Preparation method of c-axis inclined AlN thin film with homogeneous buffer layer

A technology for thin film preparation and buffer layer, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of poor controllability of c-axis inclination angle, large lattice mismatch, etc., and achieve smooth surface and structure. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

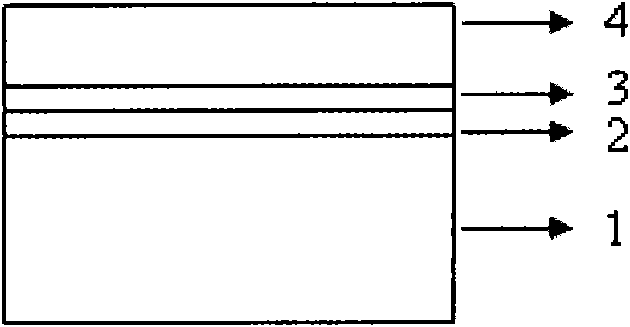

[0027] The specific steps for growing a c-axis tilted AlN film after depositing metal molybdenum (Mo) on a p-type (100) crystal-oriented Si substrate are as follows (combined with reference to the figure):

[0028] 1. Select a p-type (100) crystal-oriented Si substrate (1) deposited with a layer of 100nm metal molybdenum (2), and wash it with acetone, absolute ethanol and deionized water in sequence;

[0029] 2. Fix the Si substrate (1) on the turntable carrying the substrate holder, put it into the reaction chamber of the magnetron sputtering instrument, use 99.999% high-purity Al as the target material, and pump the reaction chamber to a vacuum degree of 0.4mPa;

[0030] 3. Introduce argon gas to make the pressure of the vacuum chamber reach 5Pa, pre-sputter the Al target for 10 minutes, remove the naturally generated oxide layer on the surface of the Al target, control the substrate temperature at 300°C, and inject N 2 , so that the air pressure in the vacuum chamber is 10P...

Embodiment 2

[0036] The specific steps for growing a c-axis tilt-oriented AlN film after depositing metal platinum (Pt) on a p-type (100) crystalline silicon substrate are as follows (combined with reference to the figure):

[0037] 1. Select a p-type (100) crystal-oriented Si substrate (1) deposited with a layer of 100nm metal platinum (2), and wash it with acetone, absolute ethanol and deionized water in sequence;

[0038] 2. Fix the Si substrate (1) on the turntable carrying the substrate holder, put it into the reaction chamber of the magnetron sputtering instrument, use 99.999% high-purity Al as the target material, and pump the reaction chamber to a vacuum degree of 0.4mPa;

[0039] 3. Introduce argon gas to make the pressure of the vacuum chamber reach 5Pa, pre-sputter the Al target for 10 minutes, remove the naturally generated oxide layer on the surface of the Al target, control the substrate temperature at 300°C, and inject N 2 , so that the air pressure in the vacuum chamber is ...

Embodiment 3

[0044] The specific steps for growing a c-axis oblique orientation AlN film after depositing metal gold (Au) on a p-type (100) crystal-oriented Si substrate are as follows (combined with reference to the figure):

[0045] 1. Select a p-type (100) crystal-oriented Si substrate (1) deposited with a layer of 100nm metal gold (2), and wash it with acetone, absolute ethanol and deionized water in sequence;

[0046]2. Fix the Si substrate (1) on the turntable carrying the substrate holder, put it into the reaction chamber of the magnetron sputtering instrument, use 99.999% high-purity Al as the target material, and pump the reaction chamber to a vacuum of 0.4mPa

[0047] 3. Introduce argon gas to make the pressure of the vacuum chamber reach 5Pa, pre-sputter the Al target for 10 minutes, remove the naturally generated oxide layer on the surface of the Al target, control the substrate temperature at 300°C, and inject N 2 , so that the air pressure in the vacuum chamber is 10Pa;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com