Curing process for piezoelectric ceramics buzzing sheet

A curing process, piezoelectric ceramic technology, applied in lamination, lamination device, lamination auxiliary operation, etc., can solve the problems affecting product frequency consistency, affecting the use of buzzers, low production efficiency, etc., to achieve bonding Stable and reliable force, improved production efficiency, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

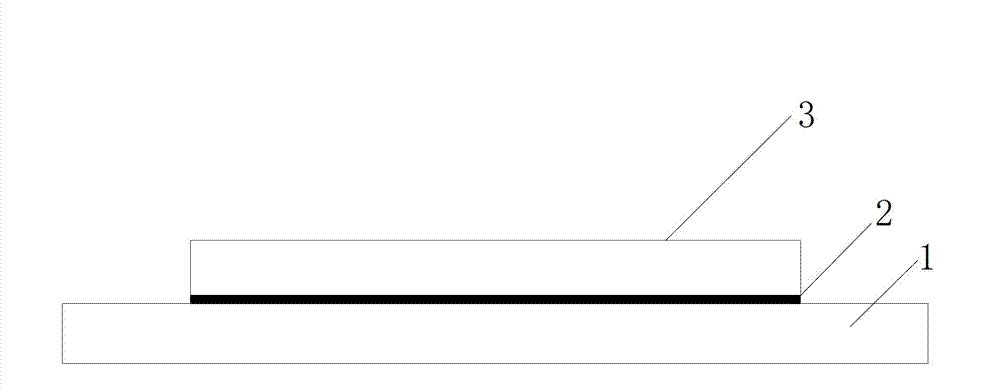

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] see figure 1 , the curing process of the piezoelectric ceramic buzzer, comprising the following steps,

[0021] Step 1. Place the metal sheet 1 on the suction sheet mold, which absorbs the metal sheet, and prints the anaerobic adhesive 2 on the upper surface of the metal sheet by screen printing; that is, install the corresponding suction sheet on the pad printing machine Die and screen, the metal sheet is put into the suction mold, and the suction mold has a vacuum adsorption through hole, so that the metal sheet can be adsorbed in the suction mold, and the screen printing area can be adjusted to make the screen printing area Basically concentric with the metal sheet, the anaerobic glue can be printed on the upper surface of the metal sheet, that is, an appropriate amount of anaerobic glue is placed on the screen, and the anaerobic glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com