Brushless dc electric machine and special stater iron core thereof

A brushed DC motor and stator iron core technology is applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., which can solve the problem of prolonged starting time, increased motor torque, and starting torque. Large and other problems, to achieve the effect of large starting torque, suppression of axial vibration, and short starting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

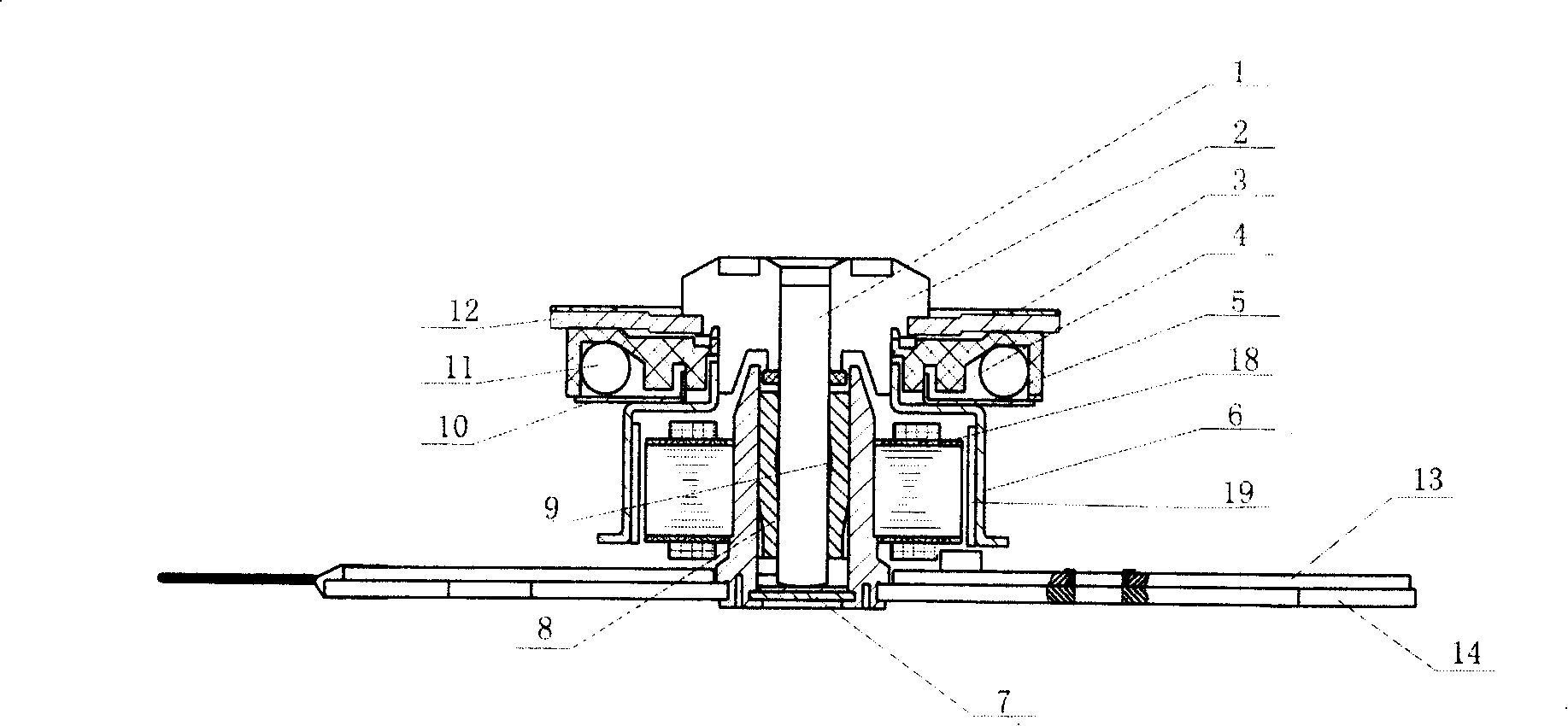

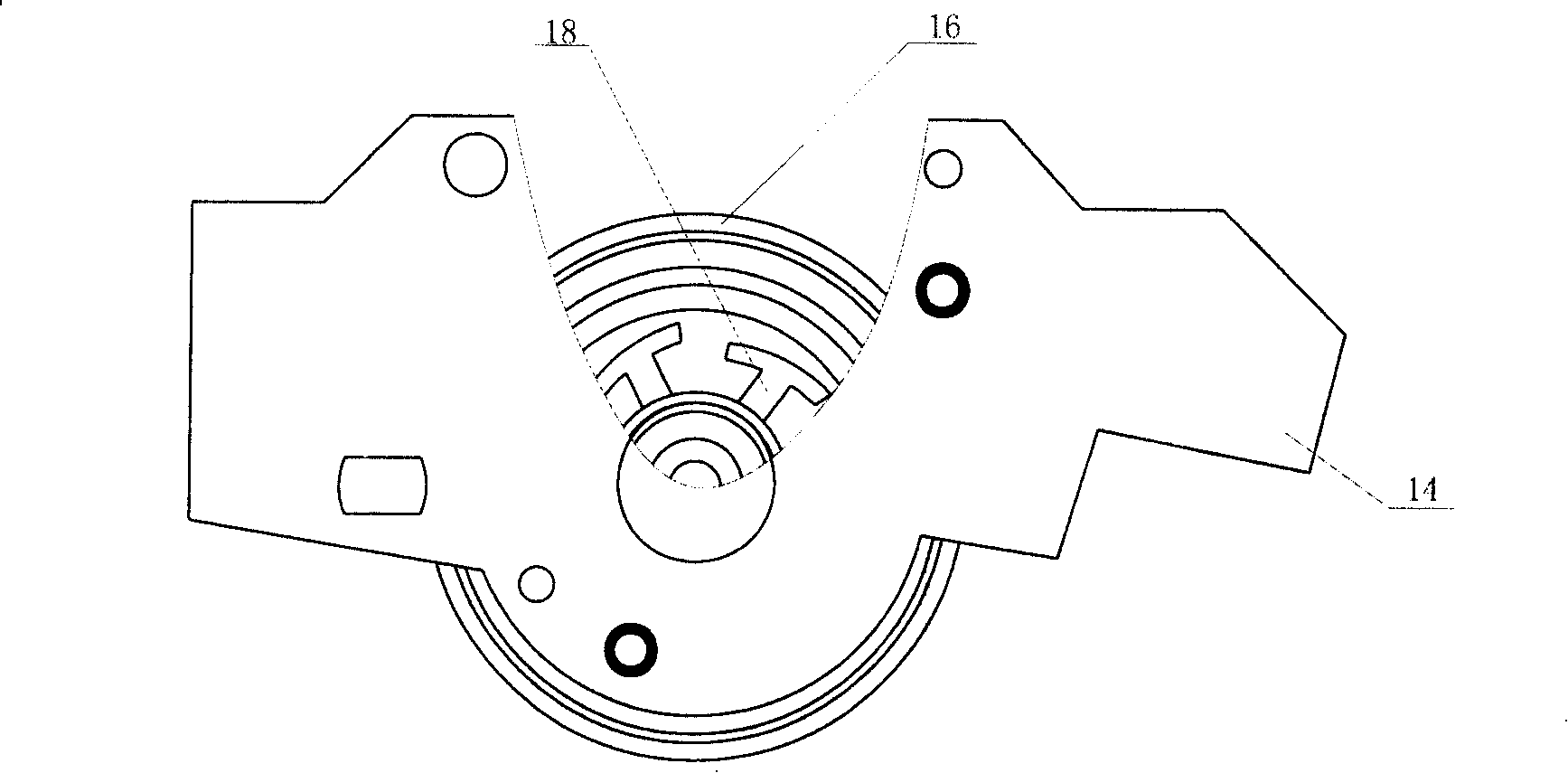

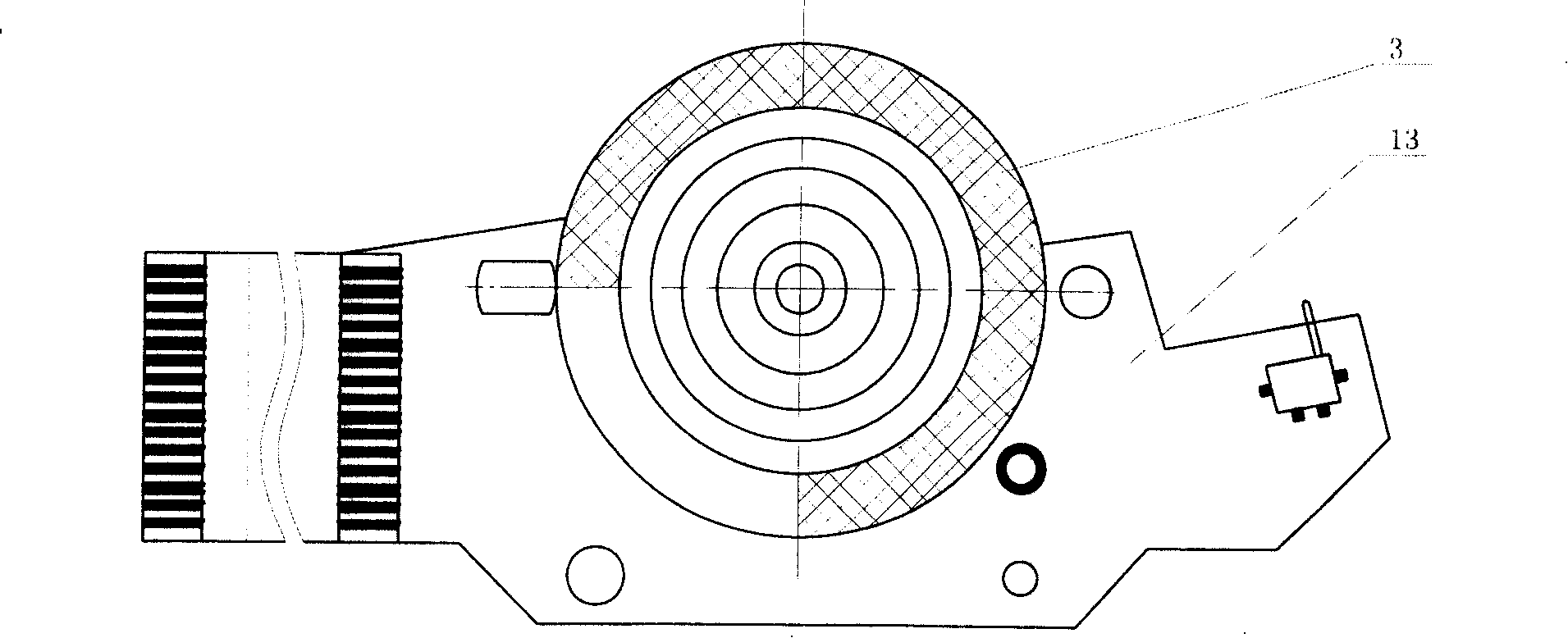

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the motor includes a stator core 18, a rotating shaft 1, a rotor cover 6 and a rotor 19 arranged on the inner wall of the rotor cover. The rotating shaft 1 passes through a through hole 182 in the center of the stator core and is rotatably supported in the stator core. The rotor The cover 6 rotates together with the rotating shaft, and the upper end of the rotating shaft is provided with a disc core 2 and a tray 5 which rotate synchronously with it. A spring is arranged between the pressure plates. The bottom of the rotor cover 6 is provided with a PCB board 13 and a PCB bottom plate 14, such as Figure 4 As shown, the PCB bottom plate is provided with an upwardly convex hollow convex body 16, the PCB board is provided with a through hole 15 for the hollow convex body 16 to pass through, and the end of the hollow convex body passing through the through hole 15 of the PCB board is p...

Embodiment 2

[0024] Embodiment 2: There are 4 poles evenly distributed on the circumference of the stator core, the distance R from the point on the outer contour of each pole to the center of the iron core gradually decreases in the same direction, and the points on the outer contour of the pole 181 of the stator core 18 The maximum and minimum distances R0:R1 to the core center are 1.01. Others are with embodiment 1.

Embodiment 3

[0025]Embodiment 3: There are 10 poles 181 evenly distributed on the circumference of the stator core, the distance R from a point on the outer contour of each pole to the center of the iron core gradually decreases in the same direction, and the distance R on the outer contour of the pole 181 of the stator core 18 The maximum distance and the minimum distance R0:R1 from the point to the core center are 1.05. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com