Frame type three-degree-of-freedom piezoelectric resonance self-actuating mechanism and excitation method thereof

An actuation mechanism and piezoelectric resonance technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, manipulators, etc., can solve problems such as slow speed and small driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

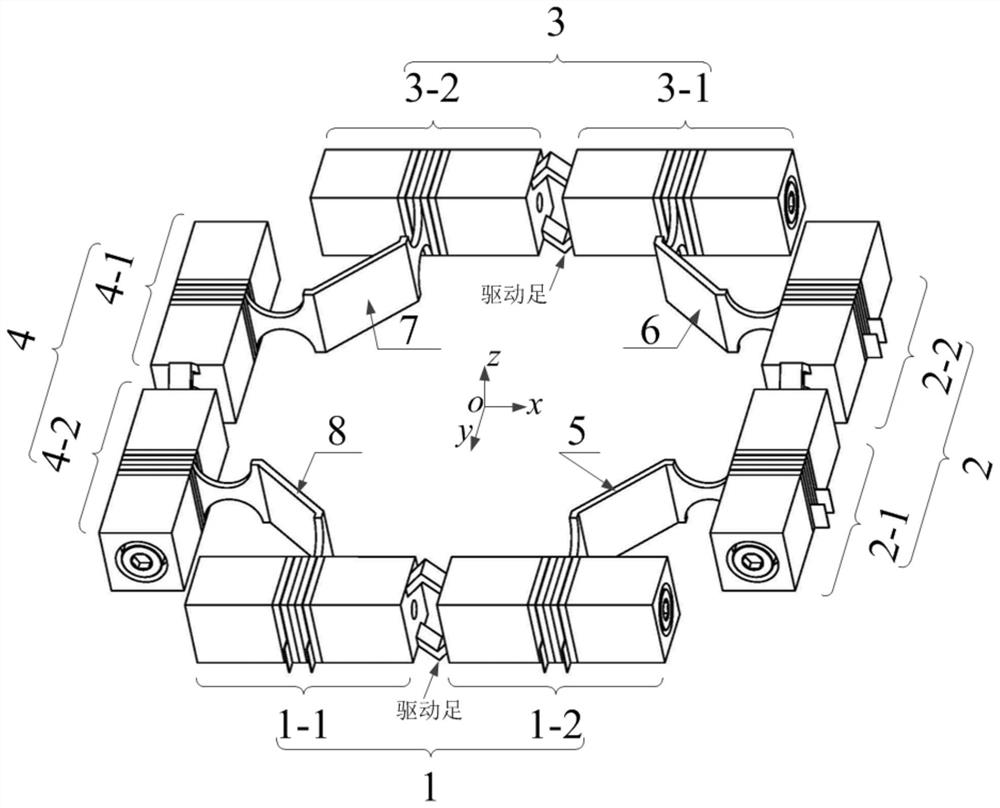

[0015] Specific implementation mode 1. Combination Figure 1-Figure 3 To illustrate this specific embodiment, the frame-type three-degree-of-freedom piezoelectric resonant self-actuating mechanism described in this embodiment includes four sets of series-type columnar piezoelectric transducers 1, 2, 3 and 4 with identical structures and their shared connecting beams 5, 6, 7 and 8,

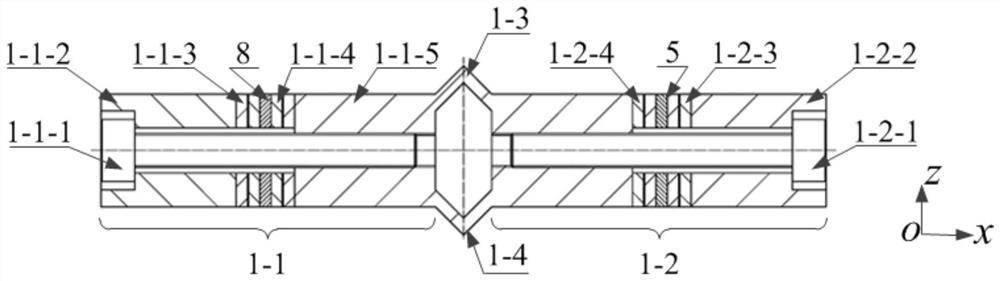

[0016] The structure of the series-type columnar piezoelectric transducer can be illustrated by taking the series-type columnar piezoelectric transducer 1 as an example, and the components included in the series-type columnar piezoelectric transducer 1 have two identical screws for fixing 1-1-1, 1-2-1, two end columns with the same structure 1-1-2, 1-2-2, four sets of piezoelectric ceramic components 1-1-3, 1-1-4, 1 -2-3, 1-2-4, two connecting beams 5, 8 and the middle beam 1-1-5, wherein the connecting beam 5 is a common part of two sets of serial columnar piezoelectric transducers 1 and 2, conne...

specific Embodiment approach 2

[0020] Specific Embodiment 2. The difference between this embodiment and the frame-type three-degree-of-freedom piezoelectric resonant self-actuating mechanism described in Specific Embodiment 1 is that two phases with a phase difference of π / 2 are provided for the columnar voltage conversion electric energy device. Periodic sinusoidal voltage signal V a , V b , the two-phase voltage signals can be V a =V m sin(ωt), V b =V m sin(ωt+π / 2), where V m Indicates the amplitude of the voltage signal, and the frequency ω of the voltage signal is close to or consistent with the first-order longitudinal vibration natural frequency of the cylindrical piezoelectric transducer to be excited.

[0021] In this embodiment, setting the working plane: first set the Cartesian rectangular coordinate system, the three axes are x, y, z respectively, o is the origin of the coordinate system, the xoy plane is selected as the horizontal working plane, and the piezoelectric resonance self-actuatin...

specific Embodiment approach 3

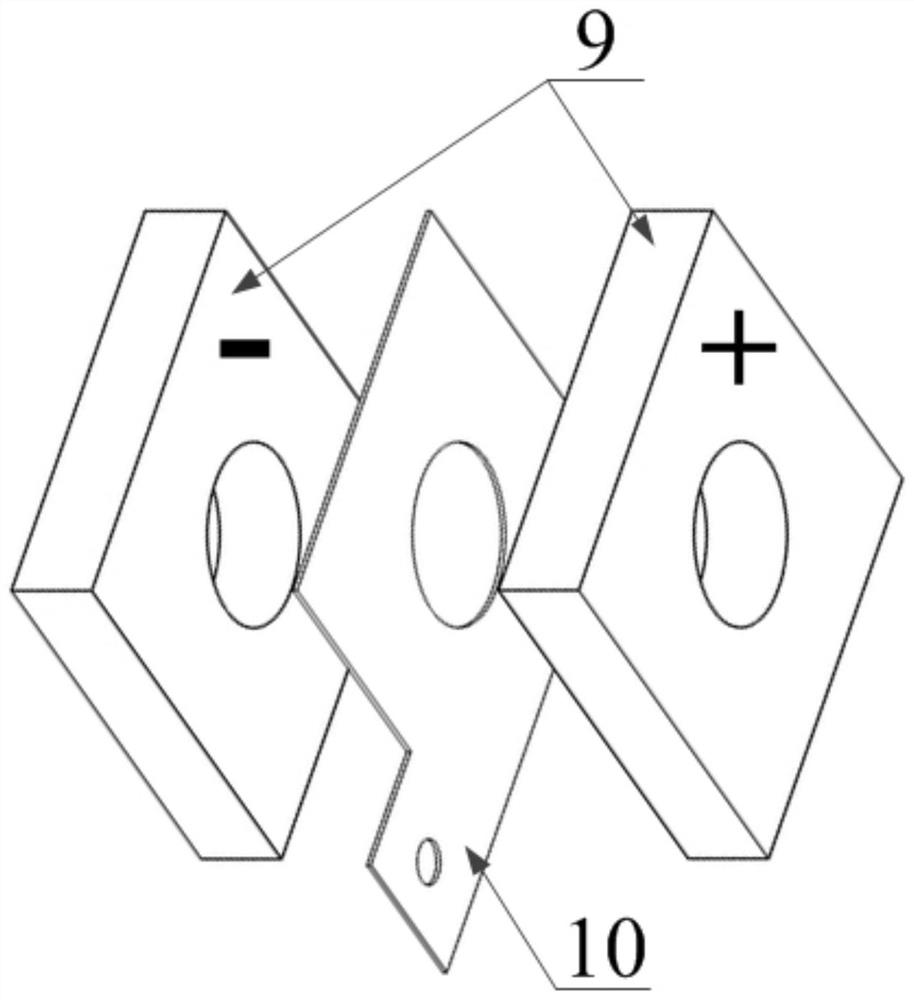

[0025] Embodiment 3. The difference between this embodiment and the frame-type three-degree-of-freedom piezoelectric resonant self-actuating mechanism described in Embodiment 1 is that each piezoelectric ceramic sheet is composed of a piezoelectric body and a pair of electrode coatings , the two coatings that make up the pair of electrode coatings are respectively located on the square surfaces on both sides of the piezoelectric body.

[0026] The piezoelectric body described in this embodiment is formed of lead zirconate titanate piezoelectric ceramics, but is not limited to lead zirconate titanate piezoelectric ceramics, and may also be formed of other piezoelectric materials such as polyvinylidene fluoride and aluminum nitride. Piezoelectric body. The electrode coating is realized by coating of appropriate metal materials such as Al, Cu, Ag, Ag-Pd alloy and the like arranged on the surface of the piezoelectric ceramic sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com