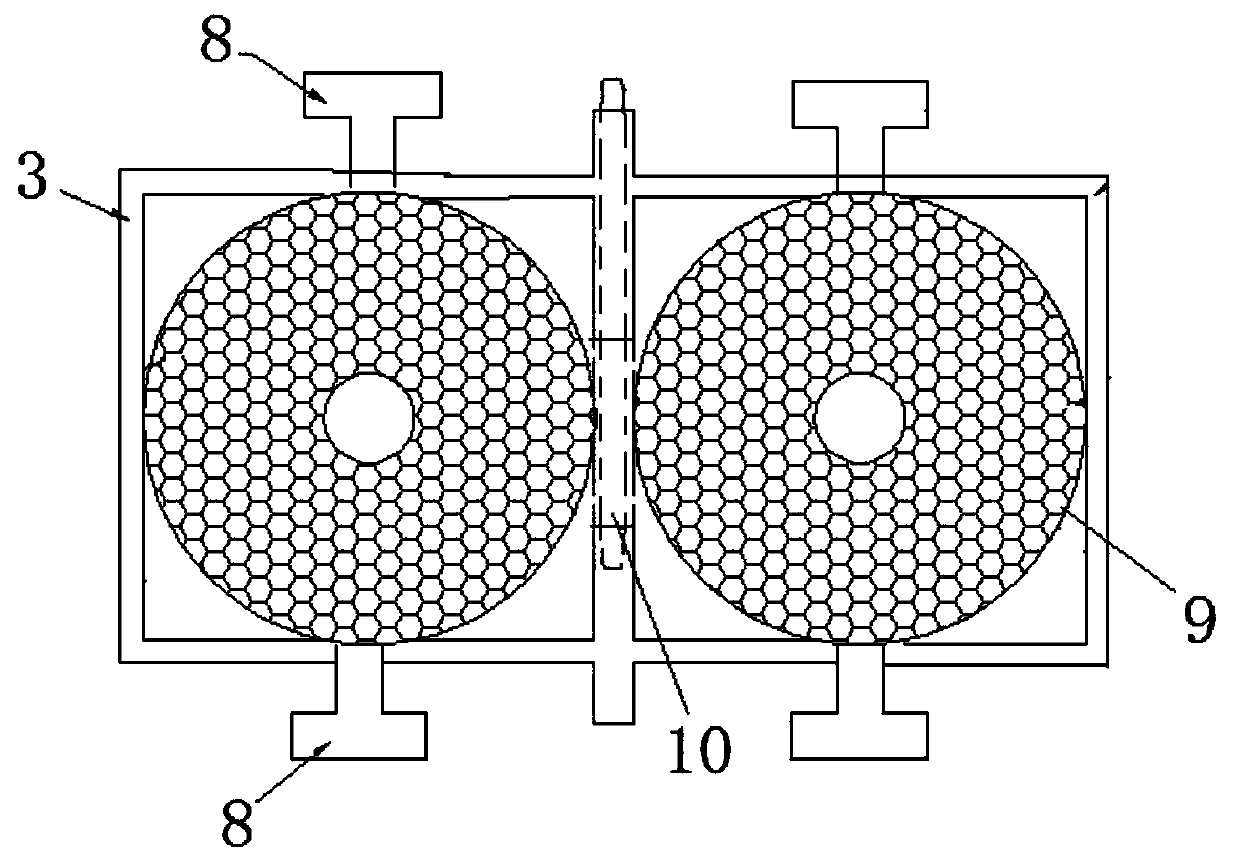

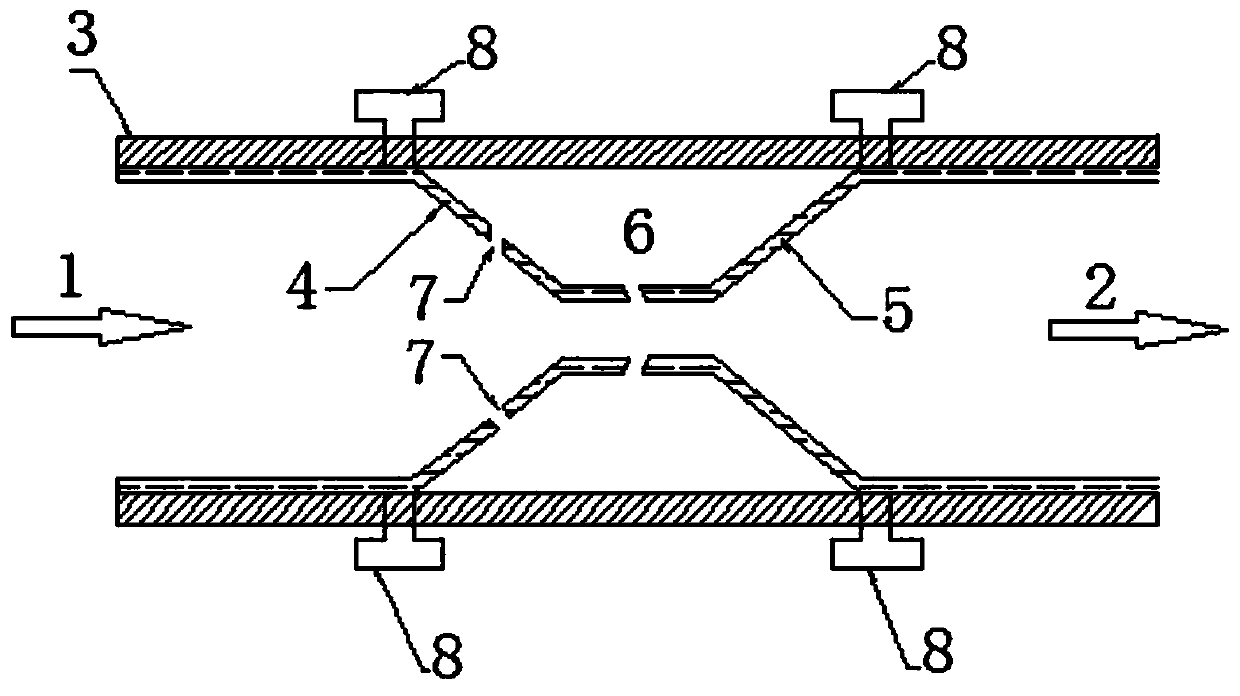

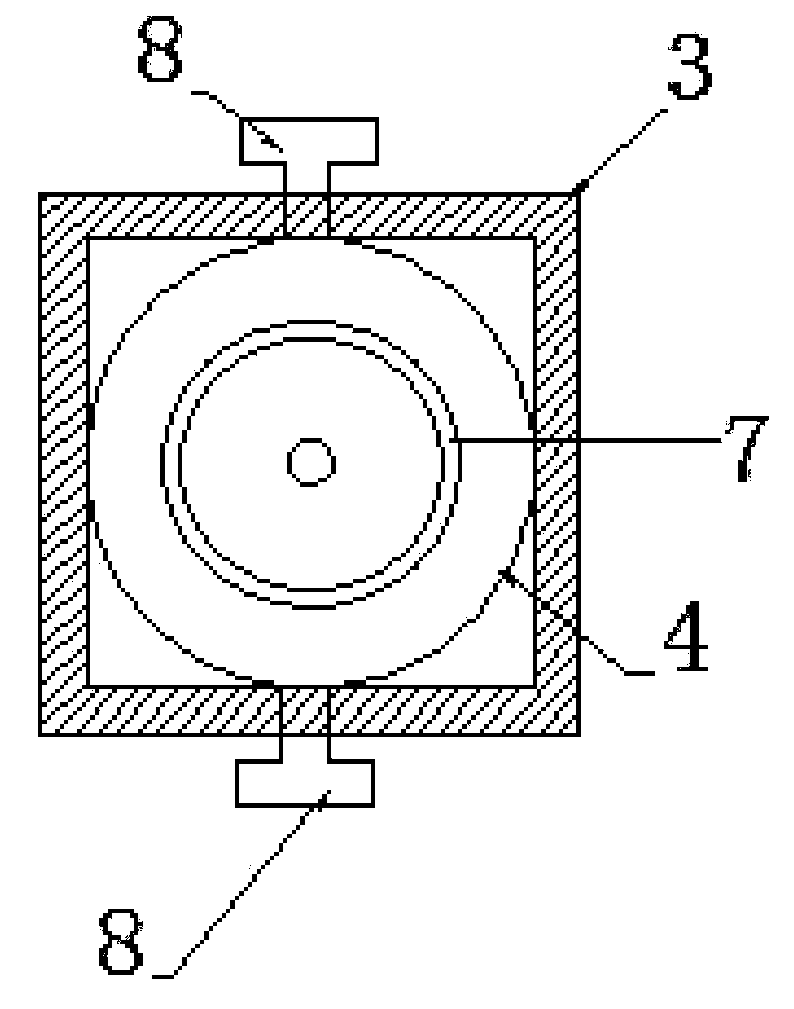

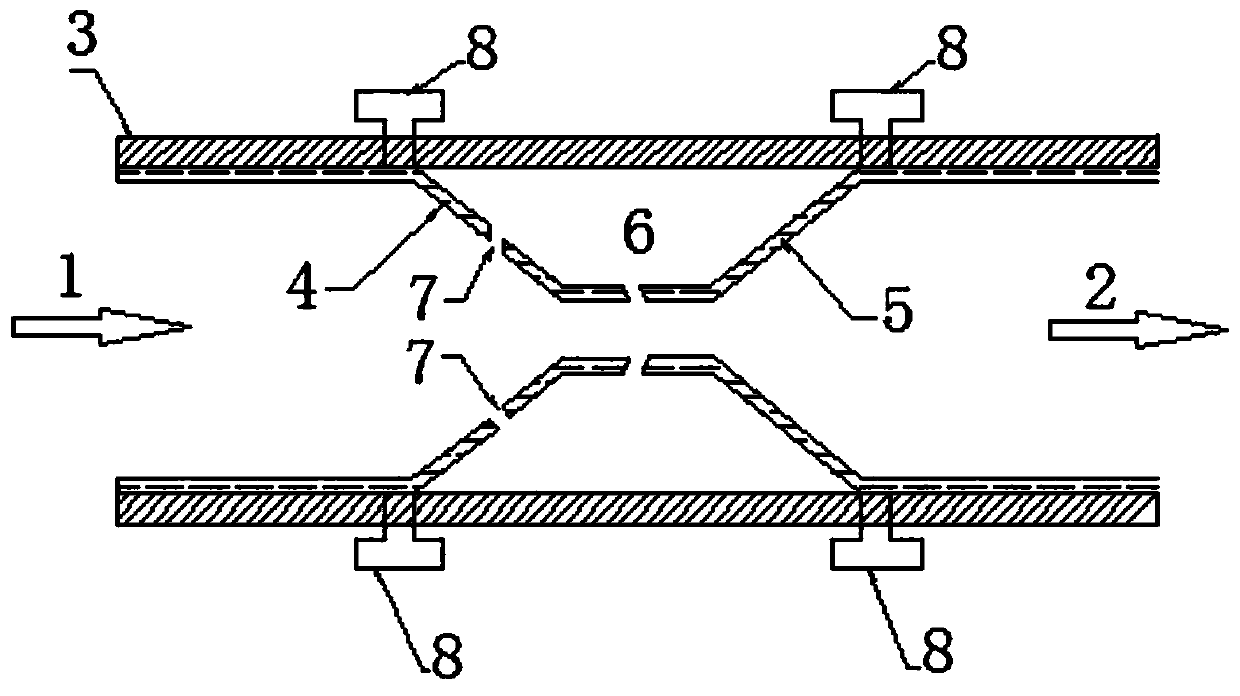

Centrifugal fan volute employing granular damping vibration attenuation

ActiveCN104675752AReduce radiated noiseReduce noisePump componentsPumpsVibration attenuationSpherical granule

The invention discloses a centrifugal fan volute employing granular damping vibration attenuation. The centrifugal fan volute comprises a volute body, wherein the volute body is provided with an air inlet (4); a centrifugal fan (7) is arranged in the volute body and is driven by a motor (8). The centrifugal fan volute is characterized in that the volute body consists of an inner volute (1) and an outer volute (2); a vibration attenuation and noise reduction chamber is formed between the inner volute (1) and the outer volute (2) and is filled with damping vibration attenuation granules (6). According to the centrifugal fan volute, the chamber between the inner volute and the outer volute is filled with spherical granules, the non-elastic collision and the friction between the granules and between each granule and the wall of the chamber are caused by the vibration of the inner volute, the energy is consumed, and the aim of vibration attenuation is achieved; meanwhile, the radiation noise of the volute can be reduced. The centrifugal fan volute can be applied to the industrial fields of energy power, petrochemical industry, petrochemical industry and the like, and the field of national defense and military industry.

Owner:SINOMACH +1

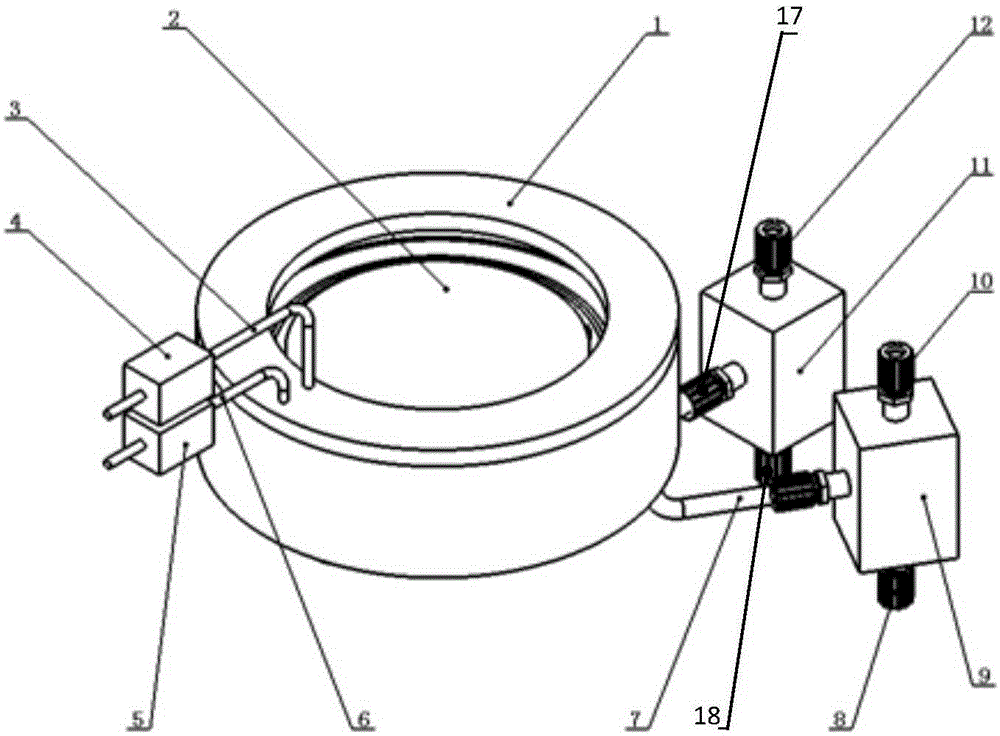

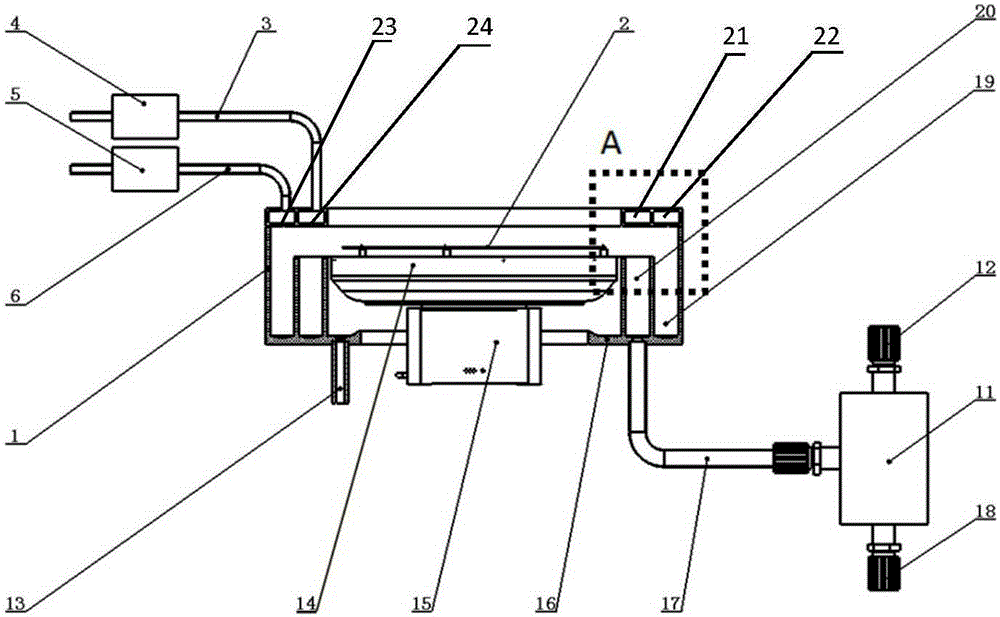

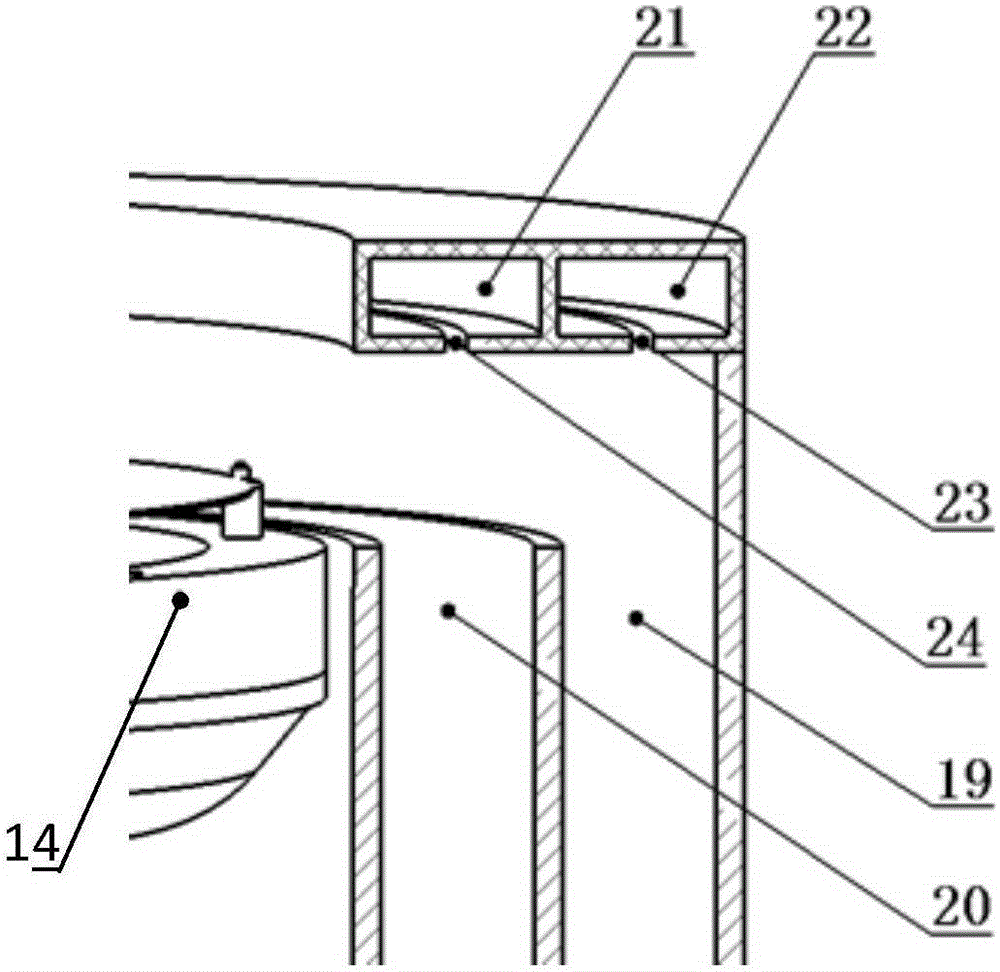

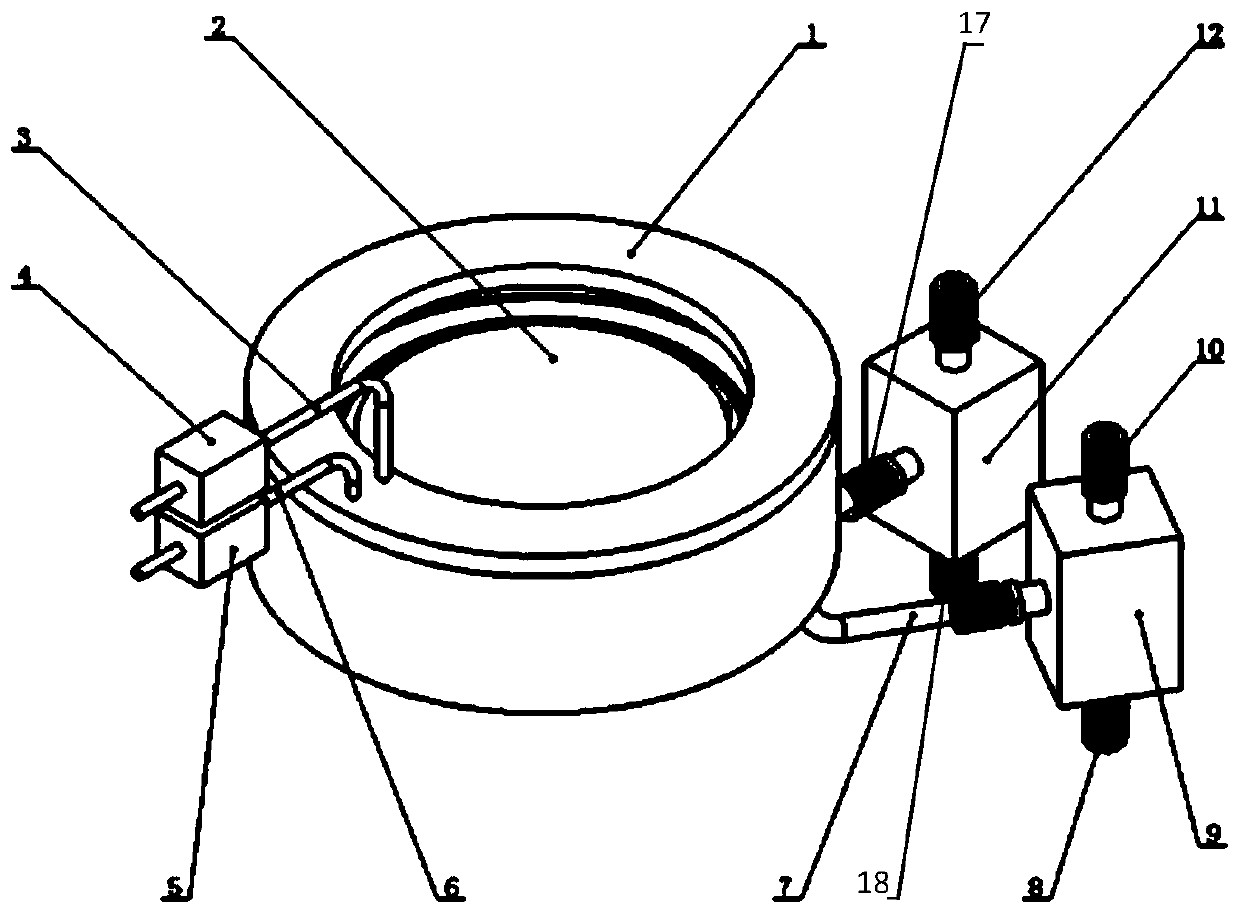

Cleaning liquid collecting device

ActiveCN105161442AElastic Collision PreventionAvoid secondary pollutionSemiconductor/solid-state device manufacturingInelastic collisionEngineering

The invention discloses a cleaning liquid collecting device comprising an air inflow portion, a cleaning liquid collecting portion, and an air-liquid separating portion. The air inflow portion supplies air to the cleaning liquid collecting portion. An annular air curtain is formed at an air outlet and achieves inelastic collision with cleaning liquid separated from the surface of a wafer. Thus, the cleaning liquid is changed in moving direction, enters an air-liquid collecting cavity and is separated and exhausted by the air-liquid separating portion. The cleaning liquid collecting device may reduce back-splash of cleaning medium at the sidewall of a cleaning liquid collecting structure, prevents secondary pollution, and improves liquid cleaning medium recovery efficiency.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

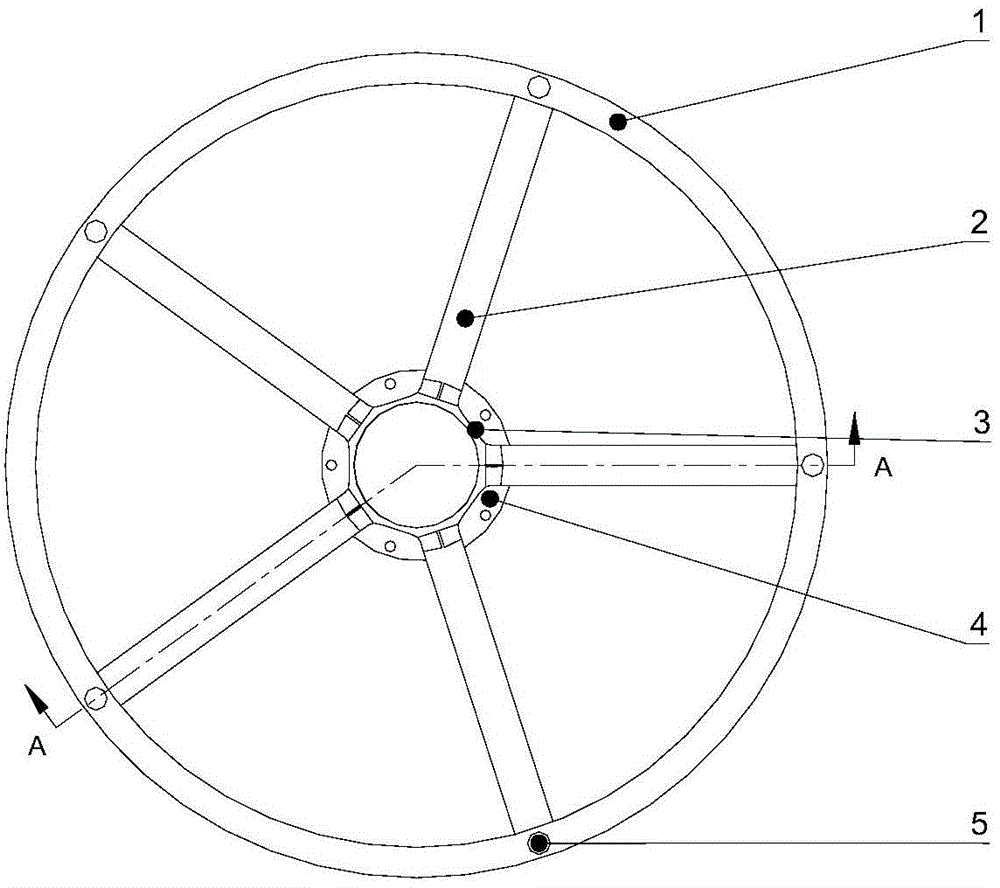

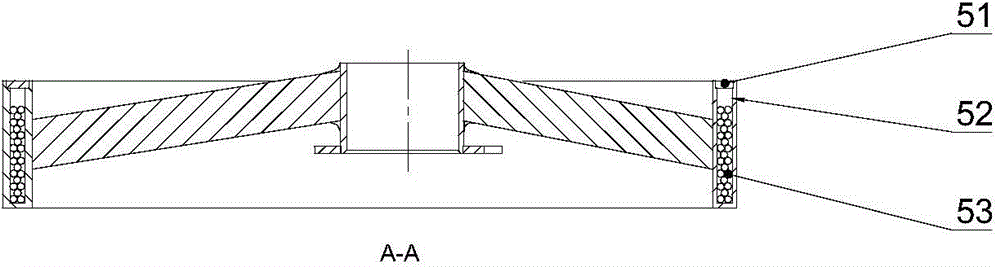

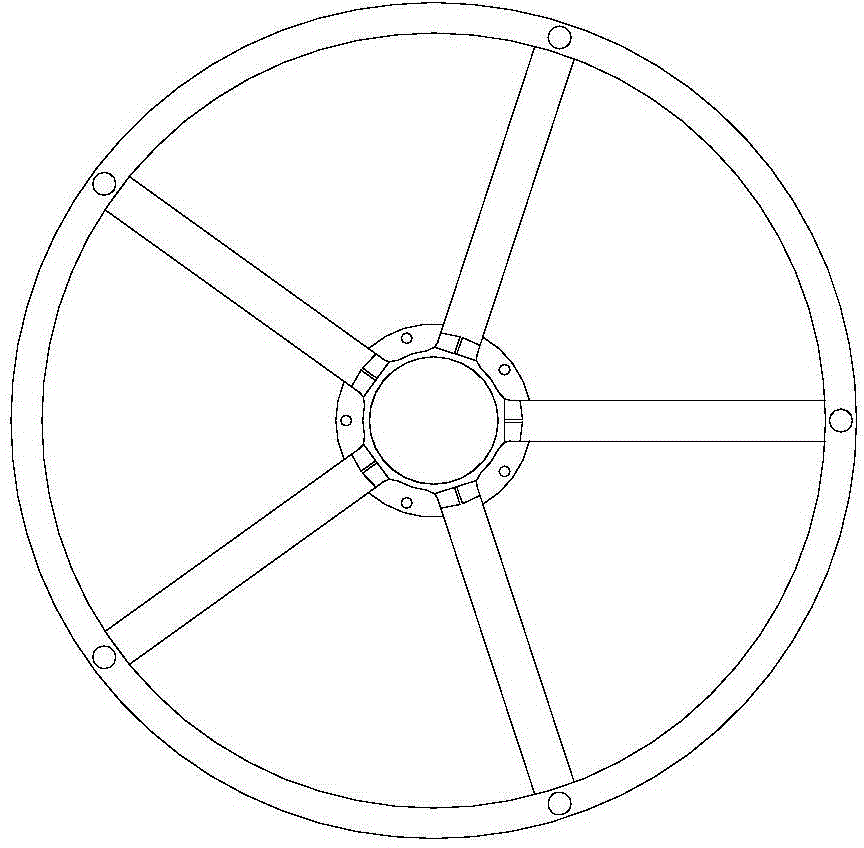

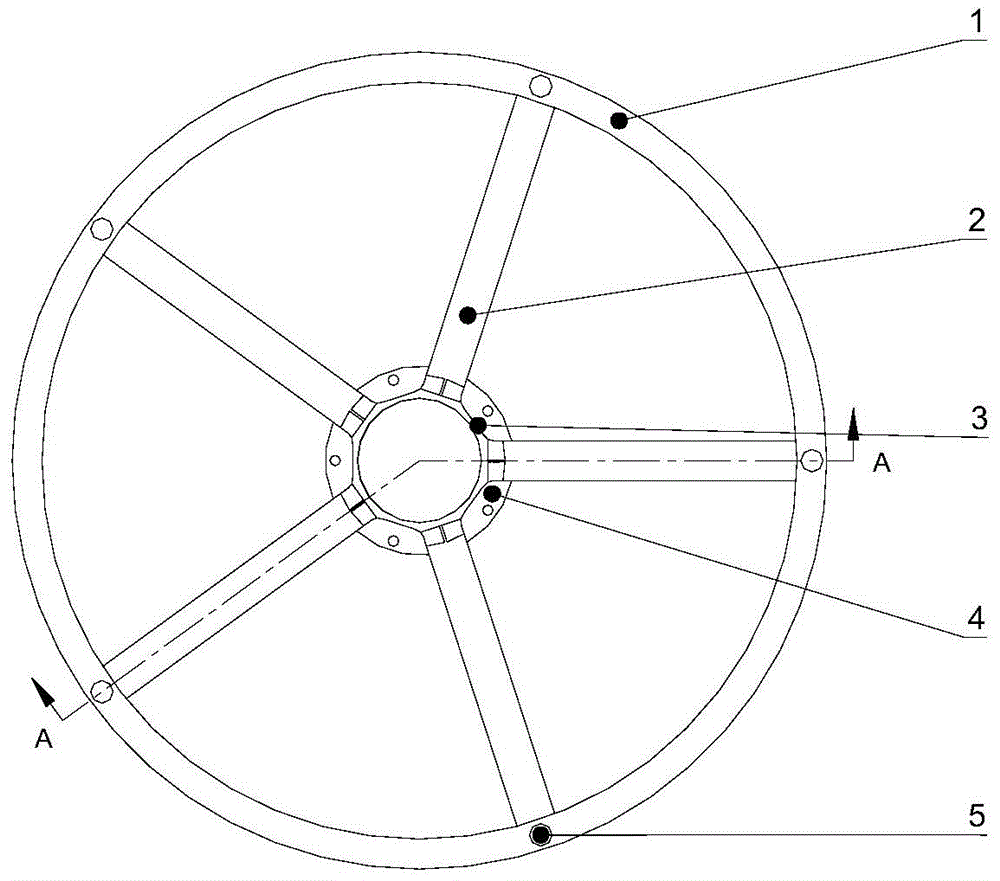

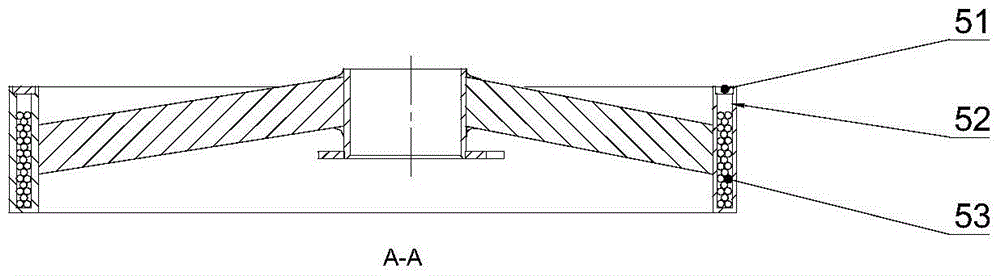

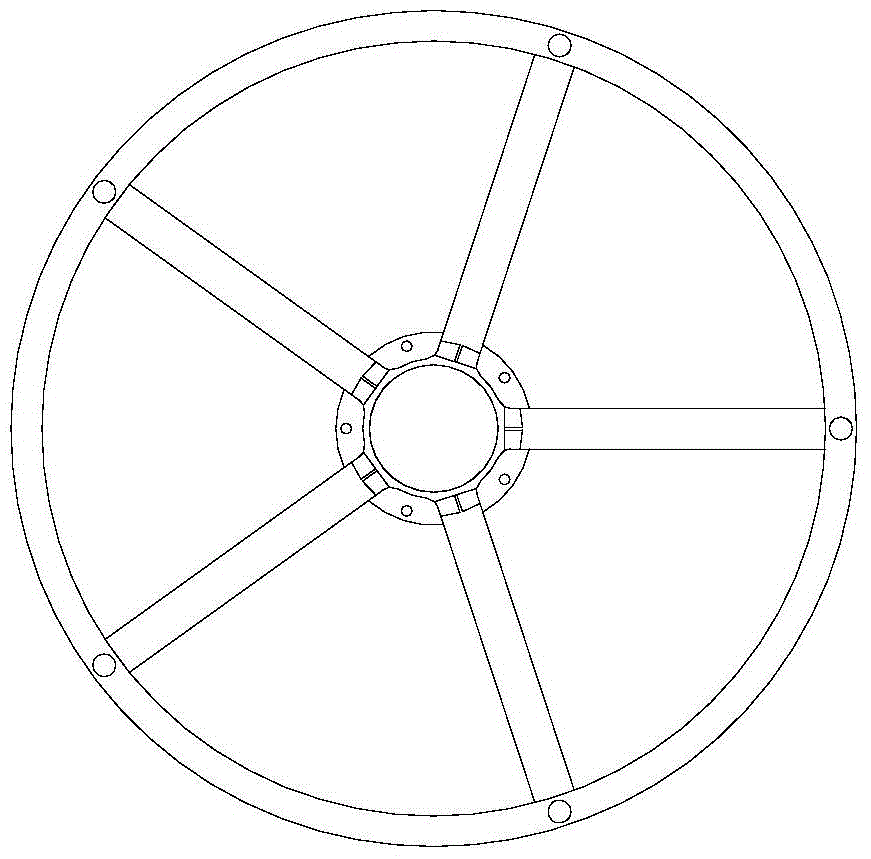

Flywheel body with shock absorber

The invention relates to a flywheel body with a shock absorber. The flywheel body with the shock absorber comprises a rim, spokes, a wheel hub, a flange and particle shock absorbers; every particle shock absorber comprises a shock absorber chamber, particles or powder and a shock absorber end cover; the particle shock absorbers are evenly distributed in the rim of the flywheel body; when the flywheel body is externally driven, system energy is consumed due to inelastic collision and abrasion between the particles and the particles and an empty chamber, and accordingly the purpose of improving the shock vibration resistance capability of the flywheel body is achieved. The flywheel body with the shock absorber has the advantages of being obvious in shock absorbing effect, low in cost, simple in structure, wide in suitable temperature range, stable in performance, long in service life, high in reliability and small in influence to integral utilization due to the fact that the unbalance capacity of the flywheel body does not change fundamentally after environment tests.

Owner:BEIJING INST OF CONTROL ENG

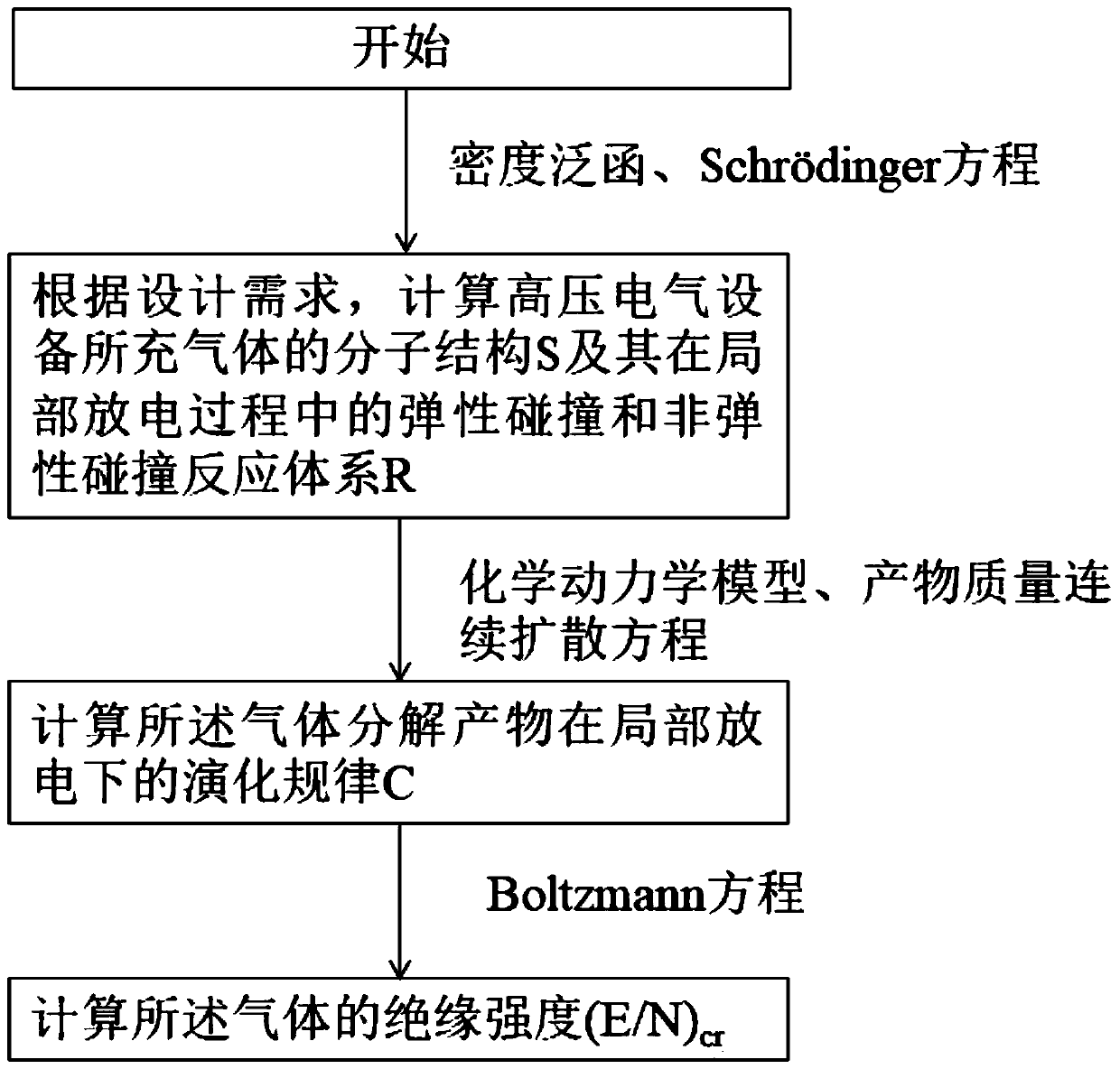

High-voltage electrical equipment insulation strength calculation method based on gas decomposition product

ActiveCN111308279AOvercoming difficulties that are difficult to obtain accuratelyAccurate calculationTesting dielectric strengthComputational theoretical chemistryThermodynamicsInelastic collision

The invention discloses a high-voltage electrical equipment insulation strength calculation method based on a gas decomposition product. The method comprises the steps of firstly, calculating a molecular structure S of gas charged into the high-voltage electrical equipment and an elastic collision and non-elastic collision reaction system R of the gas in a partial discharge process; then, according to the reaction system R, calculating an evolution law of the gas decomposition product under partial discharge; and finally, calculating the insulation strength (E / N) cr of the gas according to theevolution law of the gas decomposition product. According to the method, the problems that in the prior art, the non-equilibrium effect is not considered in the insulation characteristic research ofthe high-voltage electrical equipment, and particles with incomplete electron collision cross section data are ignored, so that insulation operation state evaluation and online monitoring of the high-voltage electrical equipment are inaccurate are solved.

Owner:XIAN UNIV OF TECH

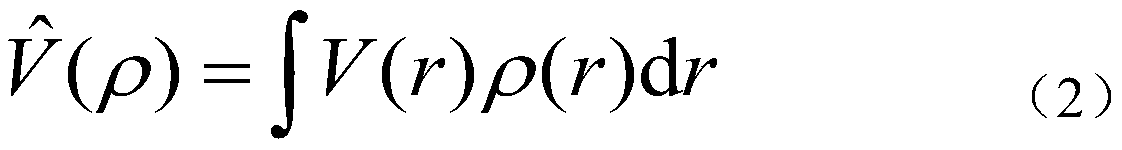

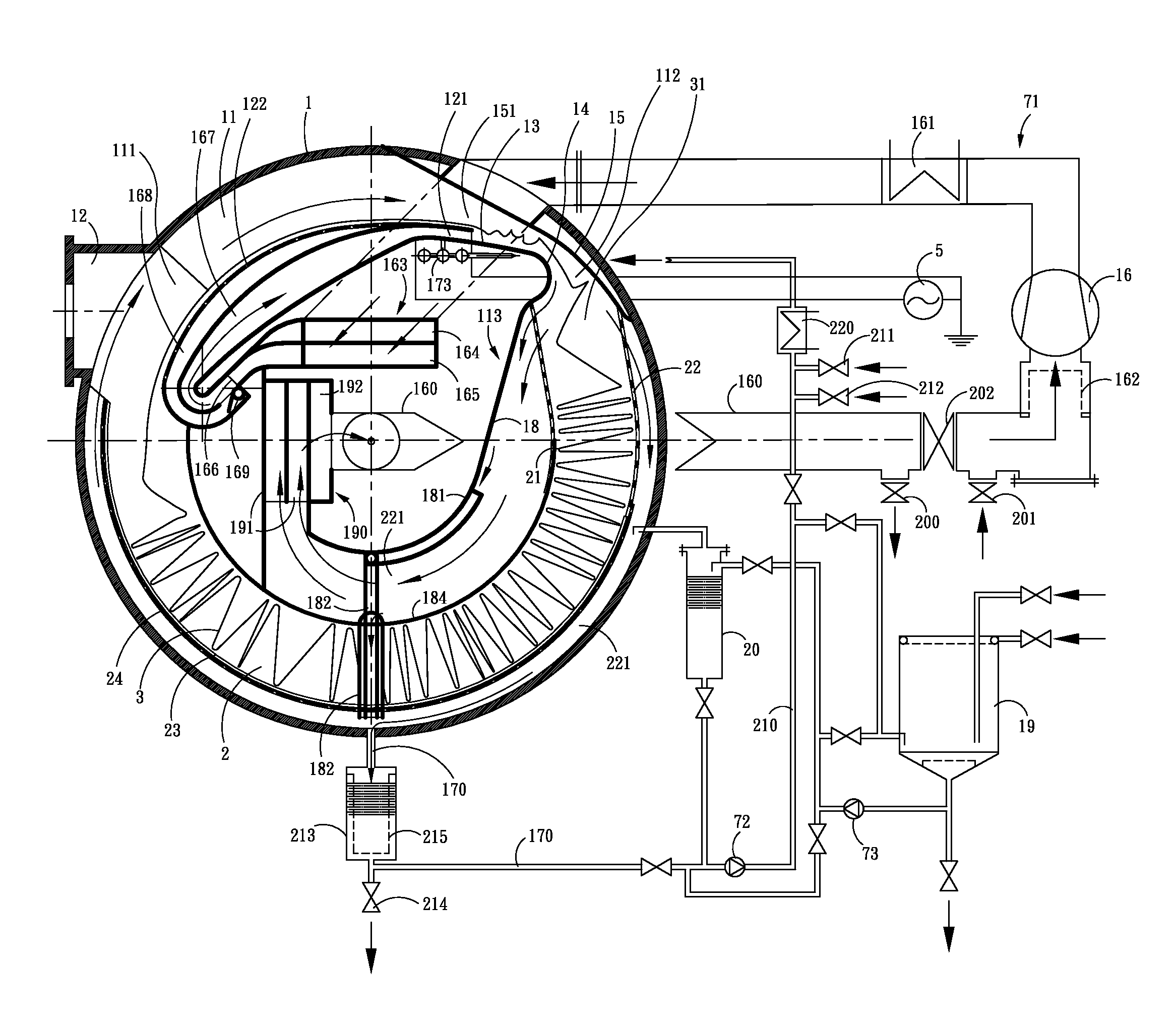

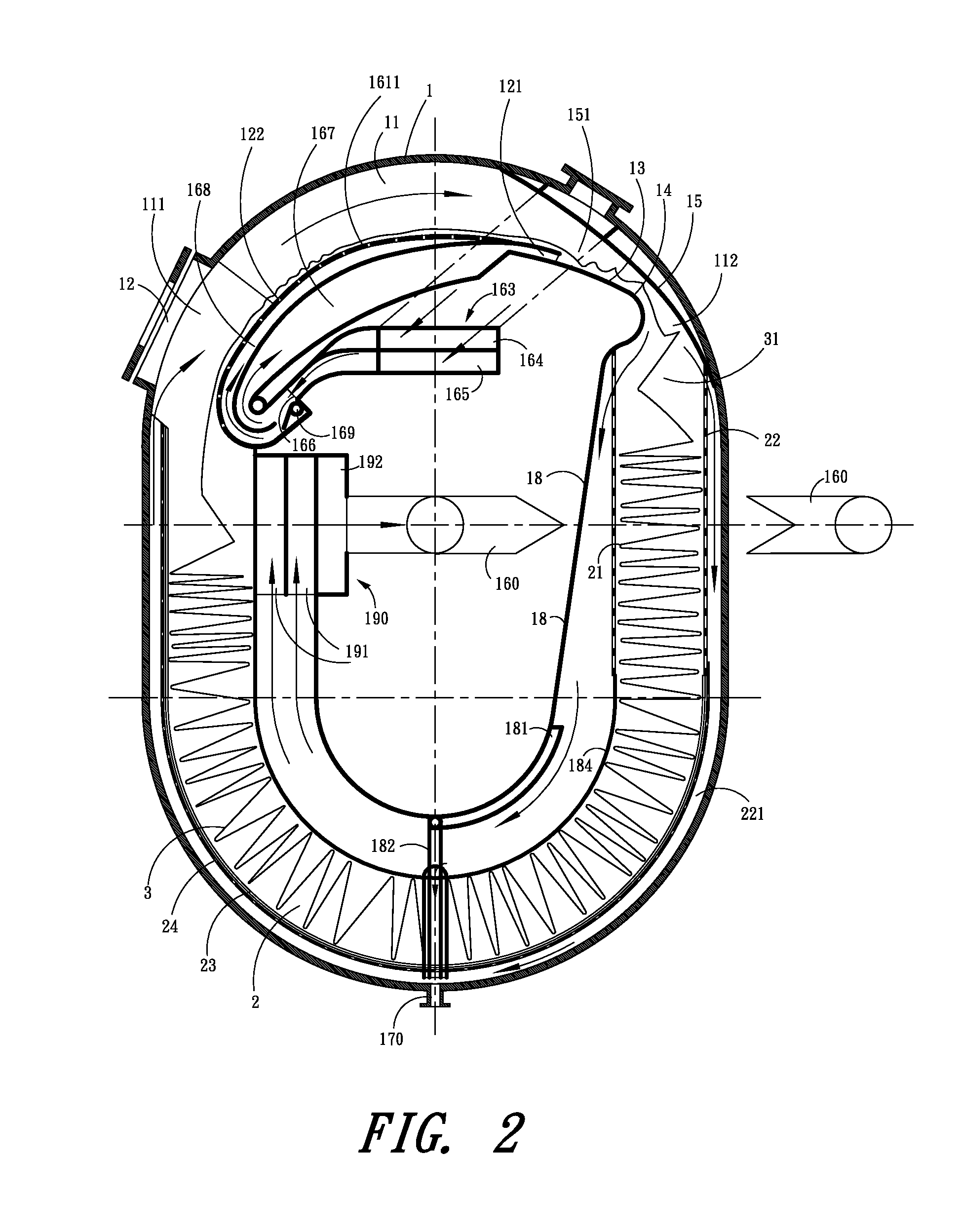

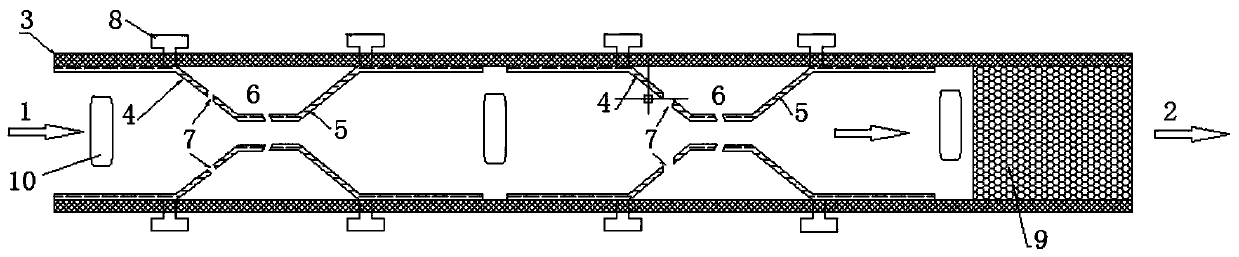

Impulse type shock wave flash dyeing machine

InactiveUS20120024017A1Reduce electricity consumptionImprove securityLiquid/gas/vapor treatment of propelled fabricsOther washing machinesShock waveElectricity

An impulse type shock wave flash dyeing machine is disclosed. A row of joint nozzles can send out high-speed air flows to prompt fibrous fabric to spread out and move in the dyeing machine through the effect of impulse. Dyes or processing agents may be converted into fine mist and is carried by the high-speed air flows to blast the fibrous fabric (3). Therefore, the dyes or processing agents can enter the fibrous fabric (3) quickly and can diffuse or spread out in the fibrous fabric (3) swiftly through strong elastic and inelastic collisions as well as the effect of shock wave. Such collisions and effect can impart enough energy to the dyes or processing agents and convert non-activated molecules into activated molecules. In addition, the effect of corona discharge may be used to generate high-energy particles and hence the goals of clean and swift processes may be achieved.

Owner:ZHAO CHENG JIANG

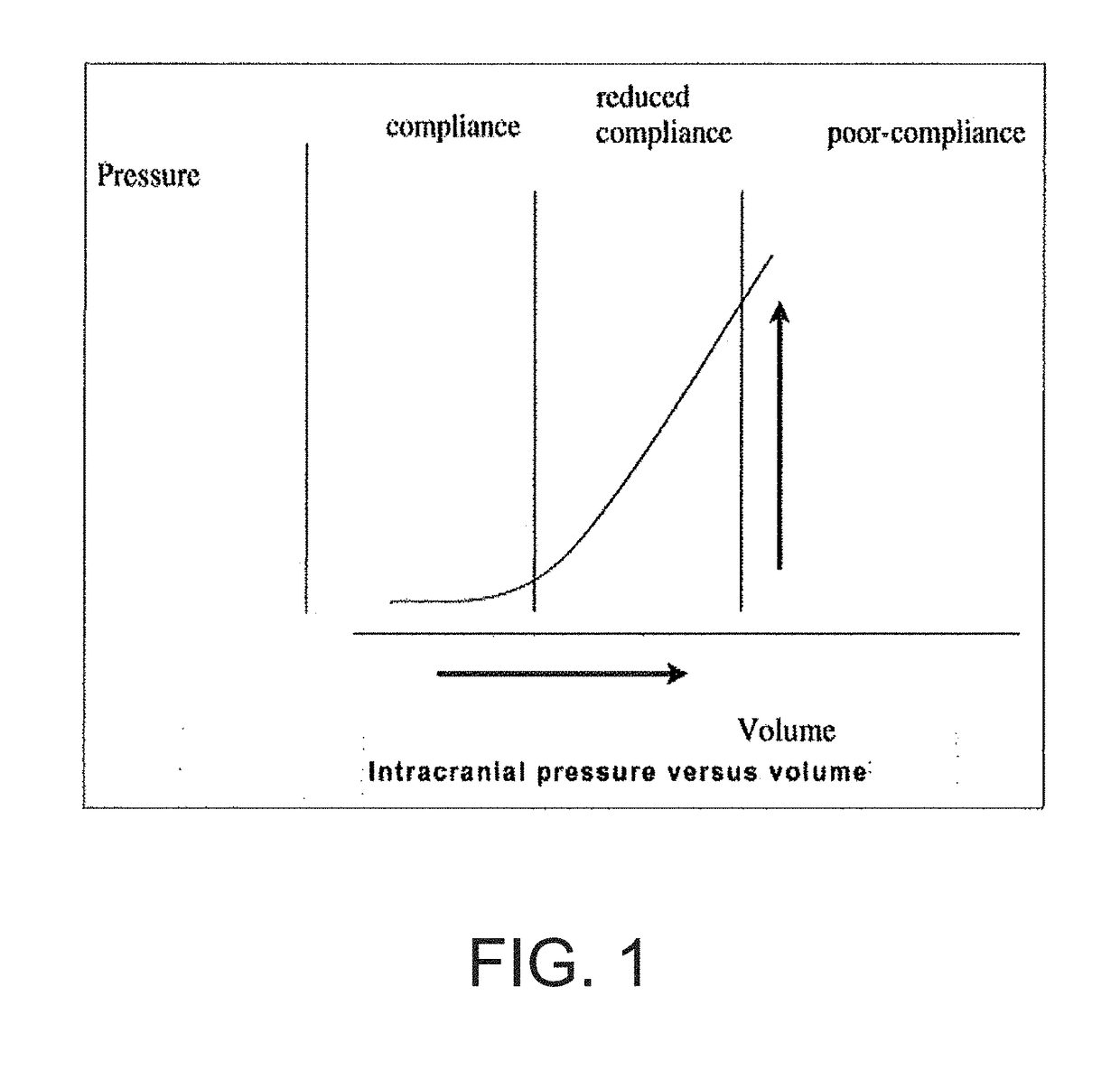

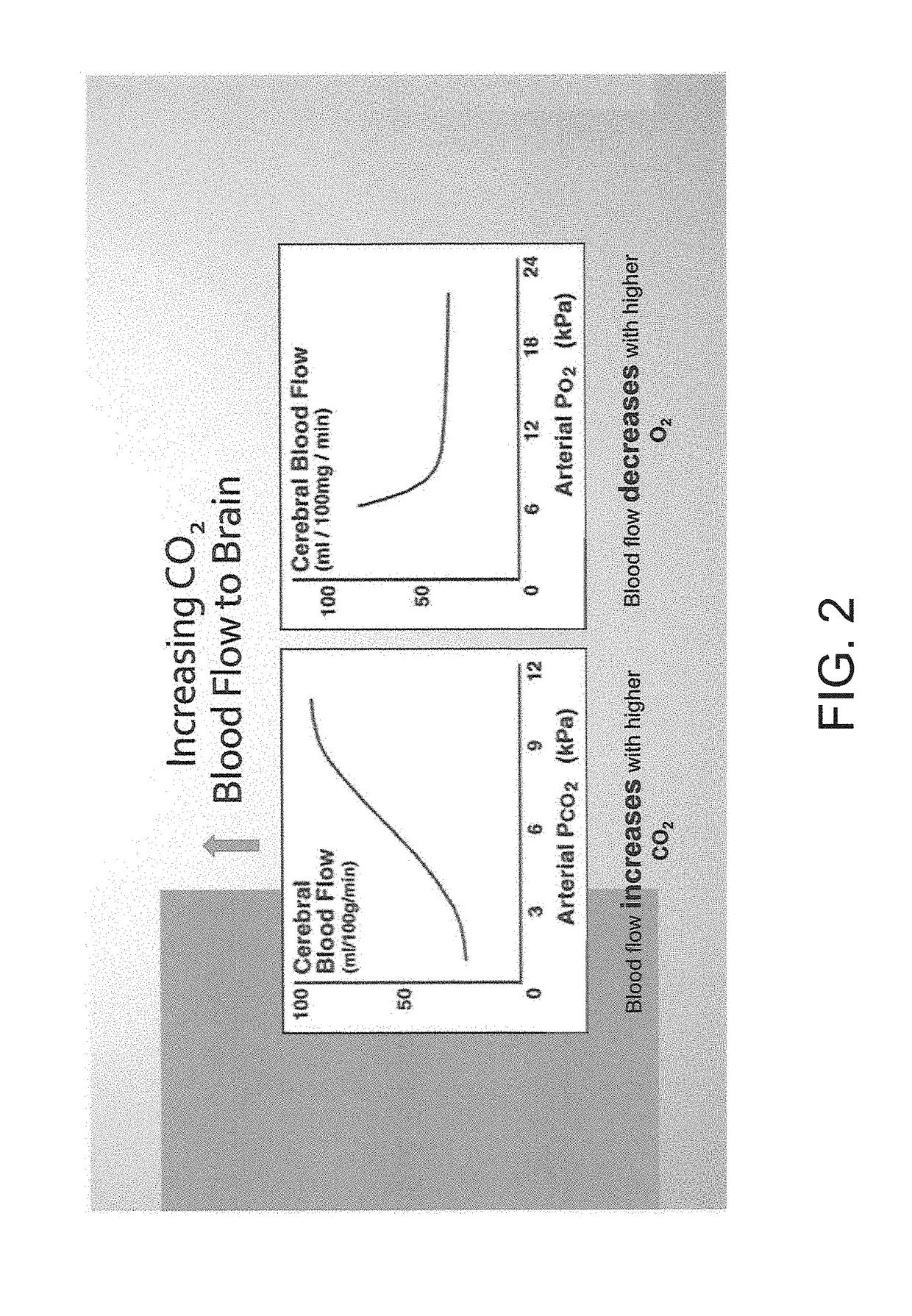

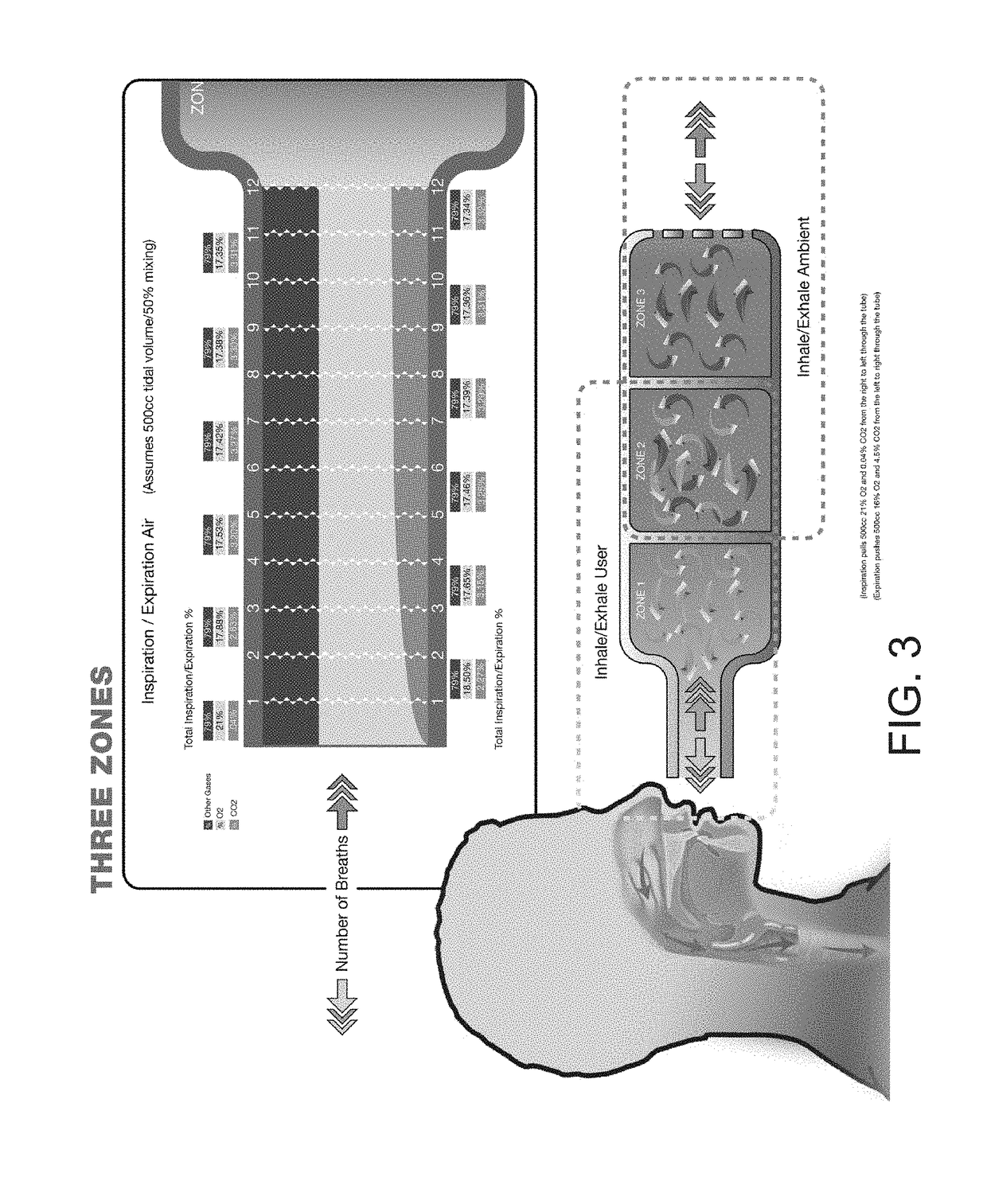

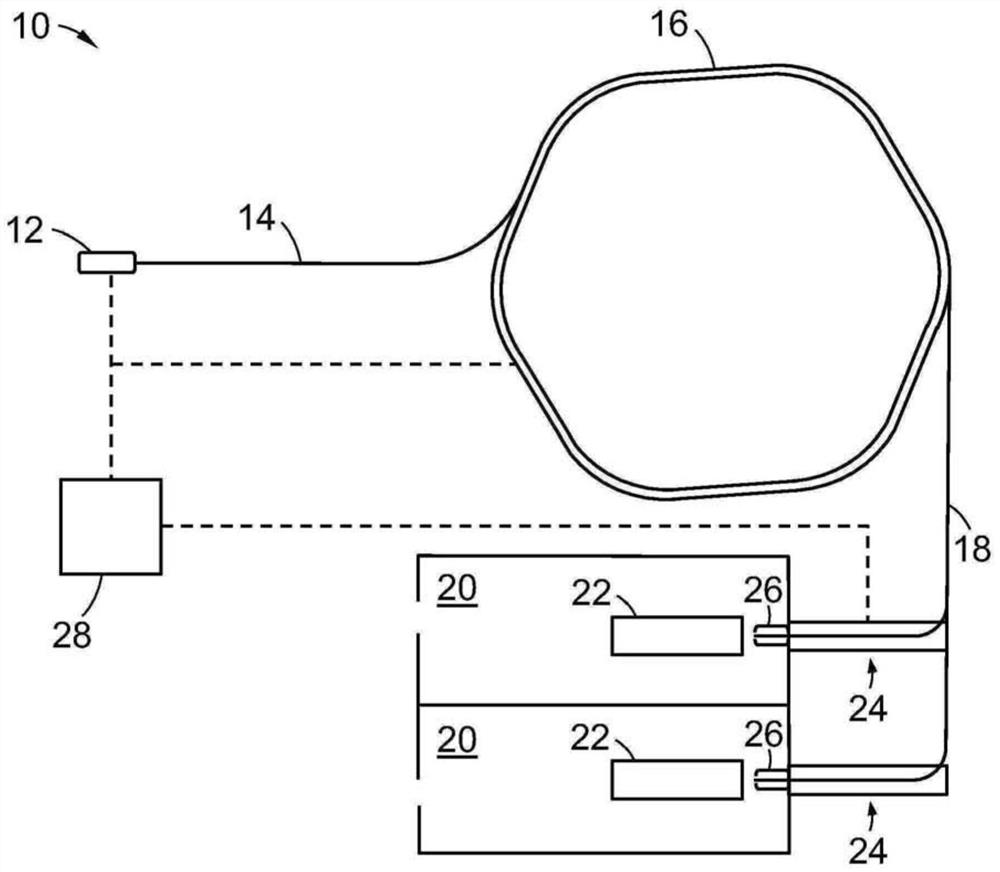

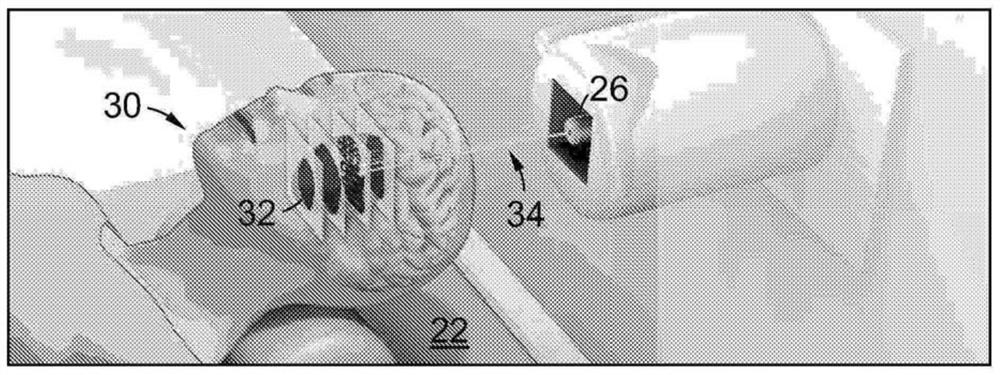

Method to Reduce Slosh Energy Absorption and its Damaging Effects Through the Reduction of Inelastic Collisions in an Organism

PendingUS20180333159A1Reduce riskSymptoms improvedHydroxy compound active ingredientsTetracycline active ingredientsSIDS - Sudden infant death syndromeEnergy absorption

A method is provided for reducing the risk of sustaining a traumatic brain injury caused by a traumatic event that includes identifying a subject at risk of sustaining a traumatic brain injury, and then precisely increasing the partial pressure of carbon-dioxide (CO2) in the blood of the subject (pCO2). This method can be applied to raise the CO2 and pCO2 to improve orthostatic hypotension in conditions such as dysautonomias (like Positional Orthostatic Tachycardic Syndrome POTS) and to facilitate the drive to breathe in conditions like Central Sleep Apnea (CSA) and Sudden Infant Death Syndrome (SIDS). The pCO2 of the person is increased by placing a breathing apparatus over the mouth of the person through which the person must breath, wherein the breathing apparatus includes an enlarged dead space volume in which expired CO2 collects to be inhaled or re-breathed by the person on the next inhalation.

Owner:SMITH DAVID

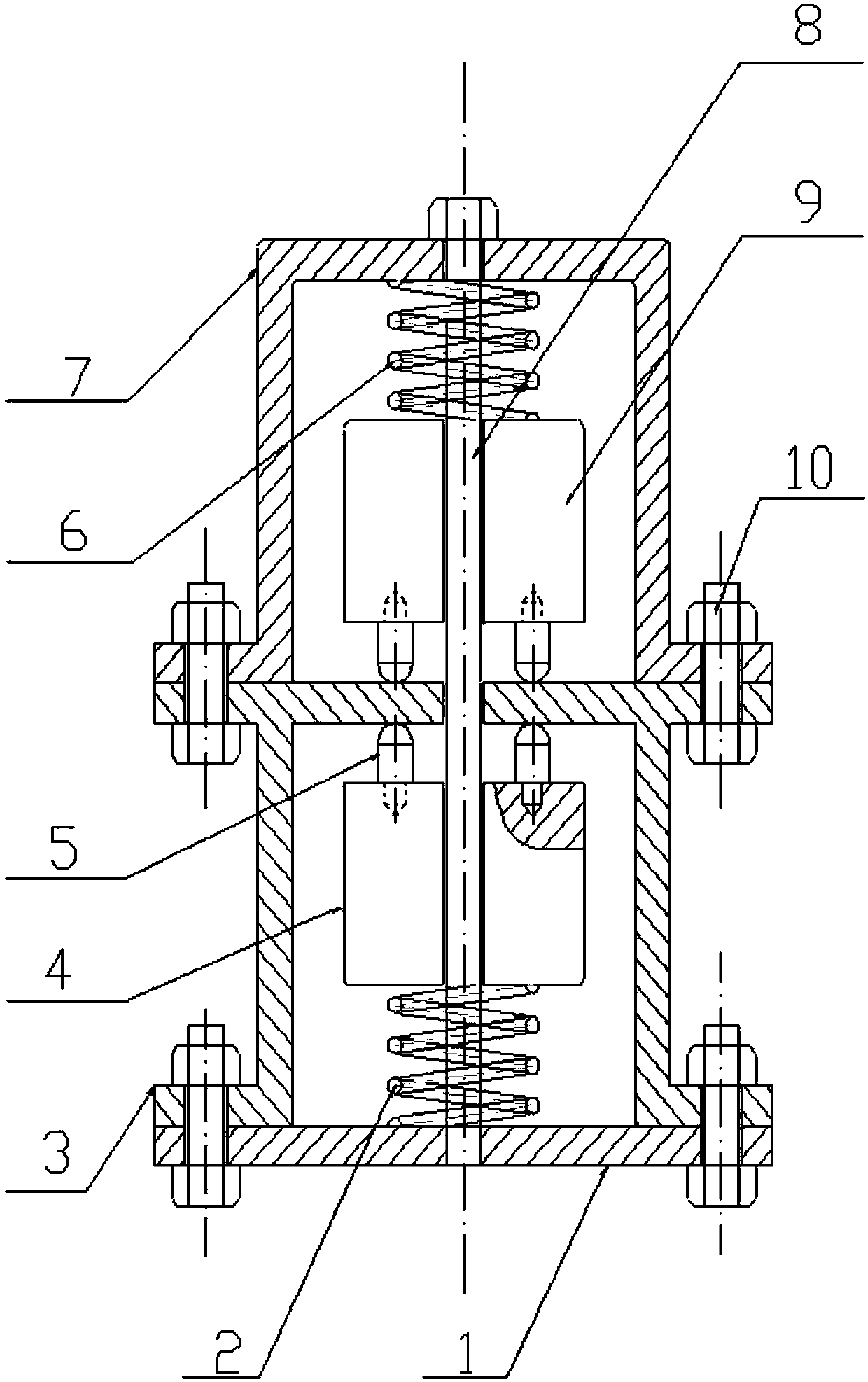

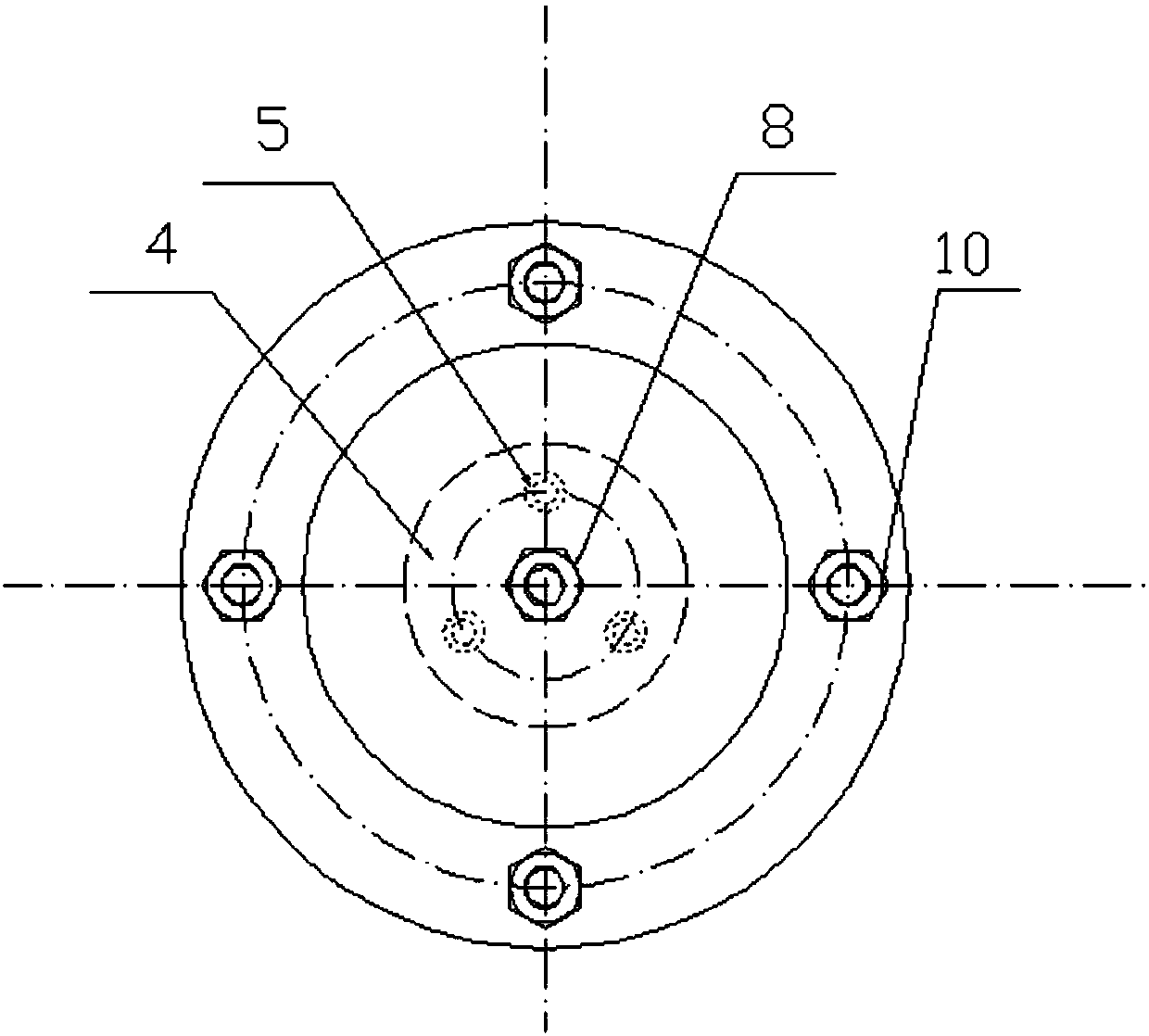

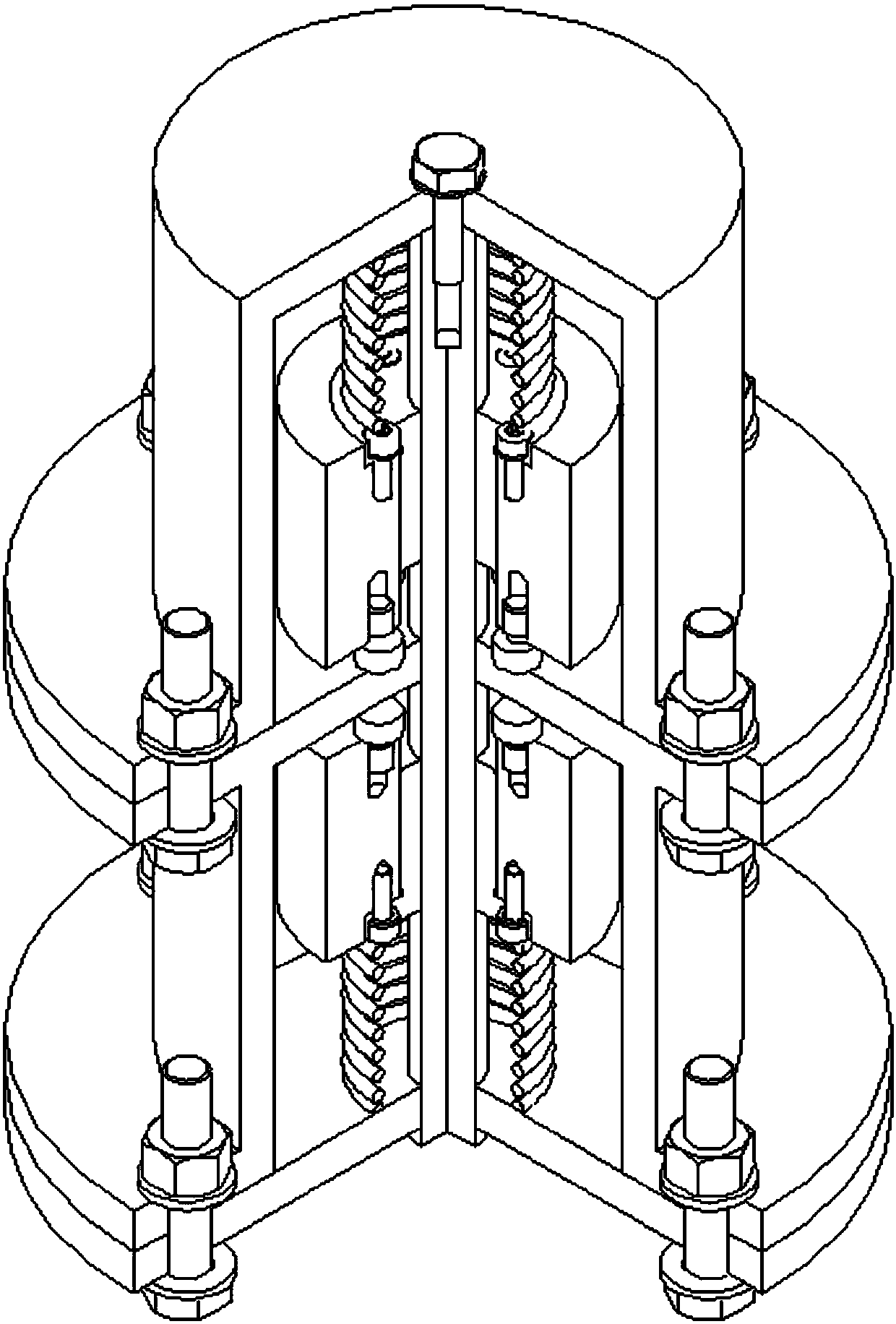

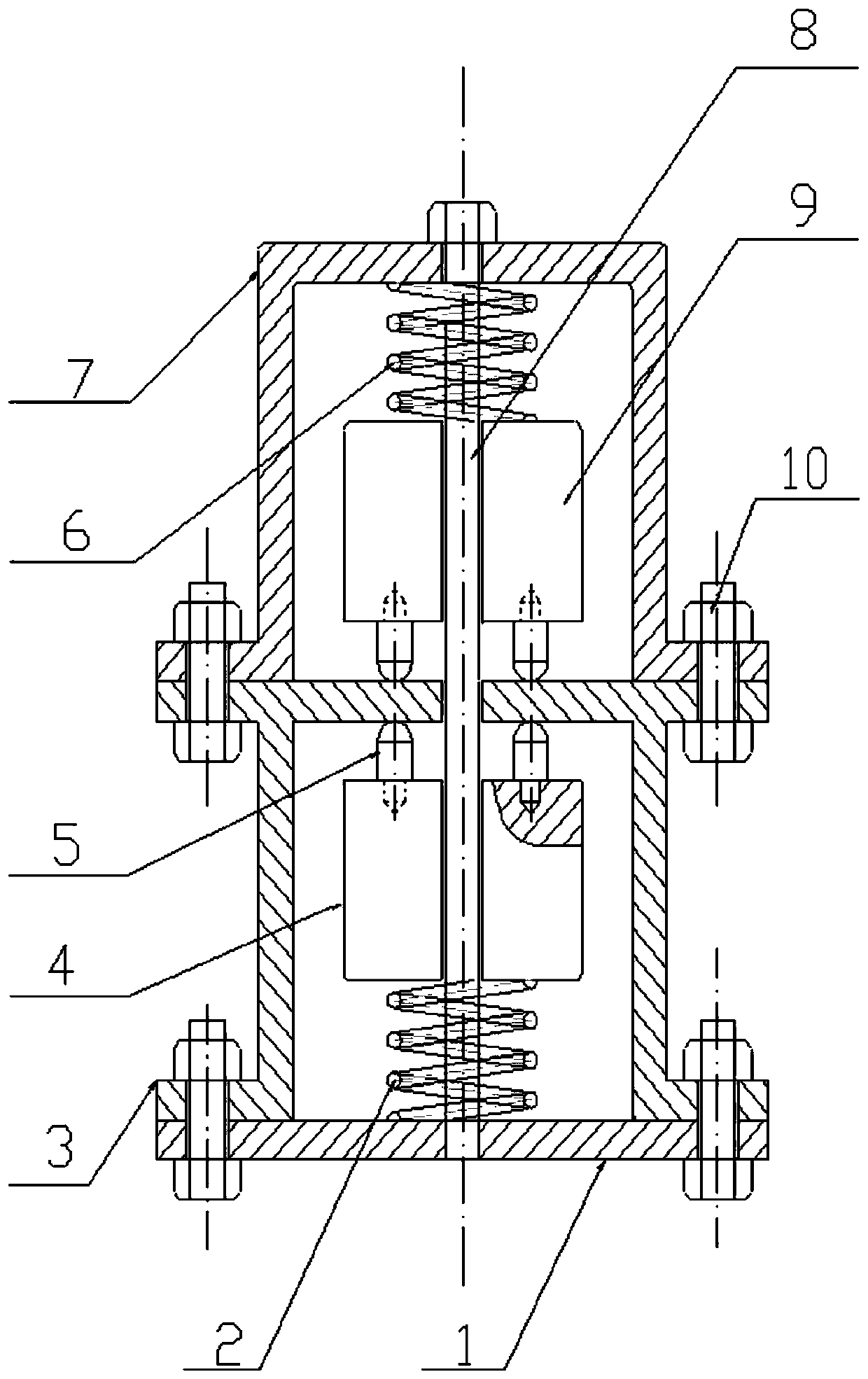

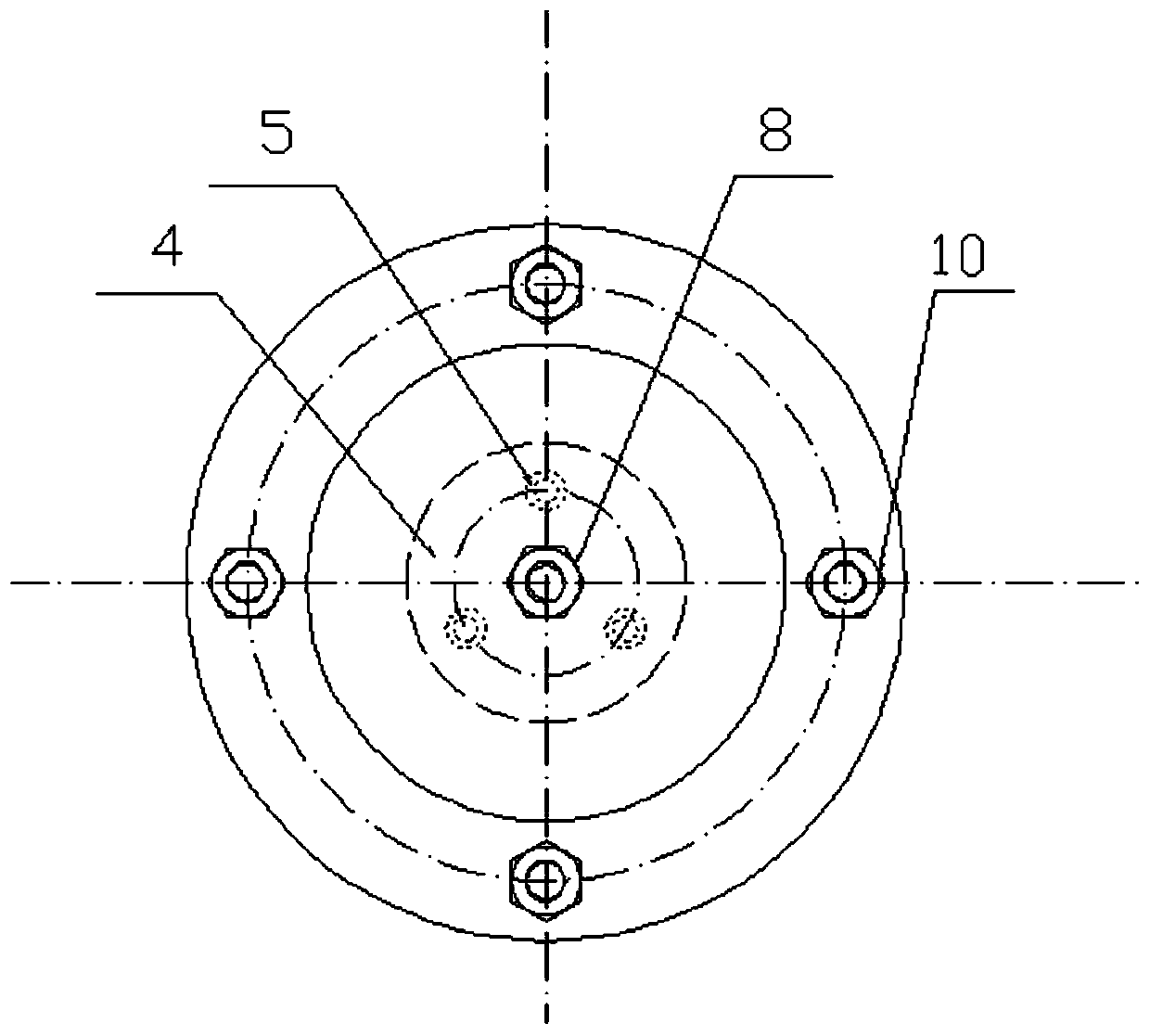

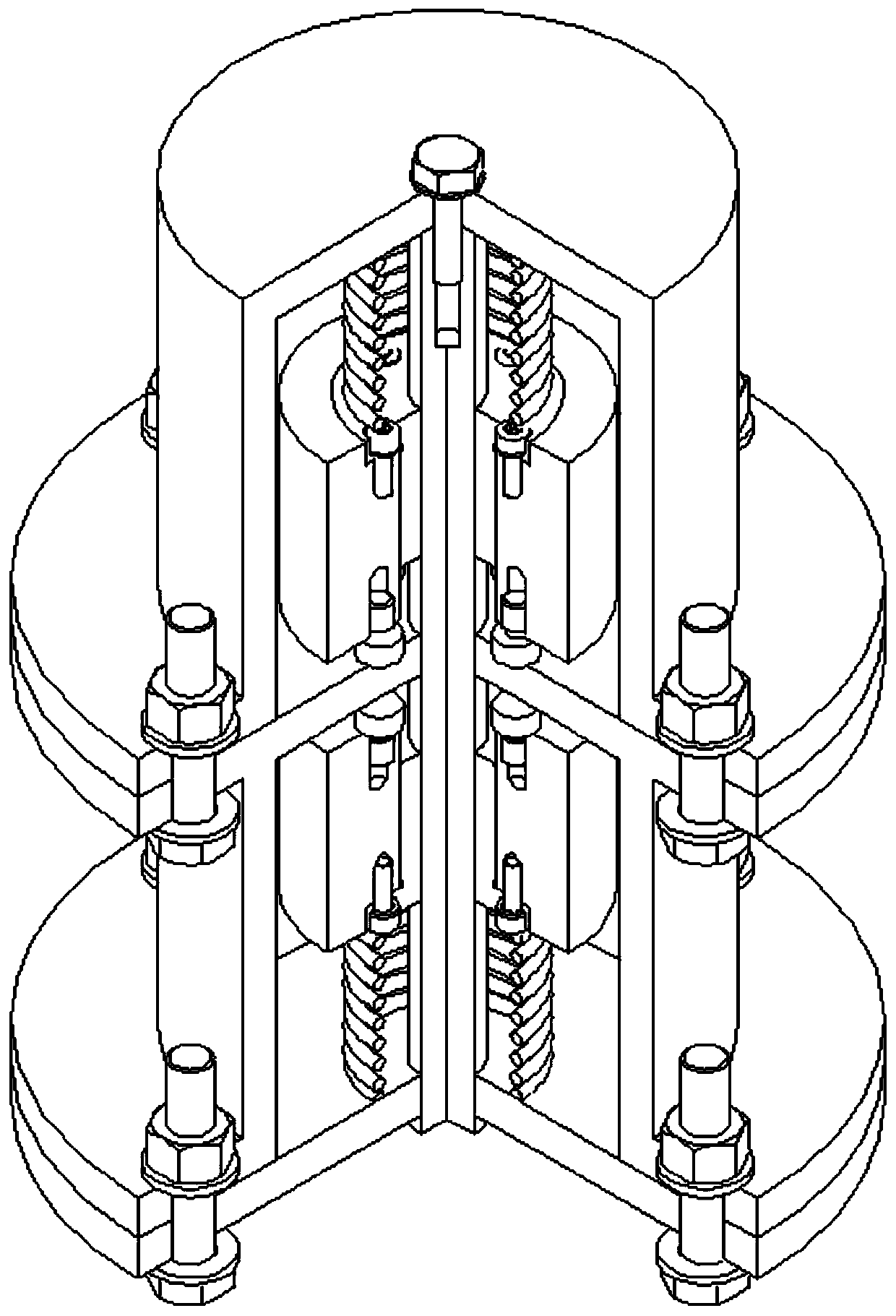

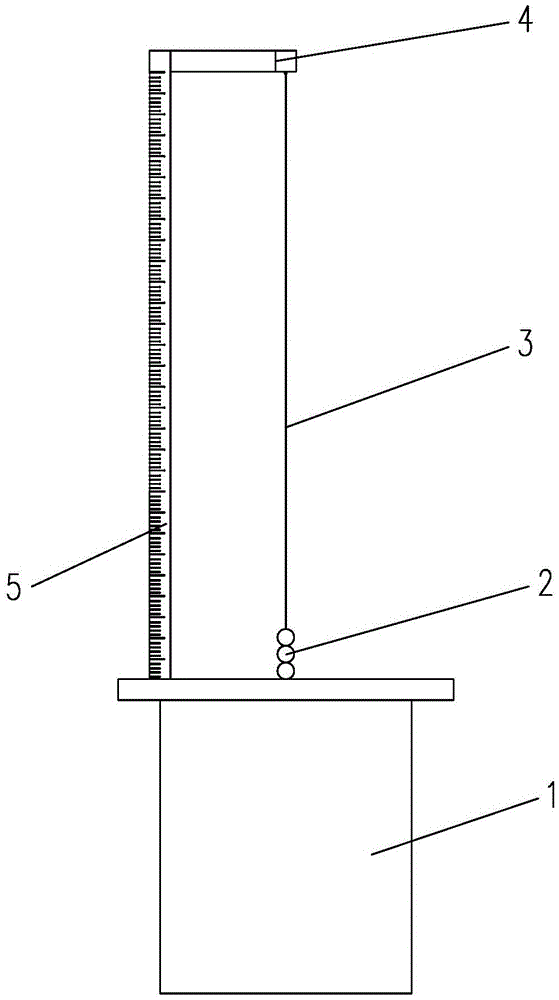

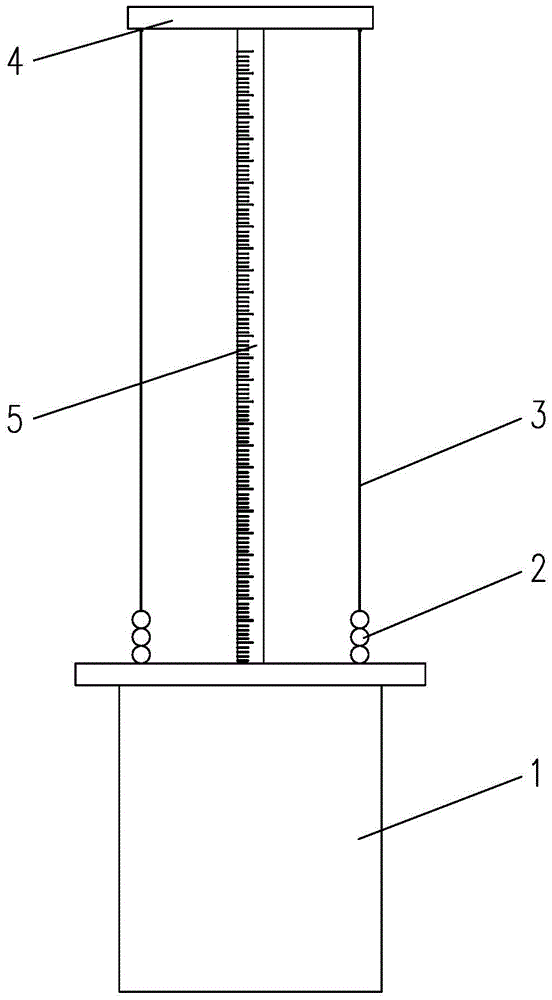

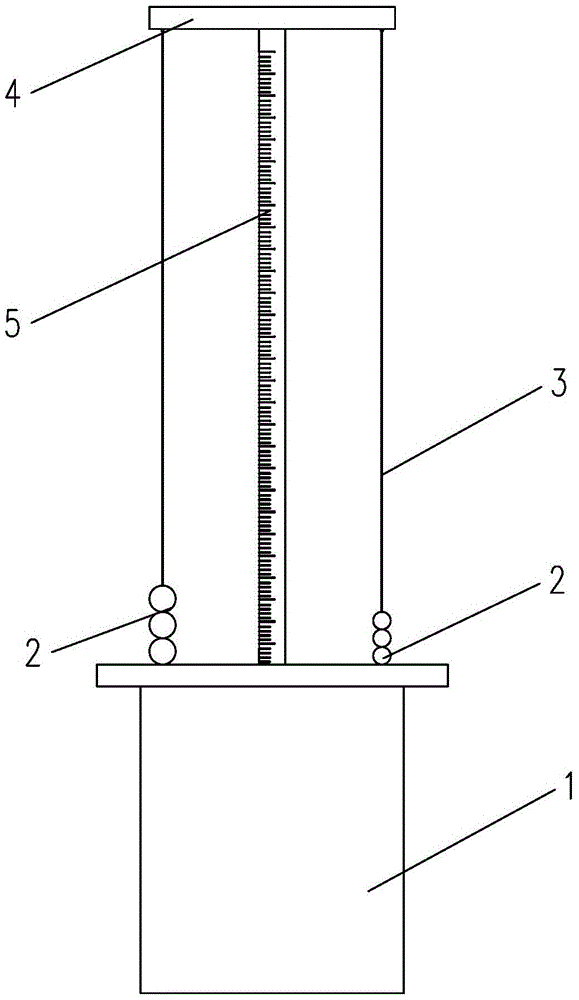

Two-degree-of-freedom collision nonlinear vibration-eliminating device

The invention relates to a two-degree-of-freedom collision nonlinear vibration-eliminating device, and belongs to the field of structural engineering vibration controlling. The two-degree-of-freedom collision nonlinear vibration eliminating device comprises a structure bottom plate 1, a lower layer shell 3, a lower layer mass block 4, an upper layer mass block 9, a collision contacting pin 5, a lower layer linear spring 2, an upper layer linear spring 6, an upper layer shell 7, a motion guiding shaft 8 and a fixing bolt 10. The lower layer mass block 4, the upper layer mass block 9 are connected with the structure bottom plate 1 and the upper layer shell 7 through the lower layer linear spring 2 and the upper layer linear spring 6; and when the vibration eliminating device reaches a specified position, inelastic collision occurs between the lower layer mass block 4 as well as the upper layer mass block 9 and the lower layer shell 4 through the collision contacting pin 5, mechanical energy in the structure is changed, and the goal of vibration reduction is achieved. According to the two-degree-of-freedom collision nonlinear vibration eliminating device, compared with a traditional vibration absorber and a damper, the mechanical energy of a system can be consumed in a wide range, and response of the structure is rapidly reduced, and the two-degree-of-freedom collision nonlinear vibration eliminating device has the prospect of wide application in practical engineering.

Owner:HARBIN ENG UNIV

A method for surface modification of metal materials by atmospheric pressure cooling plasma jet

ActiveCN103789716BNo heat damageAchieving surface modificationSolid state diffusion coatingPlasma jetChemical reaction

The invention provides a method for modifying the surface of a metal material by adopting atmospheric-pressure cold plasma jet, and belongs to the technical field of material surface treatment. The method comprises the following steps that: high-energy electrons and particles which are contained in the atmospheric-pressure cold plasma jet generate non-elastic collision with water molecules and oxygen molecules which are contained in an atmospheric environment to generate an oxygen-containing active particle; and the oxygen-containing active particle generates chemical reaction with the surface of the metal material to introduce an oxygen-containing functional group to the surface of the metal material, wherein the cold plasma jet is generated by a cold plasma jet generator with the discharge form of bare electrode corona discharge. The method provided by the invention can realize the modification of a designated-position and large-size metal surface by controlling the size or motion locus of the cold plasma jet without complex vacuum equipment, is low in cost and easily and flexibly operated without pollution on the environment, is a green surface modification method and can be applied to the surface modification of various non-metal materials.

Owner:DALIAN UNIV OF TECH

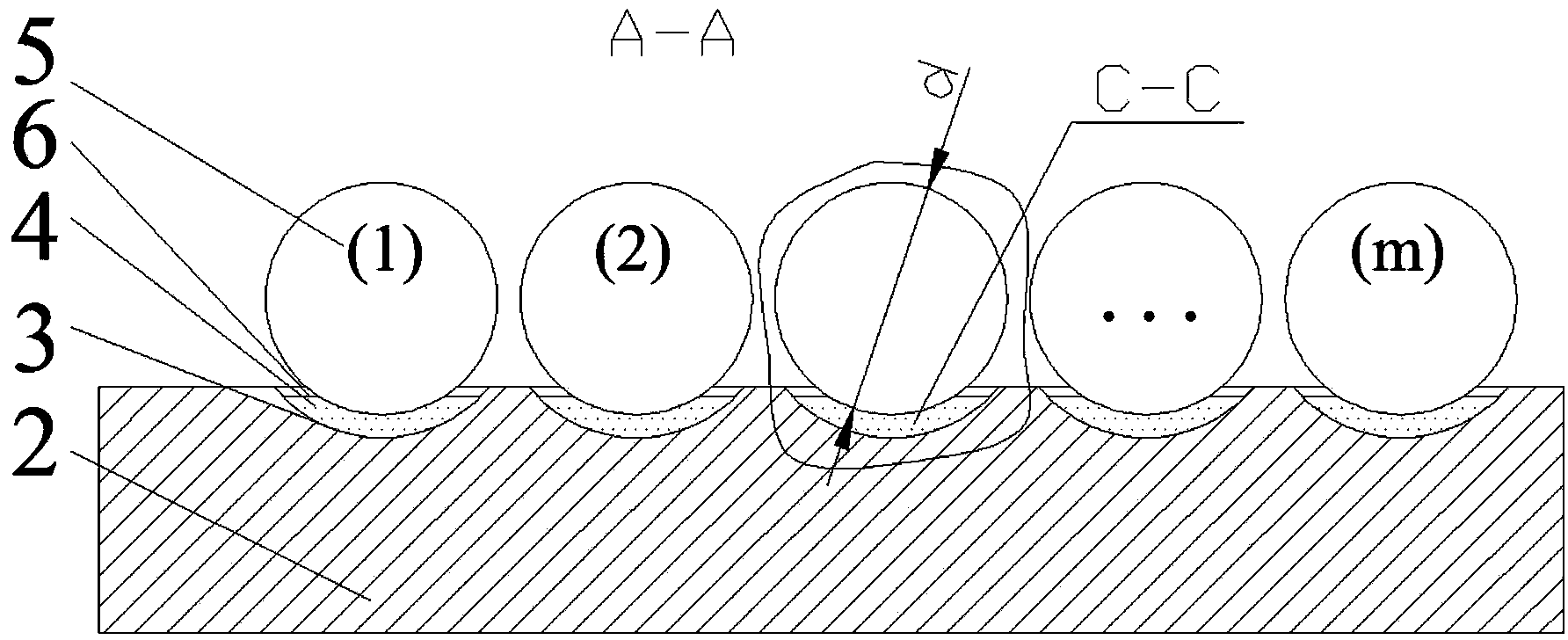

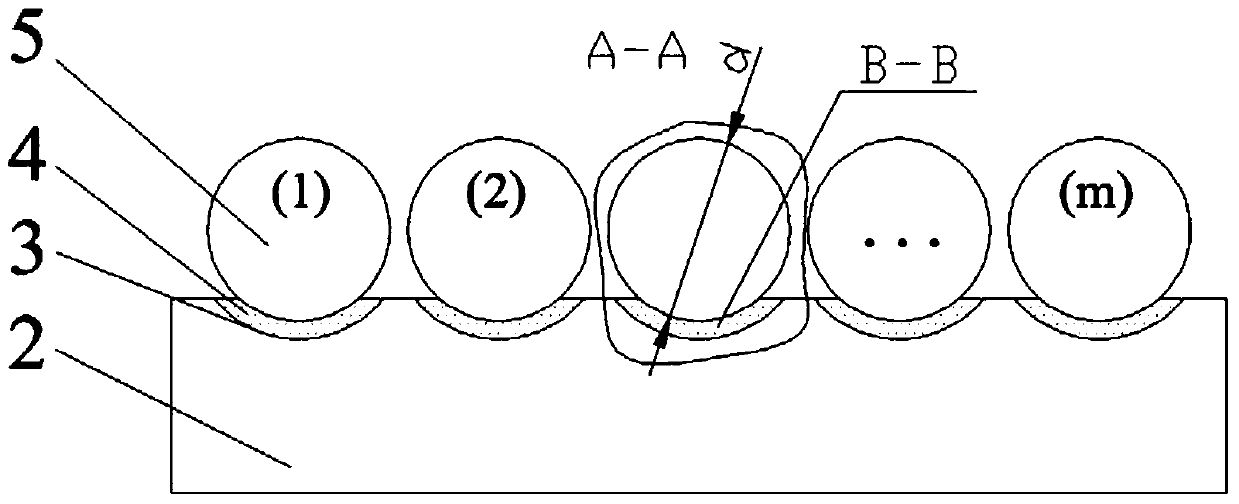

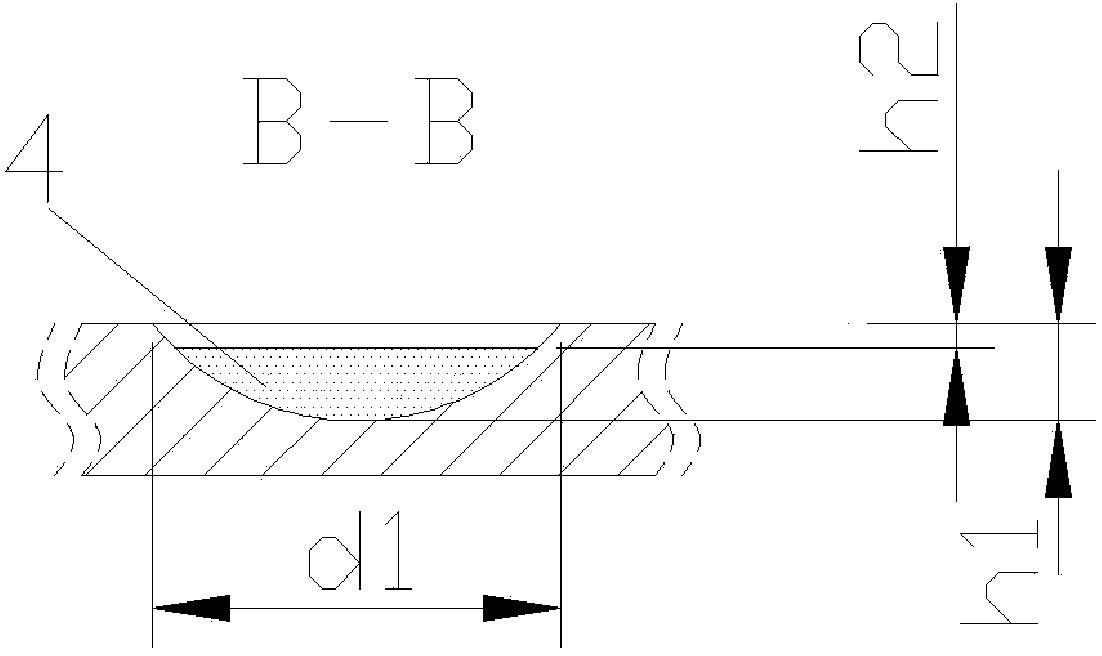

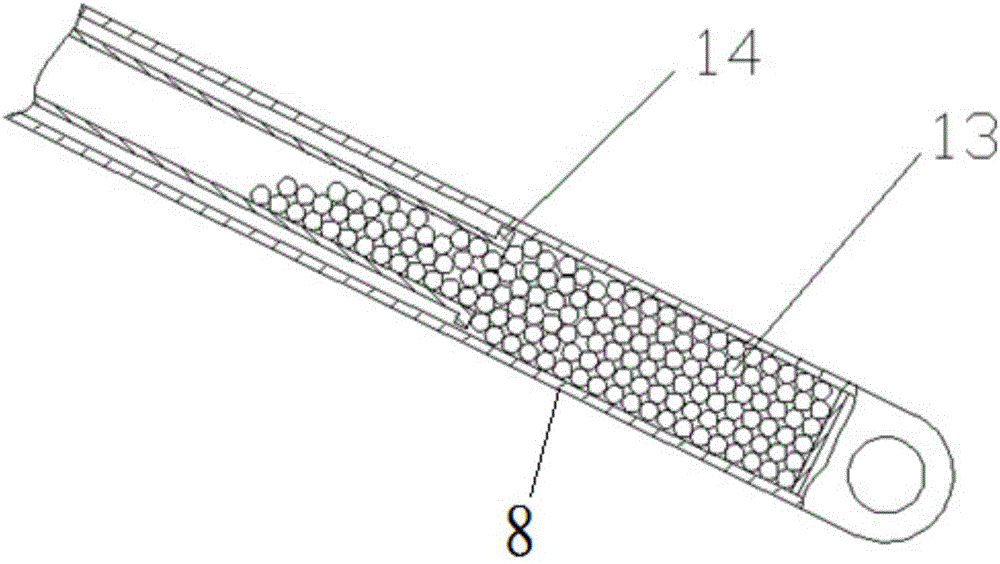

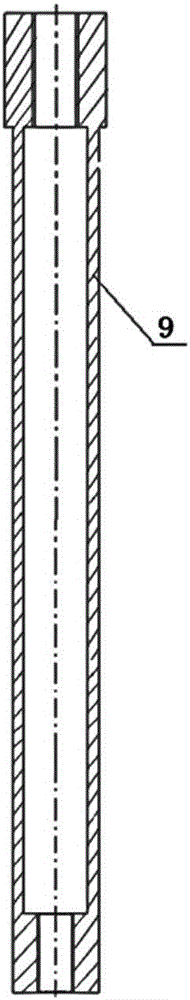

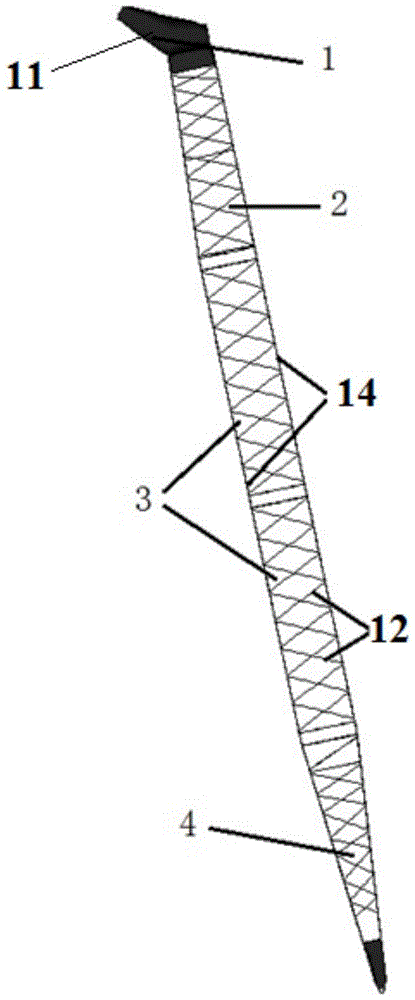

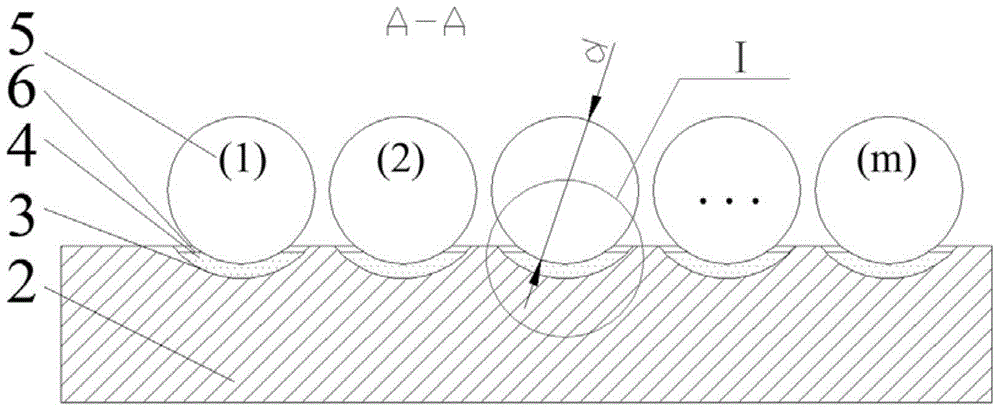

Inelastic collision and rolling viscous resistance particle coupling energy dissipation cutter rod

ActiveCN104096873AImprove stabilityHigh precisionBoring barsMetallic materialsMethyl phenyl polysiloxane

An inelastic collision and rolling viscous resistance particle coupling energy dissipation cutter rod relates to a cutting tool. The cutter rod comprises a cutter rod body, a cutter rod connection piece, a cutting head and coupling energy dissipation plates. A groove array is formed in each coupling energy dissipation plate. A surface low recovery coefficient particle and at least two high surface viscous resistance macromolecule particles are arranged in each groove, a high polymer film wraps the surface of each high surface viscous resistance macromolecule particle, and a fixed groove for installing the coupling energy dissipation plate is formed in each coupling energy dissipation plate. After multiple layers of coupling energy dissipation plates are installed in the cutter rod, vibration energy generated by cutting force can be dissipated quickly and gradually, energy dissipation factors are high, the vibration restraining effect is obvious, and boring stability and accuracy of parts with deep holes are effectively improved. The cutter rod is low in cost and easy to implement. The surface low recovery coefficient particles utilize a metal material as the base material, methyl phenyl polysiloxane and acrylate interpenetration polymer wraps the base material, and the surface low recovery coefficient particles are high in strength, not prone to corrosion, long in service life and capable of being used in a long term.

Owner:厦门粒资科技有限公司

Micro vibration reducing platform based on MEMS spring

InactiveCN104864010AExtended impact timeTo achieve the function of vibration isolationNon-rotating vibration suppressionHigh internal friction springsInelastic collisionEngineering

The invention discloses a micro vibration reducing platform based on a MEMS spring. The micro vibration reducing platform mainly consists of three layers of unit vibration reducing platforms, wherein vibration reducing glue is uniformly coated on the lower surfaces of the upper and middle layers of unit vibration reducing platforms; boss arrays are arranged on the upper surfaces of the middle and lower layers of unit vibration reducing platforms; plane springs are arranged around each layer of unit vibration reducing platforms; and edge frames are arranged around the plane springs. The micro vibration reducing platform can effectively prolong the collision time and absorb the impact energy through the deformation of the plane springs and the completely inelastic collision of the boss arrays and the vibration reducing glue. After the boss arrays and the vibration reducing glue are collided, the three layers of platforms are formed to a whole, so that the spring rigidity is multiplied, and the large-damping vibration reduction is realized. If the micro vibration reducing platform is used in a liquid environment, intervals between the plane springs and the vibration reducing platforms and intervals among all layers of vibration reducing platforms can generate higher slide film damping and pressed film damping under high-frequency impact. The main structure of the micro vibration reducing platform adopts a silicon-based material; and the micro vibration reducing platform is suitable for large-scale preparation by a MEMS process.

Owner:PEKING UNIV

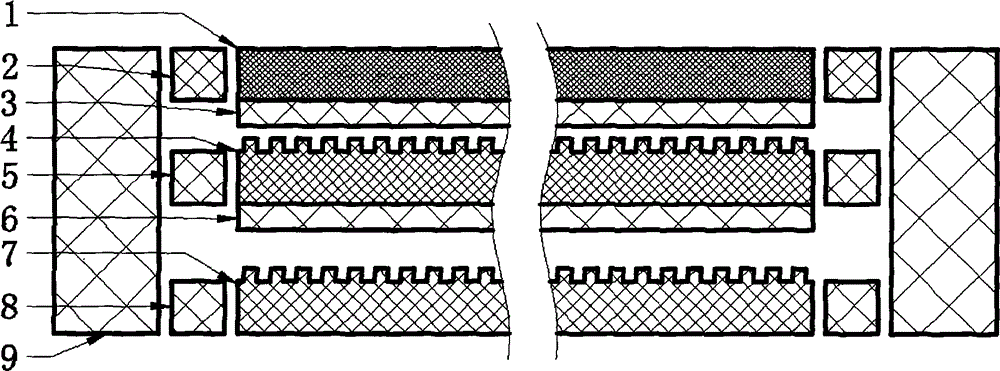

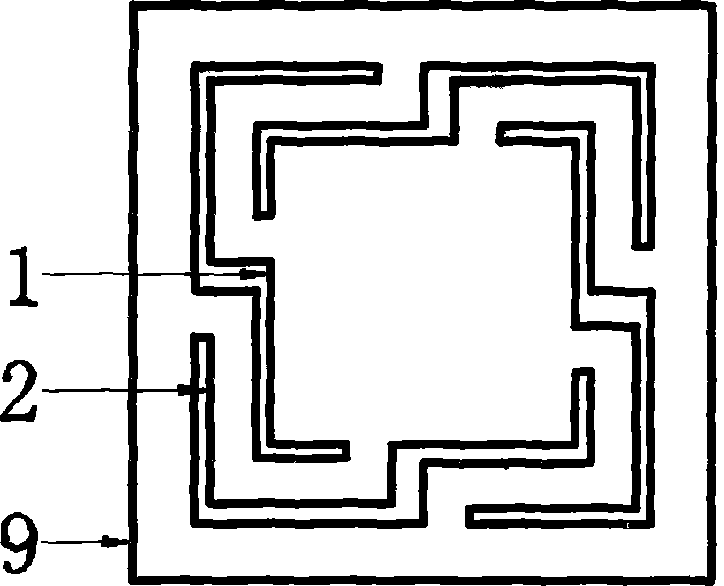

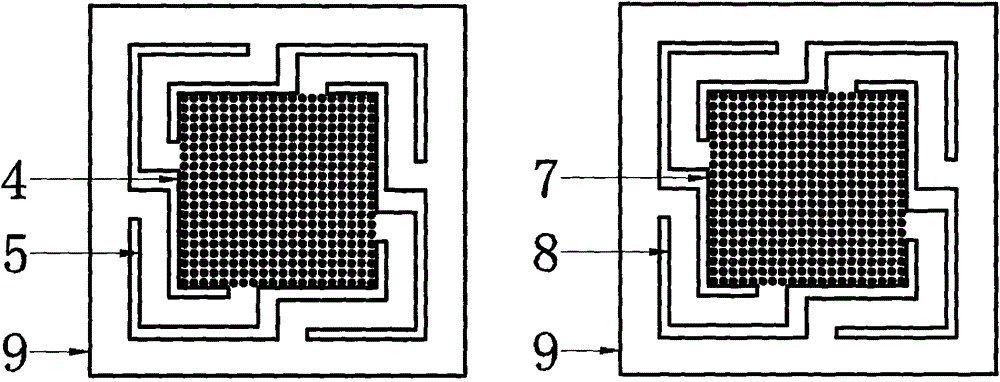

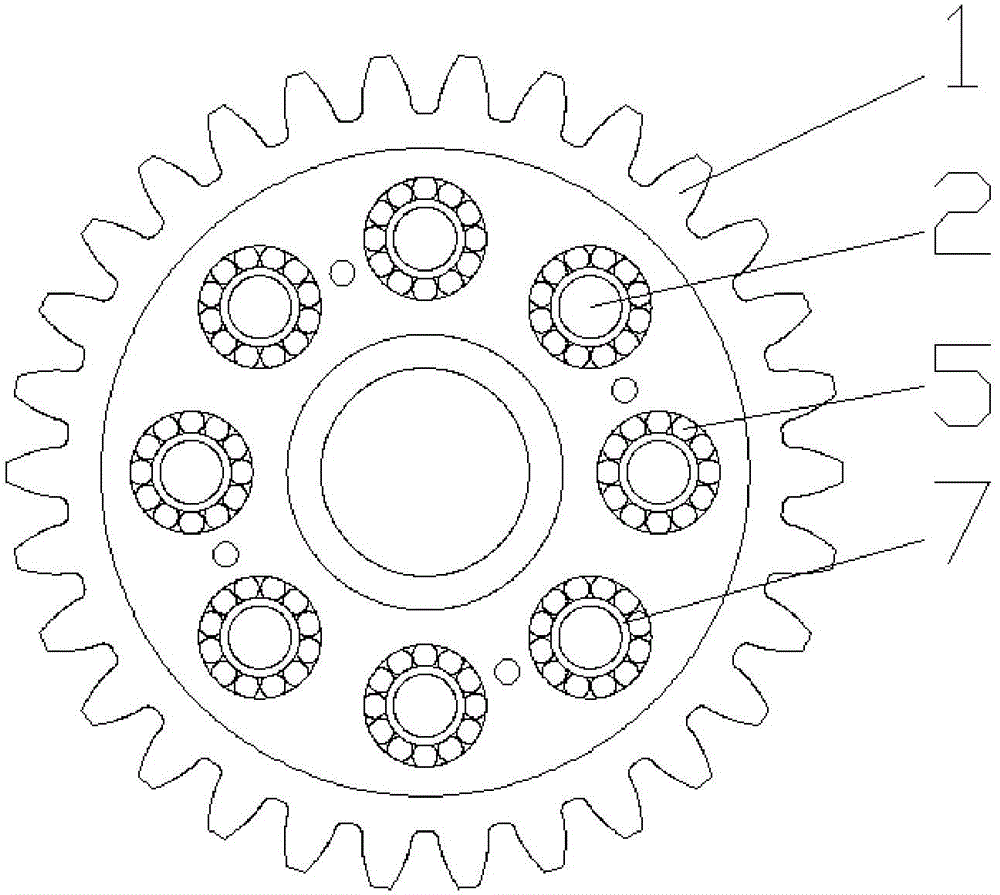

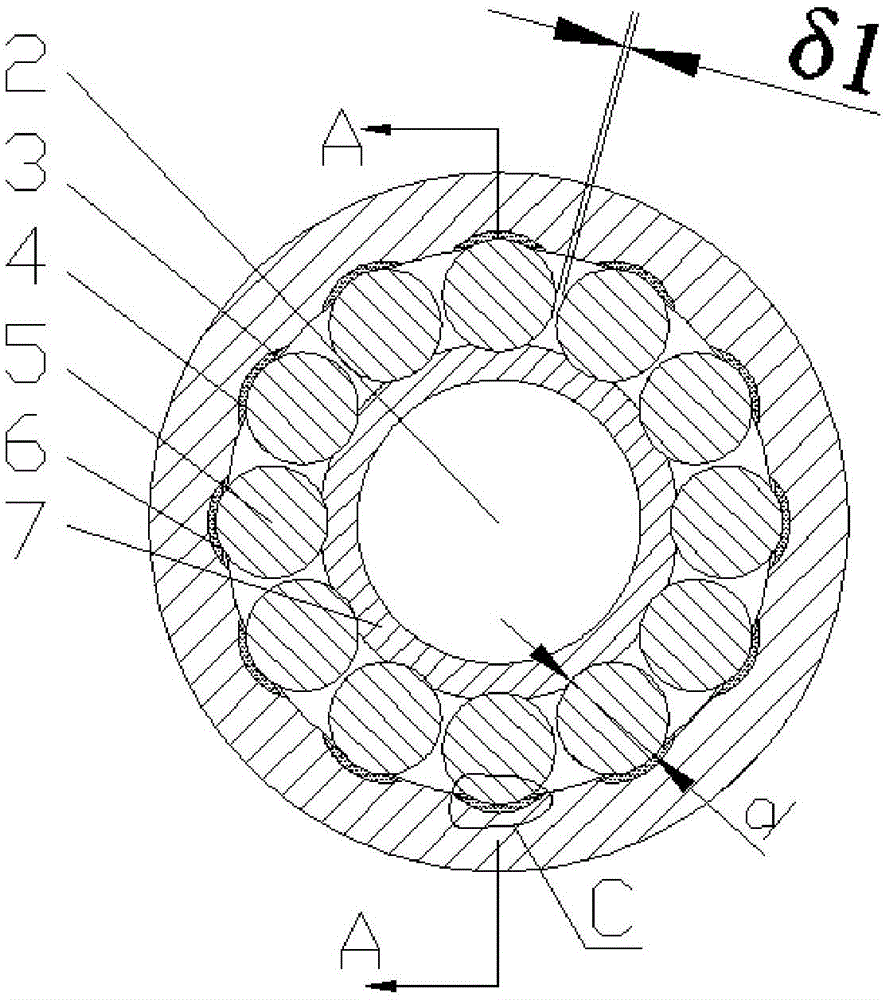

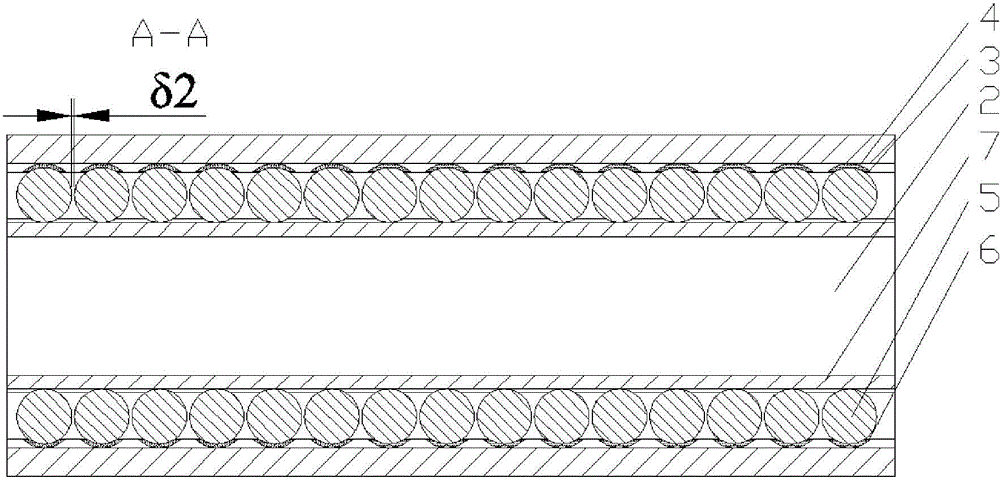

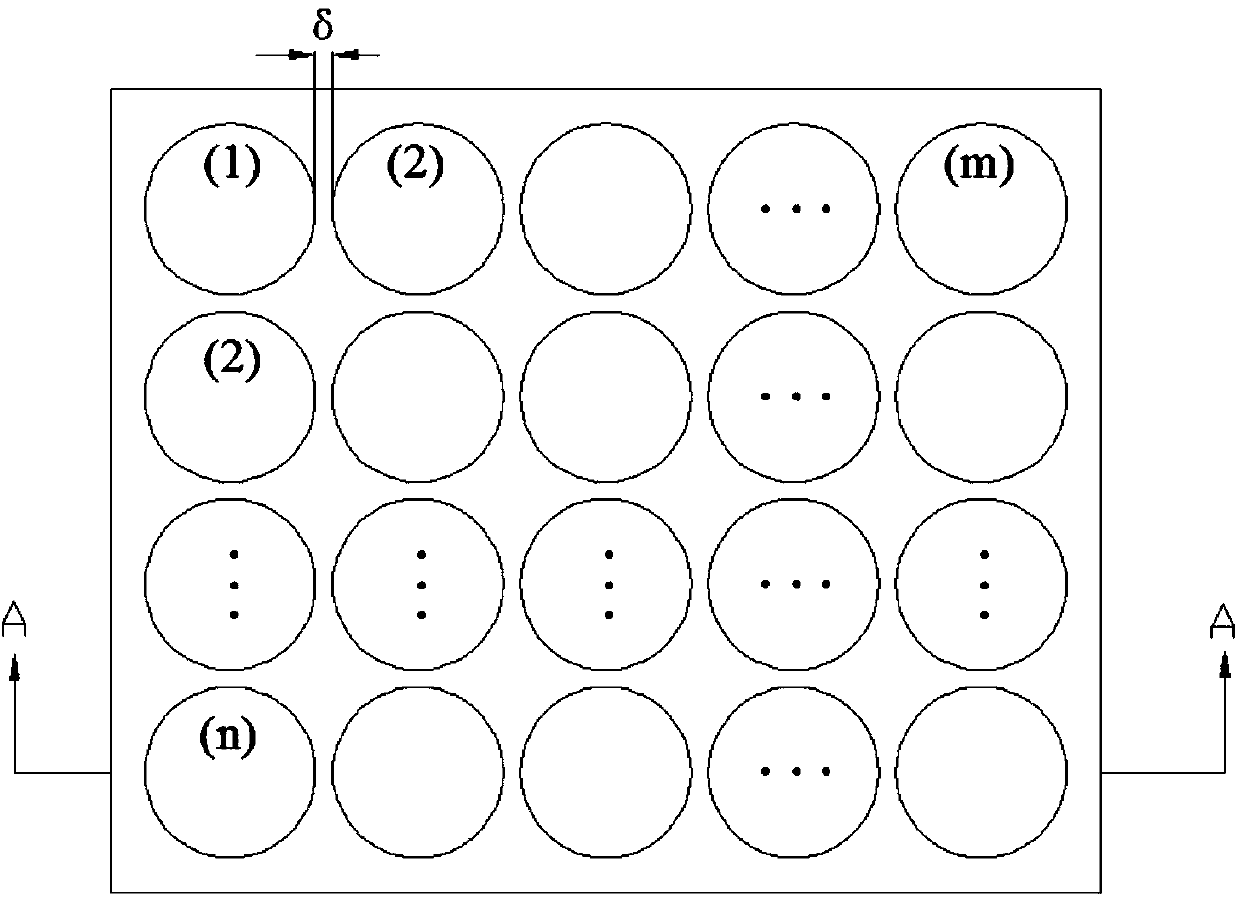

Inelastic collision and rolling viscous resistance particle coupling energy consumption low-noise gear

ActiveCN104141768ACircumferential vibration suppressionSuppress axial vibrationPortable liftingGearing elementsLow noiseInelastic collision

The invention discloses an inelastic collision and rolling viscous resistance particle coupling energy consumption low-noise gear and relates to gears. The gear is provided with a gear body, gear lightening holes, lightening hole grooves, high surface viscous resistance high polymer particles, low surface recovery coefficient particles, high polymer films, low surface recovery coefficient particle holders and a lightening hole sealing plate, wherein the lightening hole grooves are formed in the gear lightening holes; one low surface recovery coefficient particle and at least two high surface viscous resistance high polymer particles are placed in the lightening hole grooves; one low surface recovery coefficient particle holder is arranged in each gear lightening hole; the gear lightening holes are sealed by the lightening hole sealing plate; the high surface viscous resistance high polymer particles are coated with the high polymer films; a gap theta 1 is reserved between adjacent low surface recovery coefficient particles in the circumferential direction; a gap theta 2 is reserved between adjacent low surface recovery coefficient particles in the axial direction.

Owner:厦门环寂高科有限公司

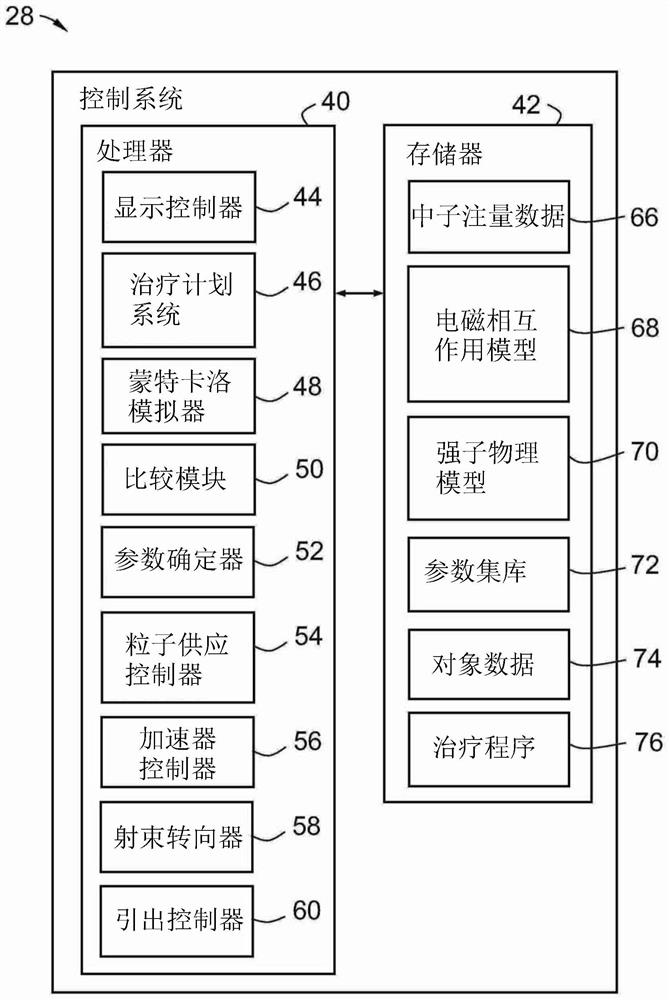

An irradiation method and system

ActiveCN111629783AAppropriate combinationRadiation/particle handlingConversion outside reactor/acceleratorsNuclear engineeringInelastic collision

An irradiation method and system for irradiating a target volume, the method comprising: providing thermal neutron absorbing nuclides (such as in the form of a high neutron cross-section agent) at thetarget volume; and producing neutrons by irradiating nuclei in or adjacent to the target volume with a beam of particles consisting of any one or more of protons, deuterons, tritons and heavy ions, thereby prompting production of the neutrons through non-elastic collisions between the atoms in the path of the beam (including the target) and the particles. The neutron absorbing nuclides absorb neutrons produced in the non-elastic collisions, thereby producing capture products or fragments that irradiate the target volume.

Owner:AUSTRALIAN NUCLEAR SCI & TECH ORGANISAT +1

A flywheel body with a shock absorber

The invention relates to a flywheel body with a shock absorber. The flywheel body with the shock absorber comprises a rim, spokes, a wheel hub, a flange and particle shock absorbers; every particle shock absorber comprises a shock absorber chamber, particles or powder and a shock absorber end cover; the particle shock absorbers are evenly distributed in the rim of the flywheel body; when the flywheel body is externally driven, system energy is consumed due to inelastic collision and abrasion between the particles and the particles and an empty chamber, and accordingly the purpose of improving the shock vibration resistance capability of the flywheel body is achieved. The flywheel body with the shock absorber has the advantages of being obvious in shock absorbing effect, low in cost, simple in structure, wide in suitable temperature range, stable in performance, long in service life, high in reliability and small in influence to integral utilization due to the fact that the unbalance capacity of the flywheel body does not change fundamentally after environment tests.

Owner:BEIJING INST OF CONTROL ENG

Automatic powder demagnetization equipment

PendingCN108014917AAvoid accumulationSimple structureSievingScreeningMachining vibrationsScreening effect

The invention provides automatic powder demagnetization equipment. According to the automatic powder demagnetization equipment, a spiral buffer mechanism is arranged, and therefore the material falling speed is reduced, the particle collision time is prolonged, meanwhile, in the process that particles are changed from movable to static, a tangential-velocity component is achieved, completely inelastic collision is avoided, shearing crushing of powder particles is effectively prevented, tiny particles such as dust attached to the surfaces of the powder particles can be separated, materials areprevented from falling on a screen net and prevented from being accumulated, and the screening effect is good; a screening mechanism is arranged, and therefore accumulation of a large amount of powderon the screen net can be avoided, the grading efficiency is high, overall machine vibration is avoided, and the service life is prolonged; a demagnetization mechanism is arranged, and therefore the demagnetization effect is good, demagnetization is carried out while screening is carried out, screening is carried out while demagnetization is carried out, the number of process steps is smaller, theworking efficiency is high, and economic returns are good; and the structure is simple, and operation is easy and convenient.

Owner:TIANJIN RUIHAI PENGXIANG TRADING

Inelastic collision and rolling viscous resistance particle coupling energy consumption numerical control machine tool

ActiveCN104175169AImprove stabilityImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesNumerical controlSurface recovery

An inelastic collision and rolling viscous resistance particle coupling energy consumption numerical control machine tool relates to a numerical control machine tool and is provided with a numerical control machine tool body, upright posts, a crossbeam, a top beam, a stiffening beam, a ram, an electric spindle and a worktable, wherein at least two coupling energy consumption boards are arranged in at least one structural part of the numerical control machine tool, and the structural part comprises at least one of the numerical control machine tool body, the upright posts, the crossbeam, the top beam, the stiffening beam, the ram and the like; a groove array is arranged on each of the coupling energy consumption boards; at least two high-surface-viscous-resistance polymer particles are arranged in each groove of the groove arrays; a low-surface-recovery-coefficient particle is placed in each of the grooves. When the machine tool is in high-speed heavy cutting, the coupling energy consumption boards can quickly dissipate unidirectional and multi-directional vibration energy generated by the cutting force step by step, the energy consumption factor is high, the vibration suppression effect is obvious, and the stability and the machining precision of the machine tool are effectively improved.

Owner:厦门环寂高科有限公司

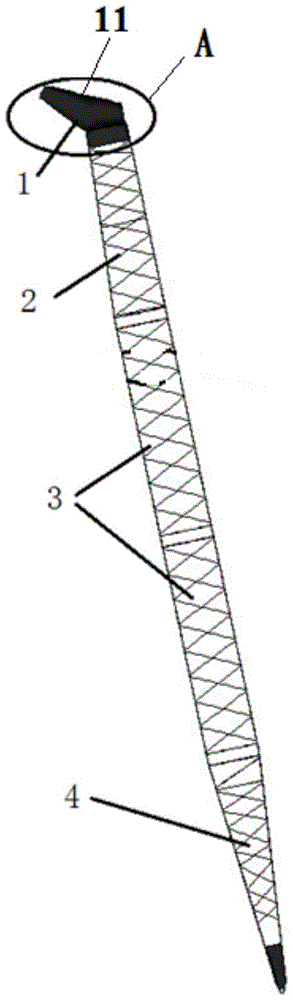

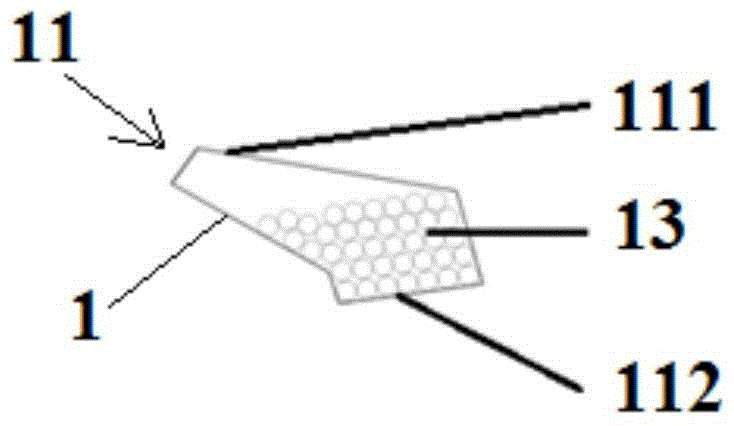

Anti-back-tipping structural piece, anti-back-tipping device and engineering machine

InactiveCN106703002AImprove dissipation efficiencyGood vibration dampingSoil preservationInelastic collisionPropeller

The invention discloses an anti-back-tipping structural piece, an anti-back-tipping device and an engineering machine, and relates to the technical field of engineering machines. The technical problem that in the prior art, the damping effect is poor is solved. The anti-back-tipping structural piece comprises a seat body and damping particles, wherein the seat body is provided with a movable cavity and an embedding opening communicated with the movable cavity; the damping particles are arranged in the movable cavity in a filling manner and occupy partial space of the movable cavity, and the damping particles can dissipate vibration energy on a stretchable movement piece at least through the manners of friction of the stretchable movement piece embedded in from the embedding opening or non-elastic collision between the damping particles. The anti-back-tipping device comprises the stretchable movement piece and the anti-back-tipping structural piece provided in the invention. The engineering machine comprises an arm support, a rotary table, a propeller strut and the anti-back-tipping device provided in the invention. By means of the anti-back-tipping structural piece, the anti-back-tipping device and the engineering machine, the damping effect of the anti-back-tipping structural piece is improved.

Owner:XCMG CONSTR MACHINERY

A Two Degrees of Freedom Collision Nonlinear Vibration Elimination Device

ActiveCN107606027BReduce vibration response amplitudeAchieve transferShock absorbersInelastic collisionClassical mechanics

The invention relates to a two-degree-of-freedom collision nonlinear vibration-eliminating device, and belongs to the field of structural engineering vibration controlling. The two-degree-of-freedom collision nonlinear vibration eliminating device comprises a structure bottom plate 1, a lower layer shell 3, a lower layer mass block 4, an upper layer mass block 9, a collision contacting pin 5, a lower layer linear spring 2, an upper layer linear spring 6, an upper layer shell 7, a motion guiding shaft 8 and a fixing bolt 10. The lower layer mass block 4, the upper layer mass block 9 are connected with the structure bottom plate 1 and the upper layer shell 7 through the lower layer linear spring 2 and the upper layer linear spring 6; and when the vibration eliminating device reaches a specified position, inelastic collision occurs between the lower layer mass block 4 as well as the upper layer mass block 9 and the lower layer shell 4 through the collision contacting pin 5, mechanical energy in the structure is changed, and the goal of vibration reduction is achieved. According to the two-degree-of-freedom collision nonlinear vibration eliminating device, compared with a traditional vibration absorber and a damper, the mechanical energy of a system can be consumed in a wide range, and response of the structure is rapidly reduced, and the two-degree-of-freedom collision nonlinear vibration eliminating device has the prospect of wide application in practical engineering.

Owner:HARBIN ENG UNIV

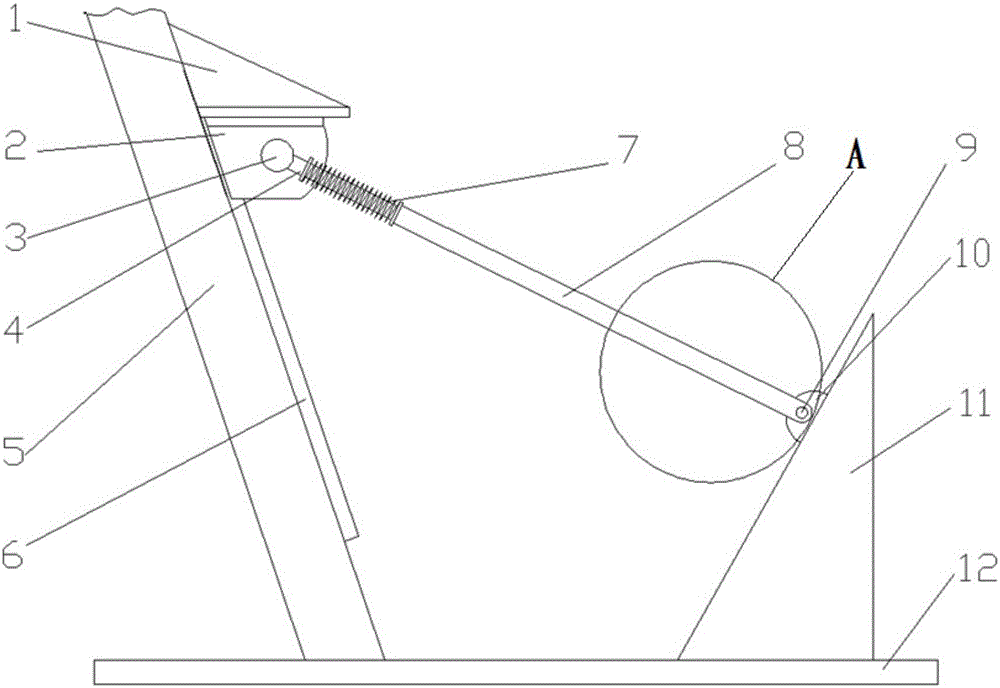

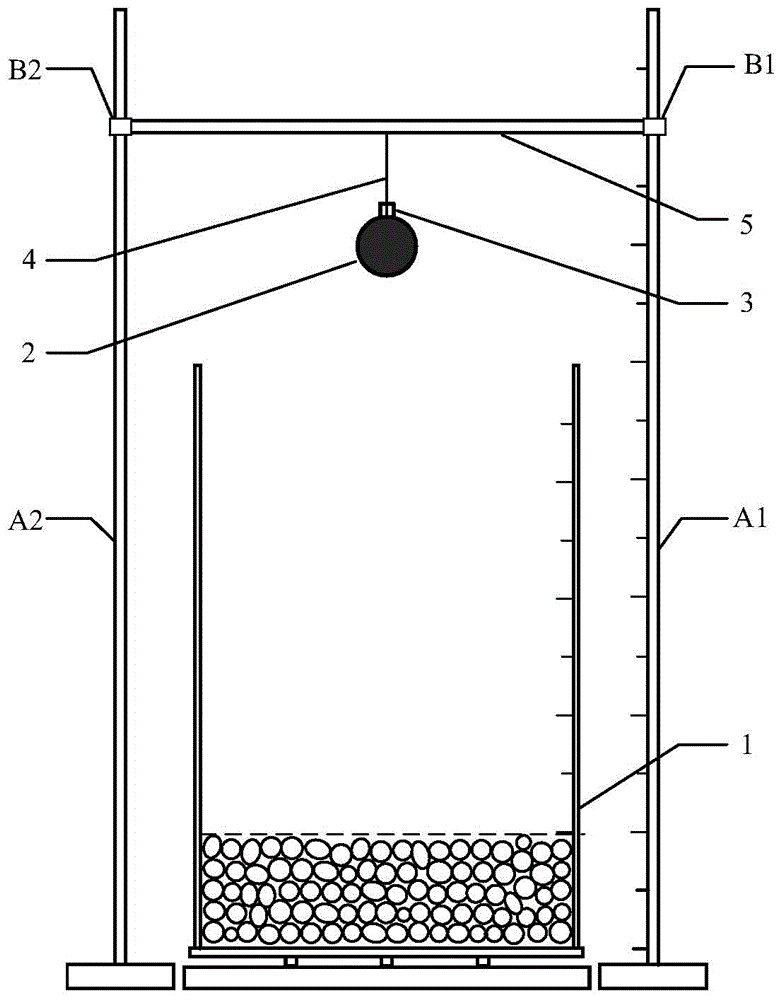

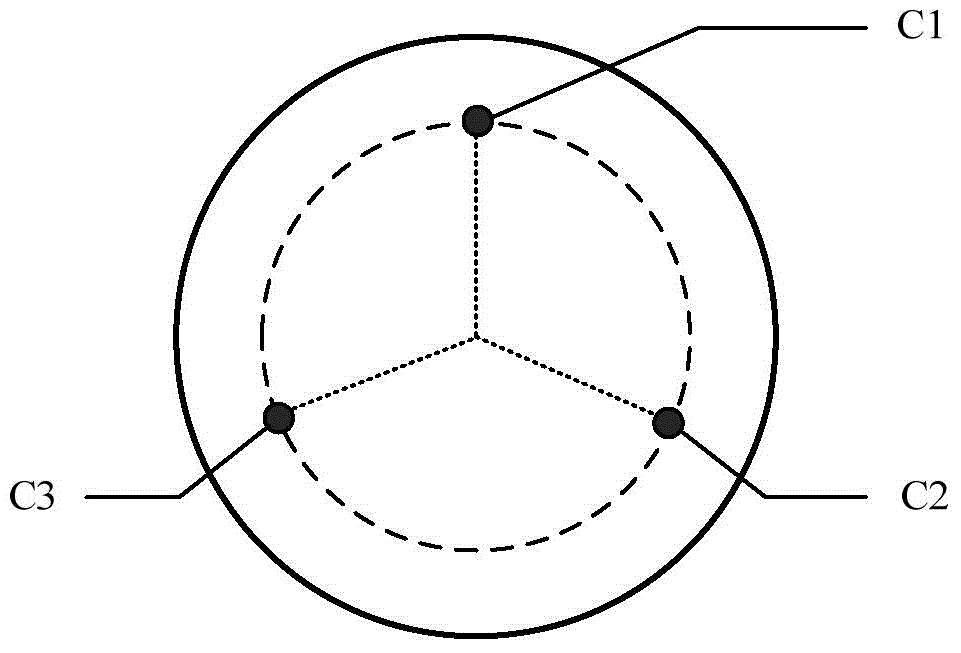

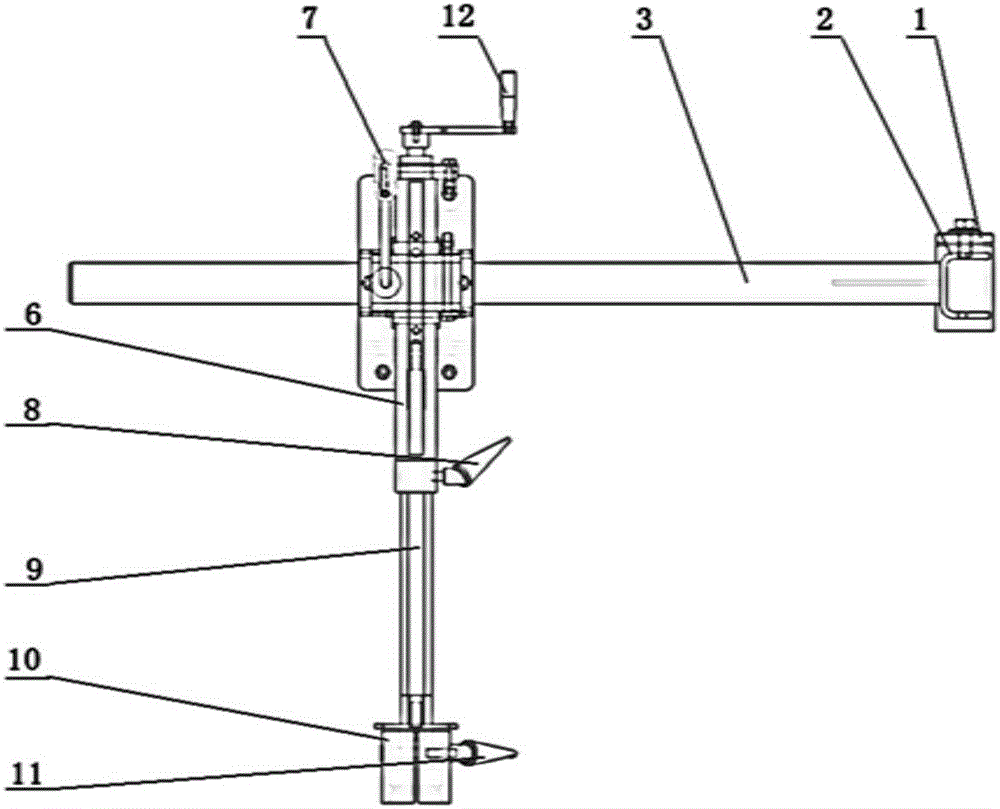

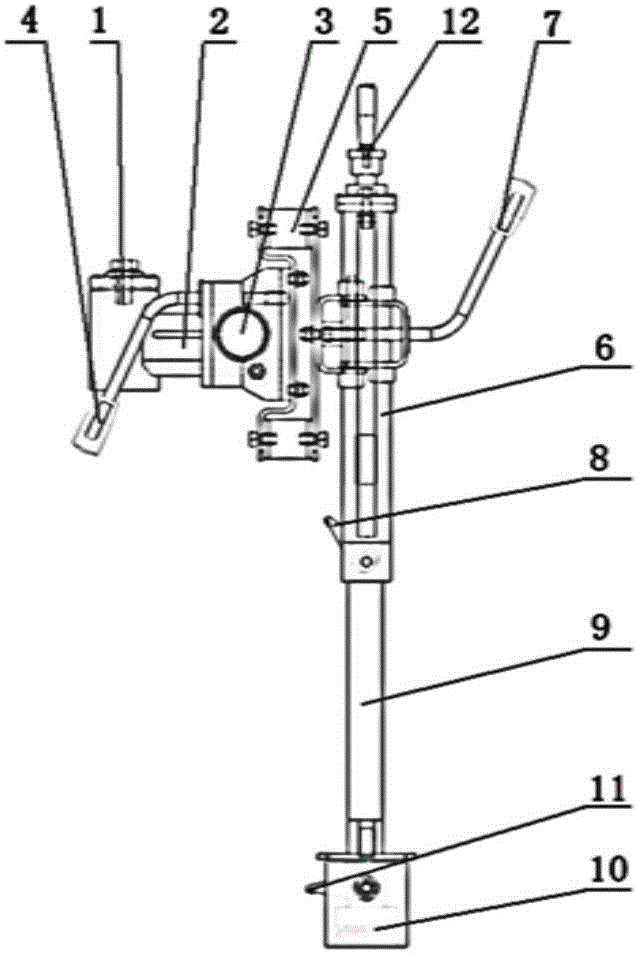

Granular material buffer performance measuring system

InactiveCN104964901ARealize impactAccurate measurementMaterial analysisImpact systemInelastic collision

The invention provides a granular material buffer performance measuring system. A granular substance is a rapid energy dissipating system, and energy is consumed mainly through intergranular non-elastic collision and sliding friction, and an intergranular force chain structure can increase the action area and the action time of external load, so impact load is certainly buffered, and destroys brought by the impact are reduced. The measuring system is composed of a fixed support, a granule impact system, a mechanical response measuring system and an image acquisition system, so vertical impact to the granular substance is realized, the acceleration of an impact substance and the impact force born by a baseboard can be accurately measured, the change of the surface form of the granule and the movement of the impact substance in the impact process is recorded, and a reliable device is provided for accurately measuring the buffer performance of the granular substance. The device can realize control and adjustment of the thickness of a granule layer and the impact height, and the influences of the thickness of the granule layer and the impact height on the buffer characteristic of the granule layer are researched.

Owner:DALIAN UNIV OF TECH

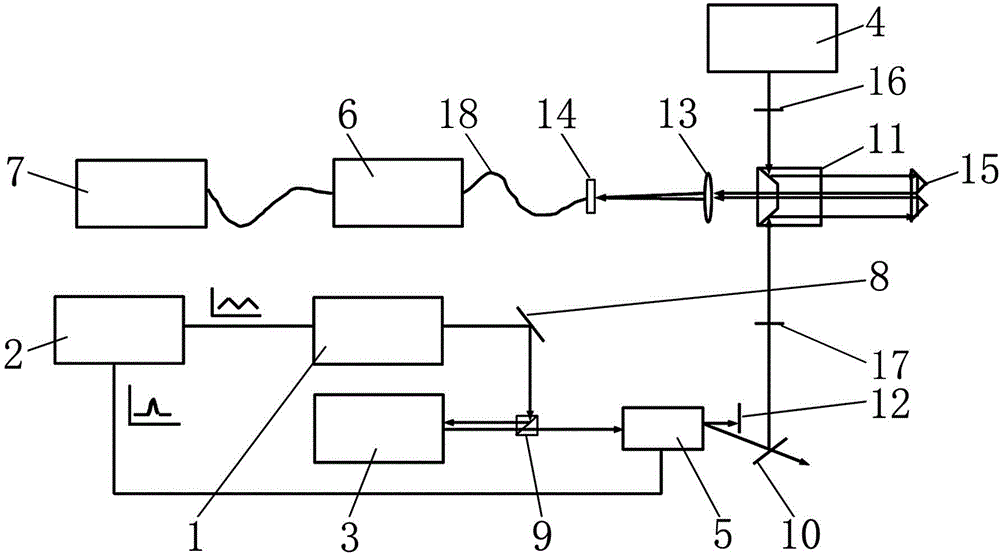

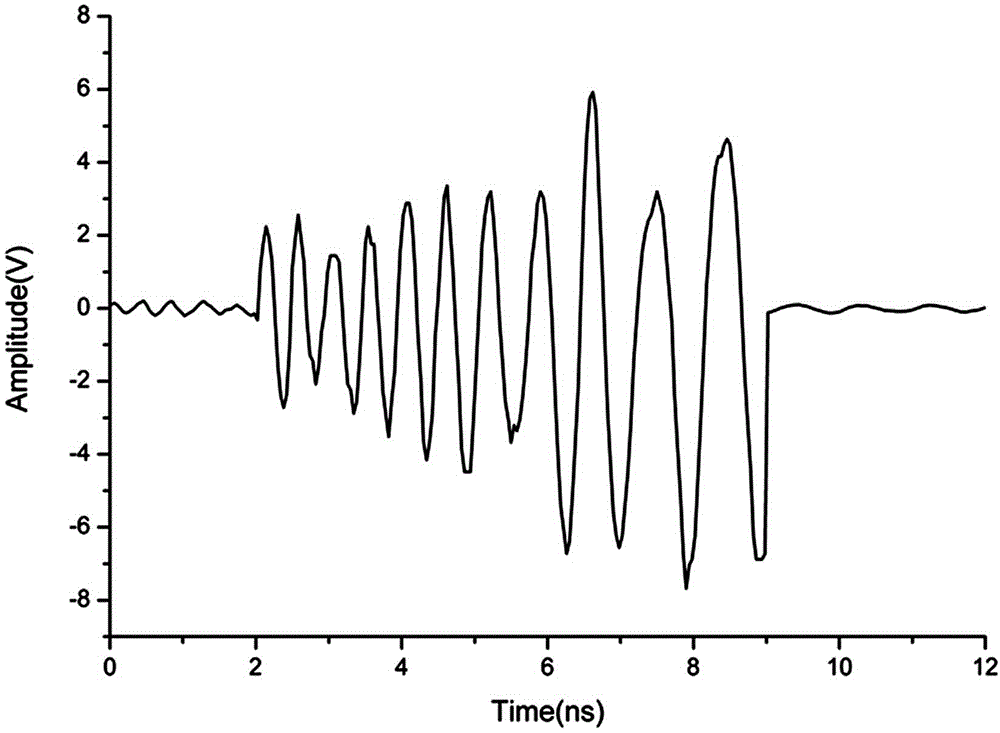

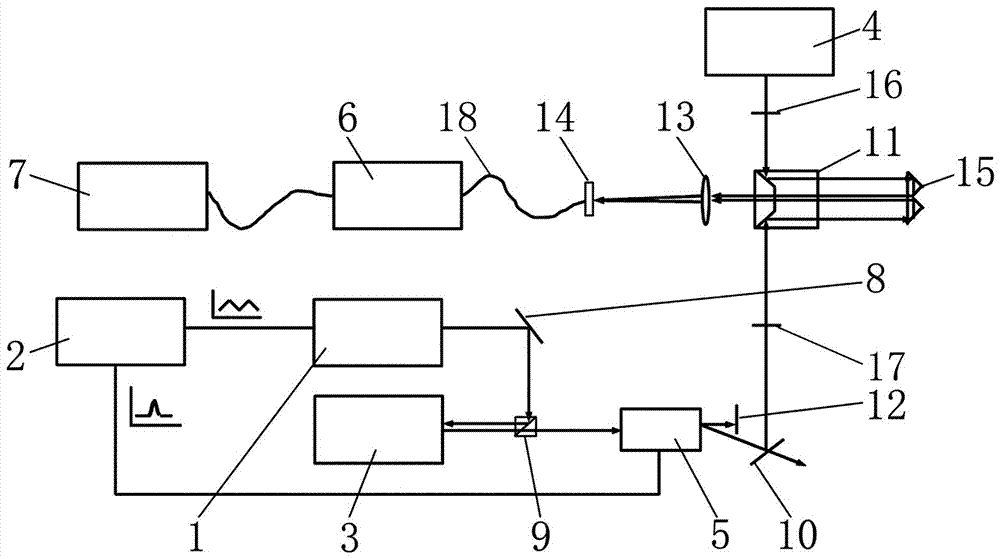

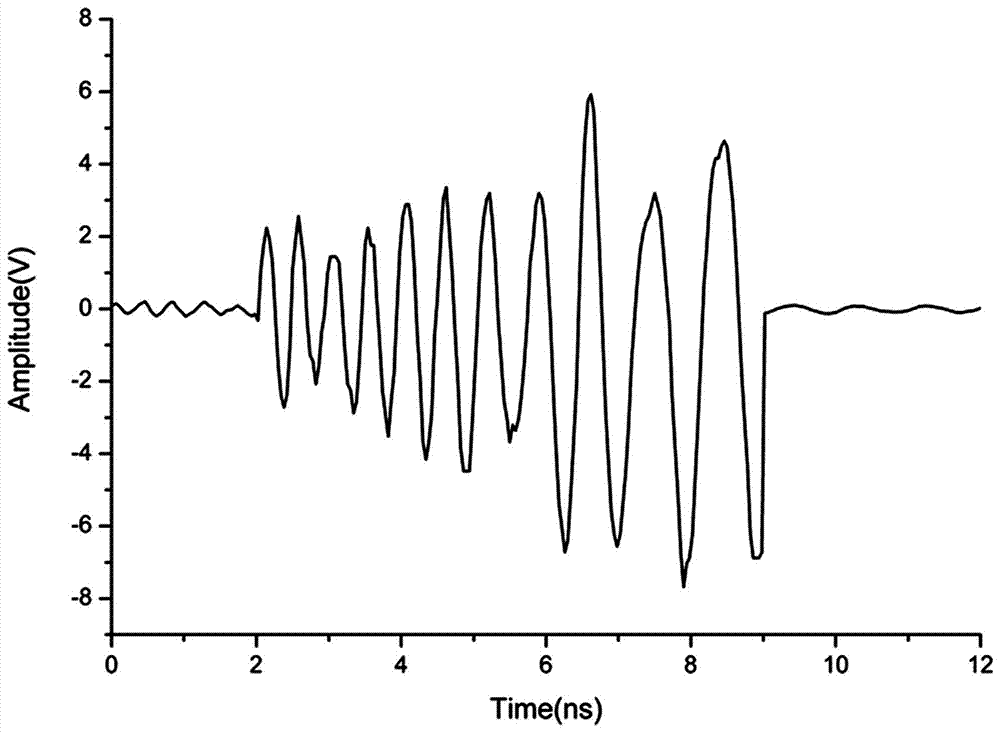

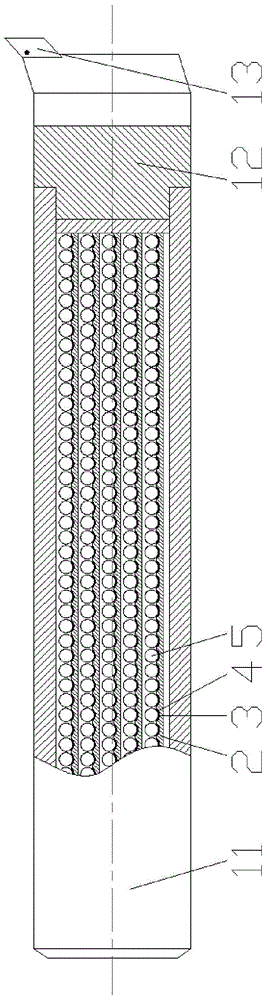

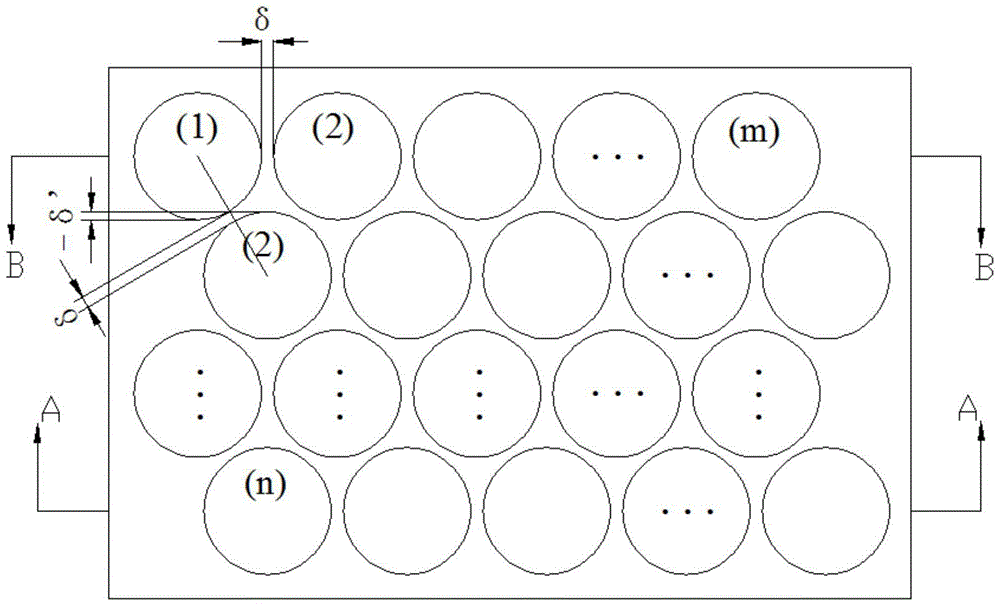

Nanosecond chirped pulse light source producing device and method

ActiveCN104466650ABlock inelastic collisionsSolve the problem of being unable to block the inelastic collision of atoms and control the coherence of atom pairsLaser detailsBeam splittingPrism

The invention relates to a nanosecond chirped pulse light producing technology, in particular to a nanosecond chirped pulse light source producing device and method. The problem that existing nanosecond chirped pulse light cannot block atomic inelastic collision and conducts coherent control on atoms is solved. The nanosecond chirped pulse light source producing device comprises a master laser device, a signal generator, a slave laser device, a reference light laser device, a TeO2 crystal, a photoelectric detector, an oscilloscope, a second polarized beam splitting prism, an optical fiber coupling head and an optical fiber, wherein a light path formed by sequentially connecting a first reflecting mirror and a first polarized beam splitting prism in series is arranged between the output end of the master laser device and the input end of the slave laser device, the first polarized beam splitting prism is arranged between the output end of the slave laser device and the input end of the TeO2 crystal, and a light path formed by sequentially connecting a second reflecting mirror and a second half wavelength plate in series is arranged between the output end of the TeO2 crystal and the input end of the second polarized beam splitting prism. The nanosecond chirped pulse light source producing device and method is suitable for nanosecond chirped pulse light production.

Owner:SHANXI UNIV

Automatic leveling system and paver

InactiveCN106480809AReduce vibration amplitudeRoads maintainenceVibration amplitudeInelastic collision

The invention relates to an automatic leveling system and a paver, the automatic leveling system includes an automatic leveling apparatus and a mounting frame for mounting of the automatic leveling apparatus, a closed cavity is arranged in the mounting frame in the cavity, and the cavity is partially filled with a granular vibration absorbing medium. The cavity is arranged on the mounting frame and partially filled with the granular vibration absorbing medium, and a granule vibration absorber is formed, so that the vibration amplitude of the automatic leveling system is significantly reduced by use of friction among the vibration absorbing medium and friction between the vibration absorbing medium and the inner wall of the cavity and non elastic collision for consumption of vibration energy of the automatic leveling system, and influence of vibration on the control accuracy of the automatic leveling system is avoided.

Owner:XCMG CONSTR MACHINERY

A centrifugal fan volute with particle damping and vibration reduction

ActiveCN104675752BReduce radiated noiseReduce noisePump componentsPumpsSpherical granuleVibration attenuation

The invention discloses a centrifugal fan volute employing granular damping vibration attenuation. The centrifugal fan volute comprises a volute body, wherein the volute body is provided with an air inlet (4); a centrifugal fan (7) is arranged in the volute body and is driven by a motor (8). The centrifugal fan volute is characterized in that the volute body consists of an inner volute (1) and an outer volute (2); a vibration attenuation and noise reduction chamber is formed between the inner volute (1) and the outer volute (2) and is filled with damping vibration attenuation granules (6). According to the centrifugal fan volute, the chamber between the inner volute and the outer volute is filled with spherical granules, the non-elastic collision and the friction between the granules and between each granule and the wall of the chamber are caused by the vibration of the inner volute, the energy is consumed, and the aim of vibration attenuation is achieved; meanwhile, the radiation noise of the volute can be reduced. The centrifugal fan volute can be applied to the industrial fields of energy power, petrochemical industry, petrochemical industry and the like, and the field of national defense and military industry.

Owner:SINOMACH +1

A cleaning liquid collection device

ActiveCN105161442BElastic Collision PreventionAvoid secondary pollutionSemiconductor/solid-state device manufacturingInelastic collisionEngineering

The invention discloses a cleaning liquid collecting device comprising an air inflow portion, a cleaning liquid collecting portion, and an air-liquid separating portion. The air inflow portion supplies air to the cleaning liquid collecting portion. An annular air curtain is formed at an air outlet and achieves inelastic collision with cleaning liquid separated from the surface of a wafer. Thus, the cleaning liquid is changed in moving direction, enters an air-liquid collecting cavity and is separated and exhausted by the air-liquid separating portion. The cleaning liquid collecting device may reduce back-splash of cleaning medium at the sidewall of a cleaning liquid collecting structure, prevents secondary pollution, and improves liquid cleaning medium recovery efficiency.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Structural member for engineering machine, cantilever crane, dynamic compaction machine and method

ActiveCN106703005AWith damping functionHigh speedNon-rotating vibration suppressionSoil preservationVibration attenuationDynamic compaction

The invention discloses a structural member for an engineering machine, a cantilever crane, a dynamic compaction machine and a method, and relates to the technical field of engineering machines. The technical problem that a structural member for the engineering machine in the prior art does not have the vibration attenuation function, and consequentially vibration energy dissipation is slow is solved. The structural member for the engineering machine comprises a shell and vibration attenuation matter arranged between the shell and an inner cavity in a filling manner, and the vibration attenuation matter occupies a part of space of the inner cavity, and can at least dissipate vibration energy on the structural member for the engineering machine through friction with the inner cavity or in an inelastic collision manner. The structural member is used for improving the vibration attenuation effect of the cantilever crane and improving the working stability and safety of the dynamic compaction machine.

Owner:XCMG CONSTR MACHINERY

Purification treatment device suitable for organic waste gas

PendingCN109966872AImprove purification effectSimple structureGas treatmentDispersed particle separationActivated carbonForming gas

The invention discloses a purification treatment device suitable for organic waste gas. Several electrode assemblies annularly fit the inner wall of a shell and are connected in series, the two ends of the device are provided with a waste gas inlet and a waste gas outlet respectively, and the waste gas outlet is provided with a honeycomb-shaped photocatalyst activated carbon postposition device; each electrode assembly comprises a positive electrode pole and a negative electrode pole, and the positive electrode poles and the negative electrode poles are externally connected with a power sourceseparately via the shell through fixing bolts; the positive electrode poles and the negative electrode poles in an ionization zone are sunken inwards towards the annular center, and form gas source cavities with the inner wall of the shell; a gas source inlet is formed in the waist of the corresponding positive electrode pole or the negative electrode pole at the gas inlet end, and a gas source outlet is formed in the junction of each positive electrode pole and the corresponding negative electrode pole. Inelastic collision between high-temperature plasma and organic waste gas occur, so thatmolecular chains and chemical bonds in organic molecules are broken and decomposed into micromolecule inorganic matter, and thus preliminary purification treatment of the organic waste gas is achieved; then the honeycomb-shaped modified activated carbon photocatalyst is adopted for adsorption, harmless treatment of the organic waste gas is achieved, and the capability of the purification device oftreating the organic waste gas is improved through the parallel parts.

Owner:南京艾尔克林工程技术有限公司

Action force and reaction force demonstration device

InactiveCN105528941AIncrease awarenessEasy to observeEducational modelsInelastic collisionEngineering

The invention relates to an action force and reaction force demonstration device. The demonstration device comprises a support arranged on the surface of a demonstration platform, wherein the support is fixedly connected with the demonstration platform. A rod guide component is fixedly arranged between the support and the surface of the demonstration platform and is vertical to the surface of the demonstration platform. The guide component is provided with at least two small balls capable of sliding up and down freely. When the demonstration device is used, a watcher or a learner, to begin with, enables the small balls to be moved to the upper end of the support along the limit direction of the guide component, and then, releases the small balls; when the balls fall onto the surface of the demonstration platform, the balls collide; since the small balls are made of different materials, the re-bounce height of the upper ball is equal to or lower than the height where the ball is released; and therefore, the physical phenomena of action force and reaction force as well as elastic collision and inelastic collision are demonstrated visually. The watcher or the learner can clearly observe the whole process of the collision phenomenon through the demonstration device, thereby greatly facilitating the watcher or the learner to perceive the mechanics principle.

Owner:HEFEI GENERAL MACHINERY RES INST

Device and method for generating nanosecond chirped pulse light source

The invention relates to the generation technology of nanosecond pulsed light, in particular to a device and method for generating a nanosecond chirped pulse light source. The invention solves the problem that the existing nanosecond pulsed light cannot block the inelastic collision of atoms and control the coherence of the atom pairs. A device for generating a nanosecond-level chirped pulse light source, including a master laser, a signal generator, a slave laser, a reference laser, and a TeO 2 Crystal, photodetector, oscilloscope, second polarizing beam splitting prism, fiber coupling head, optical fiber; wherein, between the output end of the master laser and the input end of the slave laser, a first mirror and a first polarizing beam splitting prism are arranged in sequence The optical path formed by connecting; the first polarization beam splitter is set at the output end of the slave laser and TeO 2 Between the input terminals of the crystal; TeO 2 An optical path composed of a second reflection mirror and a second half-wave plate sequentially connected in series is provided between the output end of the crystal and the input end of the second polarization beam splitter. The invention is applicable to the generation of nanosecond pulsed light.

Owner:SHANXI UNIV

Inelastic collision and rolling viscous resistance particle coupling energy dissipation toolholder

An inelastic collision and rolling viscous resistance particle coupling energy dissipation cutter rod relates to a cutting tool. The cutter rod comprises a cutter rod body, a cutter rod connection piece, a cutting head and coupling energy dissipation plates. A groove array is formed in each coupling energy dissipation plate. A surface low recovery coefficient particle and at least two high surface viscous resistance macromolecule particles are arranged in each groove, a high polymer film wraps the surface of each high surface viscous resistance macromolecule particle, and a fixed groove for installing the coupling energy dissipation plate is formed in each coupling energy dissipation plate. After multiple layers of coupling energy dissipation plates are installed in the cutter rod, vibration energy generated by cutting force can be dissipated quickly and gradually, energy dissipation factors are high, the vibration restraining effect is obvious, and boring stability and accuracy of parts with deep holes are effectively improved. The cutter rod is low in cost and easy to implement. The surface low recovery coefficient particles utilize a metal material as the base material, methyl phenyl polysiloxane and acrylate interpenetration polymer wraps the base material, and the surface low recovery coefficient particles are high in strength, not prone to corrosion, long in service life and capable of being used in a long term.

Owner:厦门粒资科技有限公司

Ionization device suitable for organic waste gas treatment

PendingCN109966873AImprove purification effectSimple structureGas treatmentDispersed particle separationForming gasSorbent

The invention discloses an ionization device suitable for organic waste gas treatment. Electrode assemblies fit the inner wall of a shell and are annularly arranged, and the two ends of a cavity are provided with a gas inlet and a gas outlet respectively; each electrode assembly comprises a positive electrode pole at one end and a negative electrode pole at the other end, and the positive electrode poles and the negative electrode poles are externally connected with a power source separately via the shell through fixing bolts respectively; the positive electrode poles and the negative electrode poles in the ionization area are sunken inwards towards an annular center to form gas source cavities with the inner wall of the shell; a gas source inlet is formed in the portion, in the waist of each positive electrode pole or each negative electrode pole, of one end of the gas inlet, and a gas source outlet is formed in the joint of each positive electrode pole and the corresponding negativeelectrode pole; a gas flow channel is a concave channel formed after inward sinking. According to the ionization device, inelastic collision occurs between generated high-temperature plasma and organic waste gas, so that molecular chains and chemical bonds in organic molecules are broken and decomposed into micromolecule inorganic matter (carbon dioxide, water, nitrogen and the like), and thus organic waste gas purification treatment is achieved; in the treatment process, adsorbents are not needed, secondary pollution problems do not occur either, and thus the device has very high practicability and wide applicability.

Owner:南京艾尔克林工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com