A vibration damping device for an expansion joint of an exhaust pipe

A technology of expansion connection and vibration damping device, which is applied to exhaust devices, electrical components, mufflers, etc., can solve the problems of unsatisfactory fixing effect, axial and radial shaking of expansion connectors, etc., to avoid deformation, reduce Friction, reducing the effect of instantaneous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is a specific embodiment of the present invention and a further description of the technical solutions of the present invention, but the present invention is not limited to these embodiments.

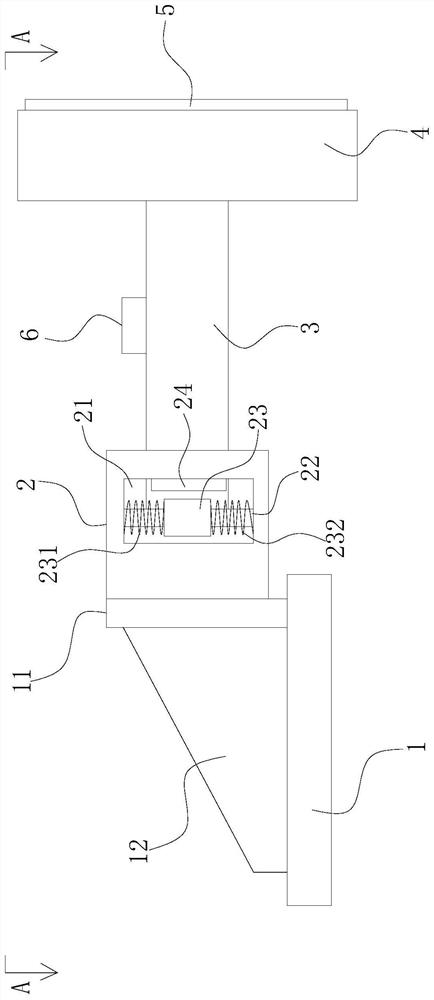

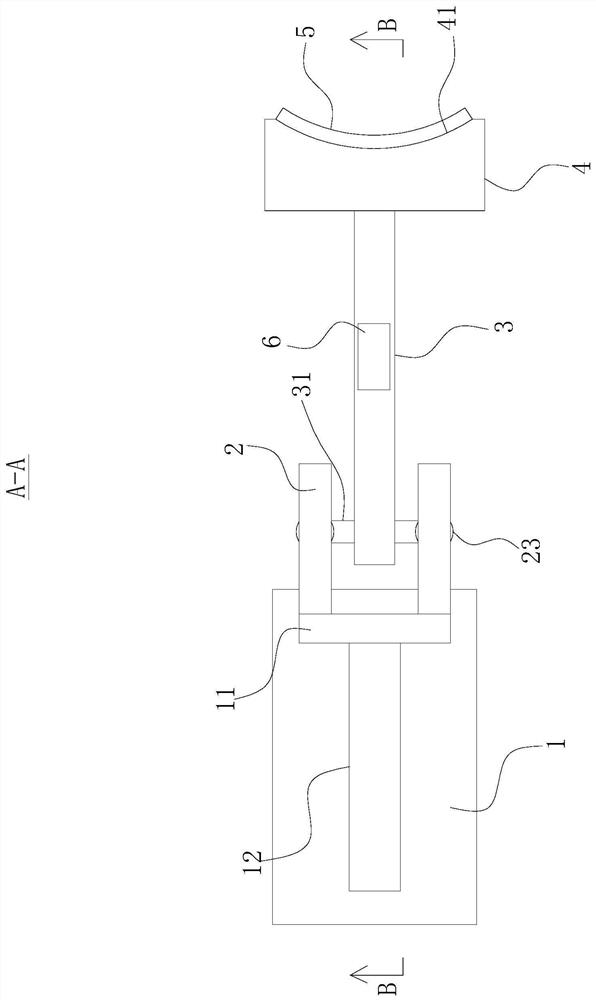

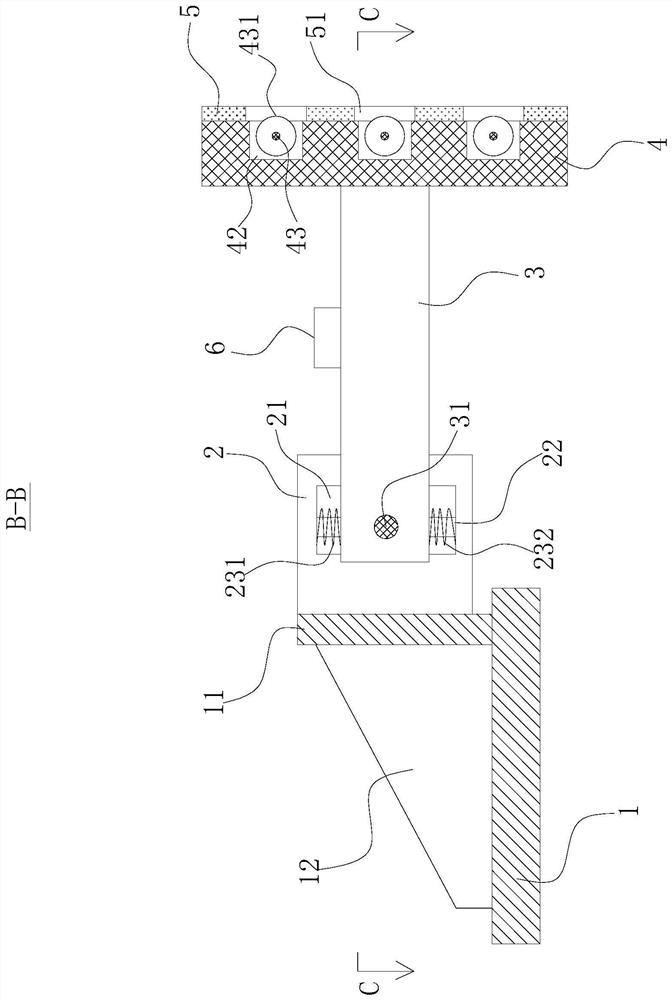

[0041] like Figure 1 to 5 As shown, a vibration damping device for exhaust pipe expansion connecting connectors comprises a bottom plate 1, two support plates 2, a connecting post 3, a fixing block 4, and a rolling mechanism.

[0042] The bottom plate 1 is rectangular, and the upper side surface of the bottom plate 1 is fixed with a fixing plate 11, the fixing plate 11 and the width direction of the bottom plate 1 are parallel, and the bottom plate 1 and the fixed plate 11 are connected to the elbow 12. Preferably, the elbow 12 is a right angle triangle, and the two right edges respectively and the bottom plate 1 and the fixed plate 11 are solid.

[0043] Two of the support plates 2 are fixed to one side of the fixing plate 11 away from the elbolane 12, and the two supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com