Method for preparing methylphenylcyclosiloxane

A technology of methylphenylcyclosiloxane and polymethylphenylsiloxane, applied in the direction of silicon organic compounds and the like, can solve the problem that methylphenyldichlorosilane cannot be directly applied, restricts the application field, and is difficult to achieve high efficiency. Methylphenyldichlorosilane and other problems, to achieve the effect of low cost, expanding application field and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

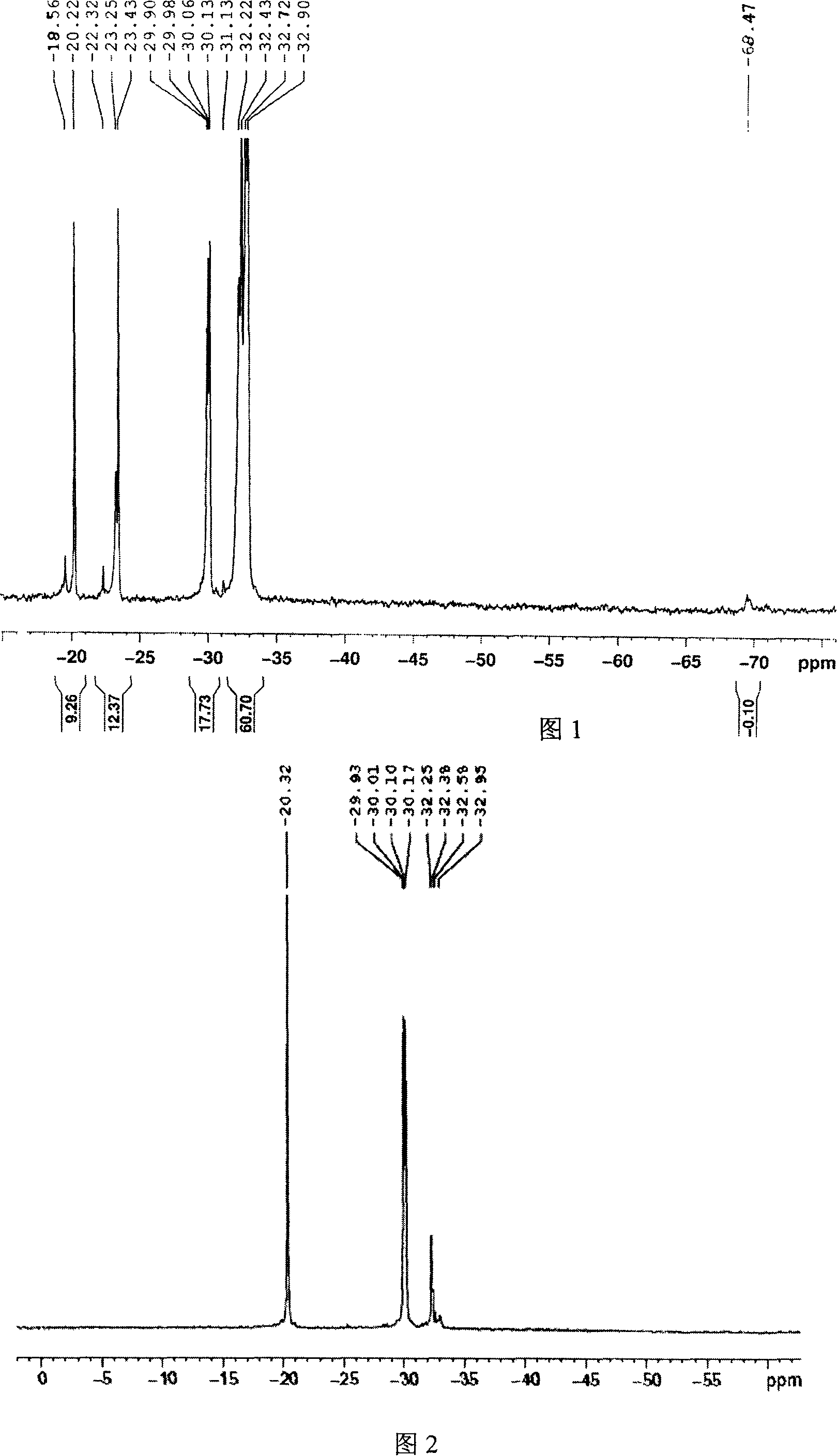

Image

Examples

Embodiment 1

[0017] Example 1. In a 1000ml flask equipped with a vacuum distillation device, add 700 grams of 10% T P Add 0.7 g of lithium hydroxide to methylphenylpolysiloxane, raise the temperature to 250° C. under 10 mmHg, and distill off a small amount of water produced by the condensation of methylphenylpolysiloxane. Raise the temperature to 350°C, increase the vacuum to 2mmHg, and collect 592 grams of distillate at 250-290°C, which is methylphenylcyclosiloxane. The yield is 94.0% of theory.

Embodiment 2

[0018] Example 2. In a 1000ml flask equipped with a vacuum distillation device, add 700 grams of 15% T P Add 38.5 grams of potassium carbonate to methylphenylpolysiloxane, heat up to 250°C under 10mmHg, and distill off a small amount of water produced by the condensation of methylphenylpolysiloxane. Raise the temperature to 350°C, increase the vacuum to 2mmHg, and collect 470 grams of distillate at 250-290°C, which is methylphenylcyclosiloxane. Yield 79.0% of theory.

Embodiment 3

[0019] Example 3. In a 1000ml flask equipped with a vacuum distillation device, add 700 grams of 10% T P Add 60.0 g of sodium carbonate to methylphenylpolysiloxane, heat up to 200°C at 7mmHg, and distill off a small amount of water produced by the condensation of methylphenylpolysiloxane. Raise the temperature to 340°C, increase the vacuum to 2mmHg, and collect 535 grams of distillate at 250-290°C, which is methylphenylcyclosiloxane. The yield is 84.9% of theory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com