Method of preparing methyl phenyl polysiloxane

A technology of methylphenylsilicon and methylphenyldichlorosilane is applied in the field of preparation of methylphenylsilicone resin, and can solve the problems of reduced heat resistance, easy sticking of paint films, and inability to completely overcome sticking back. , to achieve the effect of low curing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

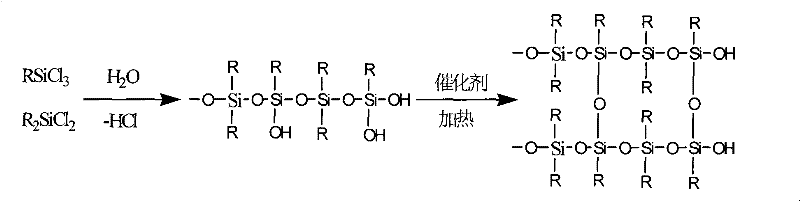

[0017] The preparation process of the present invention is as follows:

[0018] a. Add various monomers and toluene in proportion to the mixing kettle, mix evenly, add toluene and water into the reaction kettle, stir and heat up to 30-65°C, start adding the mixed monomer solution dropwise, and control the temperature at 30-65°C The dropwise addition is completed within 1.5 to 3 hours at 70°C, and then keep the temperature for half an hour to react;

[0019] b. Static layering, lower layer of acidic water;

[0020] c. Wash with hot water at 40-70°C until neutral;

[0021] d. Concentrate it to 40% to 60% (mass percentage) under high vacuum conditions and at a temperature not exceeding 60°C;

[0022] e. Adding an appropriate amount of catalyst, polycondensation reaction at a vacuum of -0.07 to -0.08MPa and a temperature of 50 to 60°C for 1 to 6 hours, and adding a corresponding amount of stabilizer to obtain a methylphenyl silicone resin.

Embodiment 1

[0024] Add 149.5g of methyltrichlorosilane, 37.5g of dimethyldichlorosilane, 38.1g of phenyltrichlorosilane and 286g of toluene into the mixing tank and mix well. Add 184g of toluene and 950g of water into the reaction kettle, stir and heat up to 65°C, start adding the mixed monomers dropwise, control the reaction temperature at 65-70°C within 3 hours, and finish the reaction for half an hour. After resting, remove the lower acidic water layer, then wash the silanol toluene solution with 65-70°C hot water until neutral, and concentrate under reduced pressure to a solid content of 60%. Take 100g of this silanol solution, add 0.03g of 10% triethylenetetraminebutanol solution as a catalyst, and then add 0.003g of acetic acid stabilizer at a vacuum degree of -0.08MPa and control the temperature at 50°C for 6 hours to obtain a viscosity of 15s (Apply 4 cups), methyl phenyl silicone resin (R / Si=1.2, Ph / R=0.1) that cures at 40°C for 1 hour and does not retack.

Embodiment 2

[0026] Add 195g of diphenyldichlorosilane, 105.8g of phenyltrichlorosilane, 81.3g of dimethyldichlorosilane, 15g of methyltrichlorosilane and 354g of toluene into the mixing tank and mix well. Add 189g of toluene and 1240g of water into the reaction kettle, stir and heat up to 30°C, start to add the mixed monomers dropwise, control the reaction temperature at 30-35°C for 1.5 hours, then stir the reaction for half an hour. After static separation, the lower acidic water layer was removed, and the silanol toluene solution was washed with warm water at 40-45°C until neutral, and then concentrated under reduced pressure to a solid content of 40%. Take 100 g of this silanol solution, add 0.12 g of 10% tetraethylammonium hydroxide butanol solution as a catalyst, and react at a vacuum degree of -0.07 MPa at 60° C. for 1 hour, then add 0.0012 g of acetic anhydride stabilizer, A methylphenyl silicone resin (R / Si=1.7, Ph / R=0.6) with a viscosity of 25 s (coating 4 cups), cured at 100° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com