Inelastic collision and rolling viscous resistance particle coupling energy consumption low-noise gear

A technology of inelastic collision and viscous resistance, used in belts/chains/gears, components with teeth, portable lifting devices, etc., it can solve the problems of high temperature and corrosion of gear transmission, and achieve high energy consumption factor and long life. , The effect of not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

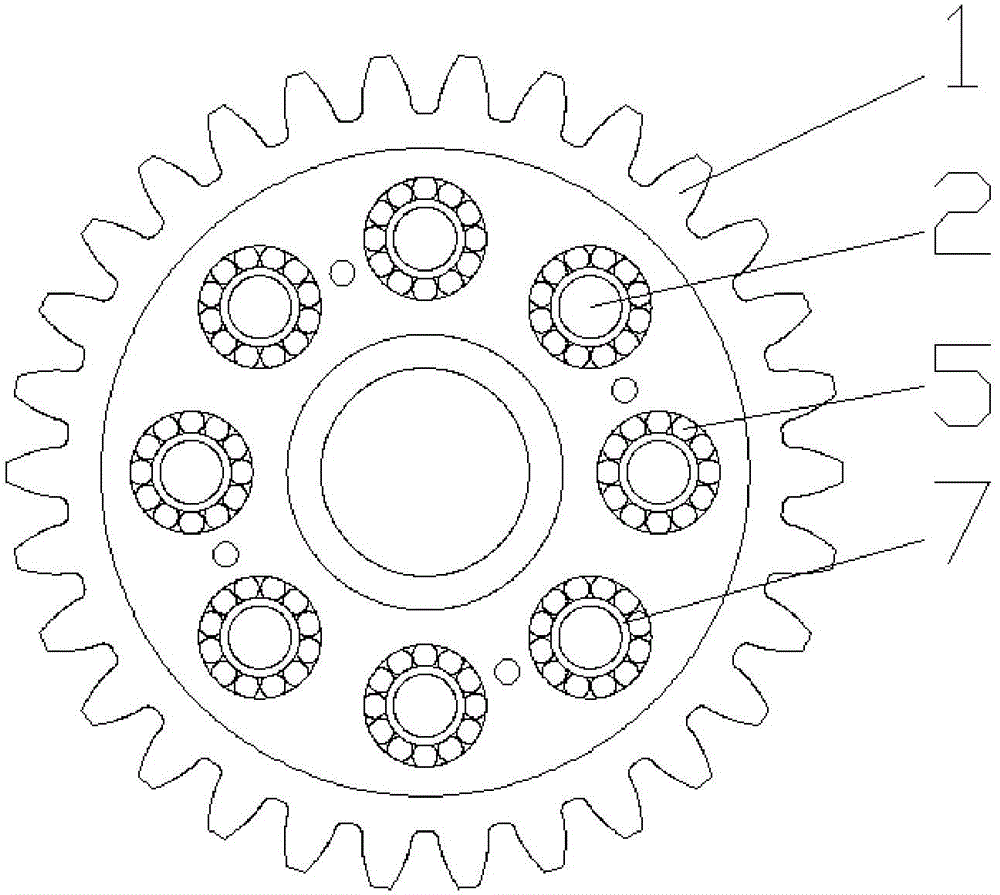

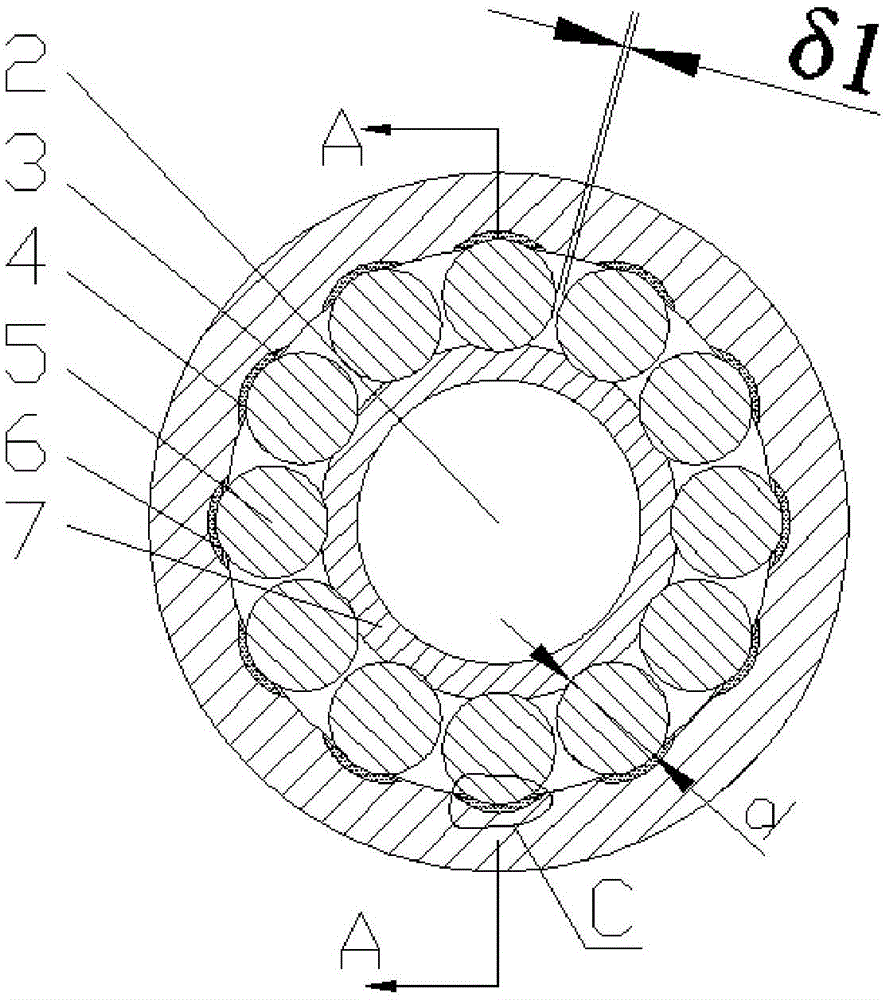

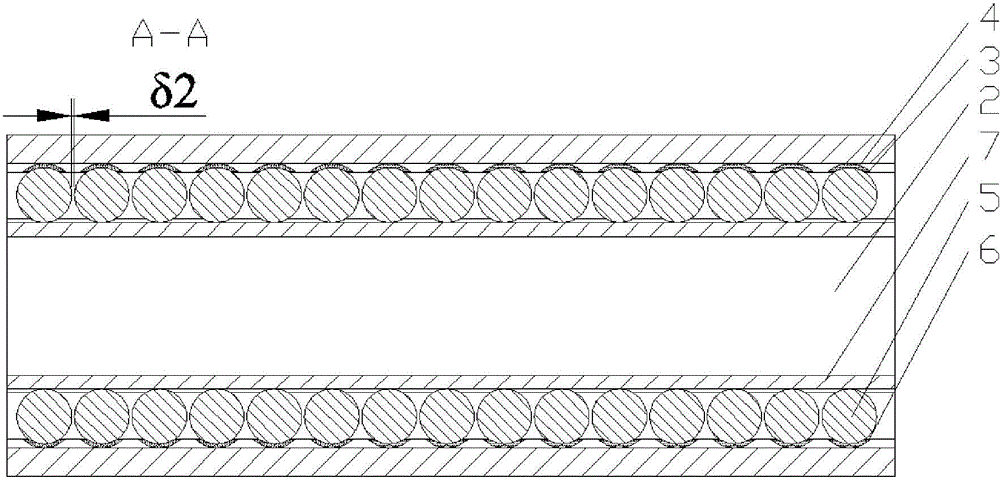

[0029] see Figure 1-7 , the embodiment of the present invention is provided with gear body 1, gear weight reduction hole 2, weight reduction hole groove 3, high surface viscous resistance polymer particles 4, low surface recovery coefficient particles 5, high polymer film 6, low surface recovery Coefficient particle fixer 7, weight loss hole sealing plate 8.

[0030] The weight-reduction hole groove 3 is set in the gear weight-reduction hole 2, and one particle 5 with a low surface restitution coefficient and at least two high-surface viscous resistance polymer particles 4 are placed in the groove 3 of the weight-reduction hole. A low surface restitution particle fixer 7 is provided on each gear weight reduction hole 2, the gear weight reduction hole 2 is sealed by a weight reduction hole sealing plate 8, and the high surface viscous resistance polymer particles 4 are coated with high polymer Thin film 6; there is a gap δ between circumferentially adjacent low surface restit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com