An Active-Passive Integrated Vibration Controller Based on Piezoelectric Actuation

A piezoelectric actuator and piezoelectric actuation technology, applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problem of real-time response to changes that cannot be externally stimulated, without vibration isolation, Problems such as narrow frequency band of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

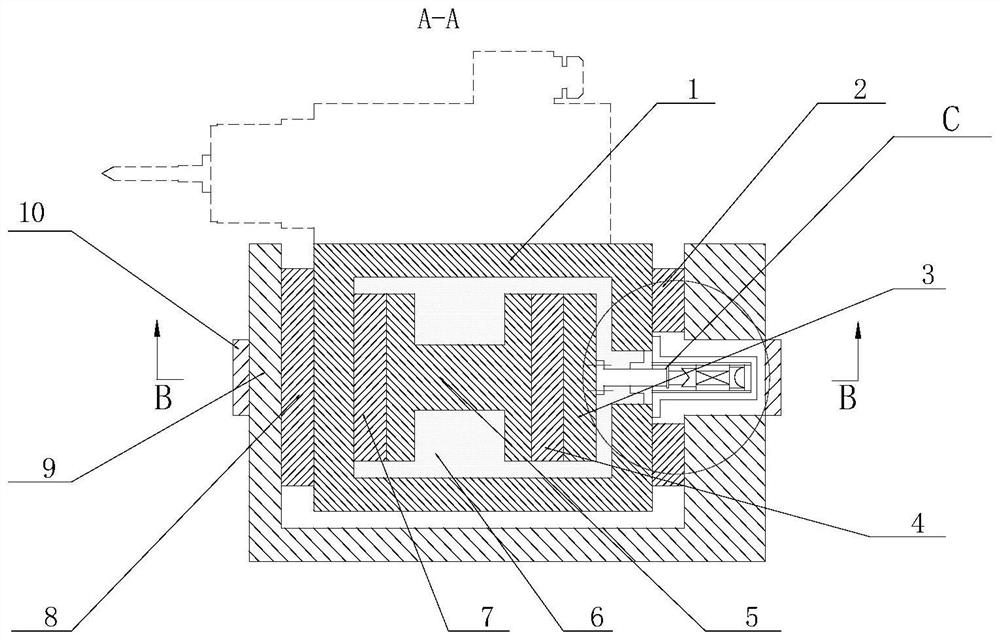

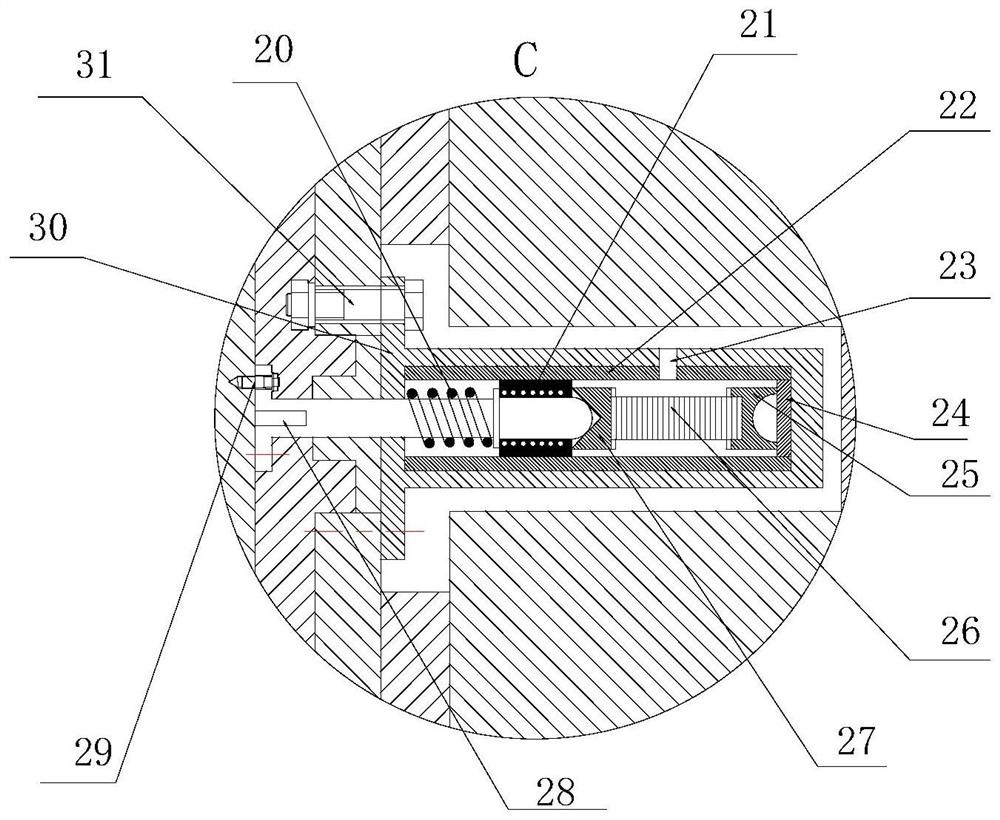

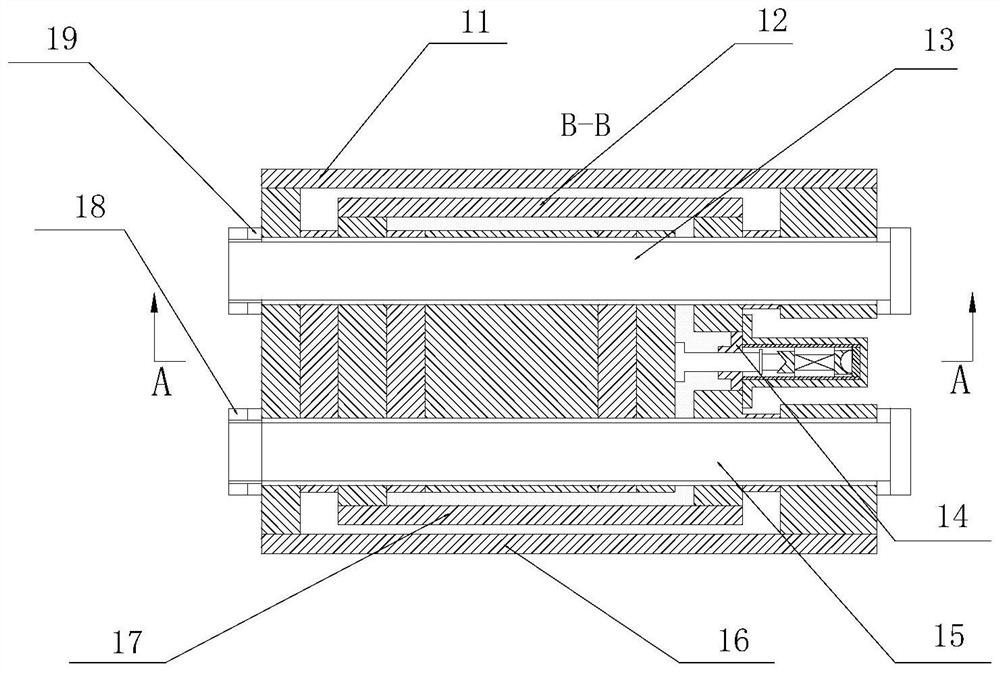

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] Since the robotic hole-making system is stimulated by three types of excitations: workpiece thin-wall vibration, vibration drilling additional vibration, and drilling vibration during the hole-making process, the frequency of external excitation is changing in real time. If there is only passive vibration control with vibration isolation and vibration absorption , The vibration controller can only work within a certain frequency range, beyond this frequency range, the vibration isolation effect of the vibration controller is not good or even loses the vibration isolation ability. Therefore, it is very important to determine the optimal stiffness of the vibration absorber corresponding to the external frequency for the vibration isolation effect of the vibration controller.

[0032] This embodiment provides an active-passive integrated vibration cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com