Liquefied natural gas storage tank capable of preventing liquid from writhing and generating overpressure

A technology for liquefied natural gas and storage tanks, which is used in gas/liquid distribution and storage, fixed-capacity gas storage tanks, pressure vessels, etc. Resolve oversaturated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

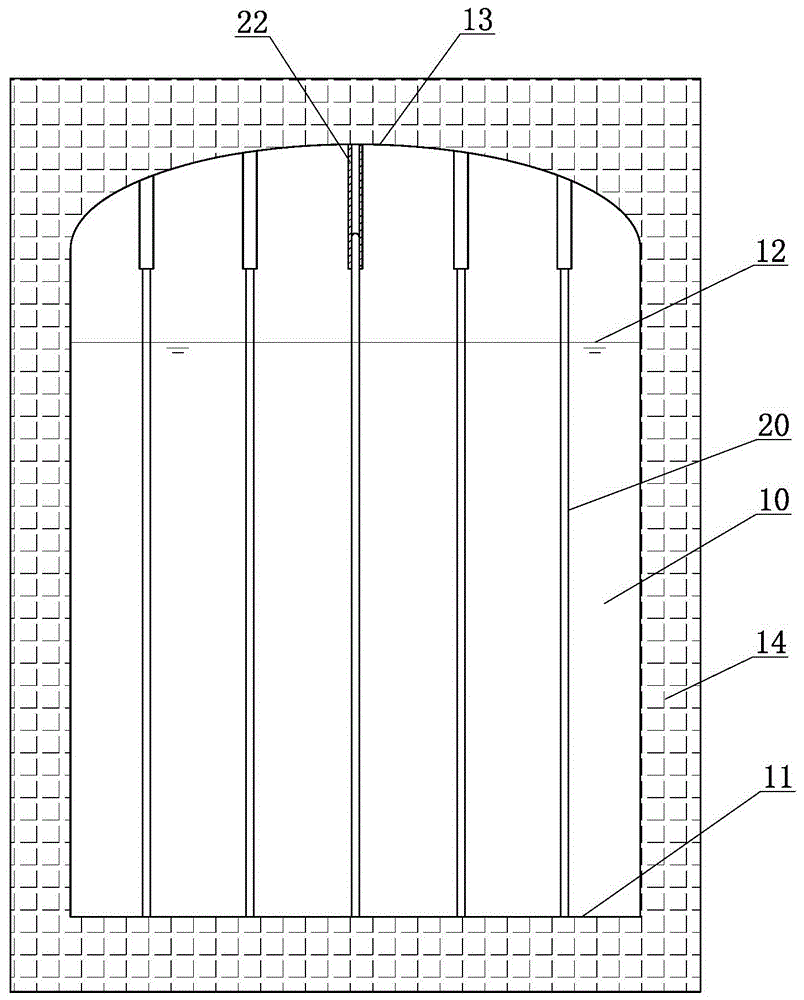

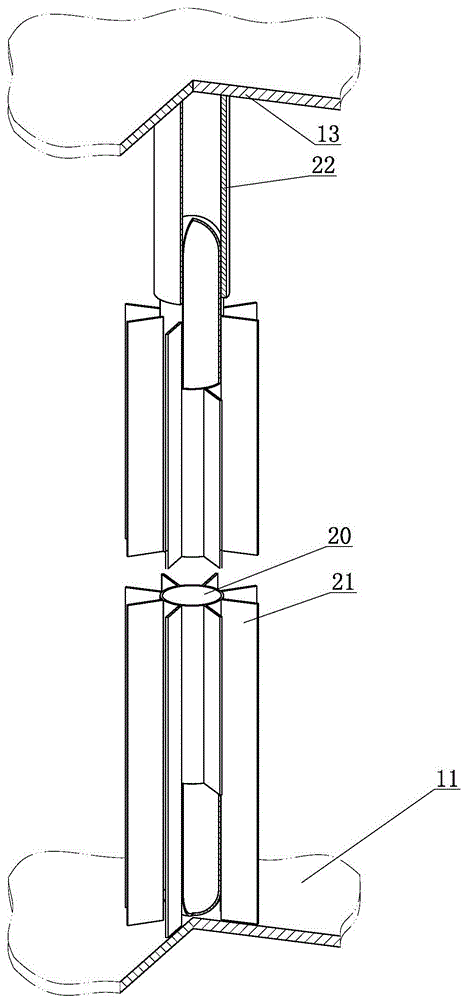

[0024] Such as Figure 1 to Figure 5 , a liquefied natural gas storage tank that prevents liquid from churning and overpressure.

[0025] The liquefied natural gas storage tank 10 of this embodiment is a circular storage tank with a diameter D of 9 meters, and an insulating layer 14 is provided around the storage tank.

[0026] There are 25 heat pipes 20 installed vertically in the liquefied natural gas storage tank.

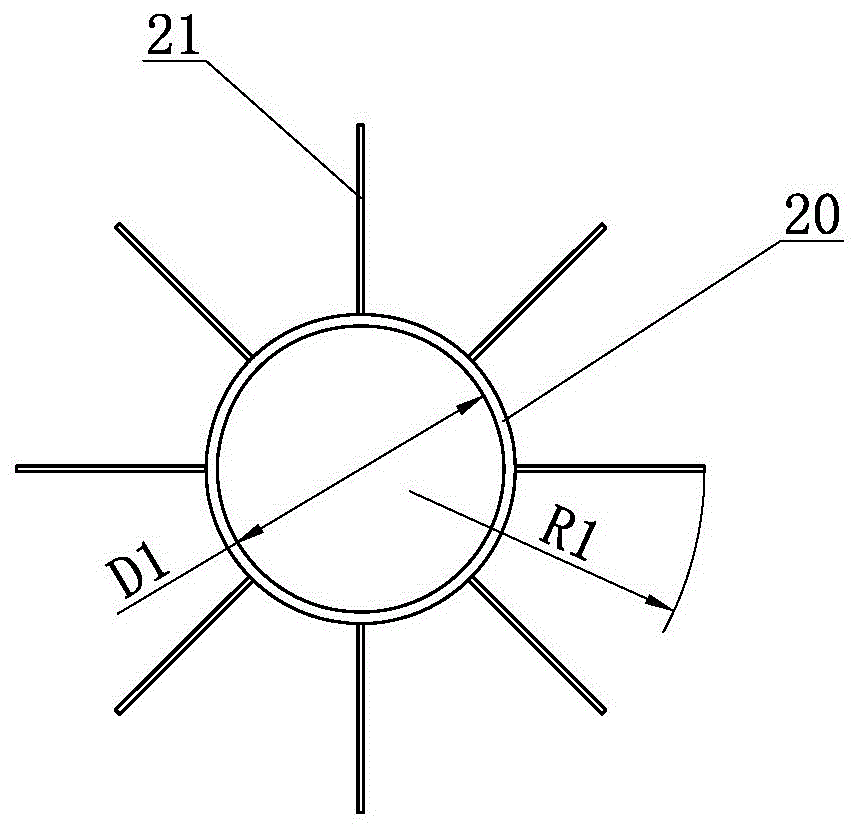

[0027] Such as figure 2 , image 3 , Figure 4 As shown, the outer diameter of the heat pipe is provided with fins 21, the diameter of the heat pipe D1=50mm, the two ends of the heat pipe are spherical to adapt to the high pressure generated inside it under normal temperature conditions, and the outer radius of the fins R1=60mm. The heat pipe is made of 304 stainless steel, and the fins are aluminum alloy fins with good thermal conductivity. The working medium inside the heat pipe is natural gas, and the pressure of the working medium in the heat pipe is 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com