Patents

Literature

56 results about "Piezoelectric resonance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

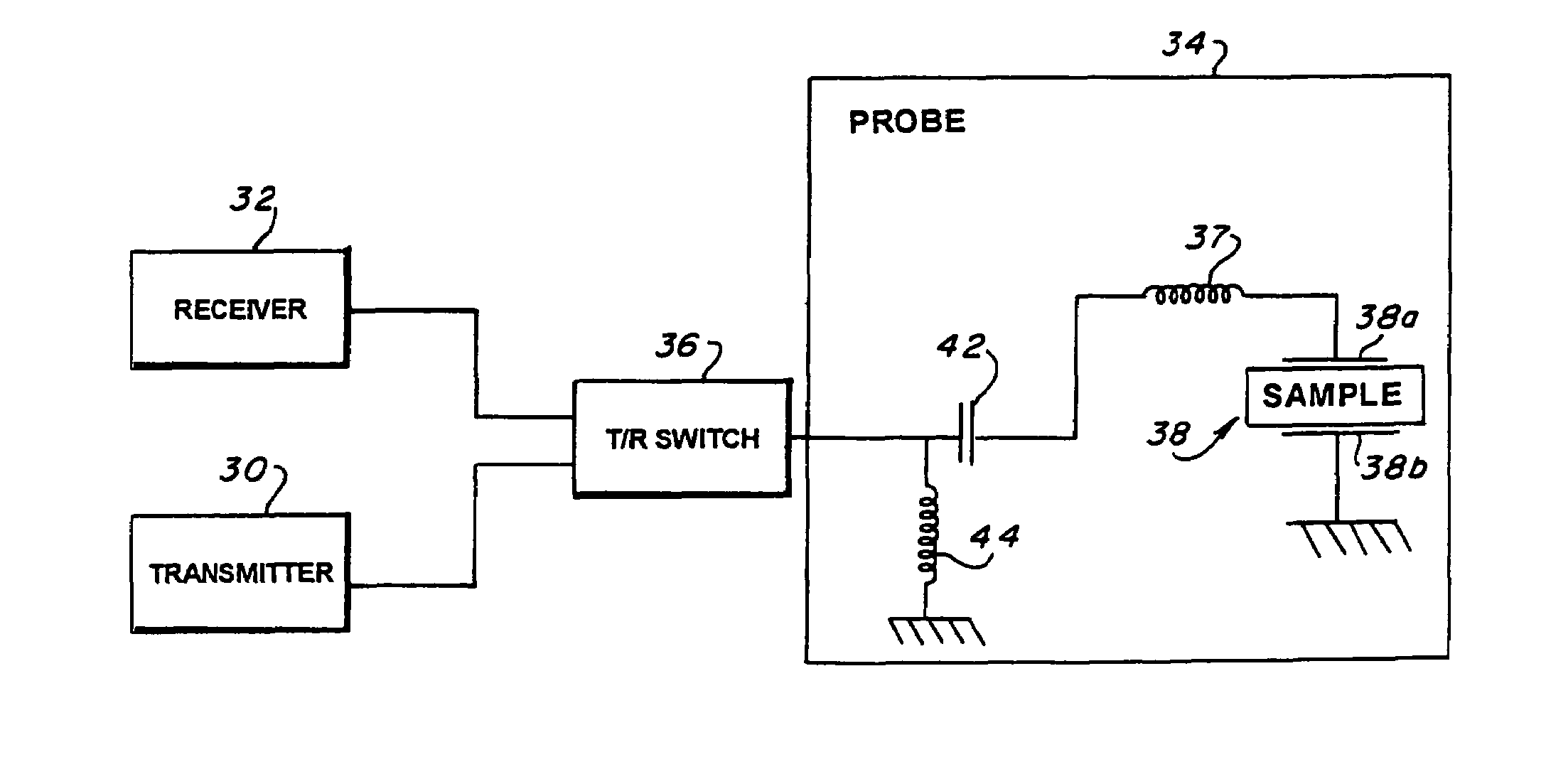

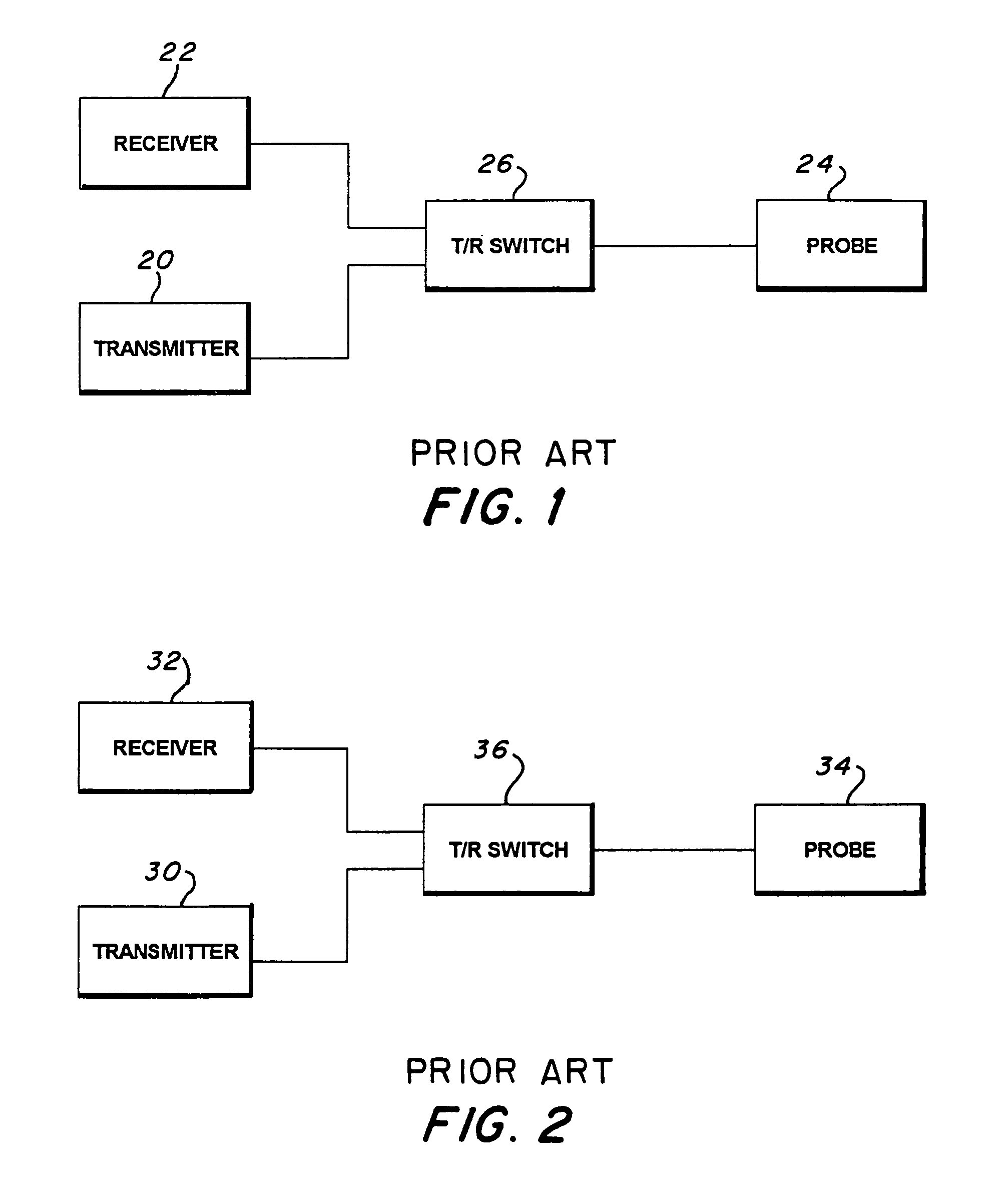

Method and apparatus for detecting a target material in a sample by pre-screening the sample for piezoelectric resonance

InactiveUS6956476B2Quick checkMaterial analysis using sonic/ultrasonic/infrasonic wavesResonant frequencyElectricityNMR - Nuclear magnetic resonance

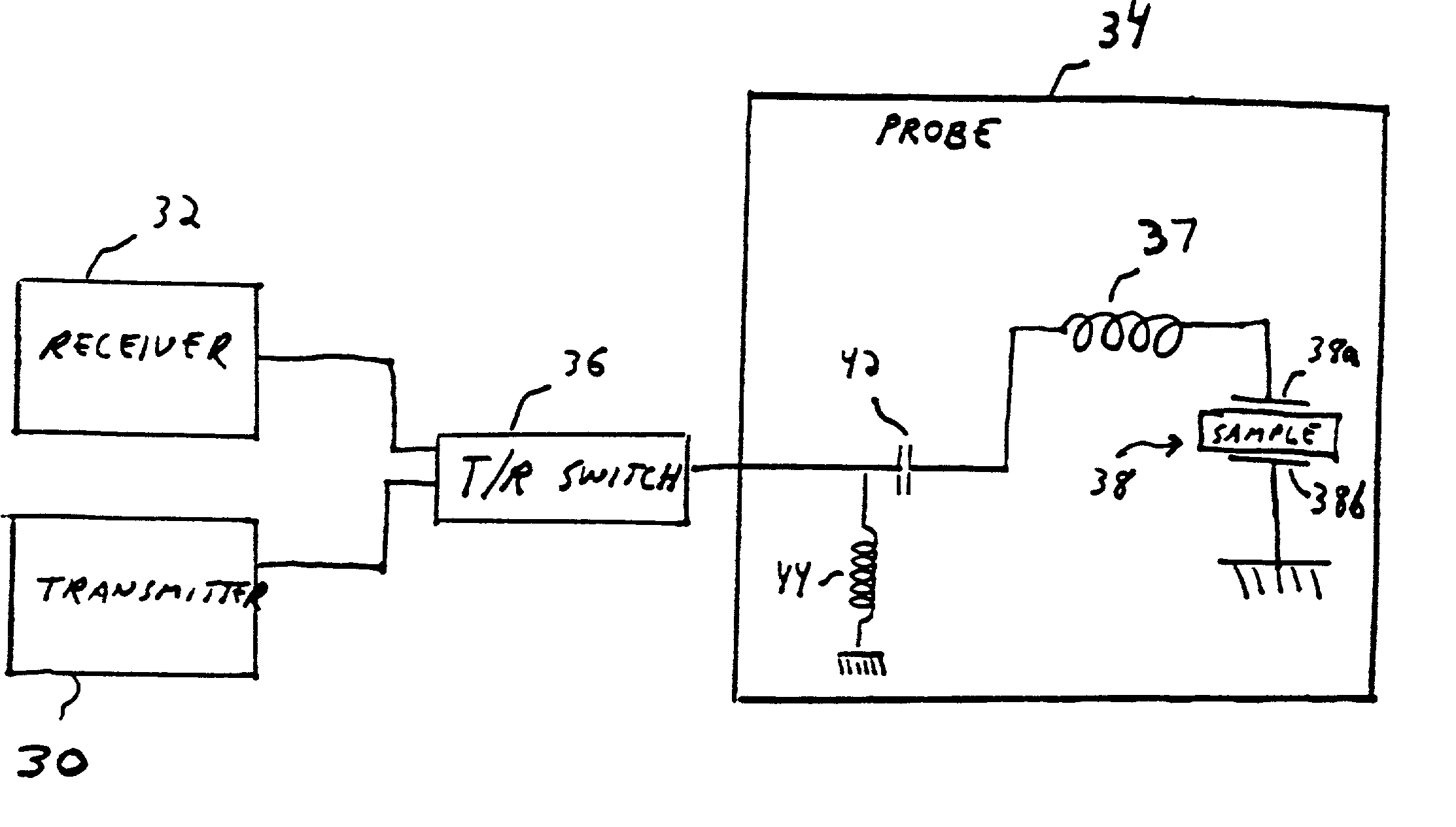

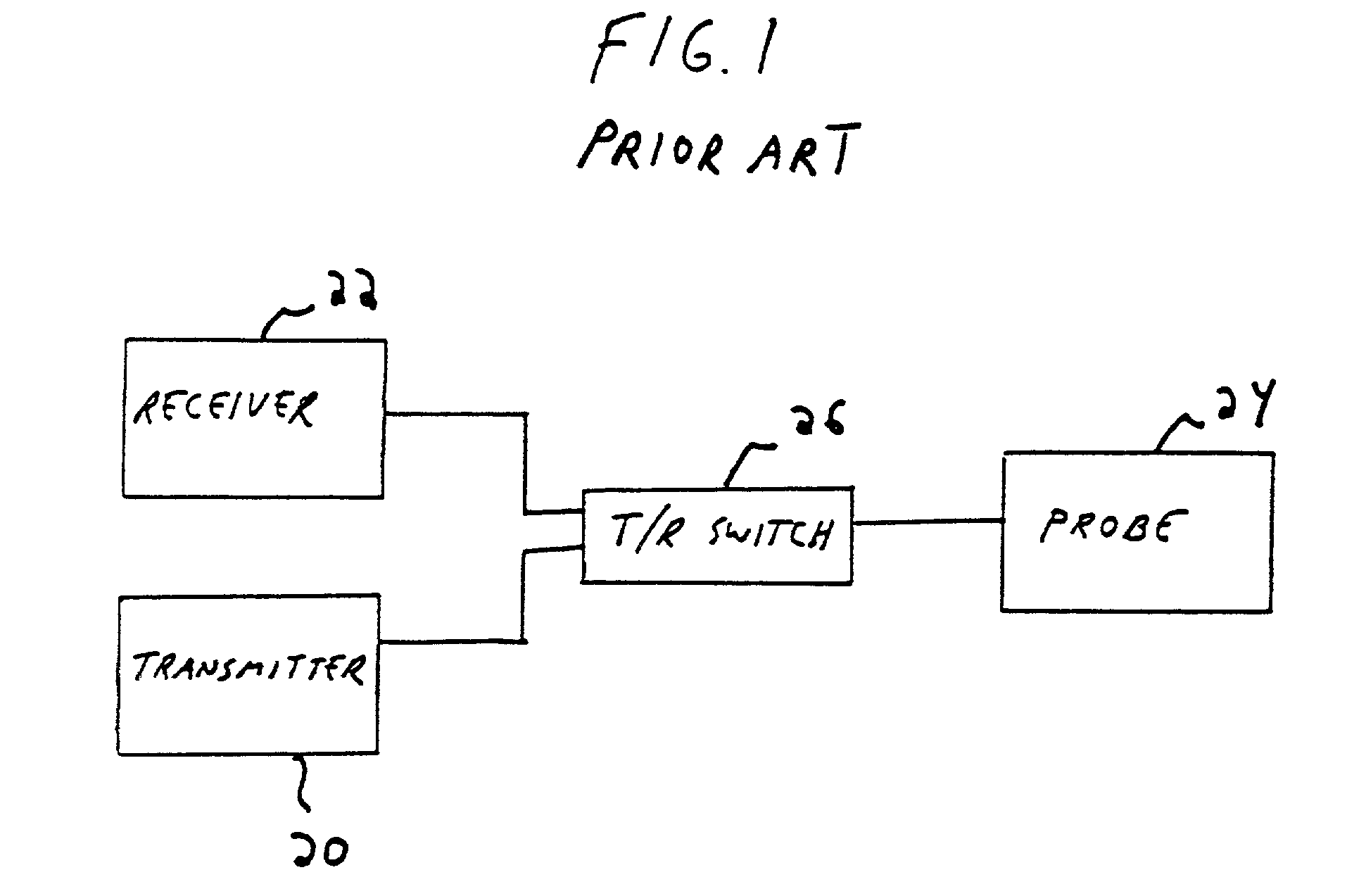

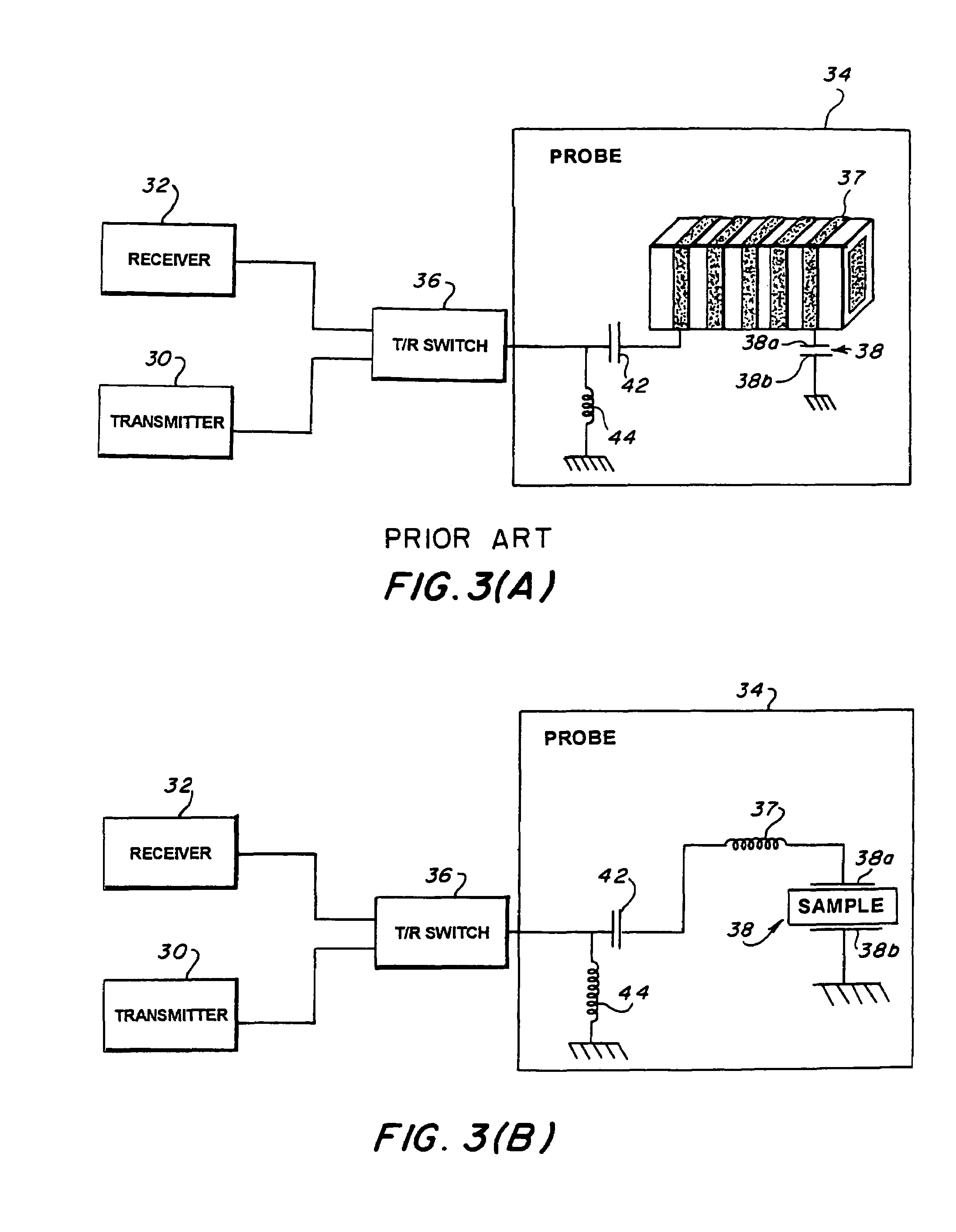

A method and apparatus for screening samples to determine which samples include a target material. Generally, the samples are pre-screened to determine which of the samples have a piezoelectric resonance when irradiated with an electric field, to thereby indicate the presence of the target material. The samples that have the piezoelectric resonance are then further screened by a different process to confirm the presence of the target material. For example, samples that have the piezoelectric resonance are further screened for a specific nuclear quadrupole resonance (NQR), a specific nuclear magnetic resonance (NMR) or a specific visual characteristic, to confirm the presence of the target material in the sample. The apparatus and method can be used, for example, to search luggage at ports of entry for the presence of cocaine hydrochloride or heroin hydrochloride.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

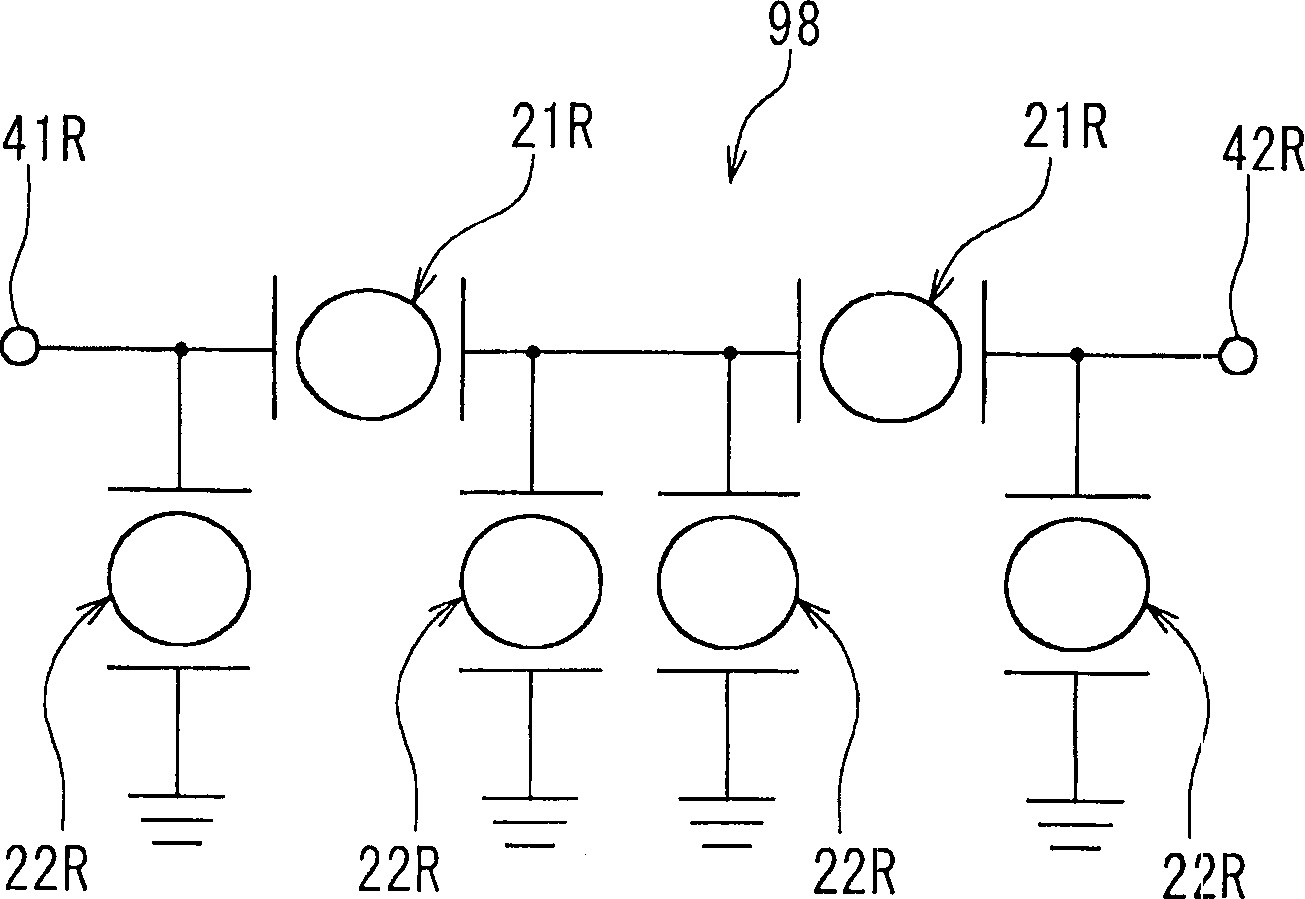

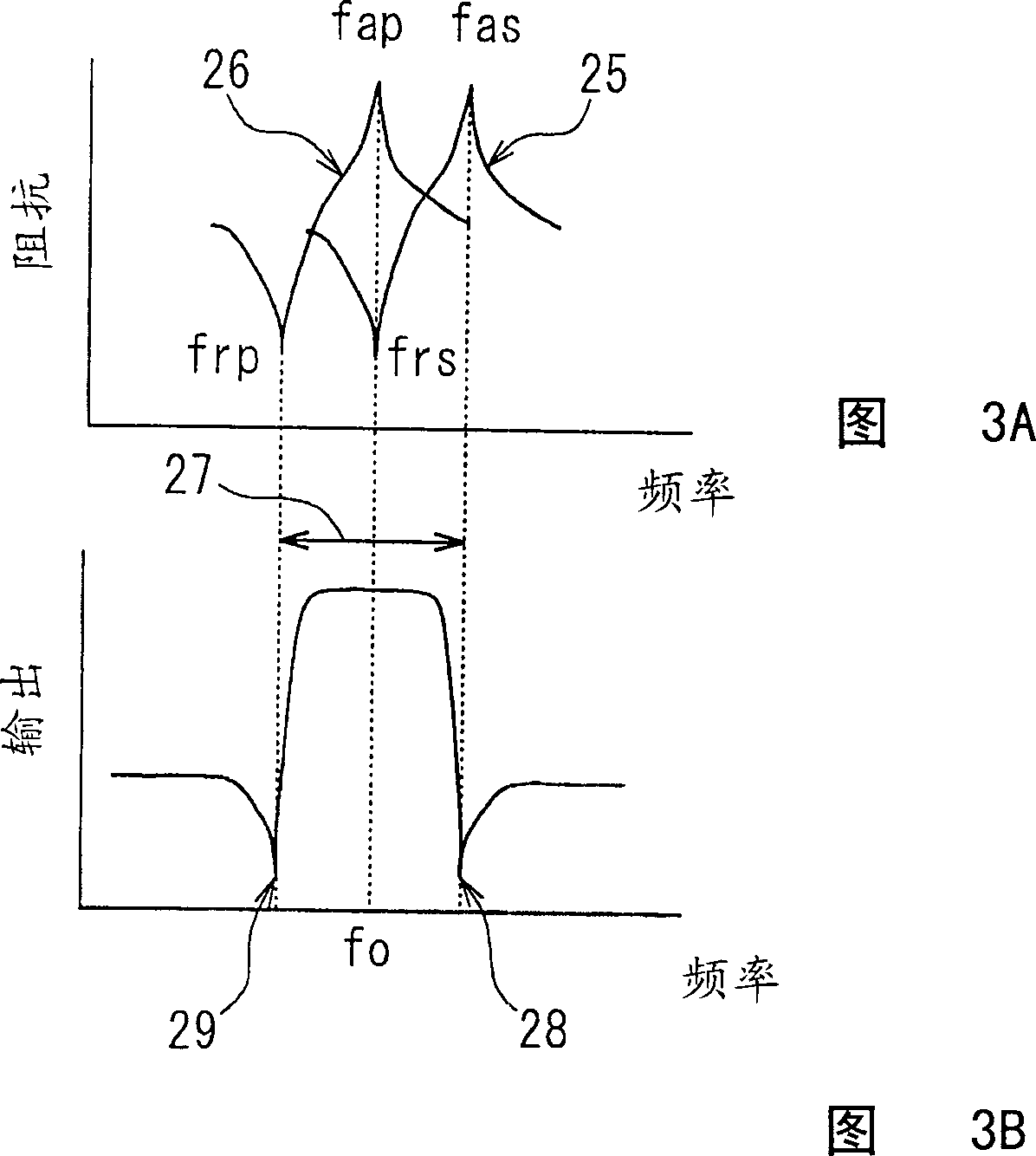

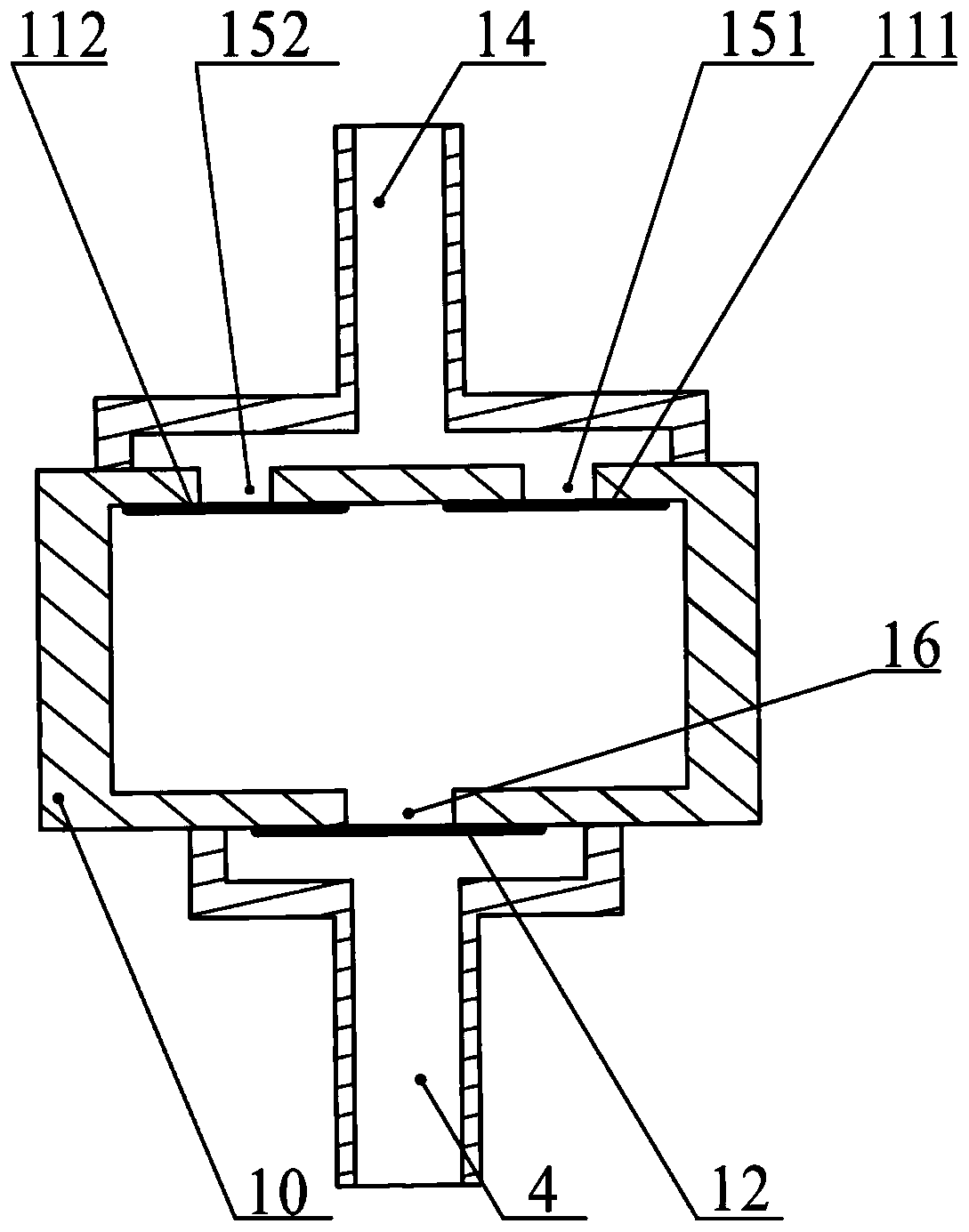

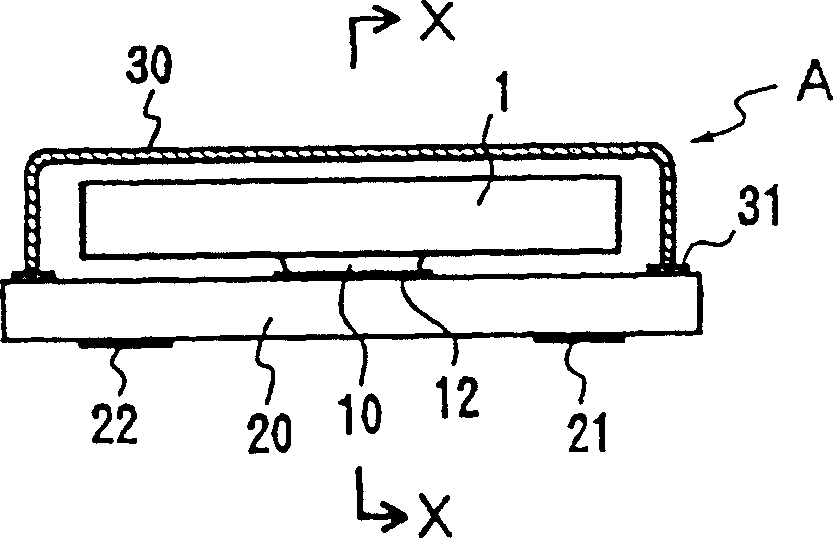

Piezoelectric resonance wave filter and duplexer

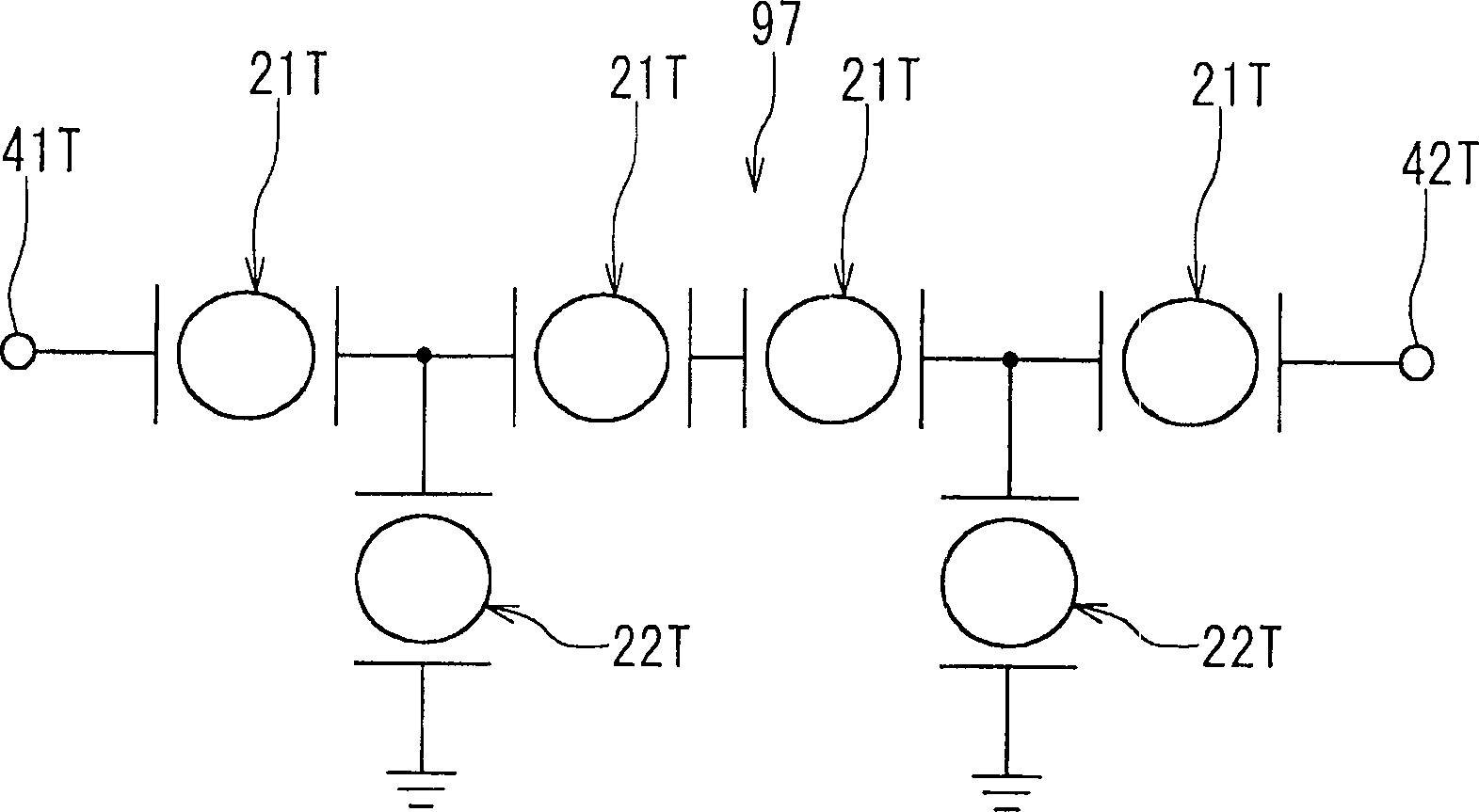

A piezoelectric resonant filter includes a group of series resonators and a group of parallel resonators for forming a ladder-type filter circuit. Each of the resonators has a piezoelectric thin film 15 having piezoelectric characteristic, and lower and upper electrodes 14 and 16 disposed on opposite surfaces of the piezoelectric thin film 15 for applying an excitation voltage to the piezoelectric thin film 15. The group of the parallel resonators exhibits a low frequency side attenuation extremum in the filter whereas the group of the series resonators exhibits a high frequency side attenuation extremum in the filter. At least one of the group of the series resonators and the group of the parallel resonators has a temperature compensating layer 20 for bringing the temperature coefficient of the resonant frequency close to zero. The thickness of the temperature compensating layer 20 in the group of the series resonators is different from the thickness of the temperature compensating layer 20 in the group of the parallel resonators.

Owner:快速追踪有限公司

Method and apparatus for detecting a target material in a sample by pre-screening the sample for piezoelectric resonance

InactiveUS7132942B1Quick checkAnalysing solids using sonic/ultrasonic/infrasonic wavesAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonancePiezoelectric resonance

A method and apparatus for screening samples to determine which samples include a target material. Generally, the samples are pre-screened to determine which of the samples have a piezoelectric resonance when irradiated with an electric field, to thereby indicate the presence of the target material. The samples that have the piezoelectric resonance are then further screened by a different process to confirm the presence of the target material. For example, samples that have the piezoelectric resonance are further screened for a specific nuclear quadrupole resonance (NQR), a specific nuclear magnetic resonance (NMR) or a specific visual characteristic, to confirm the presence of the target material in the sample. The apparatus and method can be used, for example, to search luggage at ports of entry for the presence of cocaine hydrochloride or heroin hydrochloride.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

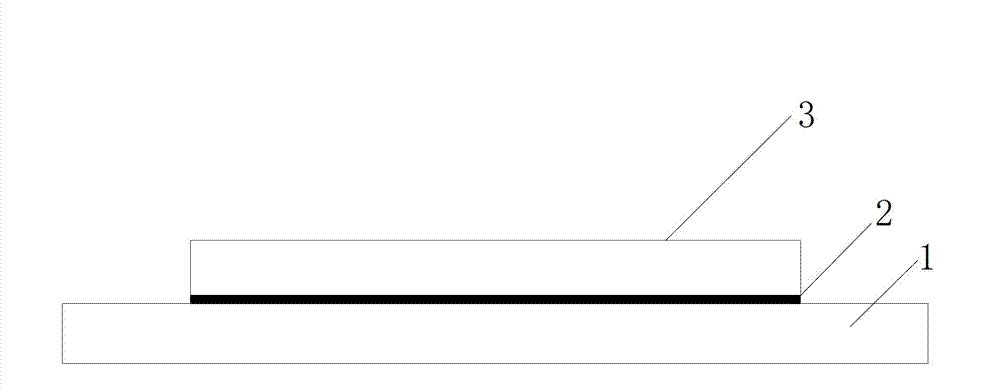

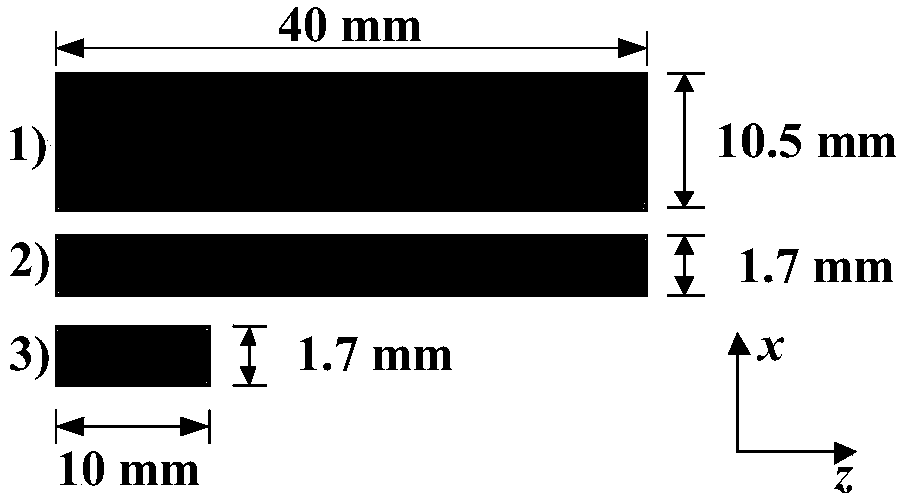

Preparation method of c-axis inclined AlN thin film with homogeneous buffer layer

InactiveCN101775584AFlat surfaceCompact structureVacuum evaporation coatingSputtering coatingSputteringLattice mismatch

The invention provides a preparation method of a c-axis inclined AlN thin film with homogeneous buffer layer, which comprises the steps that: generating an uncrystallized AlN thin film buffer layer on a substrate which is made from Si, Mo, Pt and Au or combination thereof by means of magnetron sputtering; and generating a c-axis oriented AlN thin film with different inclination degrees by adjusting the deviation angle between the substrate and the center of a target material. The preparation method can overcome the problems that the lattice mismatch between the AlN thin film and the substrate such as Si and GaAs, and the like, is larger, and the control performance of the c-axis inclination degree is worse. When being taken as a piezoelectric layer of a piezoelectric resonance sensor, the AlN thin film generated by the method can reduce the energy consumption of sound wave in liquid and is good for improving the quality factor and the sensitivity of the sensor.

Owner:HUBEI UNIV

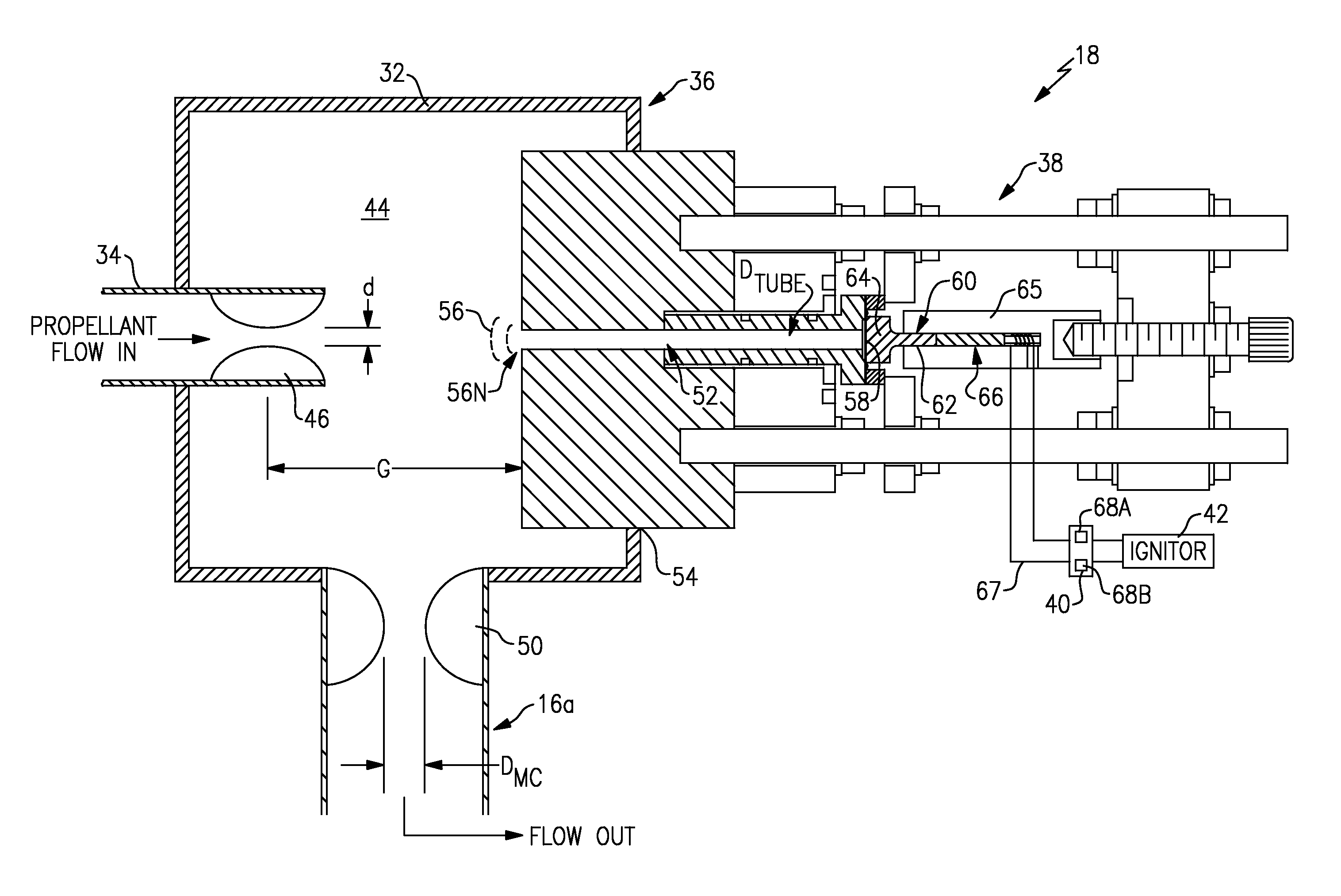

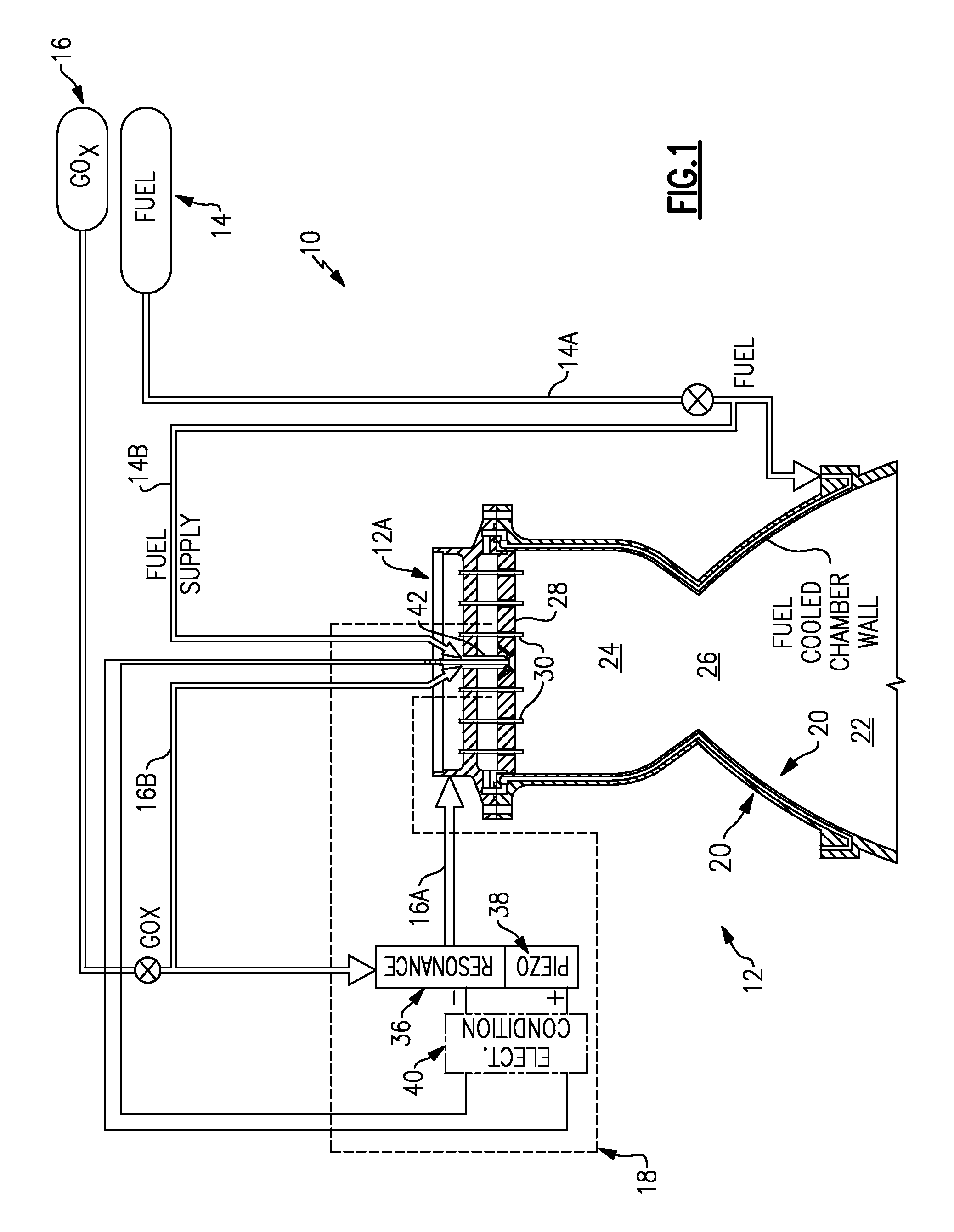

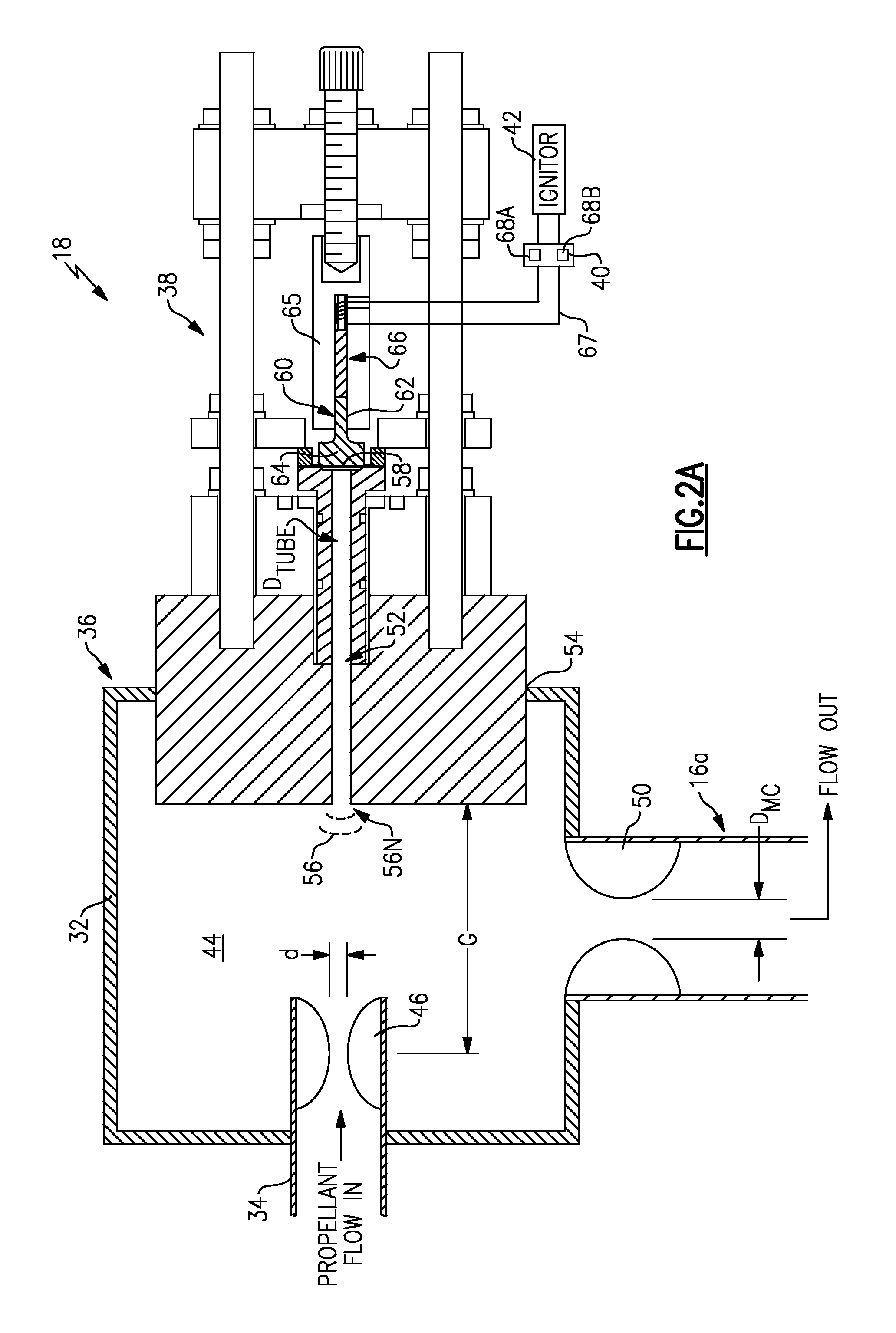

Piezo-resonance igniter and ignition method for propellant liquid rocket engine

ActiveUS7565795B1Increase net force outputAvoid smallCosmonautic vehiclesCosmonautic propulsion system apparatusCombustion chamberEngineering

Owner:AEROJET ROCKETDYNE OF DE

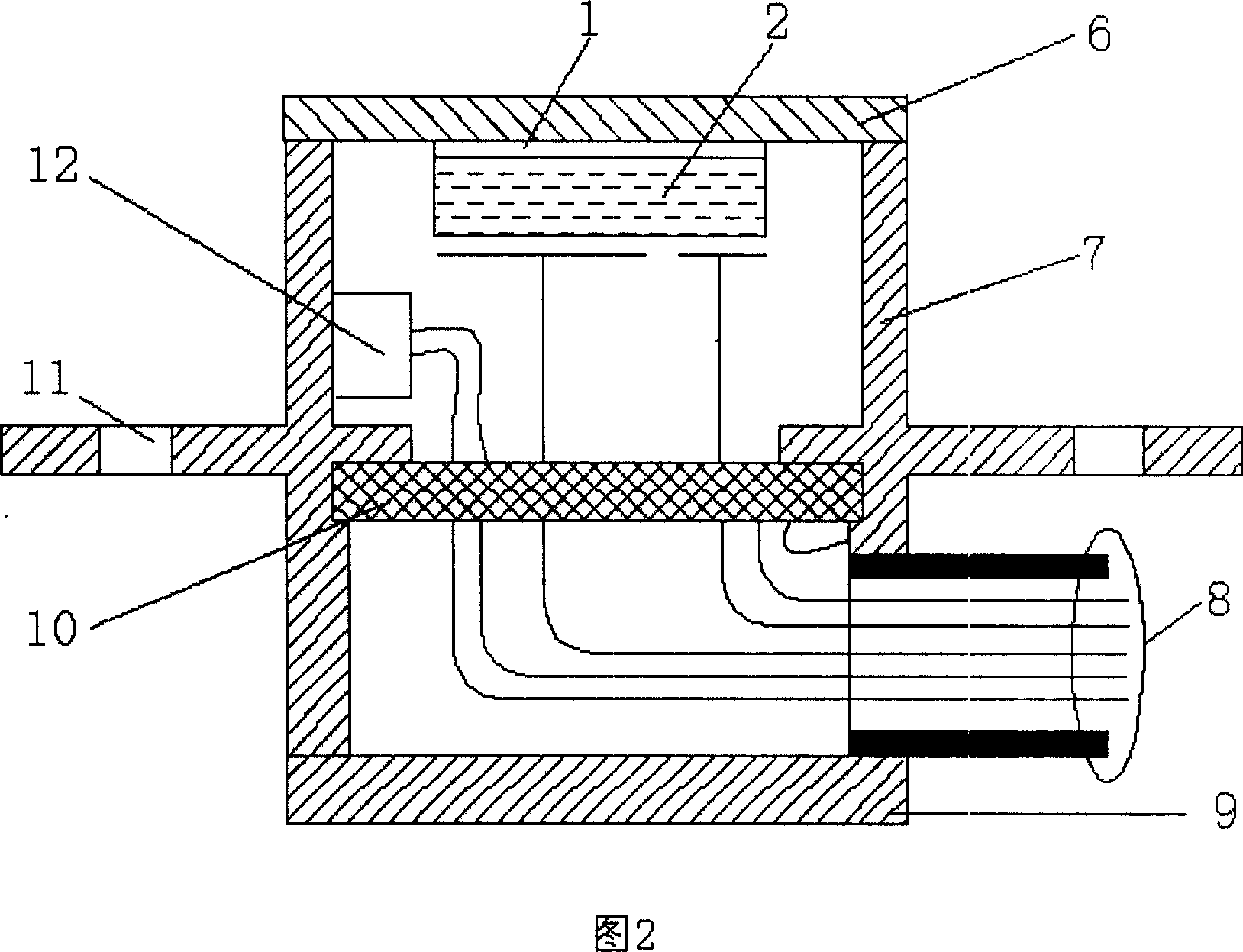

Piezoelectric resonant diaphragm type sensor

InactiveCN1967176AStable jobReduce power consumptionResonant frequencyUsing electrical meansElectricityShielded cable

The piezoelectric resonance diaphragm sensor belongs to the sensors, and it overcomes the limitation of the existing vibration tube icing sensor, for the detection of the icing phenomenon. In the invention, the tube stainless steel shell, one end jointing connects the vibration diaphragm, and another end forms a airtight cavity closed with the rear board; (1) the said vibration diaphragm is attached by the piezoelectric element, the airtight cavity wall abutting the piezoelectric element and vibration diaphragm installed temperature-detecting element, and the piezoelectric element and the temperature-detecting element electrical connect with the drive and signal detection circuit through shielding cable of the airtight cavity; (2) the said piezoelectric element comprises: the one surface of the piezoelectric element connects the reference ground electrode, and another surface connects the driven electrode and the signal electrode encircled by the driven electrode. The invention is high sensitivity for the ice layer detection, and low power consumption, and small size, and it can be installed flush on some detection surfaces, such as highways, aircraft wing leading edge, and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

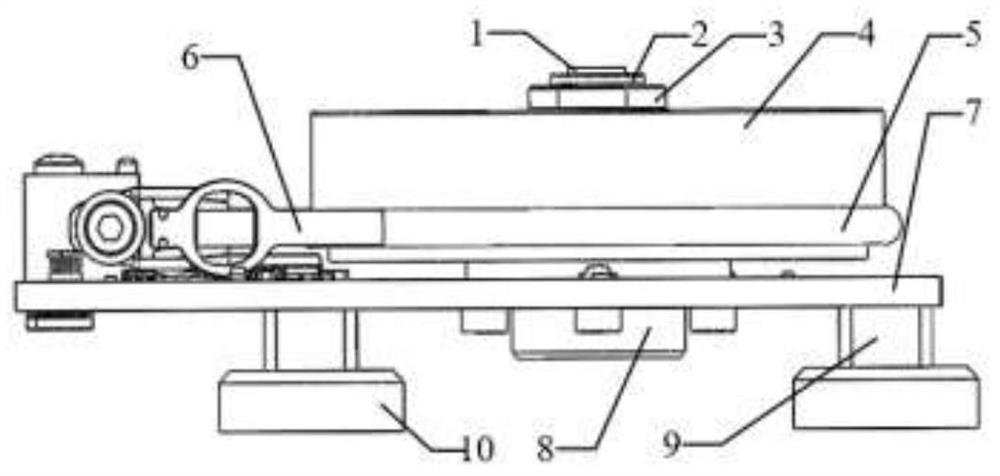

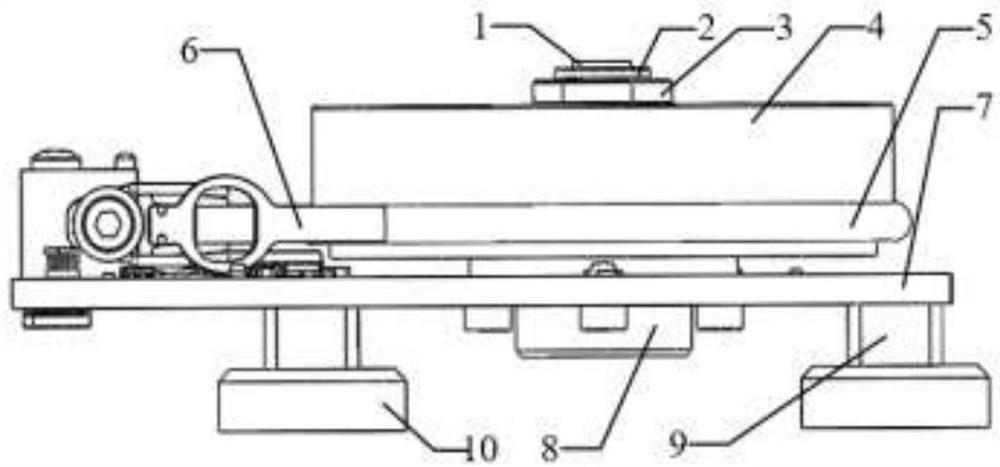

Resonant piezoelectric pump working under power frequency

ActiveCN110094329AImprove output performanceReduce complexityFlexible member pumpsPositive-displacement liquid enginesElectricityTuning fork

The invention provides a resonant piezoelectric pump working under the power frequency, and belongs to a piezoelectric resonance device. The resonant piezoelectric pump comprises a vibration excitingsystem consisting of piezoelectric ceramic, a tuning fork vibrator, a mass block, a bolt, a connector and an elliptic connecting piece, and a pump body consisting of an upper pump, an intermediate body, a lower pump body, a pump cavity film, an inlet valve, an outlet valve, a water inlet pipe plate and a water outlet pipe plate. Under driving by a power frequency power supply, the piezoelectric vibrator is bent to deform to generate periodic-changed inertia impact force; and the inertia impact force is acted on the pump cavity film through the connector and the elliptic connecting piece to realize oriented driving of fluids.

Owner:HEFEI UNIV OF TECH +1

Curing process for piezoelectric ceramics buzzing sheet

ActiveCN102729577AFast curingEven by forceLamination ancillary operationsLaminationScreen printingElectricity

The present invention relates to a curing process for a piezoelectric ceramics buzzing sheet in a buzzer. According to the curing process, a metal sheet is placed on a sheet suction mold, the sheet suction mold adsorbs the metal sheet, and silk-screen printing is adopted to print an anaerobic glue onto the upper surface of the metal sheet; a piezoelectric resonance sheet is placed on the metal sheet, and is bonded on the metal sheet through the anaerobic glue; the metal sheet and the piezoelectric resonance sheet bonded on the metal sheet are removed from the sheet suction mold, and are packaged by adopting a vacuum package bag; the vacuum package bag filled with the metal sheet and the piezoelectric resonance sheet is placed in ultra-high hydrostatic hydraulic equipment to carry out pressing curing, wherein the pressure of ultra-high hydrostatic hydraulic pressure is more than or equal to 120 MPa, and a pressure keeping time is 3-5 minutes; and the vacuum package bag is removed from the ultra-high hydrostatic hydraulic equipment, and is unpacked, the metal sheet and the piezoelectric resonance sheet are firmly bonded, and the curing process is completed. According to the present invention, the force applying on the product is uniform, the bonding force is stable and reliable, the curing time is short, the production efficiency is improved, the product is not deformed, and the frequency consistency is good.

Owner:BESTAR HLDG

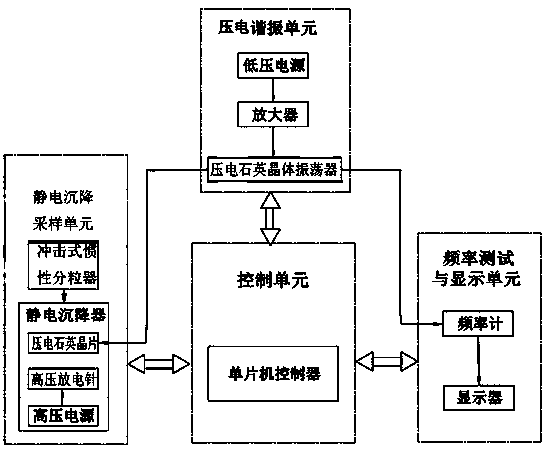

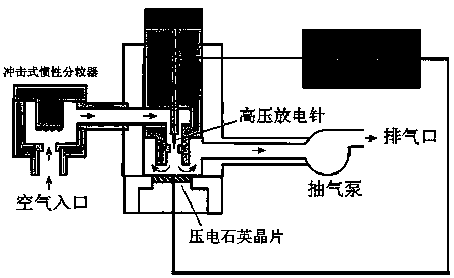

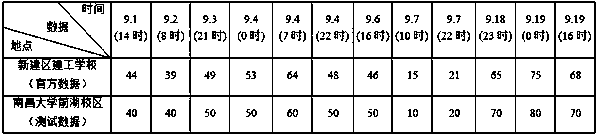

Piezoelectric resonant type PM2.5 monitoring system

PendingCN107741376AAcquisition rate is stableMonitoring Sensitivity EffectsWeighing by absorbing componentQuartz crystal resonatorPiezoelectric quartz

The invention discloses a piezoelectric resonant type PM2.5 monitoring system. Based on a piezoelectric resonant frequency difference method and by adopting a modular design, the piezoelectric resonant type PM2.5 monitoring system mainly comprises a control unit, and an electrostatic precipitation sampling unit, a piezoelectric resonance unit, a frequency testing unit and a display unit which areconnected with the control unit, wherein the electrostatic precipitation sampling unit mainly comprises an impact type inertia classifier and an electrostatic precipitator; and the piezoelectric resonance unit mainly comprises a piezoelectric quartz crystal resonator, an amplifier and a low-voltage power supply. The piezoelectric quartz crystal resonator is a double-quartz crystal resonator consisting of two identical piezoelectric quartz crystal oscillating circuits, a relational model between the piezoelectric resonant frequency and piezoelectric crystal wafer quality is established, the mass concentration of PM2.5 is determined according to the change of the piezoelectric resonant frequency, one oscillating circuit of the double-quartz crystal resonator is a measurement end, and the other oscillating circuit is a reference end. The collection rate of PM2.5 particulate matters is stable, and the monitoring sensitivity is not influenced by multiple factors including ambient temperature and the like.

Owner:NANCHANG UNIV

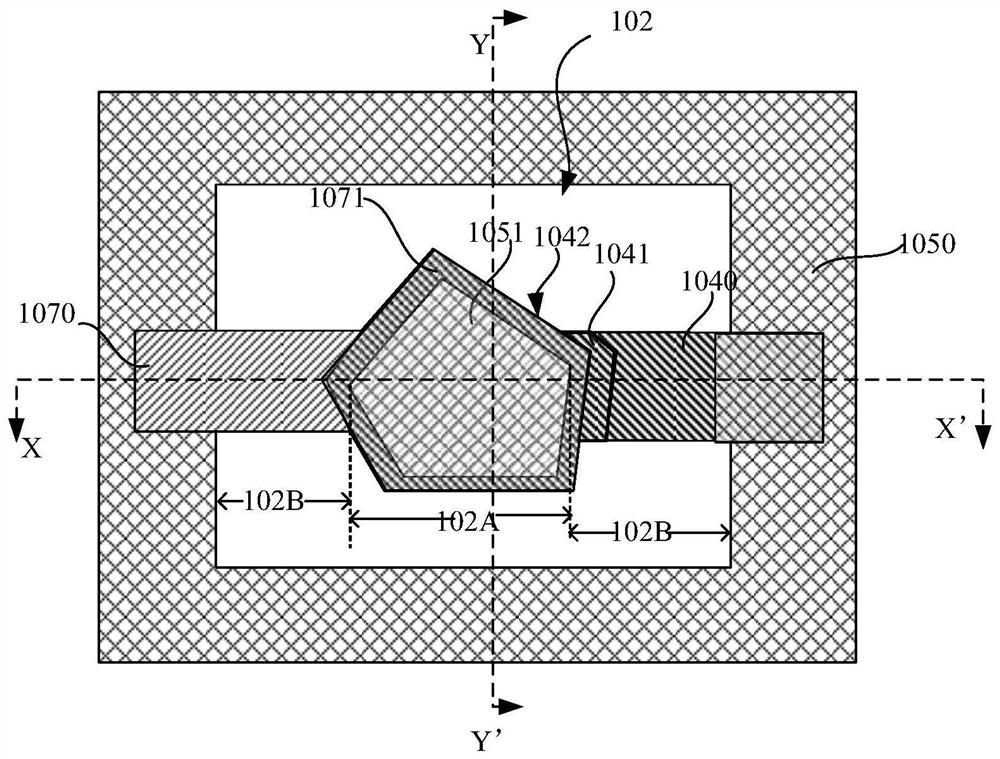

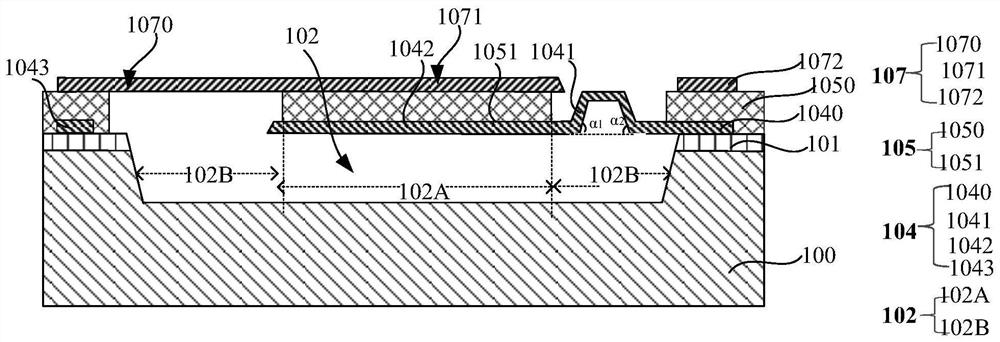

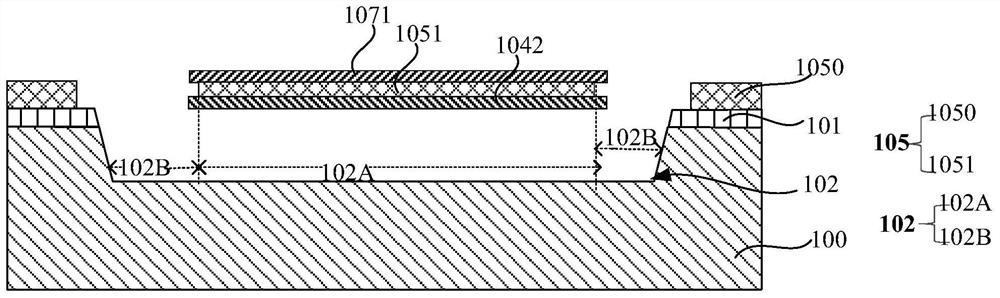

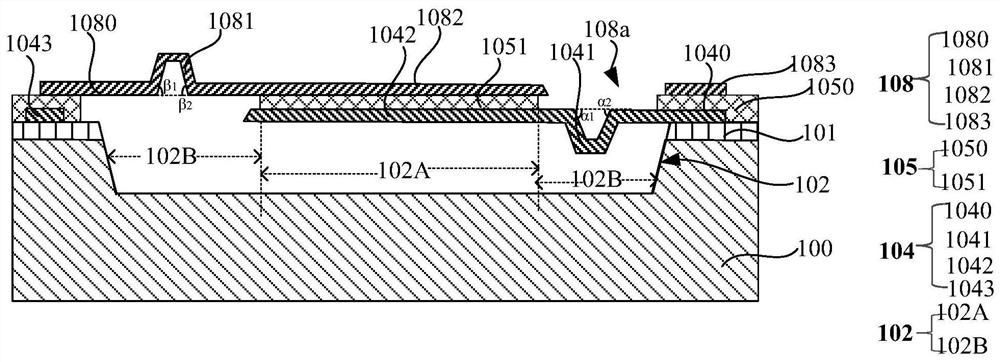

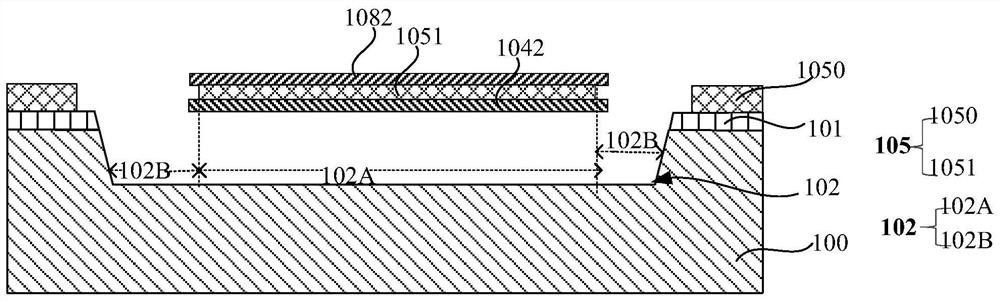

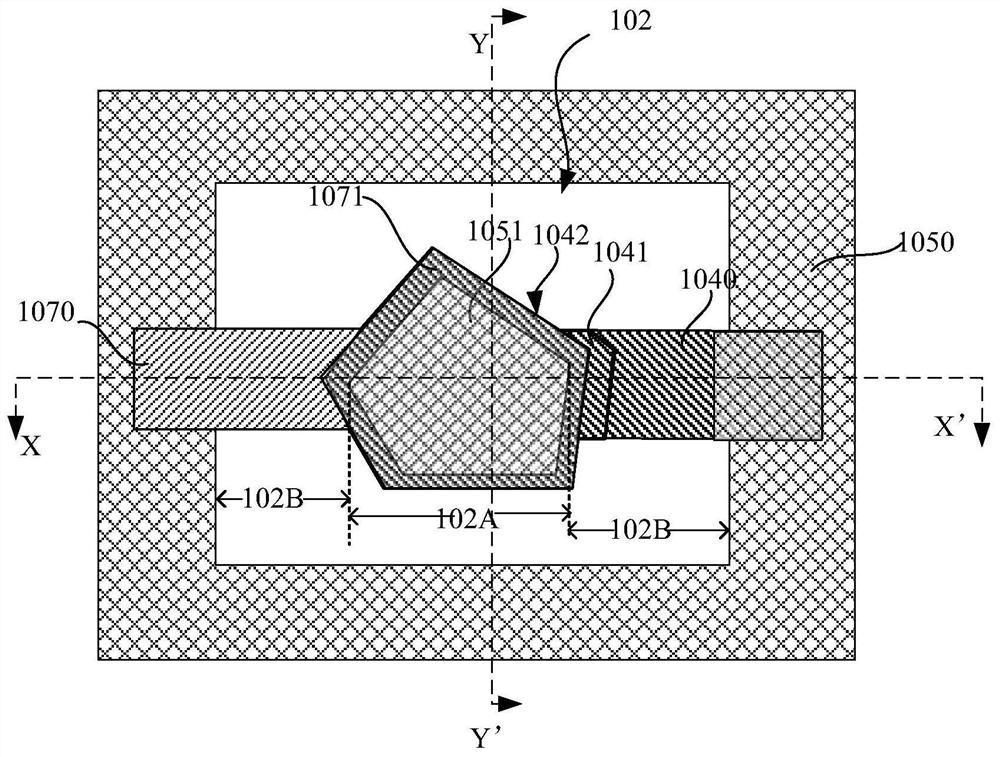

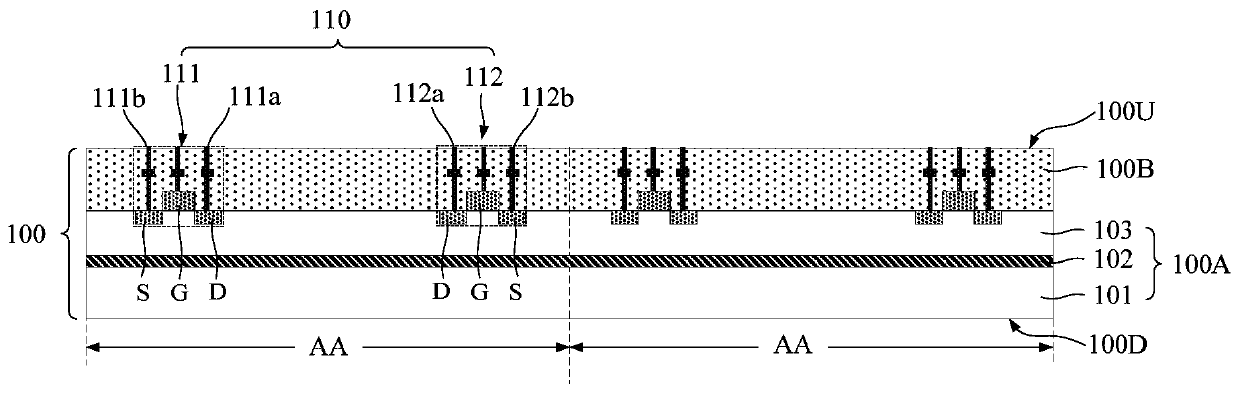

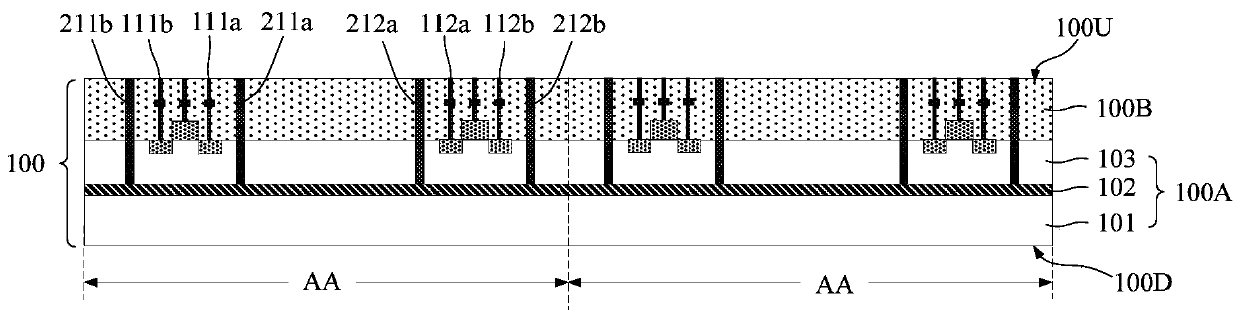

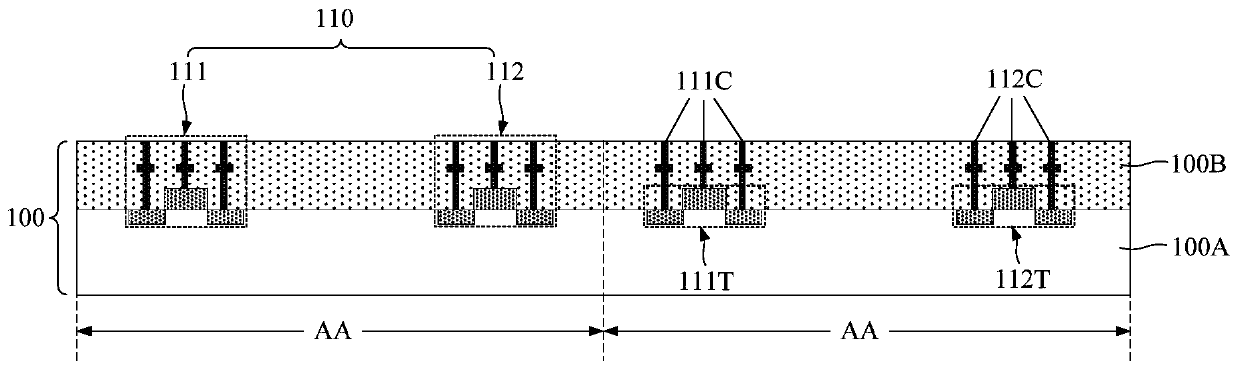

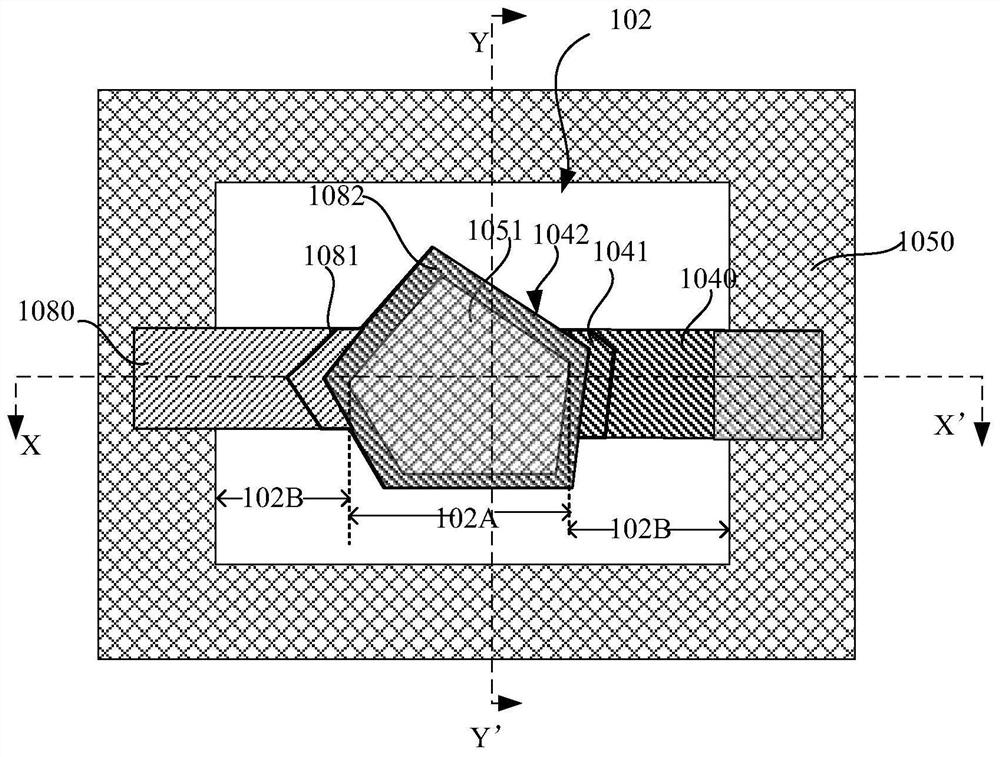

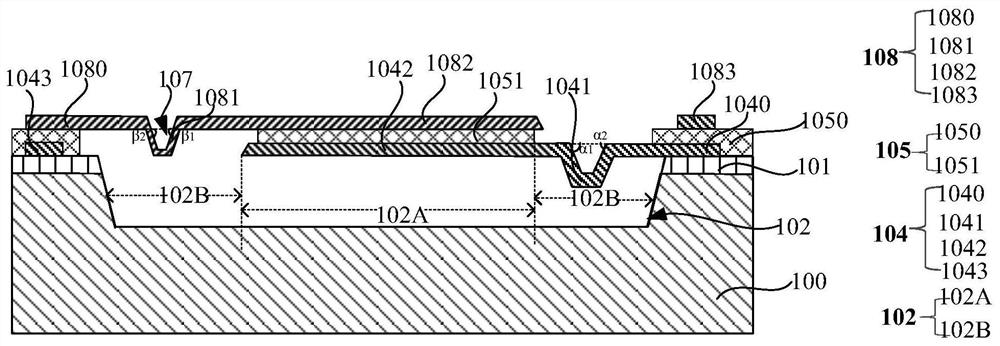

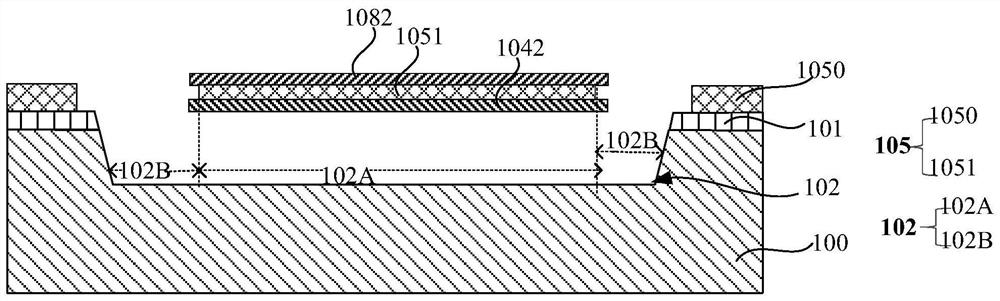

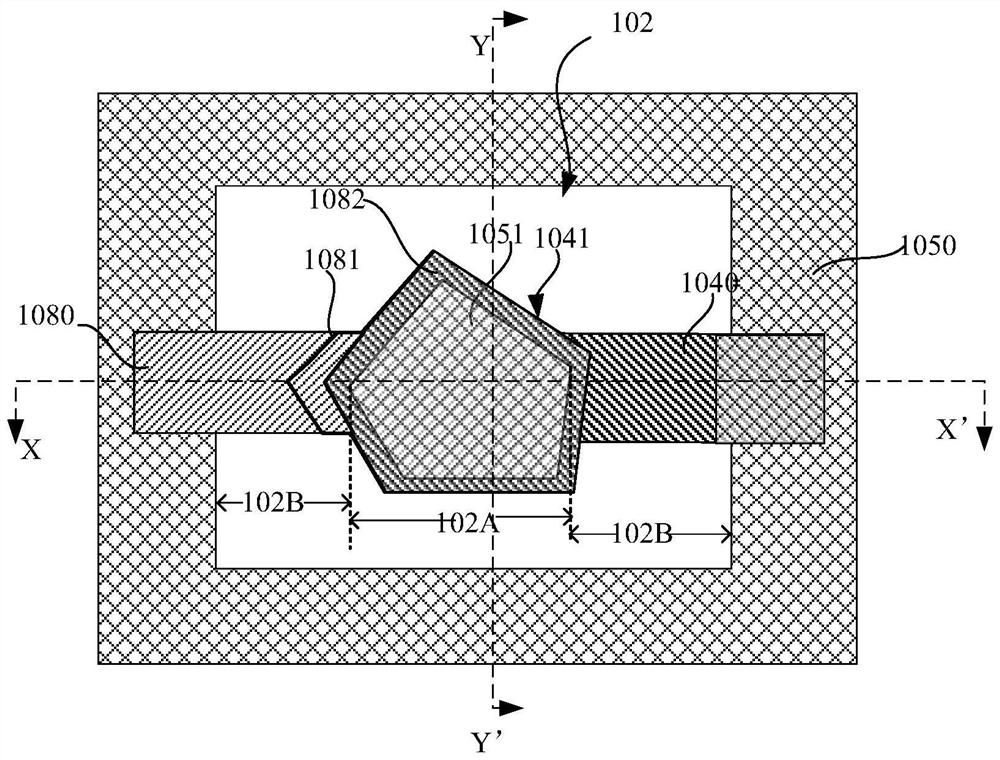

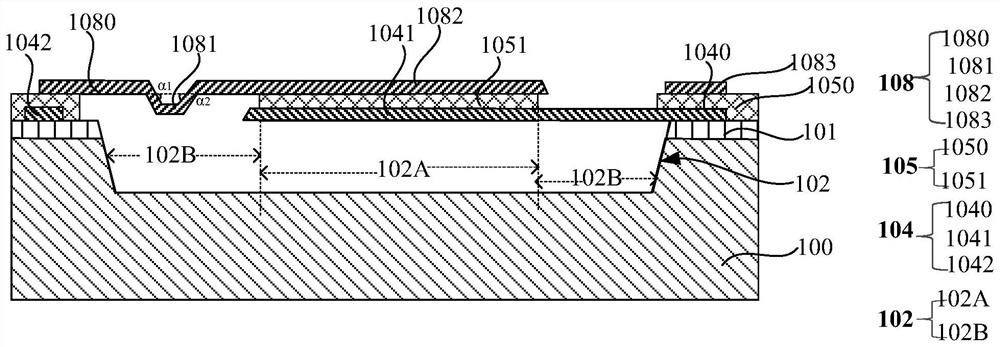

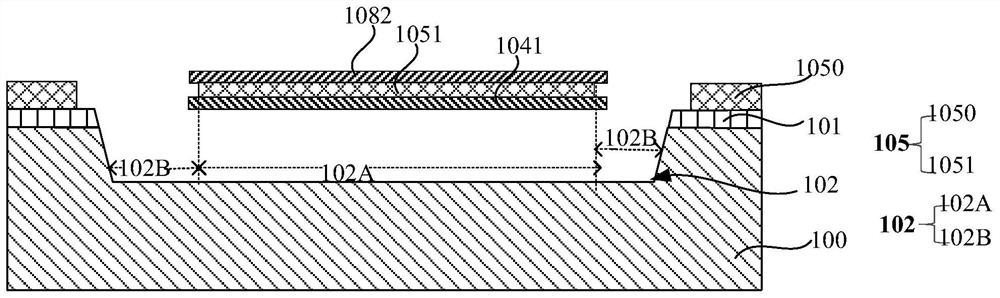

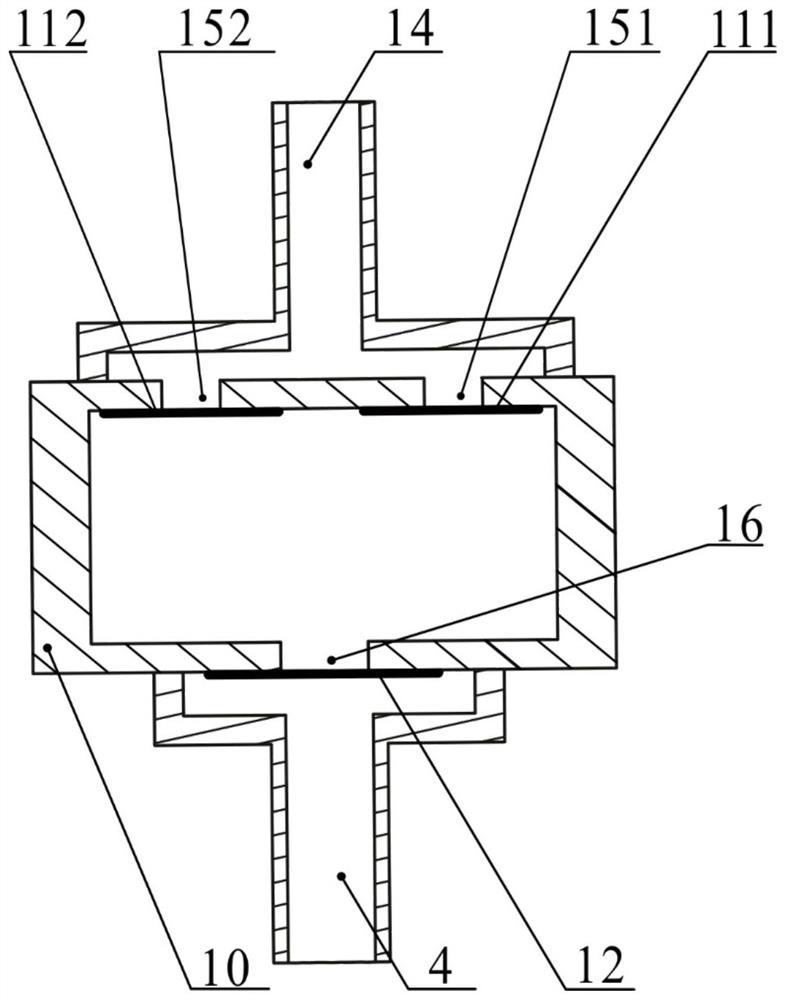

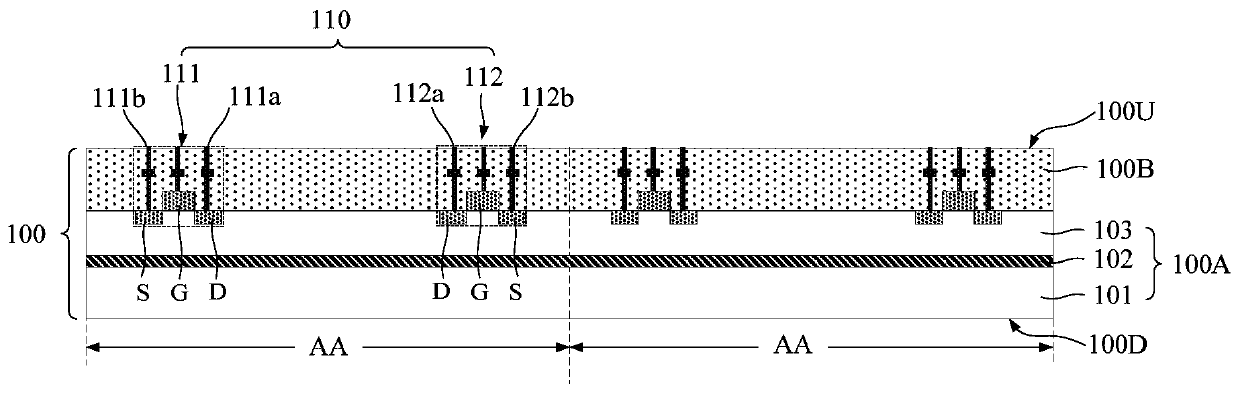

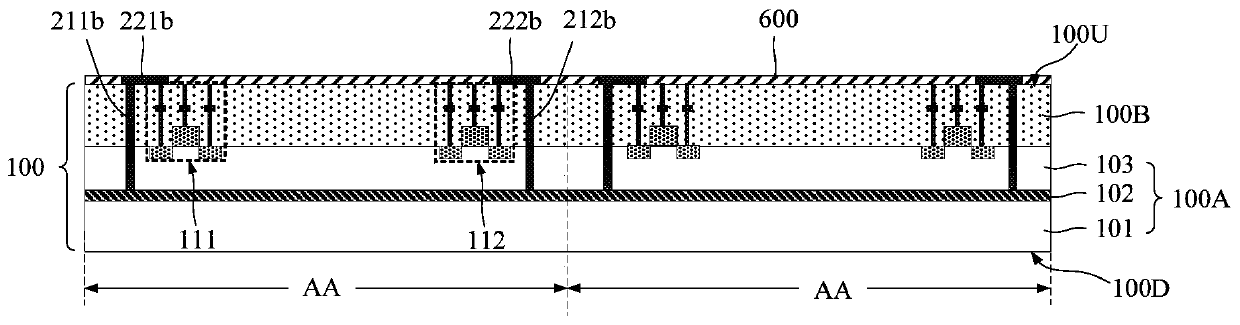

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

ActiveCN111786644AQuality factor improvedReduce lossesImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode protruding part formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity, and reflect the transverse waves back to an effective working area, so that sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottomelectrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and thelike can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

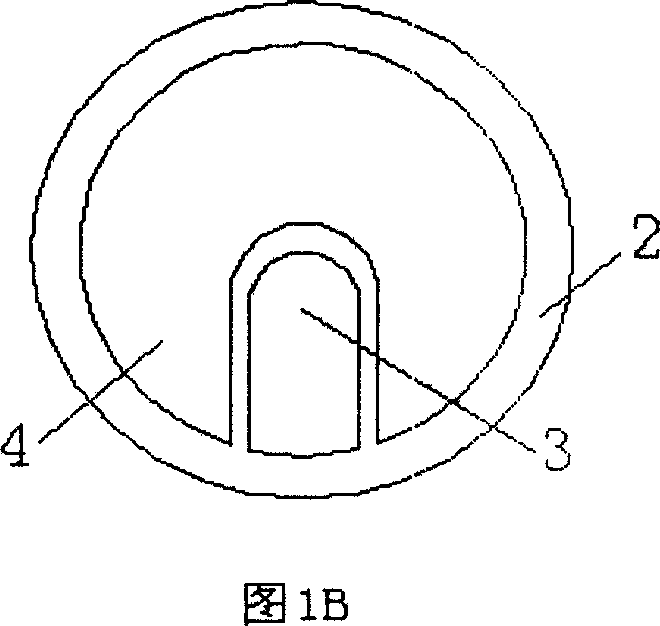

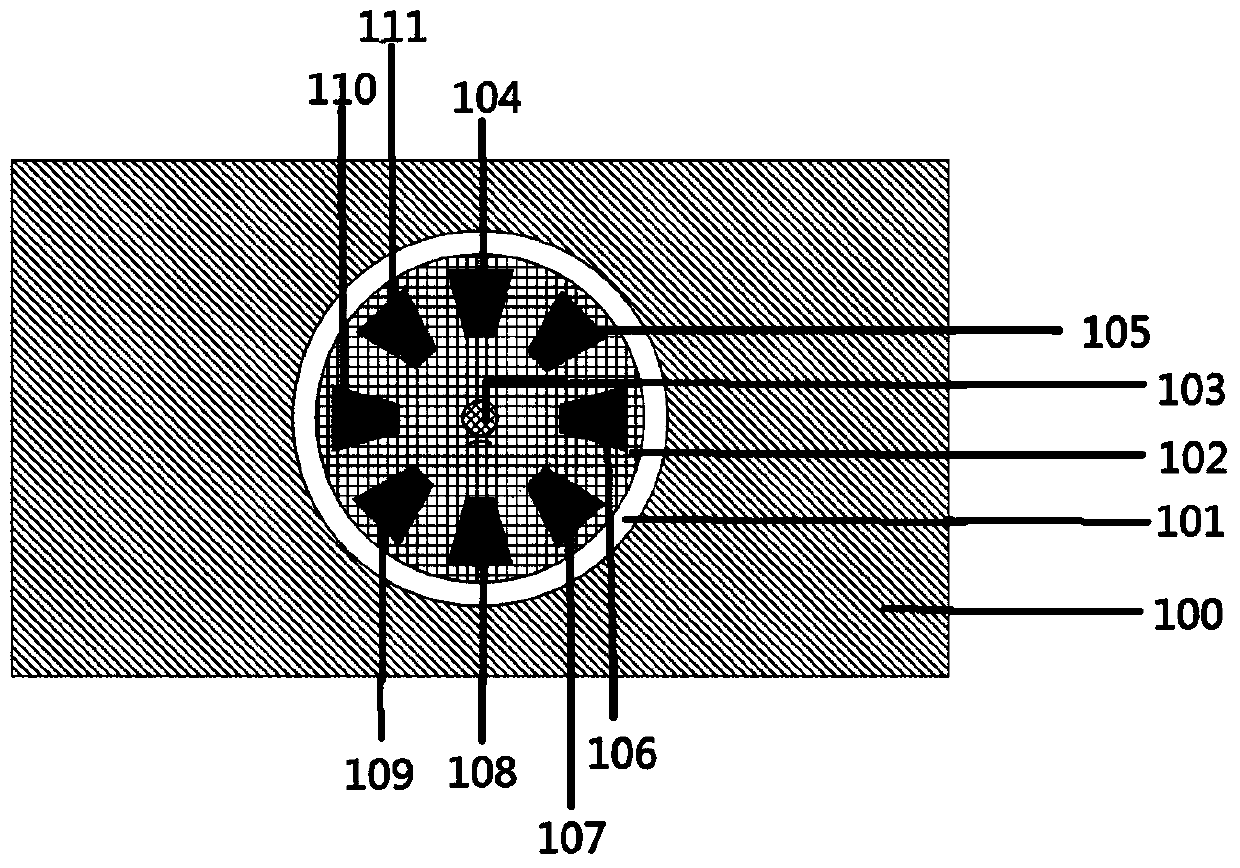

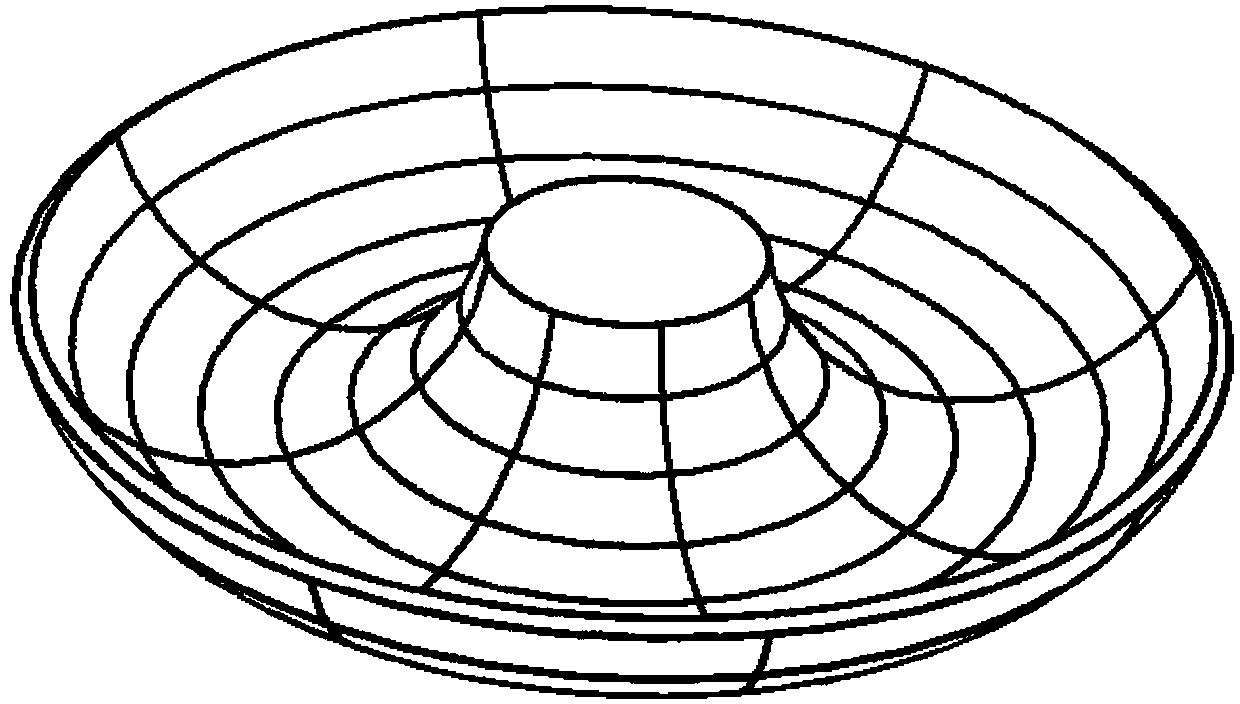

Concave annular piezoelectric resonance gyroscope and production method thereof

ActiveCN104197908AHigh sensitivityImprove stabilitySpeed measurement using gyroscopic effectsTurn-sensitive devicesGyroscopePiezoelectric resonance

The invention provides a concave annular piezoelectric resonance gyroscope and a production method of the concave annular piezoelectric resonance gyroscope. The concave annular piezoelectric resonance gyroscope comprises a substrate, a hollow annular cavity which is arranged on the periphery of a central position of the substrate, a concave annular piezoelectric resonator which is arranged on the substrate, a supporting column which is fixed on the substrate and used for supporting the concave annular resonator, an electrode on the supporting column and eight electrodes which are symmetrically distributed on the outer surface of the concave annular resonator, wherein the concave annular piezoelectric resonator is located to be separated from the upper surface of the substrate so as to allow the vibration of the piezoelectric resonance gyroscope. The resonator is supported by the supporting column which is formed on the upper surface of the substrate, so that the stability is good, the influence of the supporting damping can be reduced, and the value Q and sensitivity of the gyroscope can be improved; the process is relatively simple and easy to realize; besides the central supporting, the resonator is separated from the substrate, so that the vibration is facilitated; by adopting the piezoelectric material, the overload resistance and impact resistance are high, the working resonance frequency is high, and the starting time is short.

Owner:SHANGHAI JIAO TONG UNIV

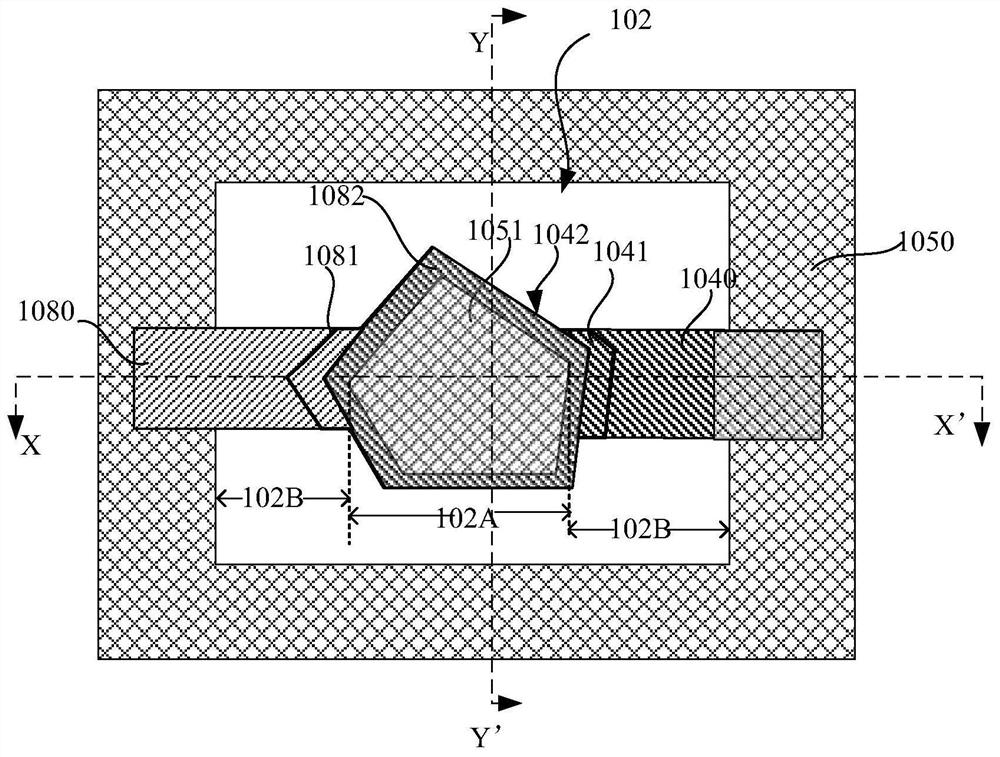

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

ActiveCN111786649AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

Owner:NINGBO SEMICON INT CORP

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786651AHigh quality factorImprove performanceImpedence networksCommunications systemPiezoelectric resonance

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode concave part formed on the periphery of apiezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that the sound wave loss is reduced, the quality factor of the resonator is improved, and finally, the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottomelectrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and thelike can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

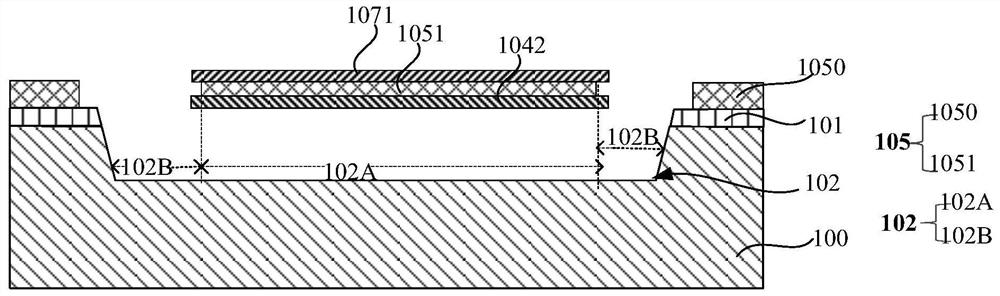

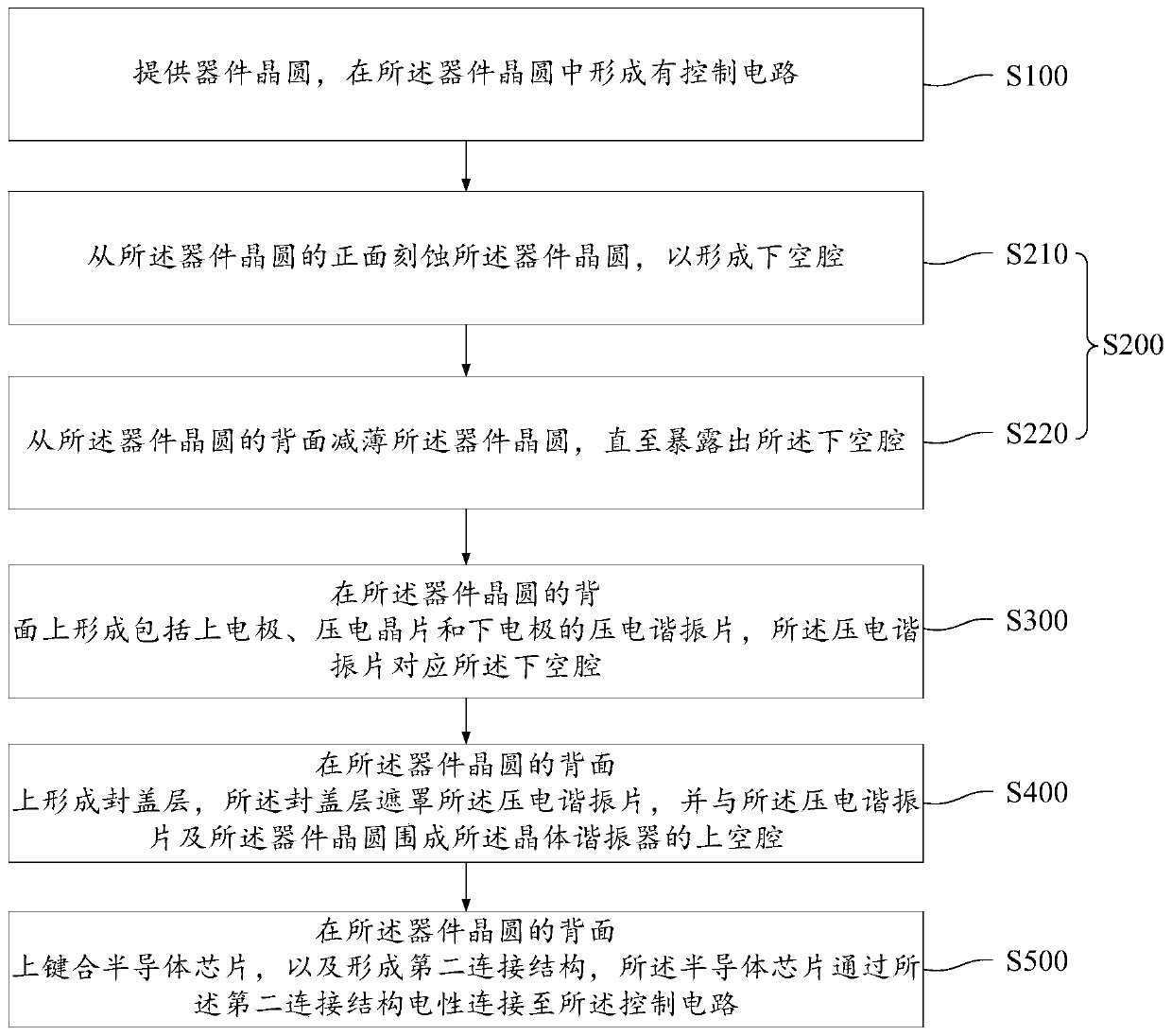

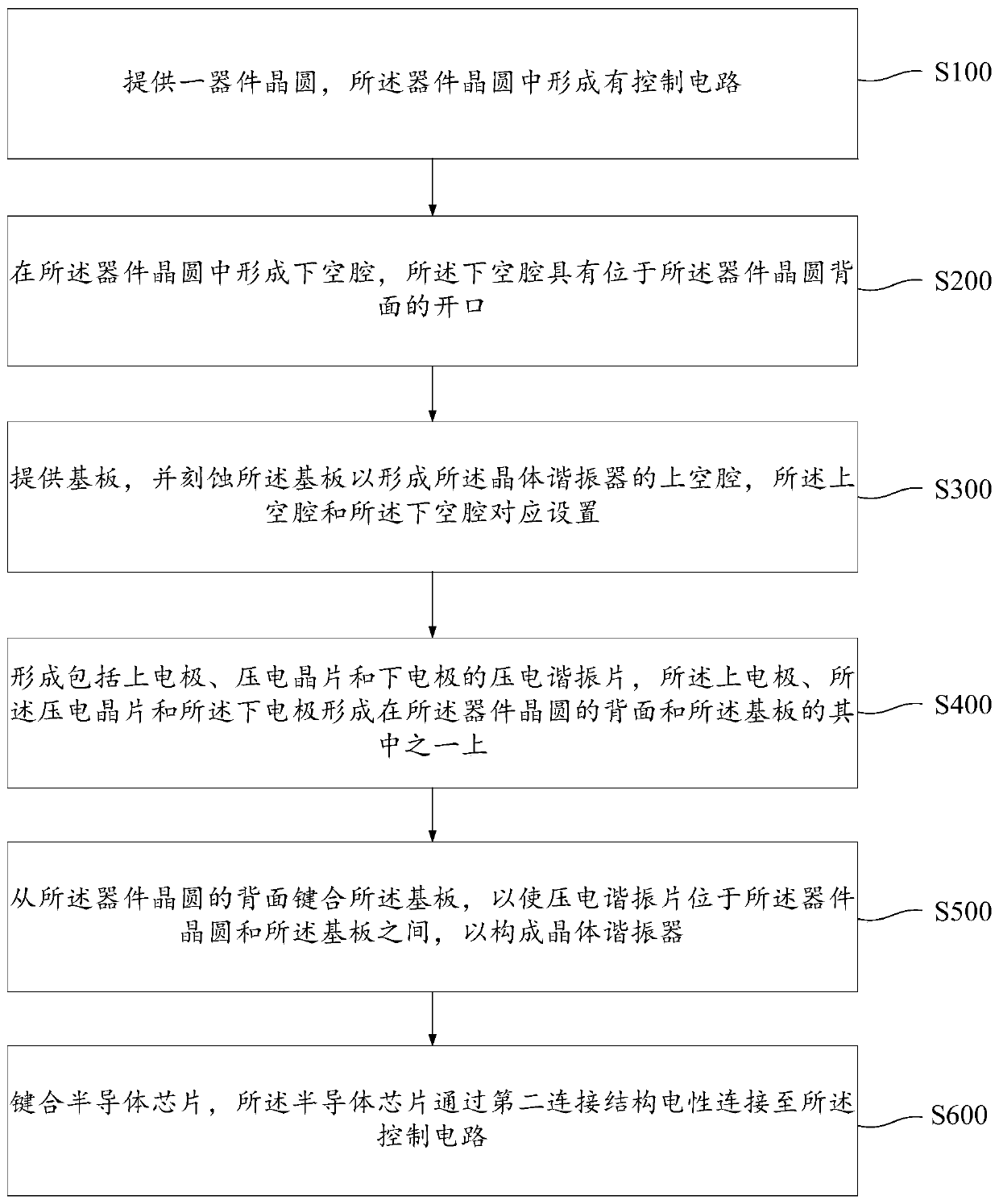

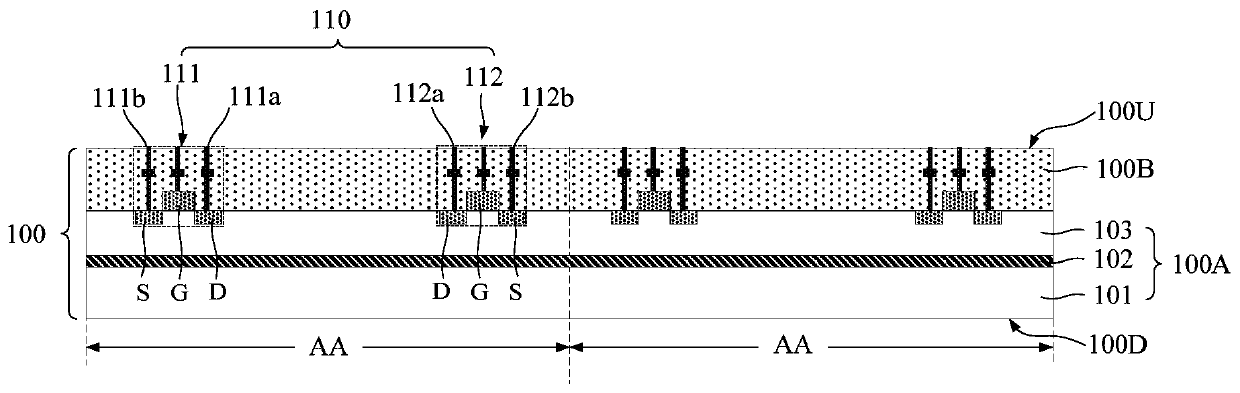

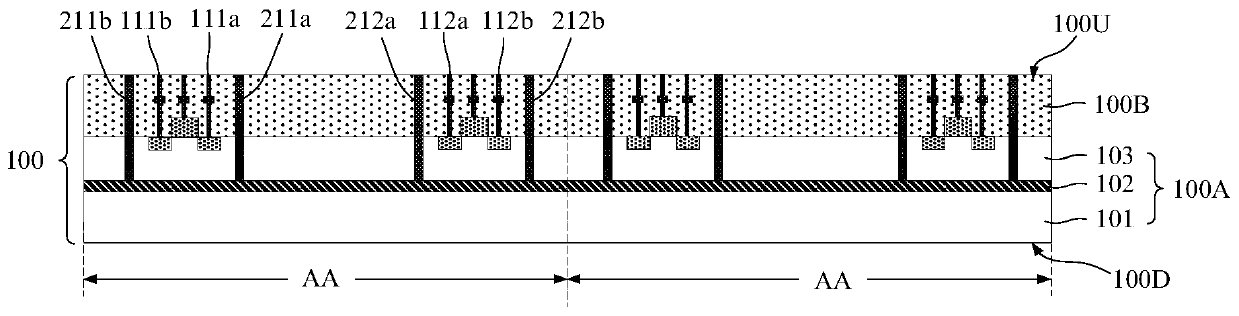

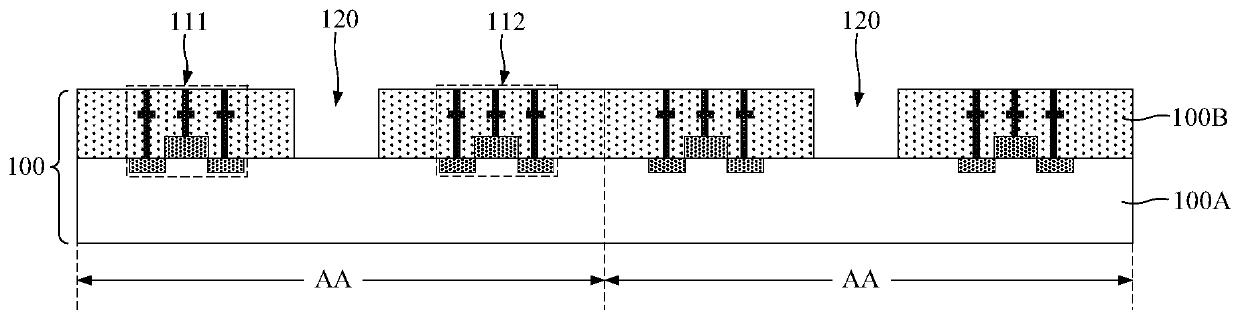

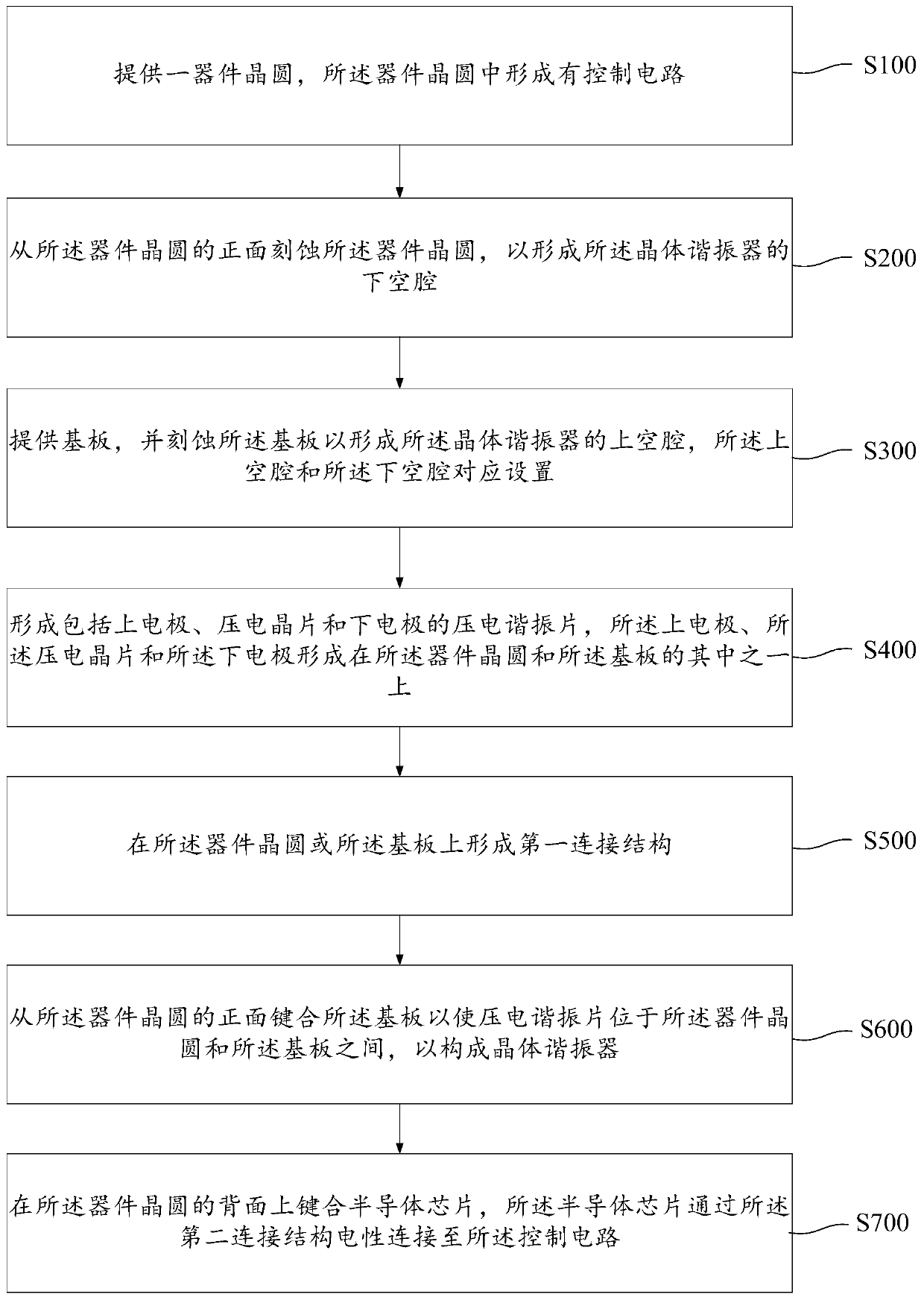

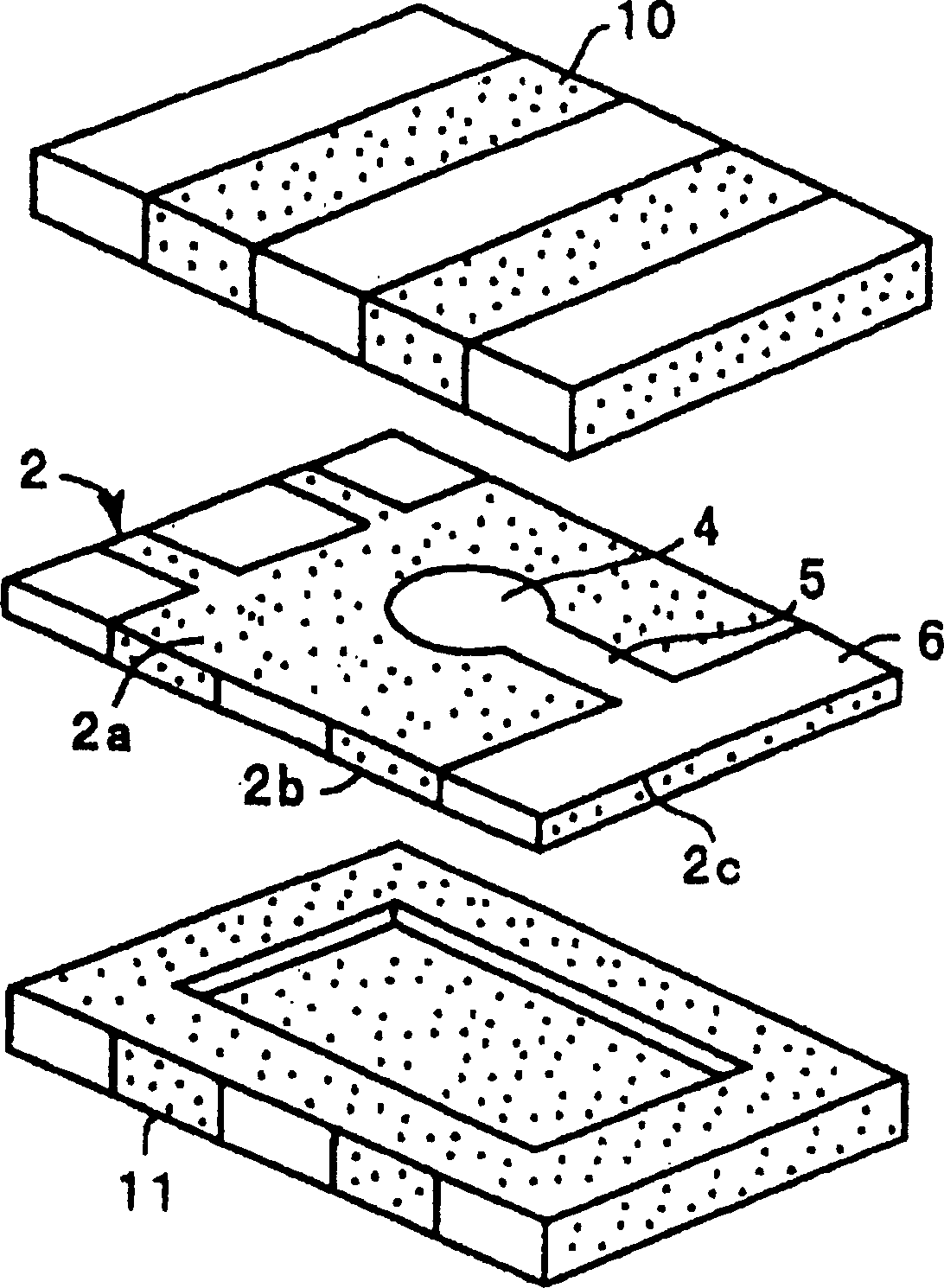

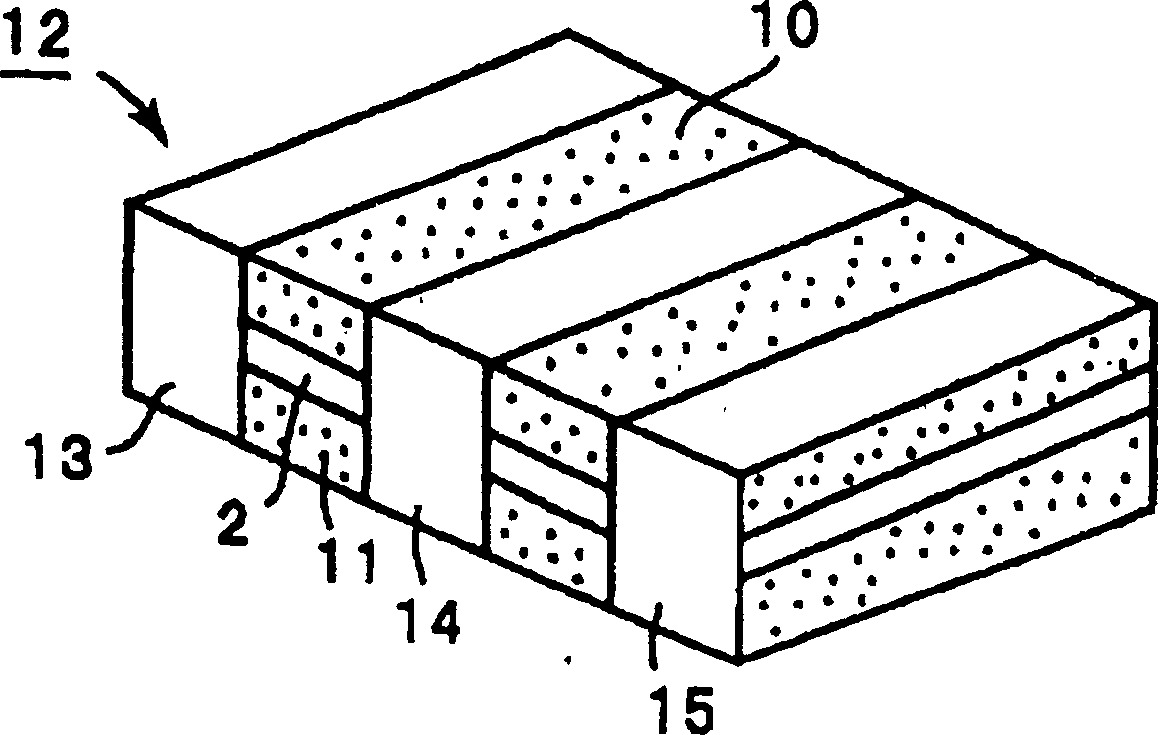

Integrated structure of crystal resonator and control circuit and integration method thereof

The invention provides an integrated structure of a crystal resonator and a control circuit, and an integration method thereof. A piezoelectric resonance sheet and a semiconductor chip are formed on the back surface of a device wafer, so that the semiconductor chip, a control circuit and a crystal resonator are arranged on the same device wafer. Thus, the integration degree of the crystal resonator can be improved, and parameters of the crystal resonator can be modulated on chip; compared with a traditional crystal resonator, the crystal resonator has the advantages that the size is smaller, and the power consumption of the crystal resonator can be reduced.

Owner:NINGBO SEMICON INT CORP

Integrated structure of crystal resonator and control circuit and integration method thereof

Owner:NINGBO SEMICON INT CORP

Integrated structure of crystal resonator and control circuit and integration method thereof

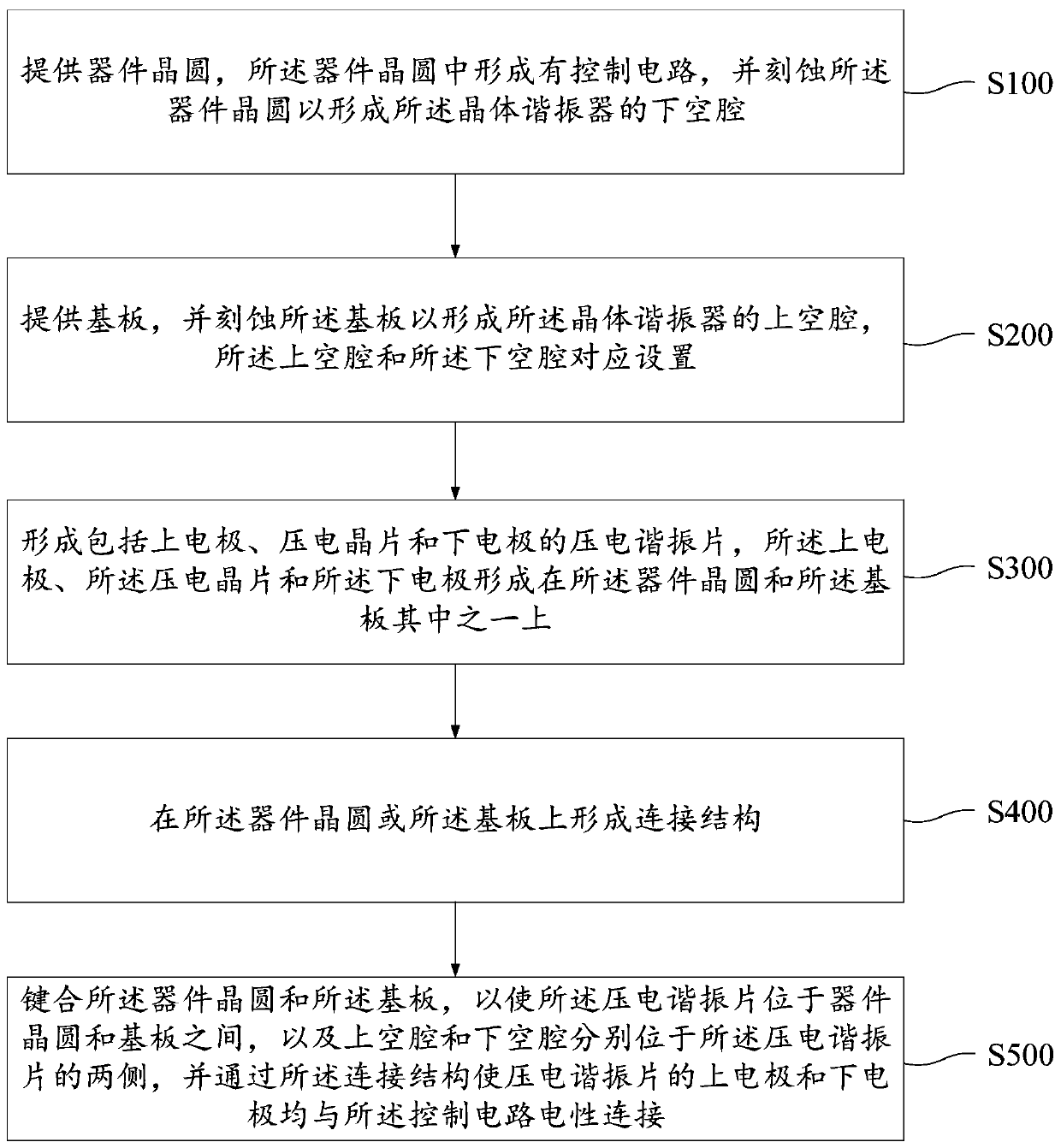

ActiveCN111403334ASmall sizeMiniaturizationImpedence networksSolid-state devicesWaferElectrical connection

The invention provides an integrated structure of a crystal resonator and a control circuit and an integration method thereof. A lower cavity is formed in a device wafer, and an upper cavity is formedin a substrate; the device wafer and the substrate are bonded by using a bonding process, so that a piezoelectric resonance sheet is clamped between the device wafer and the substrate, the lower cavity and the upper cavity are enabled to respectively correspond to two sides of the piezoelectric resonance sheet to form the crystal resonator, and the crystal resonator is enabled to be electricallyconnected with the control circuit, so the integrated arrangement of the crystal resonator and the control circuit can be realized. Compared with a traditional crystal resonator, the crystal resonatorhas the advantages that the size is smaller, the power consumption of the crystal resonator can be reduced, the crystal resonator can be integrated with other semiconductor components more easily, and therefore the integration degree of the device can be improved.

Owner:NINGBO SEMICON INT CORP

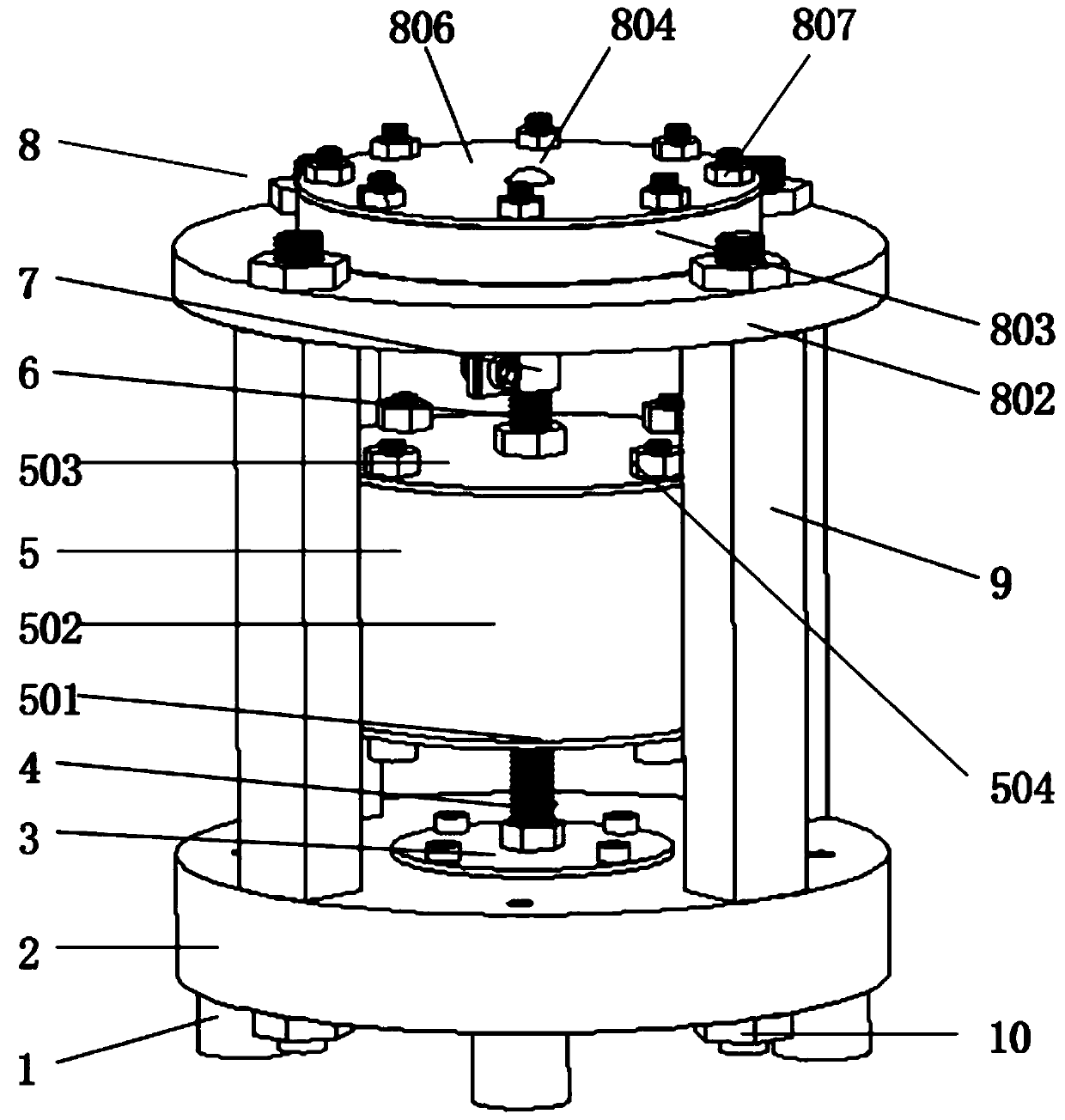

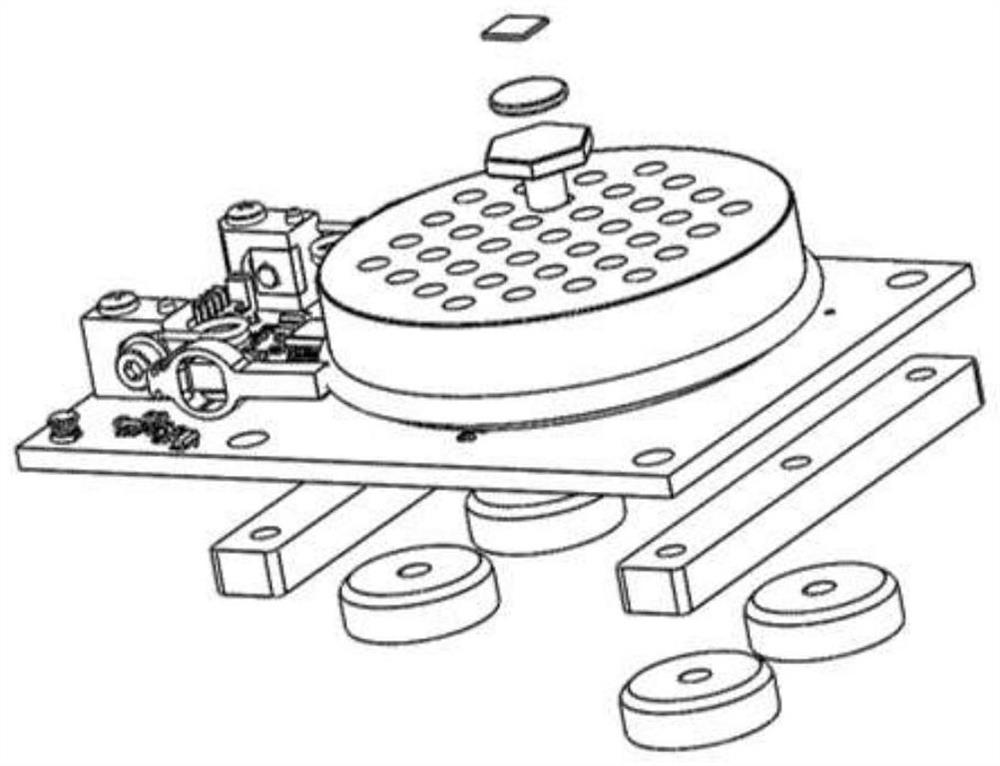

Piezoelectric resonance type flexible point display device

ActiveCN111524425AMeet the use requirements of different comfort levelsEasy to identifyPiezoelectric/electrostriction/magnetostriction machinesTeaching apparatusMagnetic disturbanceDisplay device

The invention discloses a piezoelectric resonance type flexible point display device. The device comprises rubber bottom feet in contact with a workbench, and the number of the rubber bottom feet is four. The upper ends of the rubber bottom feet are embedded in the lower end face of a base. A through hole is formed in the middle of the base and connected with a fixing disc through a screw. The fixing disc is connected with the lower part of a connecting rod through a nut; the upper part of the connecting rod is connected with the lower part of a vibration excitation device through a nut; the upper part of the vibration excitation device is connected with the lower part of a vibration transmission rod through a nut; the upper end of the vibration transmission rod is connected with the lowerpart of a hoop in a clasping manner; the upper part of the hoop is connected with the lower end of a diaphragm connecting rod in a clasping manner; a supporting column is arranged on the upper end face of the base. According to the structure, the vibration characteristic can be adjusted by adjusting a balance weight mass block, the use requirements of different people for different comfort levelsare met, moreover, the device is combined with vibration dynamic stimulation under a certain point display effect, a user can recognize character contacts more easily, and the device is simple in structure, small in displacement, high in refreshing frequency and free of magnetic interference.

Owner:CHANGCHUN UNIV

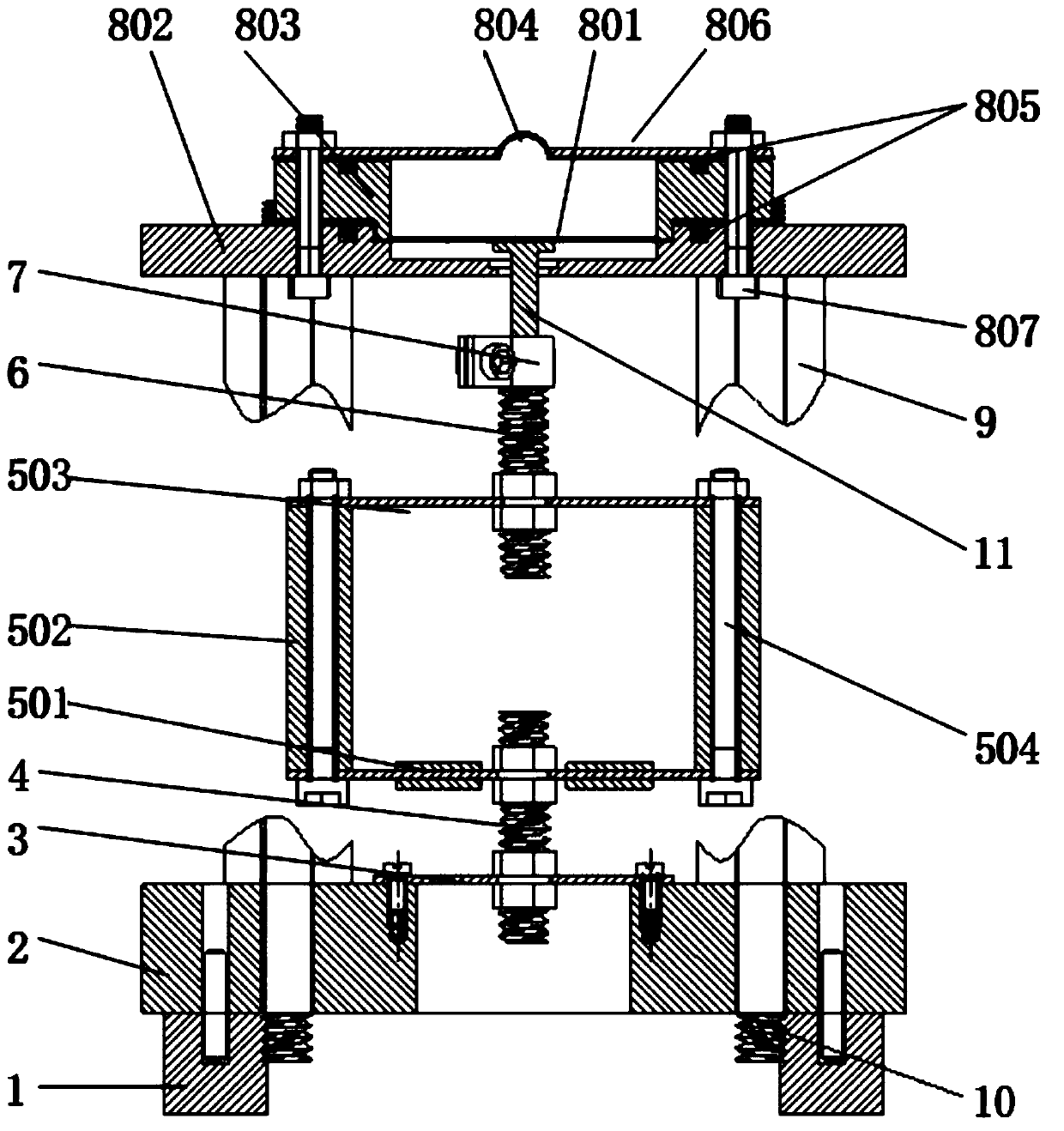

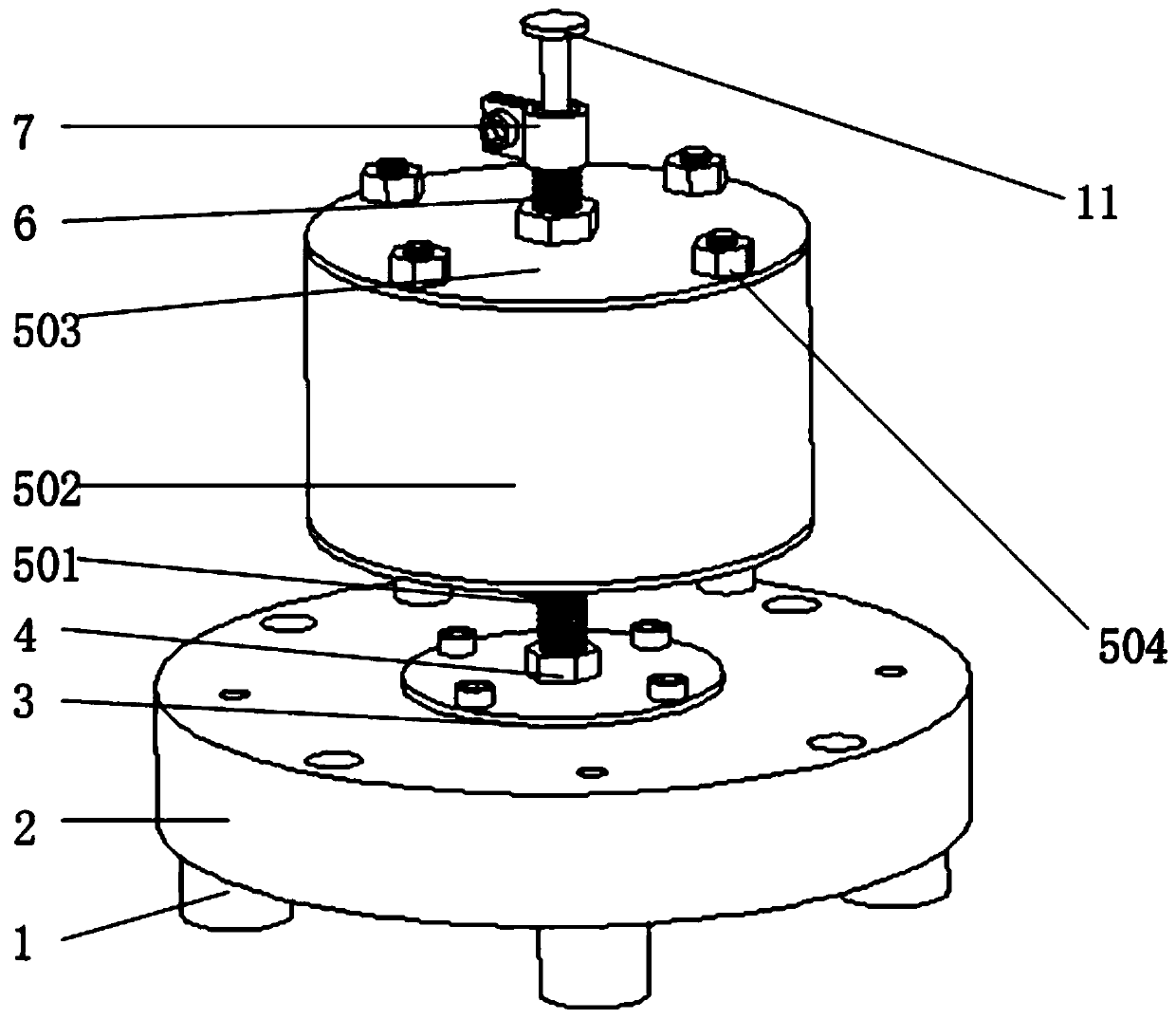

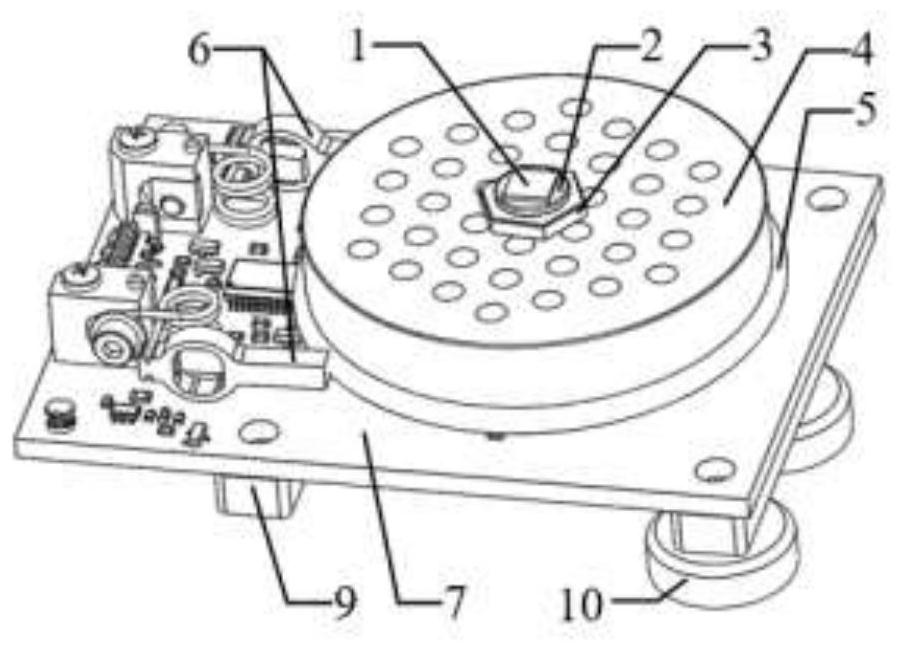

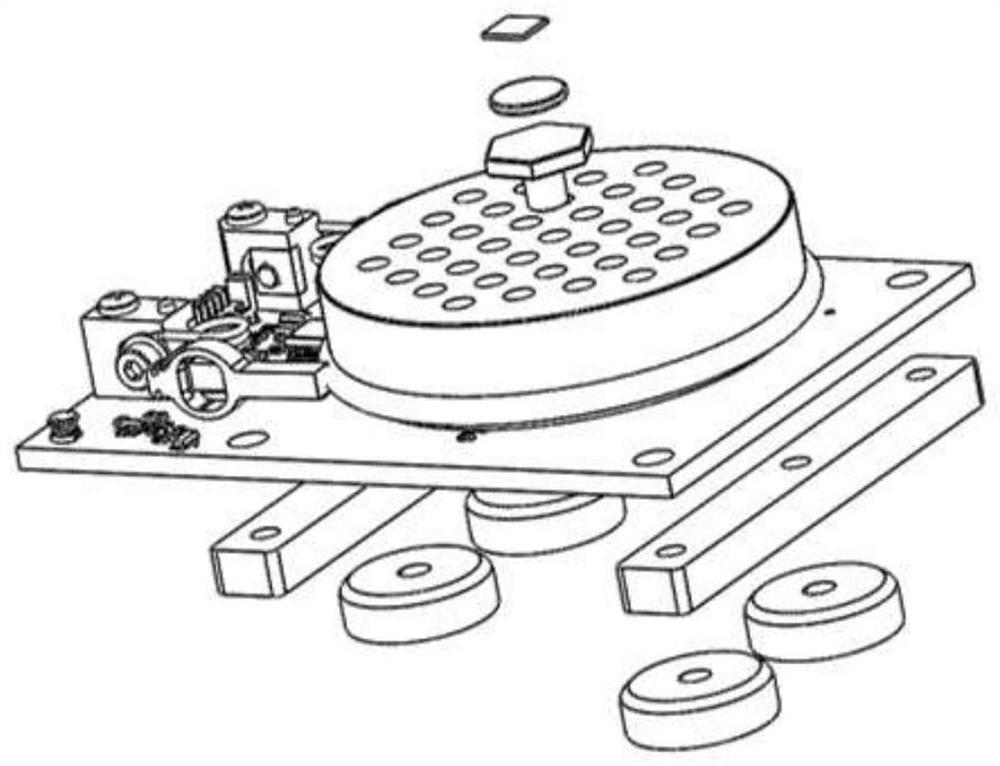

High-precision sample rotating table device based on atomic force microscope

ActiveCN112630472AAnisotropy guaranteedEliminate Experimental Measurement ErrorsScanning probe microscopyRotary stageSample rotation

The invention relates to a high-precision sample rotating table device based on an atomic force microscope. The high-precision sample rotating table device comprises a rotating table body, a sample mounting base located on the rotating table body and a magnetic attraction base used for fixing the rotating table body. The rotating table body is fixed on an atomic force microscope scanner platform through the magnetic attraction base. The rotating table body comprises a sample table, a magnetic rotary encoder and two oval piezoelectric resonance motors. A plastic ring is fixed to the side face of the sample table, the top ends of the oval piezoelectric resonance motors make close contact with the plastic ring, the two oval piezoelectric resonance motors are oppositely installed, one oval piezoelectric resonance motor is used for pushing the plastic ring to move, and the other oval piezoelectric resonance motor is used for pulling the plastic ring to move in the opposite direction. A magnetic disk of the magnetic rotary encoder is arranged on the sample table. The device provided by the invention is suitable for providing high-precision angle rotation for a sample under the conditions of limited size space and limited weight of an atomic force microscope, and widens the application occasion and research range of the atomic force microscope.

Owner:DONGHUA UNIV

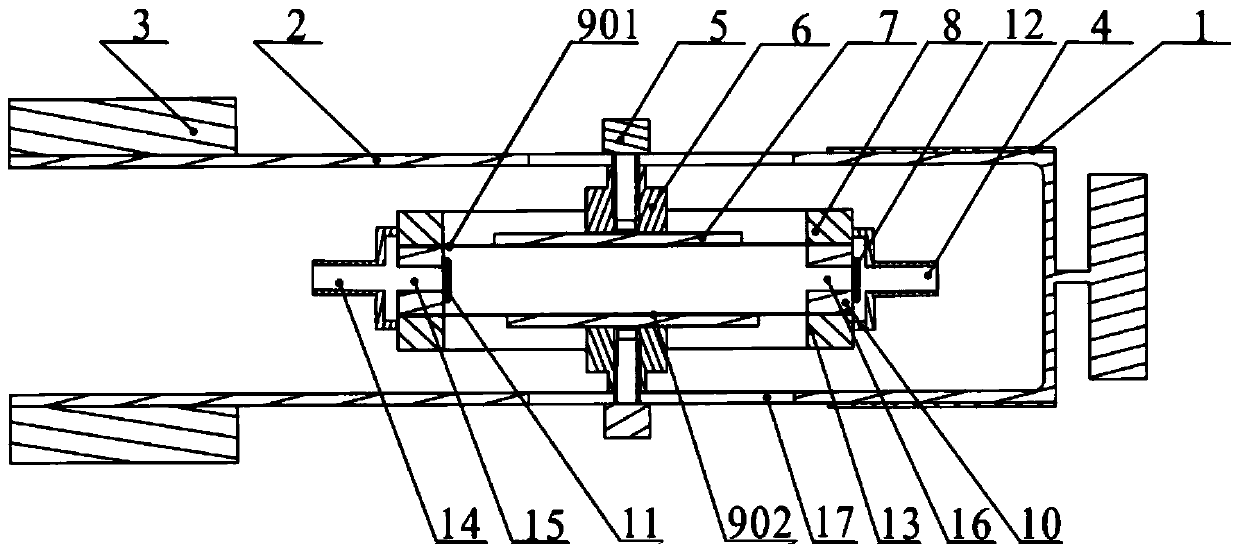

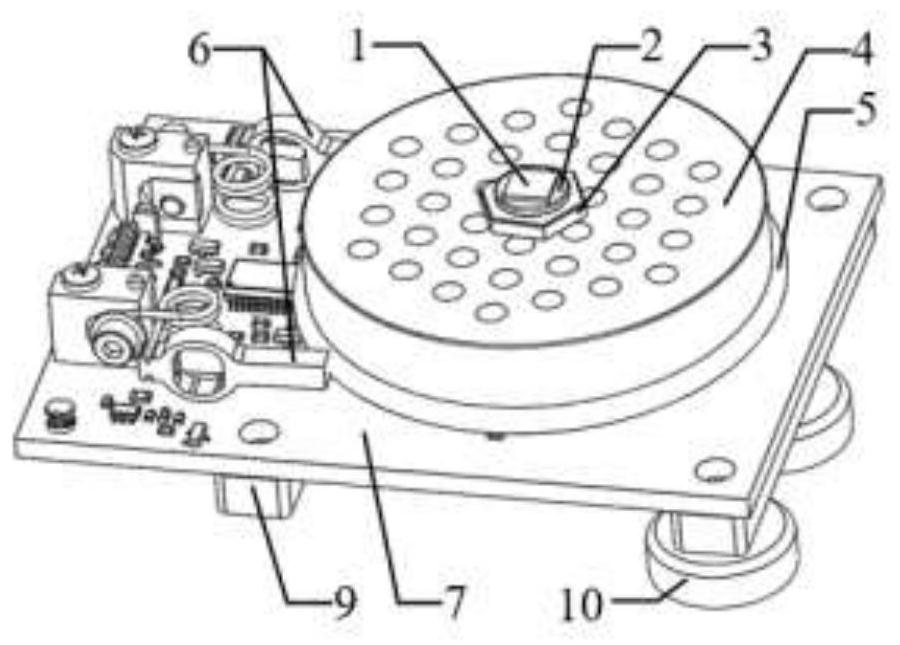

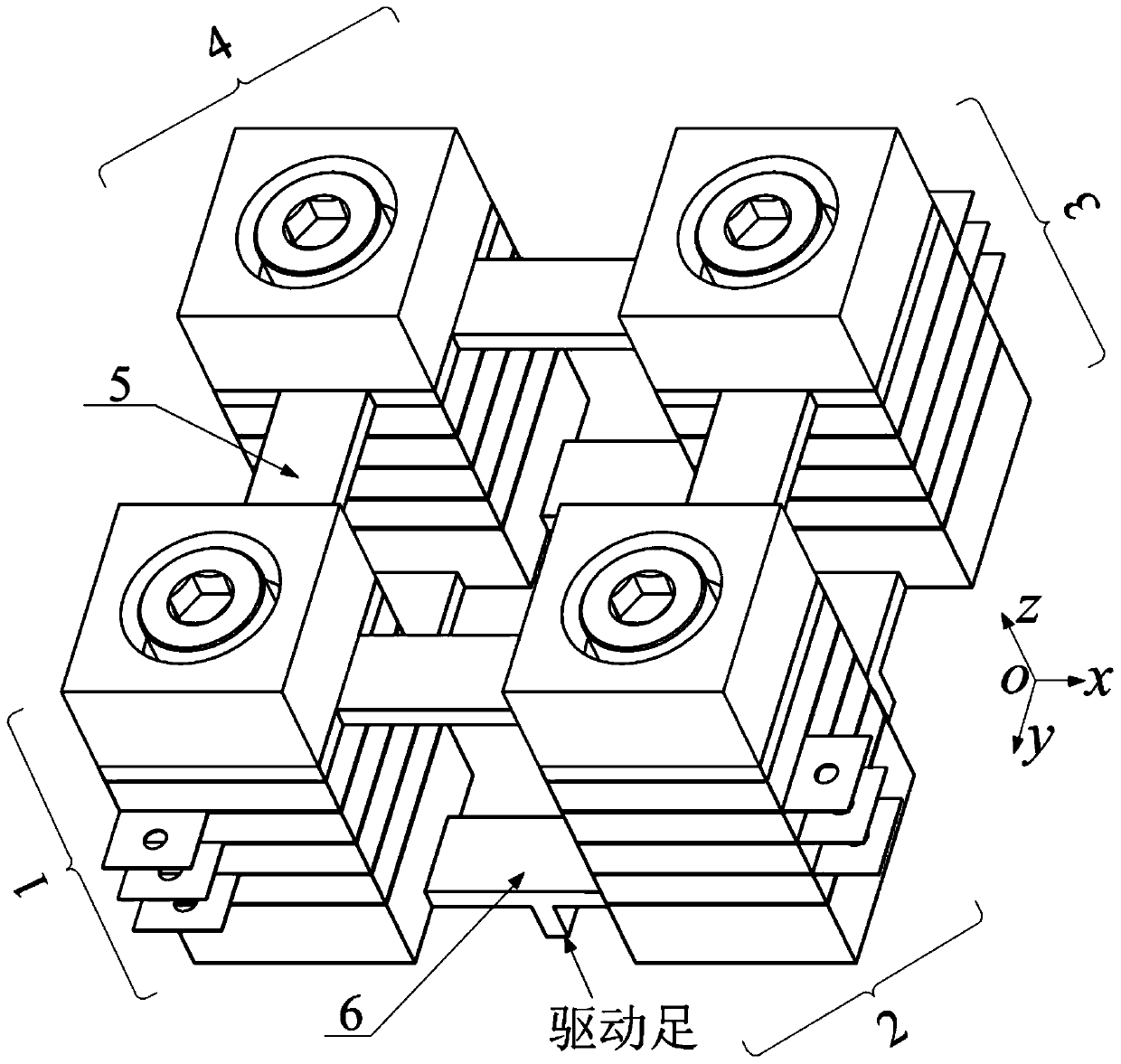

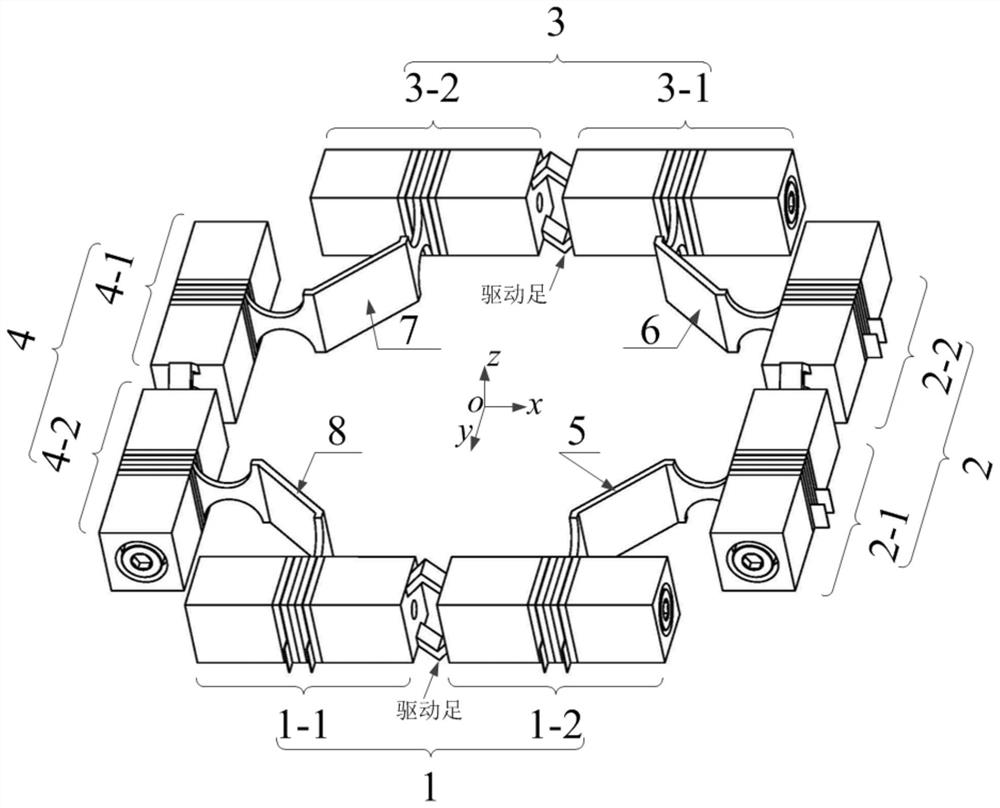

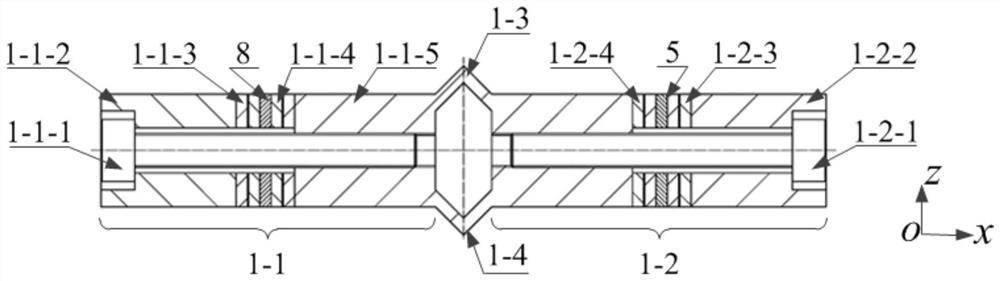

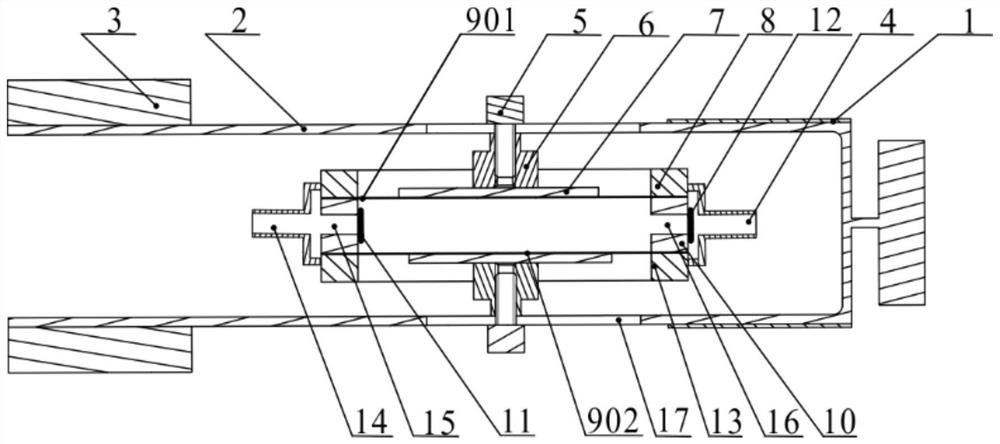

Parallel-type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and excitation method thereof

ActiveCN110661445ARealize three degrees of freedom movementPiezoelectric/electrostriction/magnetostriction machinesThree degrees of freedomTransducer

The invention relates to a parallel-type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and an excitation method thereof and belongs to the field of piezoelectric driving. The parallel-type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and the excitation method thereof can be applied to the fields of precision driving, medical treatment, micromachinery and the like. The invention aims to solve the problem that an existing three-degree-of-freedom piezoelectric self-actuating device is small in output force, high in cost and insufficient in actuating capacity. The three-degree-of-freedom piezoelectric resonance self-actuating mechanism of the invention is of a transducer parallel structure; the electric resonance self-actuating mechanism comprises four columnar piezoelectric transducers of the same structure and connecting devices of the columnar piezoelectric transducers; and the self-actuating mechanism comprises four driving feet used for combined actuation. According to the excitation method of the self-actuating mechanism, the sequential longitudinal vibration of the four columnar piezoelectric transducers is respectively excited through two-phase or four-phase voltage excitation signals according to a translation or rotation motion mode, so that the combined longitudinal vibration of the four columnar piezoelectric transducers is formed to drive the driving feet to move, and therefore, the three-degree-of-freedom actuating function of the self-actuating mechanism on a working plane is realized.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

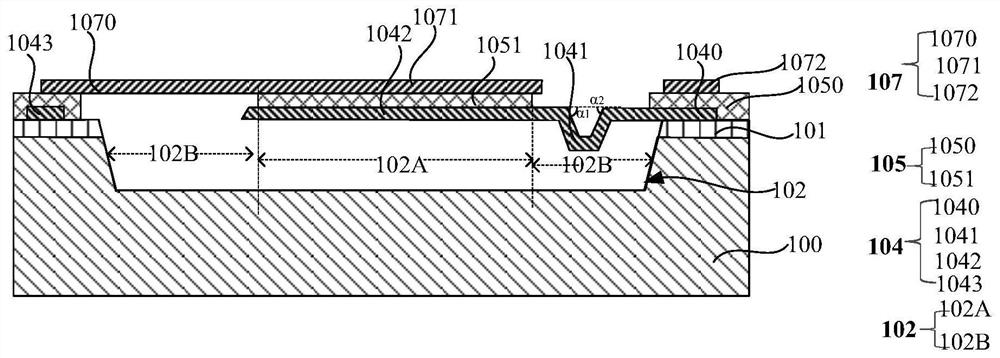

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786653AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A bottom electrode concave part and a top electrode concavepart formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that sound wave loss is reduced, the quality factor of the resonator is improved, and finally the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

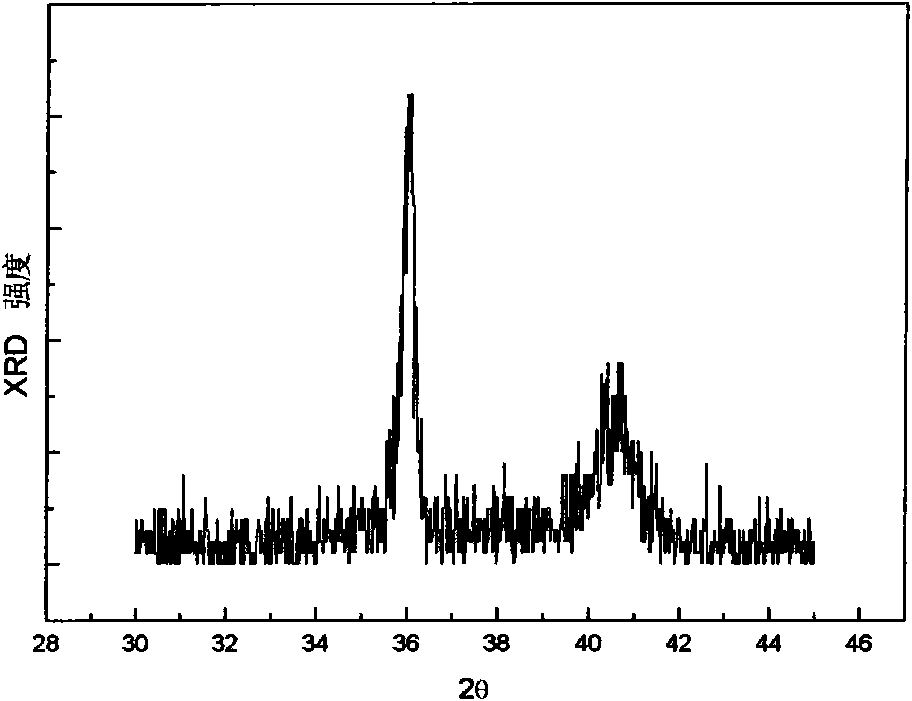

Preparation method for synthesizing crystalline/amorphous ultrafine zinc oxide (ZnO) powder at high efficiency

InactiveCN102476824ASolve overeatingResolution ratioZinc oxides/hydroxidesSodium bicarbonateUltraviolet lights

The invention belongs to the field of fine inorganic chemical material preparation and relates to a preparation method for synthesizing crystalline / amorphous ultrafine zinc oxide (ZnO) powder at high efficiency. The invention improves the method of preparing ZnO by high temperature pyrolysis of Zn(OH)2 based on sol-gel method. In the invention, solid-state zinc salt and sodium bicarbonate are mixed at a given proportion, and then thermal decomposition is carried out at a given temperature to prepare ultrafine ZnO powder. Amorphous / crystalline ZnO can be synthesized according to decomposition temperature. The inventive preparation method for synthesizing crystalline / amorphous ultrafine ZnO powder at high efficiency by solid-phase low-temperature thermal decomposition involves simple equipment, and has simple operation, low cost, and high yield (95% or higher). The prepared crystalline ZnO has a uniform particle size which can be well controlled within 10-50 nm, and the prepared amorphous ZnO has strong ultraviolet emission. The invention can find wide application in electronic, daily chemical, building material, painting and rubber products, and further find wide application in chemical sensors, high-frequency piezoelectric resonant cavities, photocells, ultraviolet light emitting devices, etc., as electronic material, and is an important fine chemical material.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

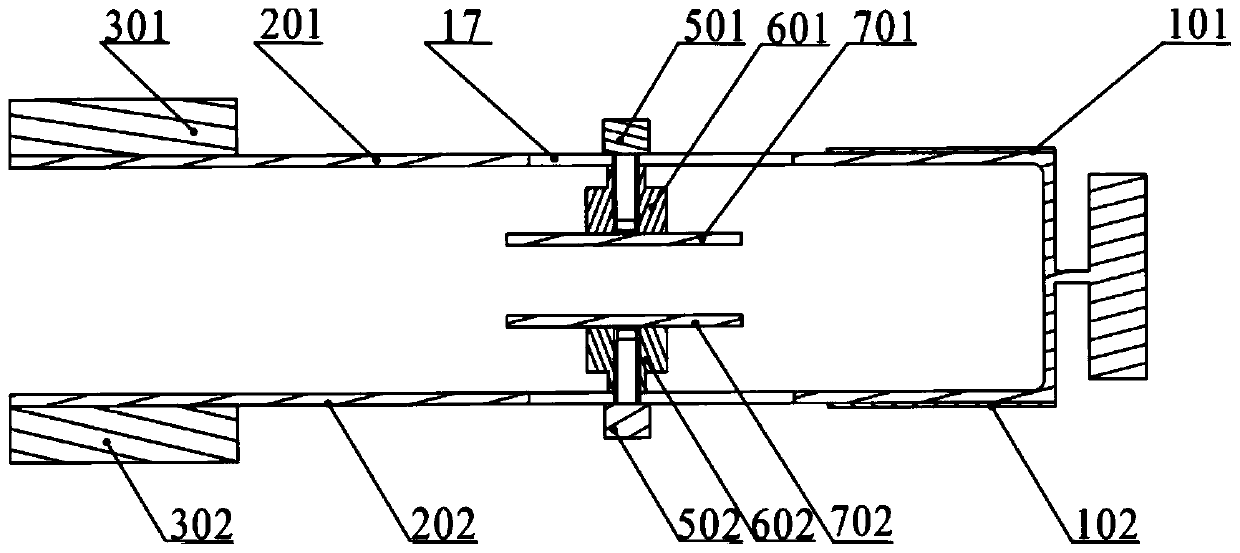

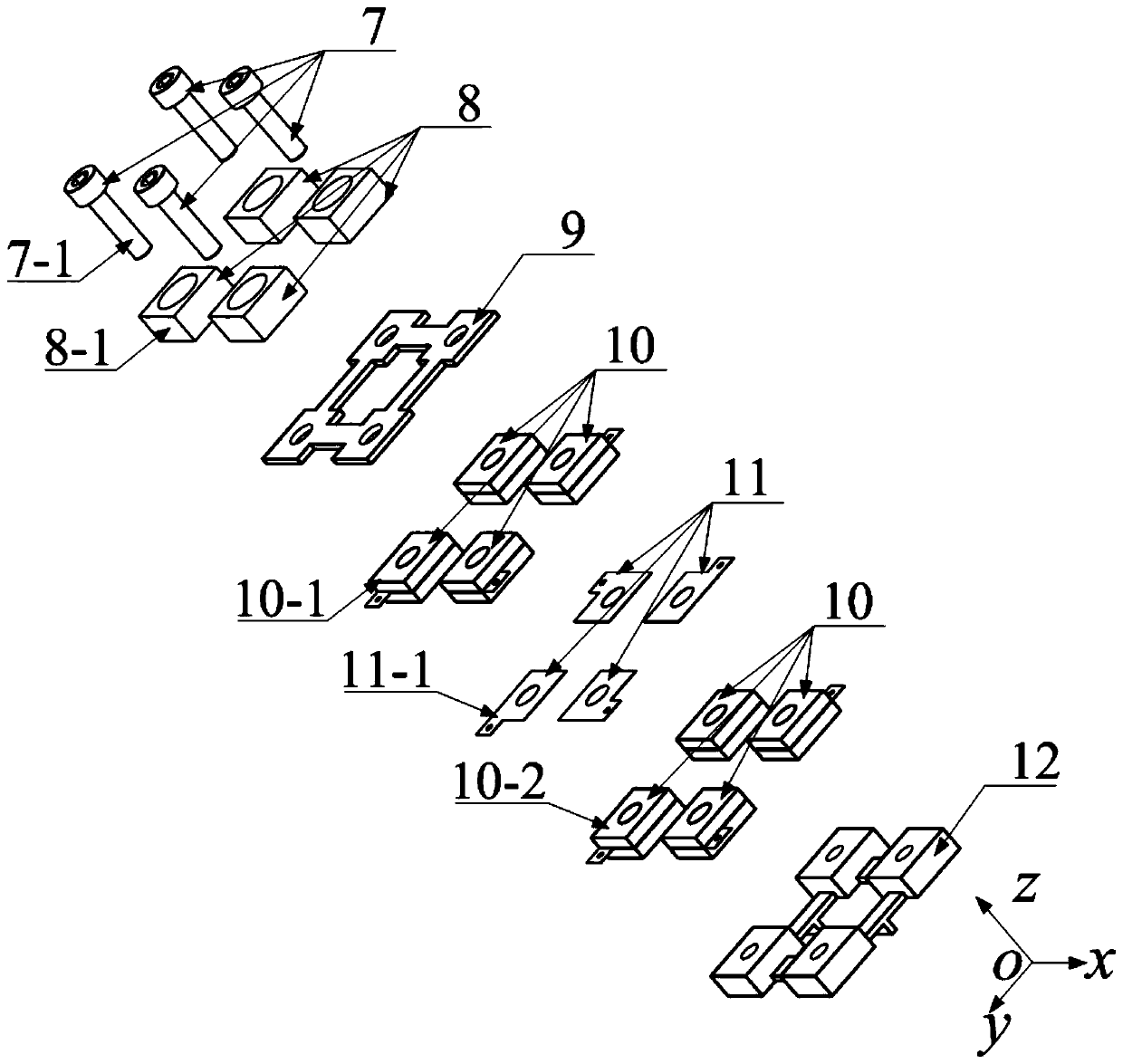

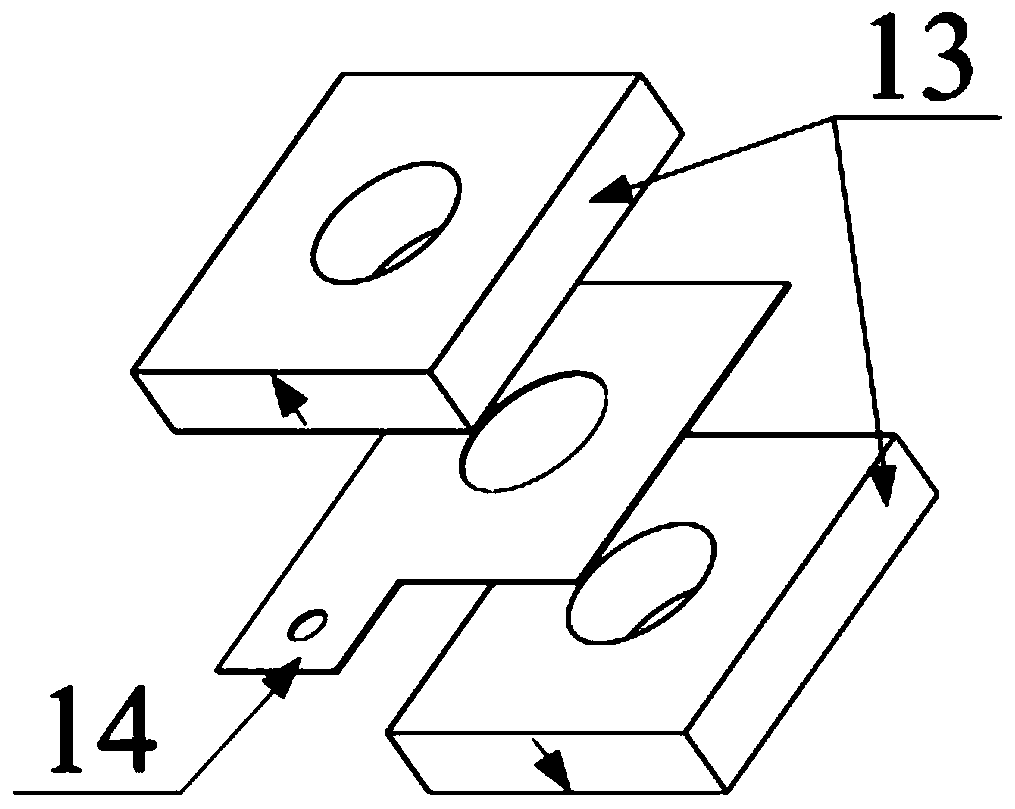

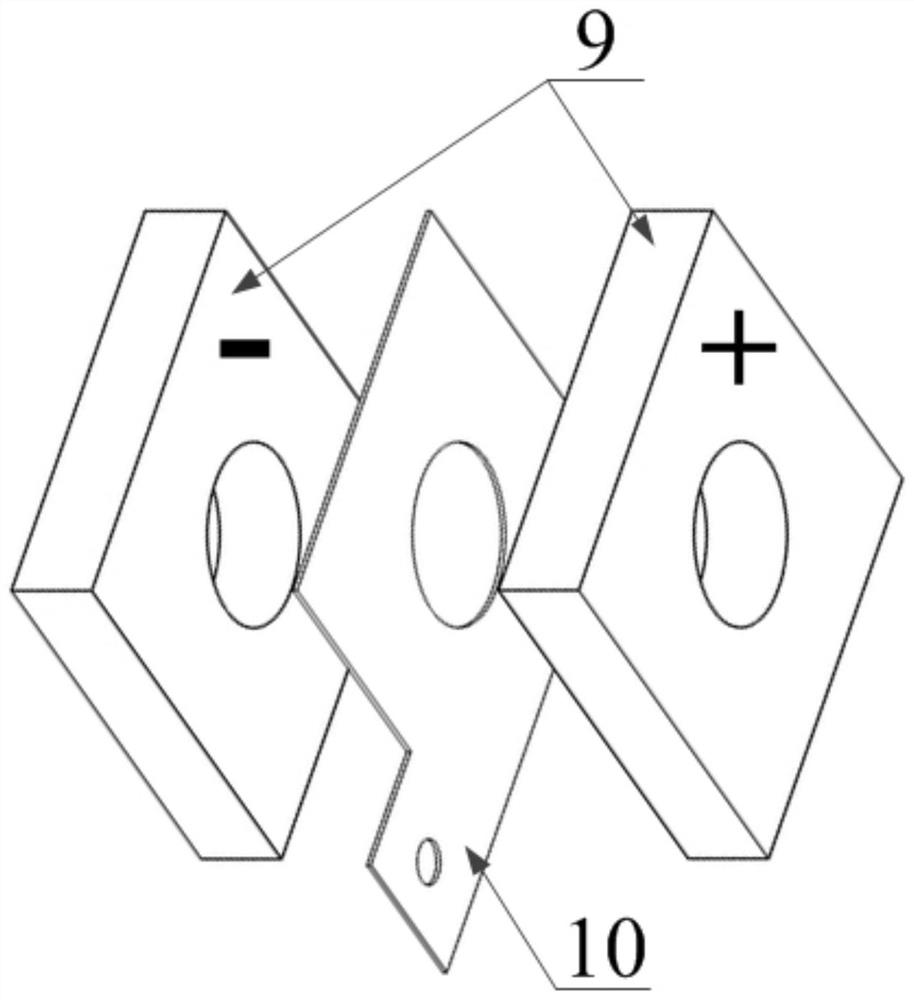

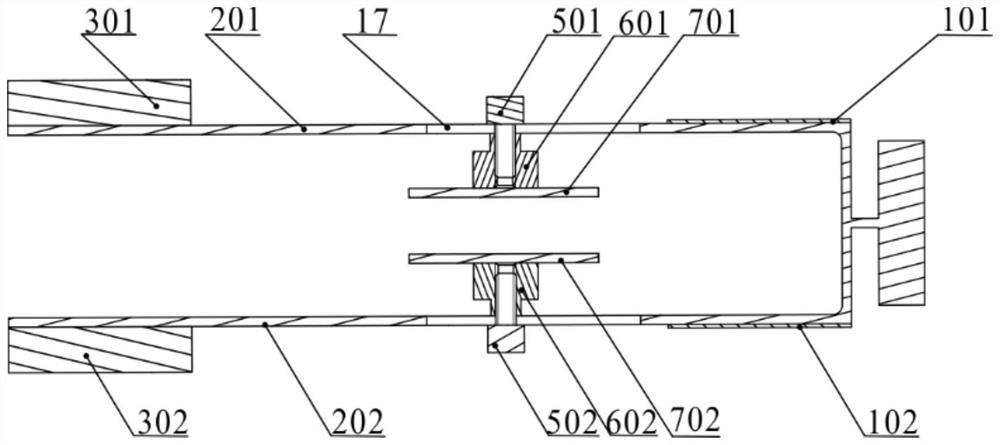

Frame type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and excitation method thereof

PendingCN112217415AProgramme-controlled manipulatorPiezoelectric/electrostriction/magnetostriction machinesTransducerPiezoelectric resonance

The invention relates to a frame type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and an excitation method thereof, belongs to the field of piezoelectric driving, and themechanism and the excitation method thereof can be applied to the fields of precision driving, medical treatment, micromachinery and the like. The invention aims to solve the problems that an existingthree-degree-of-freedom piezoelectric self-actuating device is small in output force, high in cost and insufficient in actuating capacity. The three-degree-of-freedom piezoelectric resonance self-actuating mechanism is of a frame type structure, the electric resonance self-actuating mechanism comprises four sets of series columnar piezoelectric transducers of the same structure and connecting devices of the series columnar piezoelectric transducers, and each set of series columnar piezoelectric transducers can be regarded as being composed of two columnar longitudinal vibration transducers connected through two triangular beams. According to the excitation method of the self-actuating mechanism, longitudinal vibration of the four sets of series columnar piezoelectric transducers is excited through two-phase voltage excitation signals, and the three-degree-of-freedom actuating function of the self-actuating mechanism on the plane is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

High precision sample rotating stage device based on atomic force microscope

ActiveCN112630472BAchieve positioningRealize self-lockingScanning probe microscopyRotary stageSample rotation

The invention relates to a high-precision sample turntable device based on an atomic force microscope, which includes a turntable main body, a sample mounting seat on the turntable main body, and a magnetic base for fixing the turntable main body; the turntable main body passes through the The magnetic base is fixed on the platform of the atomic force microscope scanner; the main body of the rotating stage includes a sample stage, a magnetic rotary encoder and two elliptical piezoelectric resonant motors. A plastic ring is fixed on the side of the sample stage, and the top of the elliptical piezoelectric resonant motor is connected to The plastic ring is in close contact, and two elliptical piezoelectric resonant motors are installed opposite to each other, one is used to push the plastic ring to move, and the other is used to pull the plastic ring to move in the opposite direction; the disk of the magnetic rotary encoder is installed on the sample stage. The device of the invention is suitable for providing high-precision angle rotation for samples under the condition of limited size space and limited weight of the atomic force microscope, which broadens the application occasion and research scope of the atomic force microscope.

Owner:DONGHUA UNIV

Bulk acoustic wave resonator, manufacturing method thereof, filter and radio frequency communication system

PendingCN111786650AHigh quality factorImprove performanceImpedence networksCommunications systemEngineering

The invention provides a bulk acoustic wave resonator, a manufacturing method thereof, a filter and a radio frequency communication system. A top electrode concave part formed on the periphery of a piezoelectric resonance layer and suspended above a cavity can prevent transverse waves generated by the piezoelectric resonance layer from being transmitted to the periphery of the cavity and reflect the transverse waves back to an effective working area, so that the sound wave loss is reduced, the quality factor of the resonator is improved, and finally, the performance of a device can be improved. Furthermore, the overlapping parts of a bottom electrode overlapping part and the cavity and the overlapping parts of a top electrode overlapping part and the cavity are suspended, and the bottom electrode overlapping part and the top electrode overlapping part are mutually staggered, so that a parasitic parameter can be greatly reduced, the problems of electric leakage, short circuit and the like can be avoided, and the reliability of the device can be improved.

Owner:NINGBO SEMICON INT CORP

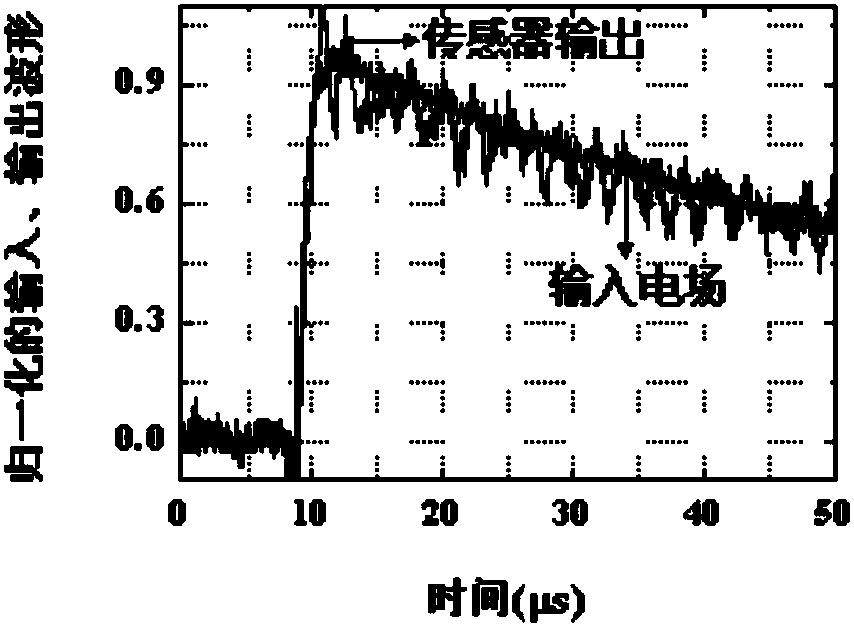

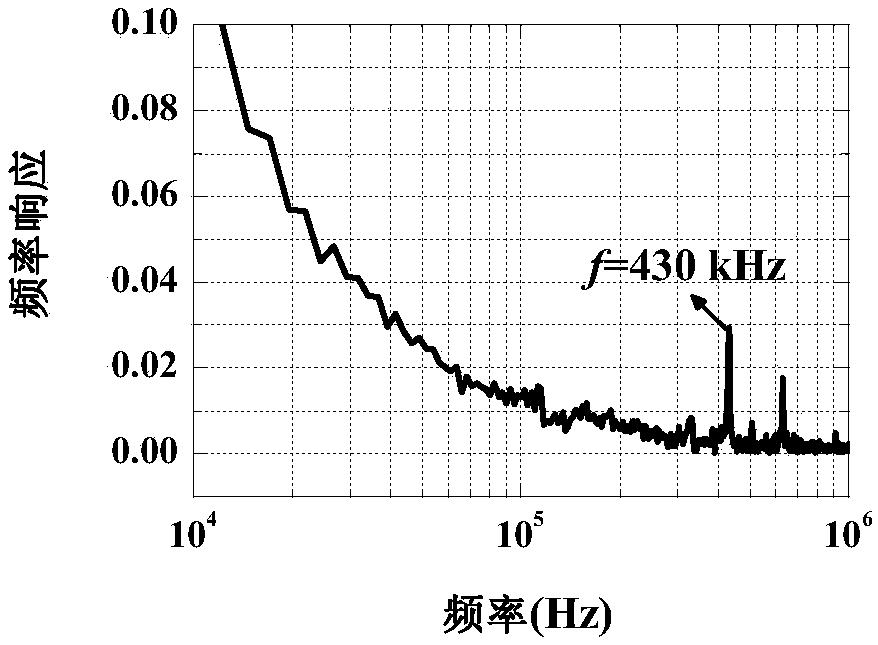

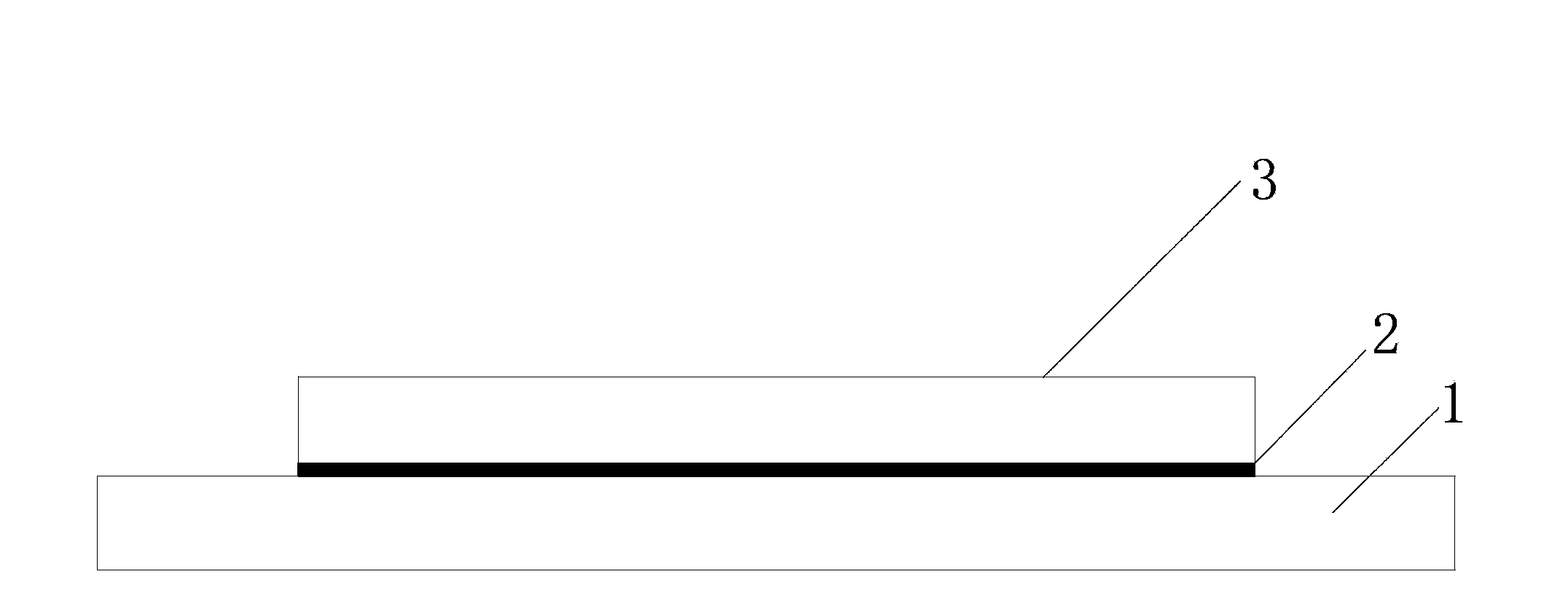

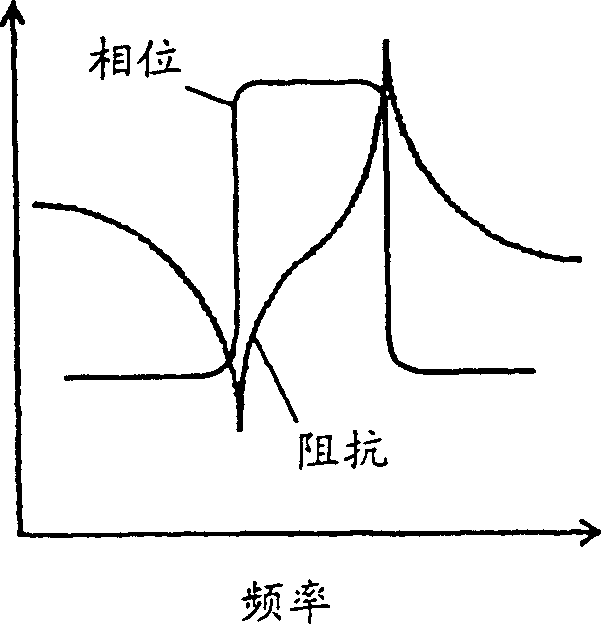

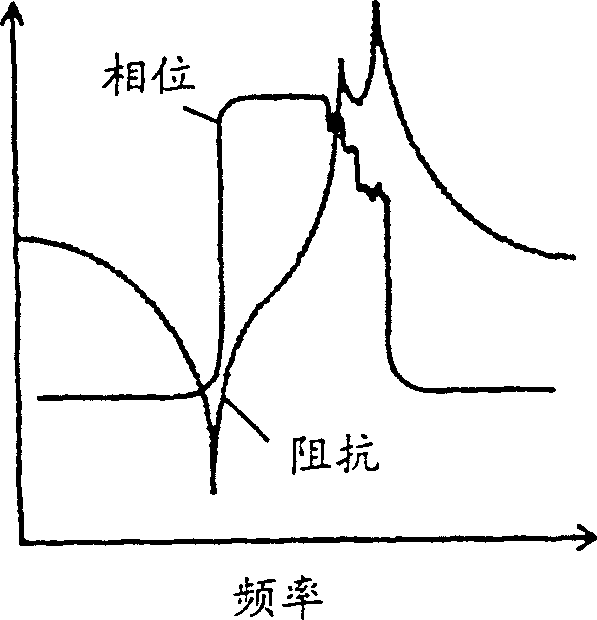

Manufacture method of optical voltage/electric field sensor wafer capable of suppressing piezoelectric resonance

InactiveCN108428788ASuppression of Piezoelectric Resonance PhenomenaSuppression of piezoelectric resonancePiezoelectric/electrostrictive device manufacture/assemblyResonant energyElectric field sensor

The invention discloses a manufacture method of an optical voltage / electric field sensor wafer capable of suppressing piezoelectric resonance and belongs to the optical voltage / electric field sensor technical field. According to one embodiment of the invention, a value in a set range is selected for the width of the wafer, and therefore, the resonant fundamental frequency of an optical voltage / electric field sensor composed of the wafer can be transferred to be a frequency outside a frequency range required to be measured; according to another embodiment of the invention, the width of the wafer is set to change gradually, so that the resonant energy of the optical voltage / electric field sensor composed of the wafer can be dispersed. The optical voltage / electric field sensor composed of thewafer prepared by the method of the invention effectively suppresses a piezoelectric resonance phenomenon under a condition of a set electric field frequency. The method is simple in operation and easy to implement.

Owner:TSINGHUA UNIV

Curing Process of Piezoelectric Ceramic Buzzer

ActiveCN102729577BFast curingEven by forceLamination ancillary operationsLaminationScreen printingPiezoelectric resonance

The present invention relates to a curing process for a piezoelectric ceramics buzzing sheet in a buzzer. According to the curing process, a metal sheet is placed on a sheet suction mold, the sheet suction mold adsorbs the metal sheet, and silk-screen printing is adopted to print an anaerobic glue onto the upper surface of the metal sheet; a piezoelectric resonance sheet is placed on the metal sheet, and is bonded on the metal sheet through the anaerobic glue; the metal sheet and the piezoelectric resonance sheet bonded on the metal sheet are removed from the sheet suction mold, and are packaged by adopting a vacuum package bag; the vacuum package bag filled with the metal sheet and the piezoelectric resonance sheet is placed in ultra-high hydrostatic hydraulic equipment to carry out pressing curing, wherein the pressure of ultra-high hydrostatic hydraulic pressure is more than or equal to 120 MPa, and a pressure keeping time is 3-5 minutes; and the vacuum package bag is removed from the ultra-high hydrostatic hydraulic equipment, and is unpacked, the metal sheet and the piezoelectric resonance sheet are firmly bonded, and the curing process is completed. According to the present invention, the force applying on the product is uniform, the bonding force is stable and reliable, the curing time is short, the production efficiency is improved, the product is not deformed, and the frequency consistency is good.

Owner:BESTAR HLDG

Piezoelectric resonance element

InactiveCN1236555CImpedence networksPiezoelectric/electrostrictive device detailsOptoelectronicsPiezoelectric resonance

Owner:MURATA MFG CO LTD

A Resonant Piezoelectric Pump Working at Power Frequency

ActiveCN110094329BDriver forExtended service lifeFlexible member pumpsPositive-displacement liquid enginesPump chamberInlet valve

The invention provides a resonant piezoelectric pump working at power frequency, which belongs to piezoelectric resonance devices. It includes an excitation system composed of piezoelectric ceramics, tuning fork vibrator, mass block, bolts, connectors, oval connecting pieces, upper pump body, intermediate body, lower pump body, pump cavity membrane, inlet valve, outlet valve, The pump body is composed of inlet tube plate and outlet tube plate. Driven by a commercial frequency power supply, the piezoelectric vibrator bends and deforms to produce a periodically changing inertial impact force, which acts on the membrane of the pump cavity through the connector and the elliptical connecting piece, thereby realizing the directional drive of the fluid.

Owner:HEFEI UNIV OF TECH +1

Integrated structure of crystal resonator and control circuit and integration method thereof

The invention provides an integrated structure of a crystal resonator and a control circuit, and an integration method thereof. A lower cavity is formed in a device wafer on which a control circuit isformed, an upper cavity is formed in a substrate, and the device wafer and the substrate are bonded by using a bonding process, so that a piezoelectric resonance piece is clamped between the device wafer and the substrate, and the integrated arrangement of a crystal resonator and the control circuit is realized. Moreover, the semiconductor chip can be further bonded to the back surface of the same device wafer, so that the integration level of the crystal resonator is further improved, and parameters of the on-chip modulation crystal resonator are realized. Compared with a traditional crystalresonator, the crystal resonator has the advantages that the size is smaller, the power consumption of the crystal resonator can be reduced, the crystal resonator can be integrated with other semiconductor components more easily, and therefore the integration degree of the device can be improved.

Owner:NINGBO SEMICON INT CORP

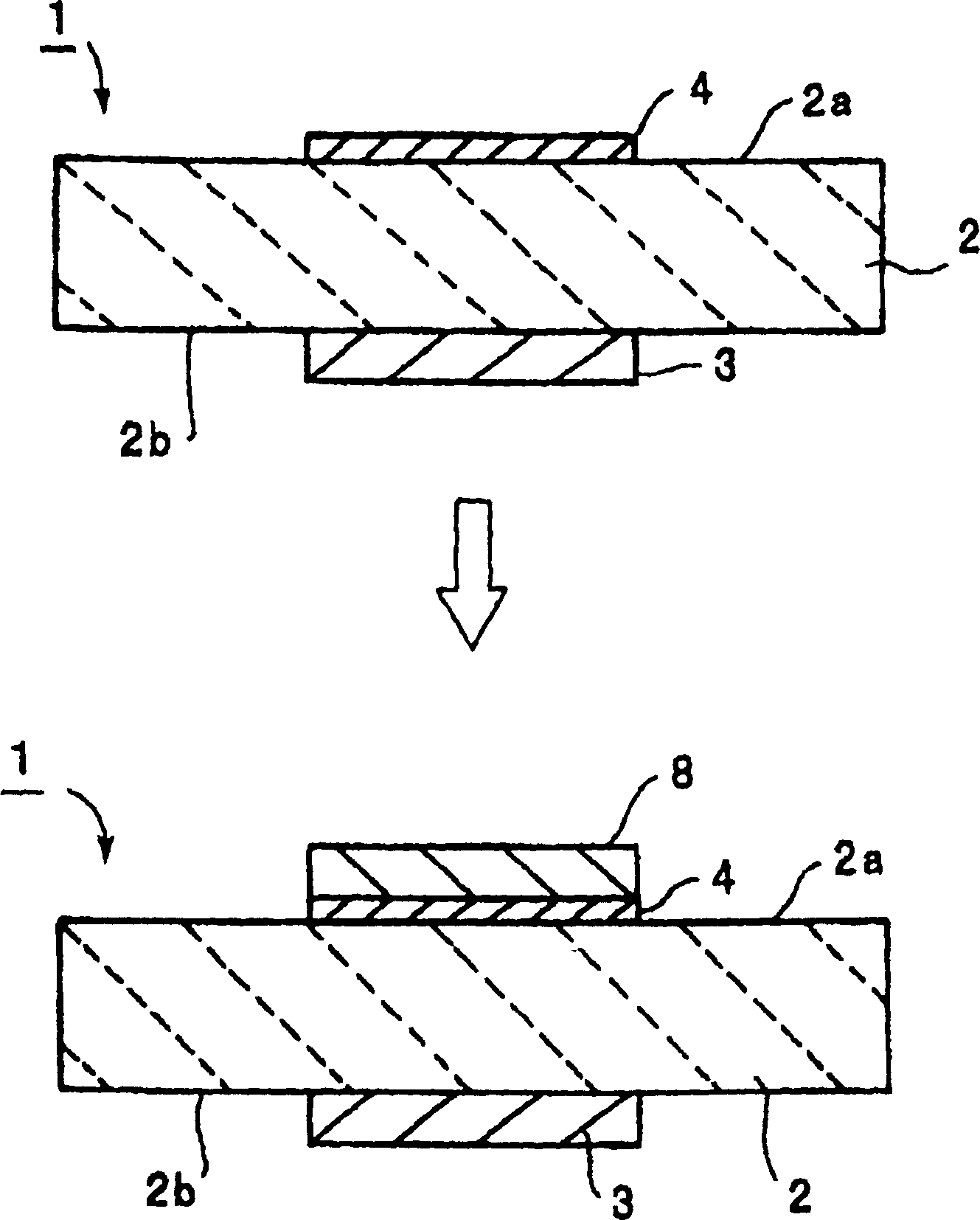

Method for adjusting frequency of piezoelectric resonator

InactiveCN1164028CImpedence networksPiezoelectric/electrostrictive devicesPiezoelectric resonancePiezoelectric resonators

A method of adjusting a frequency of an energy-trap type piezoelectric resonance element includes the steps of preparing a piezoelectric resonance element including first and second vibration electrodes formed partially on both of the main surfaces of a piezoelectric plate, the thickness of the first vibration electrode being larger than that of the second vibration electrode, and modifying the first vibration electrode or the second vibration electrode in such a manner that the thicknesses of the first and second vibration electrode electrodes are substantially equal to each other such that the piezoelectric resonance element has a desired frequency.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com