A centrifugal fan volute with particle damping and vibration reduction

A centrifugal fan and particle damping technology, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the large vibration of the volute, reduce the service life of the equipment, and affect the sound stealth of ships and other problems to achieve the effect of reducing radiation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

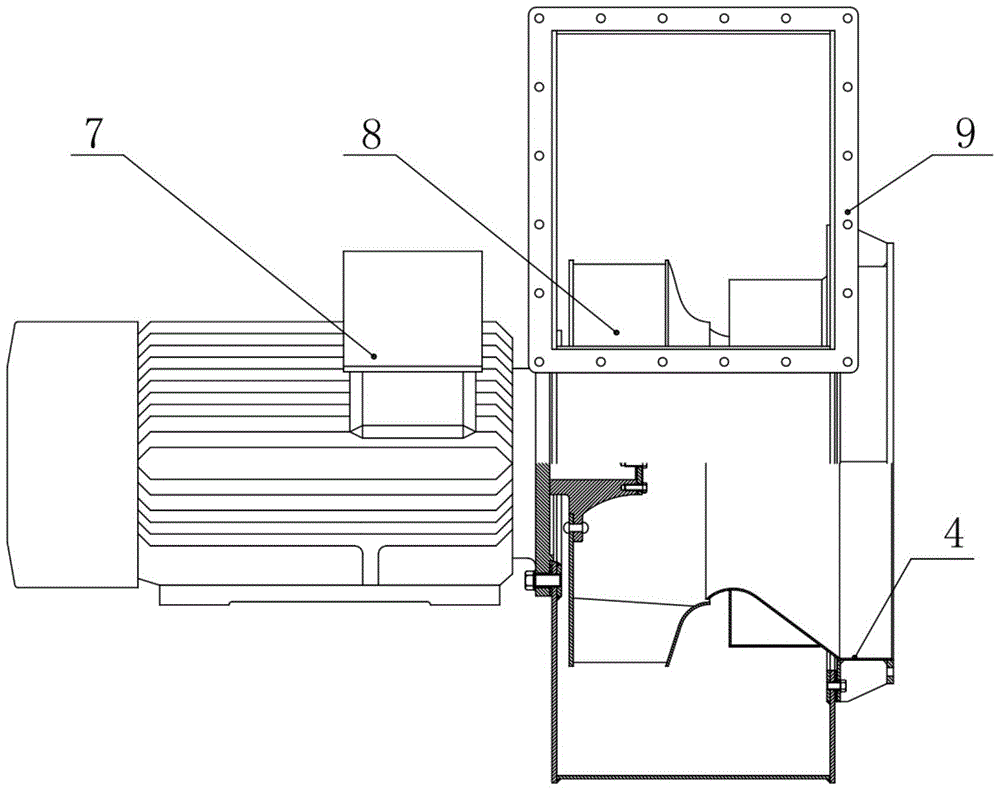

[0018] The typical centrifugal fan structure is shown in the appendix figure 1 , its main components are: motor 7, impeller 8, volute 9 and air inlet 4. The impeller 9 is directly installed on the shaft extension end of the motor 8, the volute 10 is connected and fixed with the flange at the end of the motor, the air inlet and outlet of the fan are connected to the air supply system pipe network, and the fan is connected to the installation base through the motor feet.

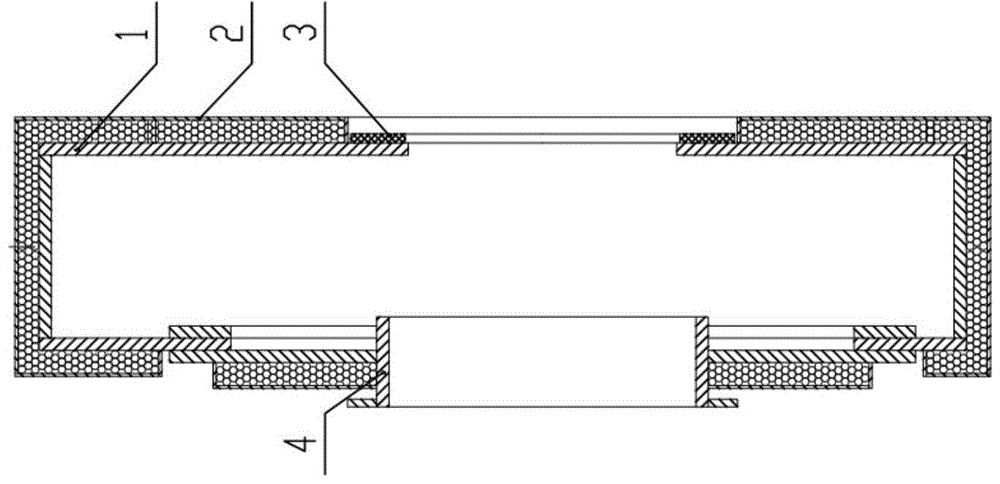

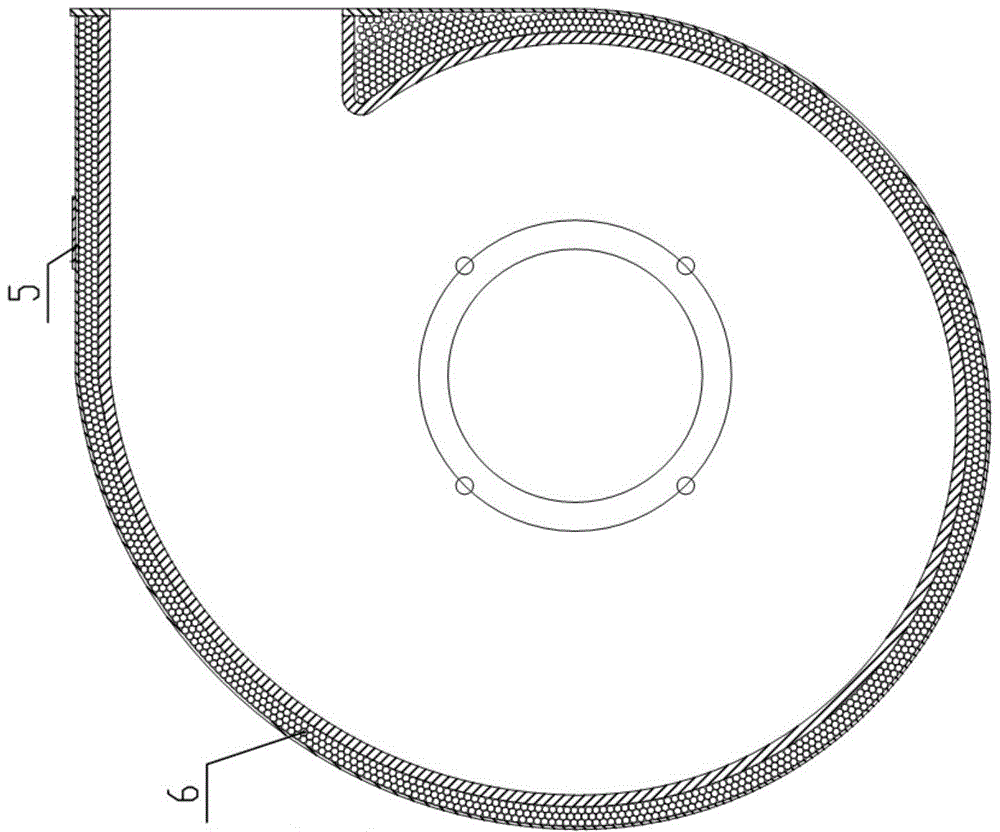

[0019] See attached Figure 2a , 2b , in this embodiment, the centrifugal fan volute includes a volute body, and the volute body is provided with an air inlet 4, and a centrifugal fan is conventionally arranged in the volute body, and the centrifugal fan is driven by a motor, wherein the volute body is composed of the inner volute 1 and The outer volute 2 is formed, and a vibration and noise reduction chamber with a thickness of 50-60 mm is formed between the inner volute 1 and the outer volute 2. The chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com