Preparation method for synthesizing crystalline/amorphous ultrafine zinc oxide (ZnO) powder at high efficiency

A technology of zinc oxide powder and amorphous state, which is applied in the field of high-efficiency synthesis of crystalline and amorphous ultrafine zinc oxide powder, can solve the problems of high supersaturation ratio of zinc hydroxide, difficult operation, etc. Achieve the effect of uniform particle size, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

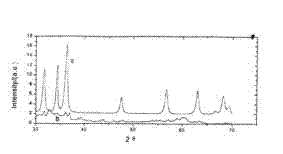

[0008] Detailed ways (a) in Fig. 1 is the present invention at 250 0 The X-ray diffraction pattern of C heat treatment, (b) is the present invention at 160 0 X-ray diffraction pattern of C heat treatment.

[0009] (a) and (b) in Fig. 2 are the present invention at 200 0 C, 250 0 C is the transmission electron micrograph of heat treatment; (c) is the present invention at 160 0 C Transmission electron microscope image of heat treatment.

[0010] (a) in Fig. 3 is the present invention at 160 0 C photoluminescence spectrum during heat treatment, (b) is the present invention at 25 0 Photoluminescence spectra during heat treatment at 0C.

Embodiment 1

[0011] Example 1: Preparation of amorphous ultrafine ZnO: Weigh 2g Zn (CH 3 COO) · 2H 2 O and ZgNHCO 3 Place in a mortar and mix thoroughly. Place the mixture on a quartz boat in a tube furnace under NZ flow at 16O O C heat treatment for 3 hours, cooling water washing, and drying the product at 90°C for 3 hours to obtain white ZnO·H 2 O 0. 86g, yield 95. 3%. The temperature in the furnace can be between 150 – 170 0 C option, the heat treatment time can be selected from 1-5 hours. At this time, amorphous ultrafine ZnO was prepared.

Embodiment 2

[0012] Example 2: Preparation of crystalline nano-ZnO: Weigh 2g Zn (CH3COO) · 2H 2 O. with 2gNHCO 3 Place in a mortar and mix thoroughly. Place the mixture on a quartz boat at N 2 Flow down in a tube furnace at 25O 0 C heat treatment for 3 hours, cooling water washing, the product 90 0 C was dried for 3 hours to obtain 0.69 g of off-white 25nm ZnO with a yield of 94%. The temperature in the furnace can be between 180 - 300 0 C option, heat treatment time can be selected from 1 - 5 hours. At this time, crystalline ultrafine ZnO was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com