Single-component addition-type silicone rubber and preparation method thereof

An addition type, silicone rubber technology, applied in the field of one-component addition type silicone rubber and its preparation, can solve the problems of reducing the use value of the original package, poor low temperature resistance of the silicone rubber, corrosion of the package components, etc., and achieves low cost and good quality. The effect of high temperature resistance and low temperature aging resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

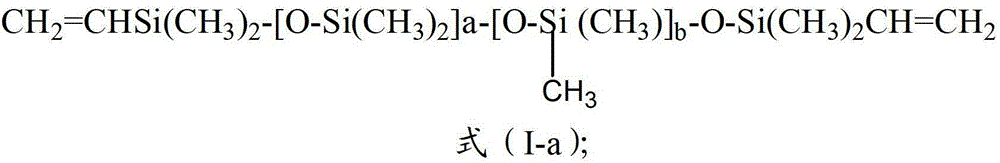

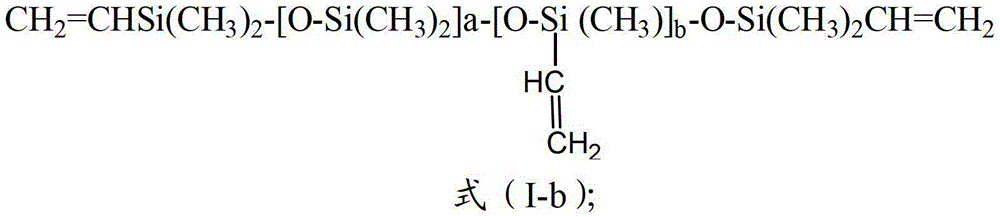

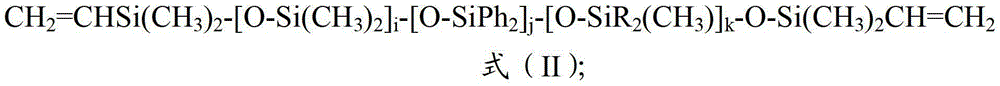

Method used

Image

Examples

preparation example Construction

[0077] The present invention also provides a preparation method of one-component addition type silicone rubber, comprising the following steps:

[0078] 20-50 parts by mass of vinyl polysiloxane, 3-18 parts by mass of vinylmethylphenylpolysiloxane, 40-70 parts by mass of filler, 2.0-10 parts by mass of additives and 0.5- 3.0 parts by mass of tackifier are mixed to obtain the first mixture;

[0079] Mixing 0.01-0.1 parts by mass of platinum catalyst, 0.3-2.5 parts by mass of inhibitor and 4-20 parts by mass of hydrogen-containing polysiloxane to obtain a second mixture;

[0080] The first mixture and the second mixture are mixed, defoamed and vulcanized to obtain a one-component addition type silicone rubber.

[0081] In the present invention, 20-50 parts by mass of vinyl polysiloxane, 3-18 parts by mass of vinylmethylphenyl polysiloxane, 40-70 parts by mass of filler, 2.0-10 parts by mass of additive Mix with 0.5-3.0 parts by mass of tackifier to obtain the first mixture. T...

Embodiment 1

[0096] Add 400g of vinyl polysiloxane (viscosity 500mPa·s, vinyl mass fraction 0.68%) to a planetary mixer with a volume of 2 liters, and then add 200g of vinylmethylphenyl polysiloxane (viscosity 400mPa·s s, vinyl mass fraction 0.55%, phenyl mass fraction 3.2%), then add 300g of quartz powder with a particle size of 5μm, 250g of alumina with a particle size of 10μm, 40g of iron oxide red and 10g of hexamethyldisilica The azane-treated fumed silica was stirred for 30 minutes under a vacuum of -0.098 MPa, then 16 g of vinyltriethoxysilane was added, and the vacuum was stirred for 60 minutes under a vacuum of -0.098 MPa, and the machine was shut down. Discharging to obtain the first mixture.

[0097] 0.2g of methylvinyl polysiloxane complexed platinum catalyst (Pt mass fraction is 5000ppm), 4.0g of ethynylcyclohexanol and 100g of hydrogen-containing polysiloxane (viscosity of 40mPa s, silicon-hydrogen bond -H mass fraction 0.38%) were uniformly mixed under the condition of vacu...

Embodiment 2

[0101] Add 400g of vinyl polysiloxane (viscosity of 1000mPa s, vinyl mass fraction 0.52%) to a planetary mixer with a volume of 2 liters, and then add 200g of vinylmethylphenylpolysiloxane (viscosity of 400mPa s, vinyl mass fraction 0.55%, phenyl mass fraction 3.2%), then add 450g of quartz powder with a particle size of 5μm, 150g of alumina with a particle size of 10μm, 80g of iron oxide red and 20g of hexamethyldisilazide The fumed silica obtained after alkane treatment was stirred for 30min under the condition of -0.098MPa in vacuum, then 20g of vinyltriethoxysilane was added, stirred for 60min under the condition of -0.098MPa in vacuum, and the material was stopped and discharged. A first mixture is obtained. 0.2g of methyl vinyl polysiloxane complexed platinum catalyst (Pt mass fraction is 5000ppm), 10g of triallyl cyanurate and 85g of hydrogen-containing polysiloxane (viscosity of 40mPa s, silicon The mass fraction of -H in the hydrogen bond is 0.38%), mixed uniformly u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com