Chemical method for preparing organic silicon modified epoxy resin

A technology of epoxy resin and chemical method, which is applied in the direction of adhesives, etc., can solve the problems of low reaction efficiency, difficulty in compatibility, and phase separation, and achieve the effects of simple preparation process, high modification efficiency, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

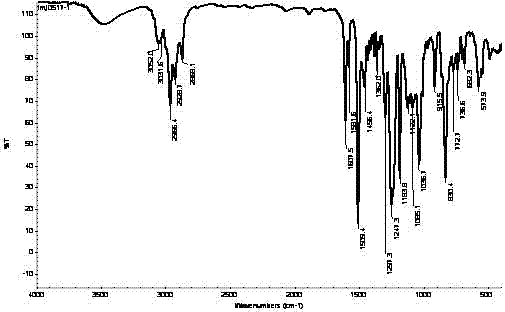

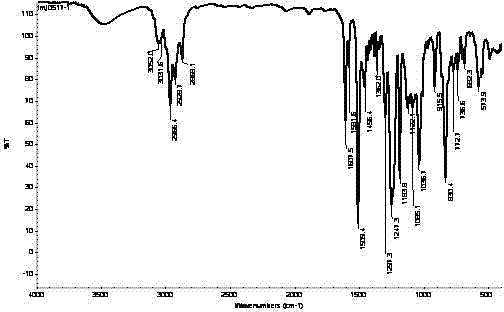

[0018] Example 1. Add 25g of hydroxyl-terminated methylphenylpolysiloxane (the mass fraction of hydroxyl group is 9.4%), 100g of bisphenol A epoxy resin E-51, and 2.0g of triphenylphosphine into a 250mL three-necked flask. After stirring evenly, heat to 120°C and react for 4h. Continue at 125°C / 10mmHg for 0.5h, and remove low boiling point compounds in vacuum to obtain a homogeneous and non-layered silicone-modified epoxy resin. The yield was 98%. From figure 1 It can be seen that 915cm -1 The absorption peak at the place is the absorption peak of the epoxy group, at 1085-1122cm -1 There is an absorption peak of Si-O-C, which proves the formation of polymethylphenylsiloxane-epoxy resin graft copolymer.

[0019] Take 50g of the prepared silicone-modified epoxy resin, add 3g of tris-(dimethylaminomethyl)phenol, mix evenly, and bond the aluminum alloy at 180°C for 2h, and the measured shear strength is 125kg / cm 2 ;After aging for 12 hours at 300℃, the measured shear stren...

Embodiment 2

[0020] Example 2. Add 40g of hydroxyl-terminated methylphenyl polysiloxane (the mass fraction of hydroxyl group is 5.6%), 100g of bisphenol F epoxy resin DER-354, and 5.0g of dibutyltin dilaurate into a 250mL three-necked flask. After stirring evenly, heat to 80°C and react for 6h. Continue at 125°C / 8mmHg for 0.5h, and remove low boiling point compounds in vacuum to obtain a homogeneous and non-separated silicone-modified epoxy resin. The yield was 97%.

[0021] Take 50g of the prepared silicone-modified epoxy resin, add 3g of tris-(dimethylaminomethyl)phenol, mix evenly, and bond the aluminum alloy at 180°C for 2h, and the measured shear strength is 143kg / cm 2 ;After aging at 300℃ for 12h, the measured shear strength is 85kg / cm 2 .

Embodiment 3

[0022] Example 3. Add 35g of hydroxyl-terminated methylphenylpolysiloxane (0.6% of the hydroxyl mass fraction), 100g of bisphenol A epoxy resin E-44, and 7.0g of tetramethylammonium hydroxide into a 250mL three-necked flask. Heated to 110°C and reacted for 5h. Continue at 125°C / 8mmHg for 0.5h, and remove low boiling point compounds in vacuum to obtain a homogeneous and non-separated silicone-modified epoxy resin. The yield was 95%.

[0023] Take 50g of the prepared silicone-modified epoxy resin, add 3g of tris-(dimethylaminomethyl)phenol, mix evenly, and bond the aluminum alloy at 180°C for 2h, and the measured shear strength is 106kg / cm 2 ;After aging at 300℃ for 12h, the measured shear strength is 59kg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com