Axial damping device and system for shaftless rim propeller

A vibration damping device and thruster technology, which is applied in transportation and packaging, special-purpose ships, non-rotational vibration suppression, etc., can solve the problems of inability to adapt to pulse thrust excitation frequency changes, poor vibration damping effect, etc., and achieve high reliability, Effect of reducing pulsating thrust and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are specifically described below with reference to the accompanying drawings, wherein the accompanying drawings constitute a part of the present application, and together with the embodiments of the present invention, are used to explain the principles of the present invention, but are not used to limit the scope of the present invention.

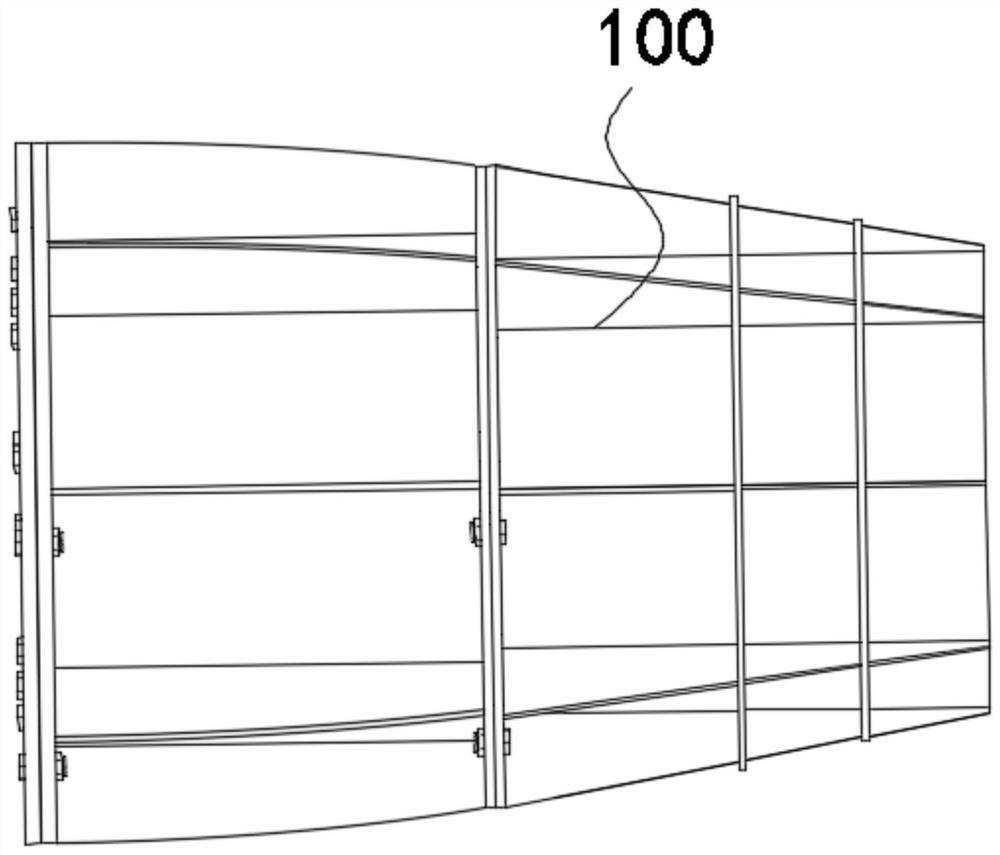

[0028] For ease of understanding, the application scenarios of the axial damping device and the damping system will be described first. The damping device and the damping system in the embodiment of the present invention are both installed in the propeller body 100, such as figure 1 As shown, the thruster body 100 includes a housing and a shaftless rim thruster 140 built into the housing.

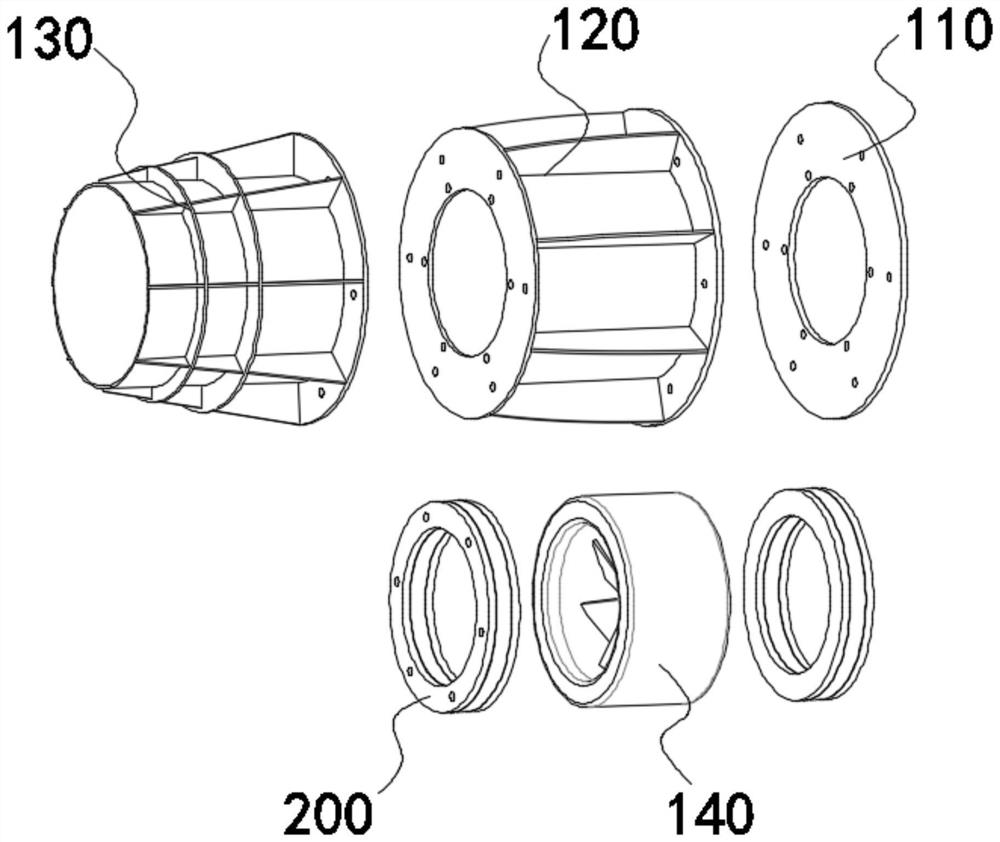

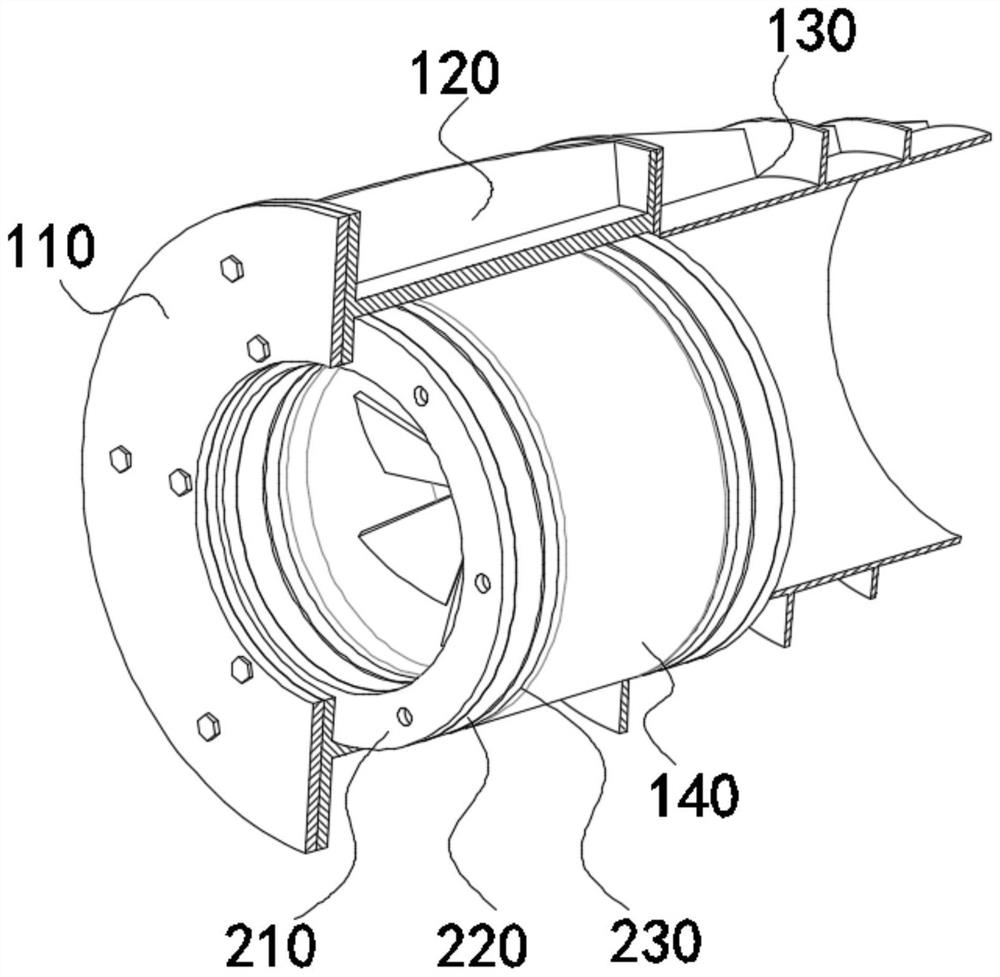

[0029] Specifically, as Figure 2-3 As shown, the housing includes a flange 110, a rim base 120 and a shaft end sleeve 130 that are connected end to end along an axis direction, wherein the shaftl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com