Ionization device suitable for organic waste gas treatment

A technology of organic waste gas and gas source, applied in the direction of gas treatment, separation method, dispersed particle separation, etc., can solve the problems of secondary pollution, difficult regeneration of adsorbent, etc., achieve low maintenance cost, strong practicability, and solve secondary pollution problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

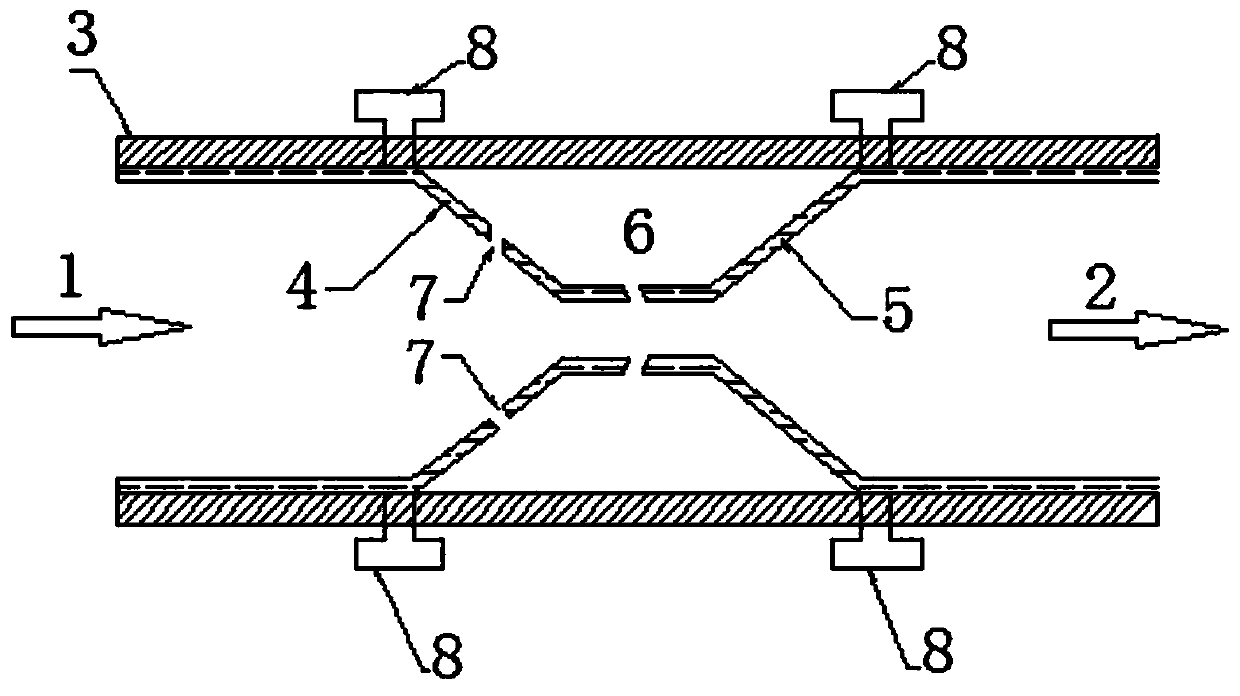

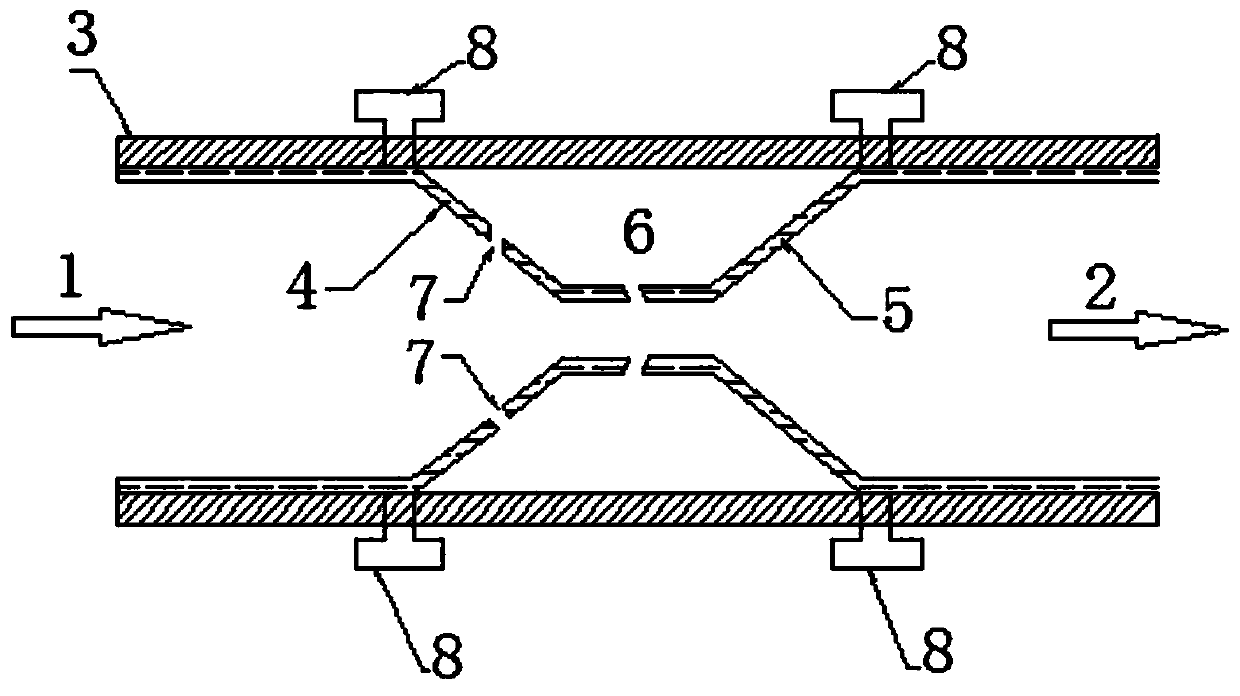

[0021] An ionization device suitable for treating organic waste gas is composed of a casing and an electrode assembly.

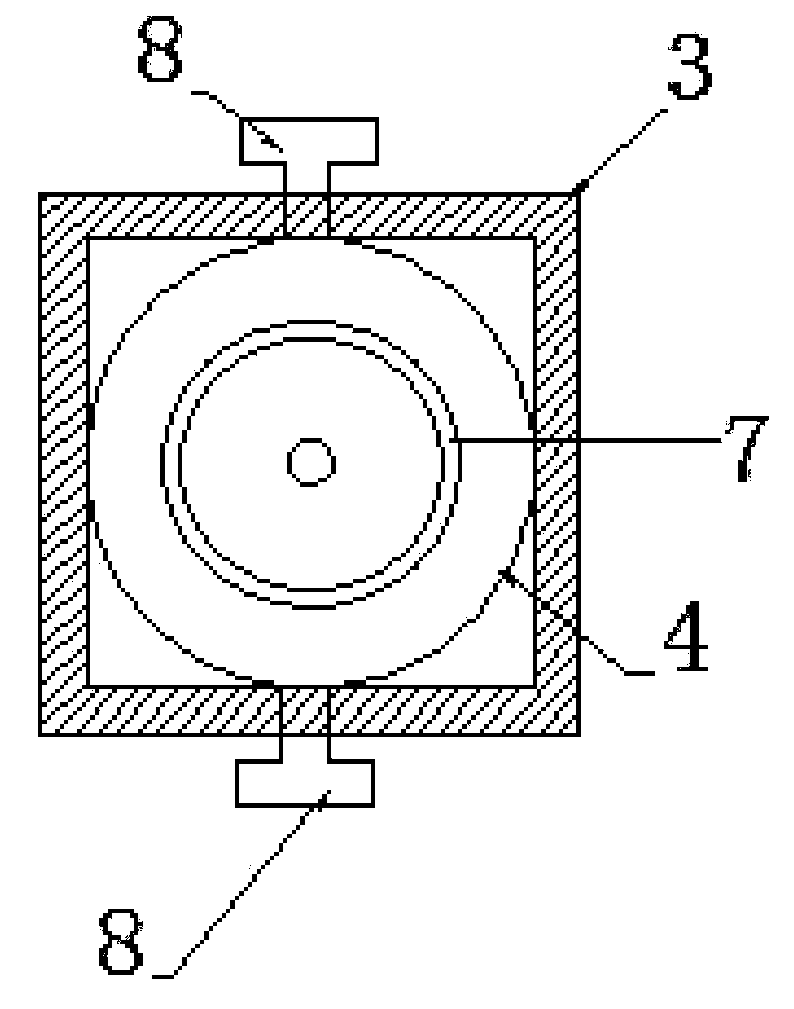

[0022] The casing is preferably rectangular, and the electrode assembly is preferably cylindrical.

[0023] The electrode assembly is attached to the inner wall of the housing, including the anode column at one end and the cathode column at the other end, which are respectively connected to the external power supply through the housing through fixing bolts; the two ends of the cavity are respectively the exhaust gas inlet and the exhaust gas outlet; along the exhaust gas flow direction , preferably the anode column is arranged at the front end, and the cathode column is arranged at the rear end.

[0024] The anode column and cathode column in the ionization area are respectively concave toward the center of the circle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com