Organic silicone adhesive containing nano-silver material and preparation method thereof

A technology of organic silica gel and nano-silver, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of short service life, cracking, poor durability, etc., achieve good UV resistance, prolong service life, The effect of enhancing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

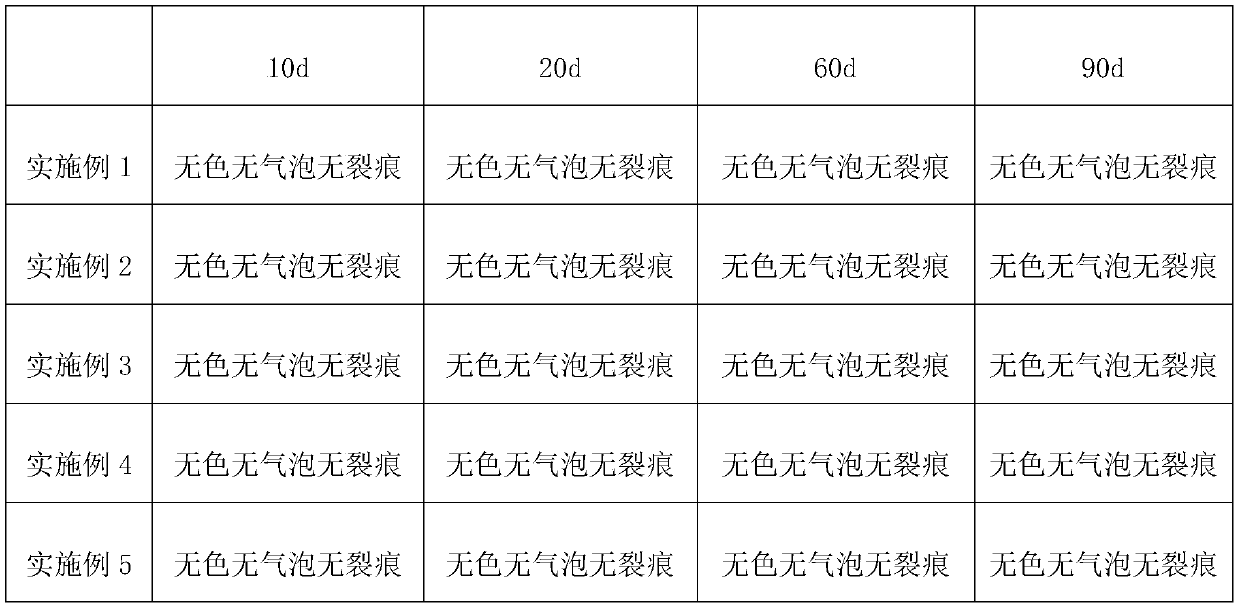

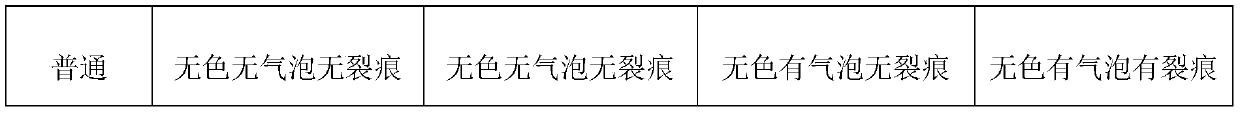

Examples

preparation example Construction

[0030] The present invention proposes a method for preparing a silicone adhesive containing nano-silver material as described above, comprising the following steps: weighing 28-55 parts of vinyl-terminated methylphenyl polysiloxane and 12-18 parts of amine compounds , 20-40 parts of terminal hydrogen-containing polysiloxane, 1-3 parts of toughening agent and 0.004-0.008 parts of platinum catalyst are added to a sealed reaction device under the protection of an inert gas, heated to 40-60 ° C, heated for 1- 2h; then add 3-6 parts of nano-silver and 1-5 parts of heat-resistant filler, stir at 40-60°C for 20-30min; then add 3-12 parts of o-hydroxybenzophenone and 1-2 parts of curing agent, continue Stir for 20-30 minutes and cool to room temperature to obtain a colorless liquid; then decompress the colorless liquid to remove air bubbles, heat and solidify at 40-80°C for 20-40 minutes to obtain a silicone adhesive.

[0031] Using the above method to prepare the silicone adhesive co...

Embodiment 1

[0034] Weigh 28 parts of 400cps terminal vinylmethylphenyl polysiloxane, 12 parts of N'N-4,4'-diphenylmethane type bismaleimide resin, and the terminal group hydrogen content is 0.01%. 20-40 parts of methyl phenyl polysiloxane, 1 part of carboxyl liquid nitrile rubber and 0.004 parts of chloroplatinic acid-tetramethyldivinyl disiloxane complex, add the sealing reaction under the protection of inert gas In the device, heat to 40°C for 1 hour; then add 3 parts of nano-silver and 1 part of benzimidazole, and stir at 40°C for 20 minutes; then add 3 parts of o-hydroxybenzophenone and 1 part of m-phenylenediamine, and continue stirring Cool to room temperature after 20 minutes to obtain a colorless liquid; then decompress the colorless liquid to remove air bubbles, and heat and solidify at 40°C for 20 minutes to obtain a silicone adhesive.

Embodiment 2

[0036] Weigh 55 parts of terminal vinylmethylphenylpolysiloxane at 2000cps, 18 parts of N'N-4,4'-diphenylmethane type bismaleimide resin, and the hydrogen content of the terminal group contains hydrogen at 0.5%. 40 parts of methyl phenyl polysiloxane, 3 parts of carboxyl liquid nitrile rubber and polysulfide rubber, 0.008 parts of chloroplatinic acid-tetramethyldivinyl disiloxane complex, under the protection of inert gas Put it into a sealed reaction device, heat to 60°C, and heat for 2 hours; then add 6 parts of nano-silver and 5 parts of benzimidazole, and stir at 60°C for 30 minutes; then add 12 parts of o-hydroxybenzophenone, triethanolamine and spirocyclic amine or 2 parts of N-(3-methyl)-N,N-dimethylurea, continue to stir for 30 minutes and cool to room temperature to obtain a colorless liquid; Under heating and curing for 40 minutes, the silicone adhesive can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com