Method for adjusting frequency of piezoelectric resonator

A technology of piezoelectric resonance and resonance frequency, which is applied in the field of frequency adjustment of energy-trap piezoelectric resonance components, and can solve problems such as the difference in thickness of vibration electrodes and the reduction of electrical characteristics of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

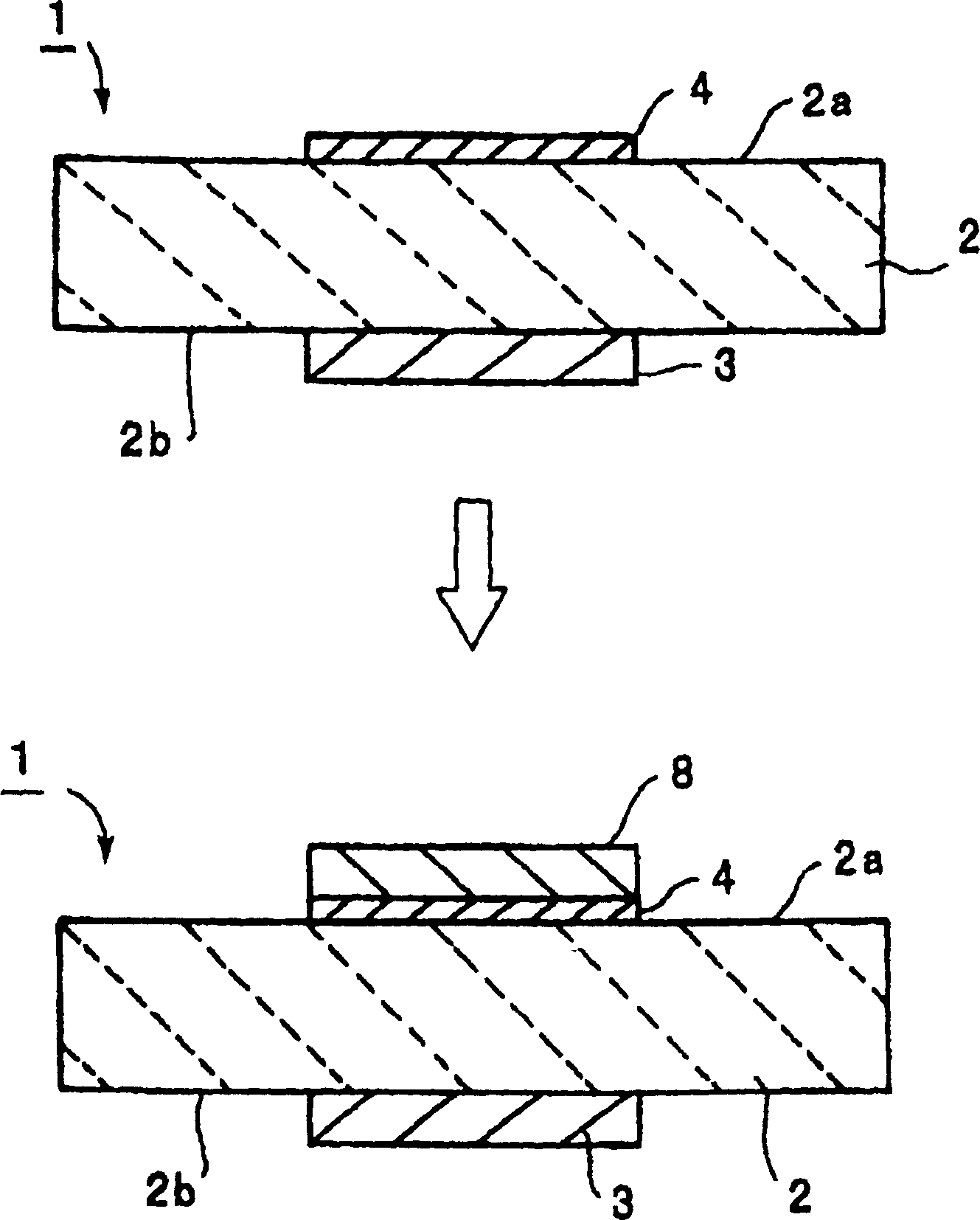

[0025] figure 1 is a cross-sectional view showing a preferred embodiment of the method of adjusting the frequency of a piezoelectric resonance element according to the present invention.

[0026] In this embodiment, an energy-trap type piezoelectric resonance element 1 is prepared. The energy-trap type piezoelectric resonant element 1 preferably includes a piezoelectric plate 2 formed from ceramics such as sphene zirconate ceramics. The first vibration electrode 3 is located on the lower surface of the piezoelectric plate 2 , and the second vibration electrode 4 is located on the upper surface of the piezoelectric plate 2 . The first and second vibrating electrodes 3 and 4 are arranged in such a manner that their front and rear surfaces face each other.

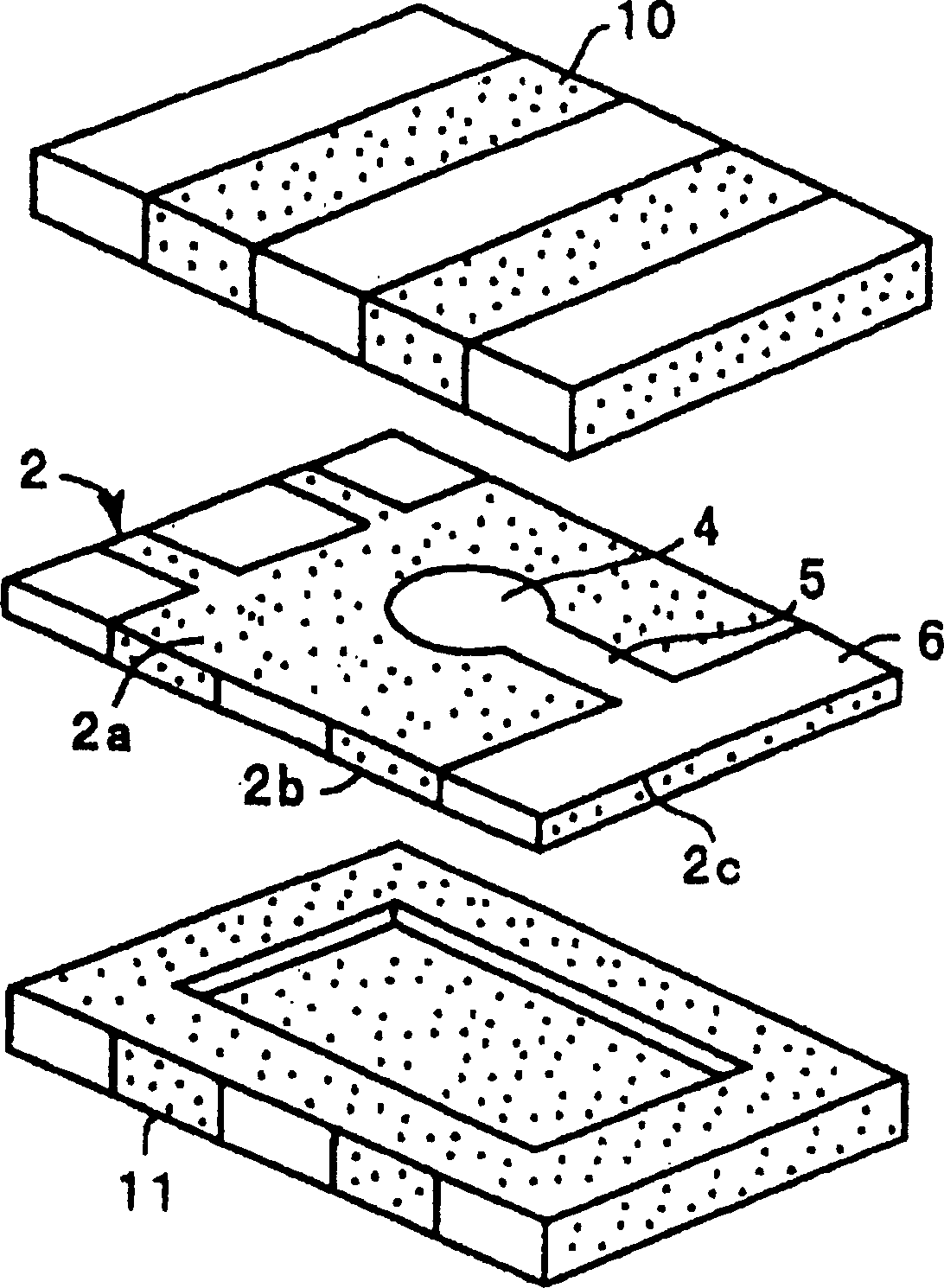

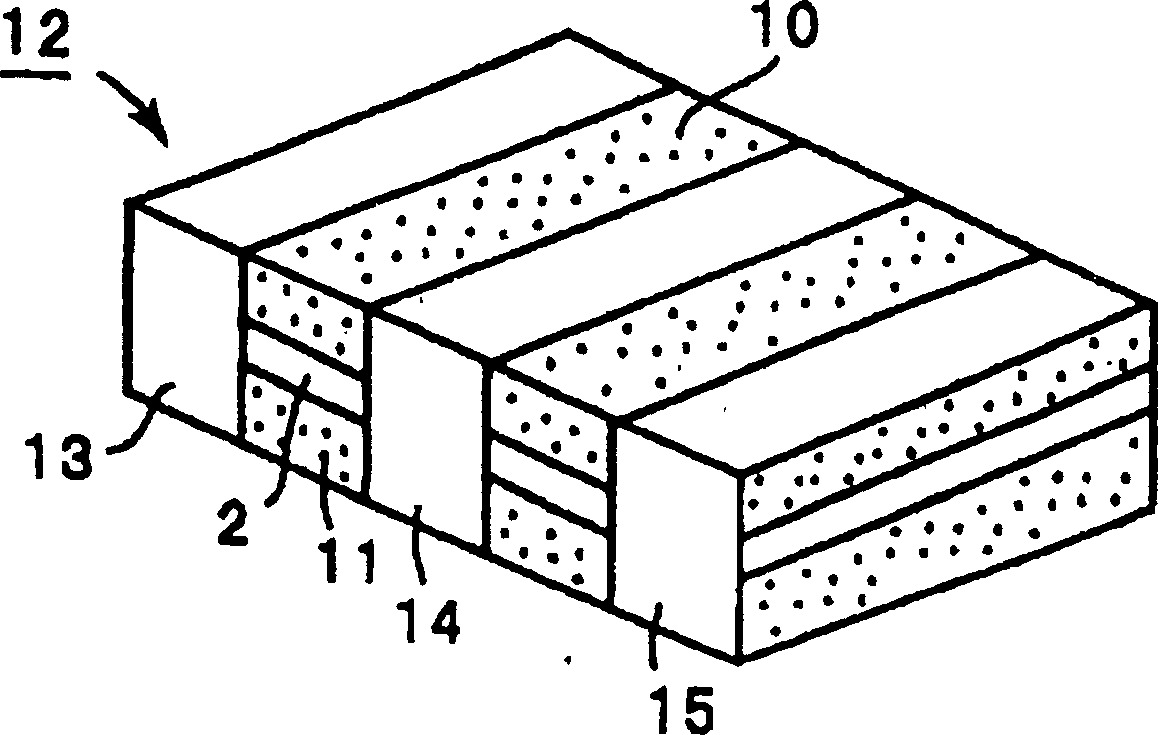

[0027] figure 1 The piezoelectric resonance element 1 is schematically shown. The piezoelectric resonant element 1 has the figure 2 in the structure. figure 2 is an exploded perspective view of the piezoelectric reson...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com